IM-S02-30 CMGT Issue 14 7

FT43, FT44, FT46 and FT47 Ball Float Steam Traps

2.1 General description

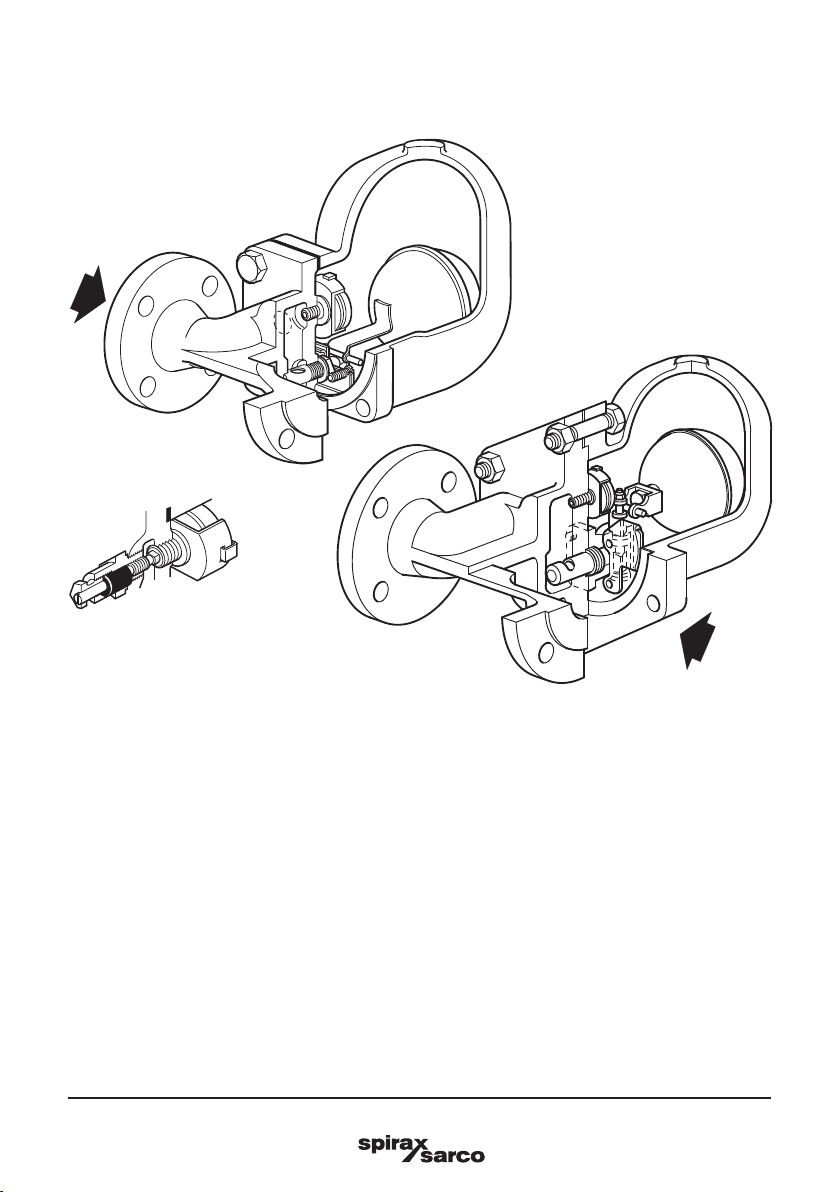

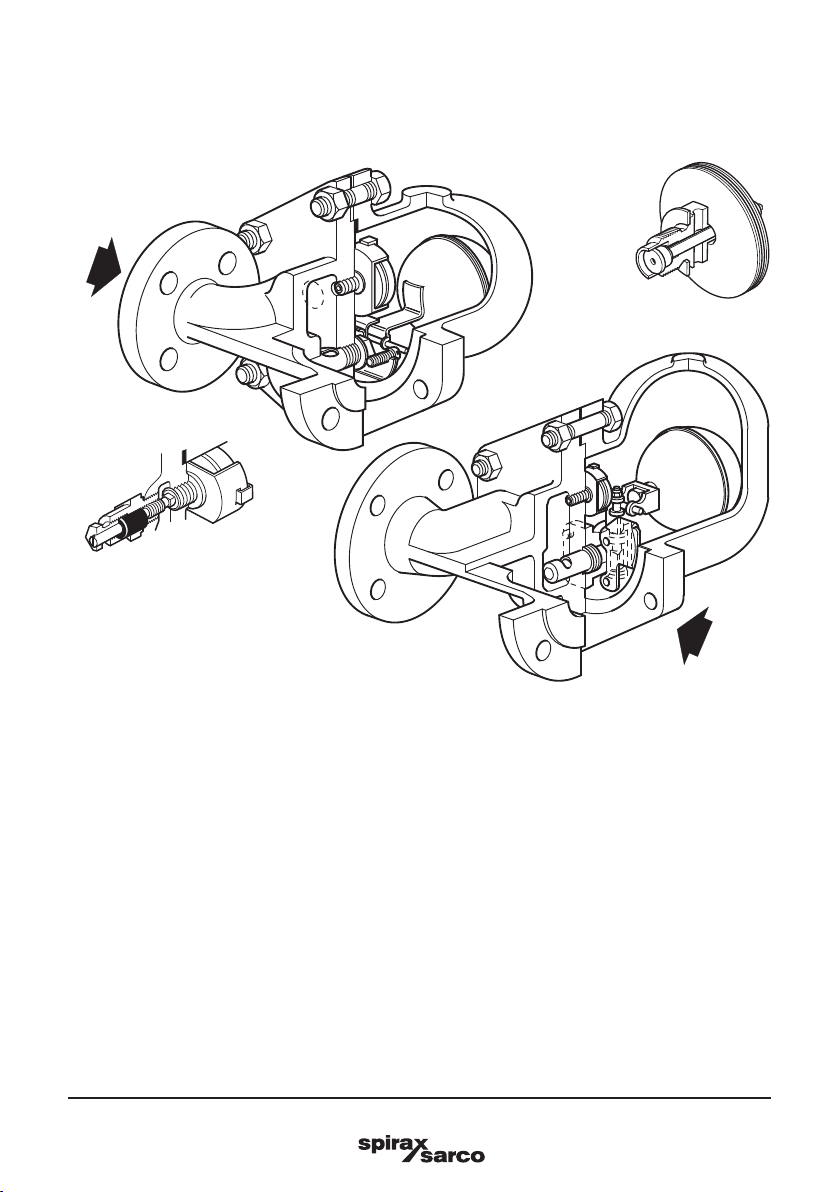

The FT43 - cast iron, FT4 4 - carbon steel, FT46 - austenitic stainless steel and FT47 - SG iron ball float

steam traps have stainless steel working internals and automatic built-in air venting facility. These traps are

supplied with integrally flanged connections (for horizontal or vertical installations) and can be maintained

without disturbing the pipework. Please be aware that the flow direction is not the same for all FT trap types

or sizes but will be clearly marked on the trap body. For vertically orientated traps, identified by the added

'V' on the nomenclature i.e. FT44V, the flow is downwards only. The body and cover castings for the FT44,

FT46 and FT47 are produced by a TÜV approved foundry.

Air vent

The BP99/32 capsule which is used in 4.5 bar - 21 bar ball float steam traps is suitable for use on 150 °C

superheat @ 0 bar g. This value reduces with elevated pressure.

The bimetallic element is fitted as standard to the 32 bar variants to provide additional superheat

resistance. It is also available on other variants on request. Please refer to the pressure/temperature

graphs in the following pages.

Optional extras

A manually adjustable needle valve (designated 'C' on the nomenclature i.e. FT46- C) can be fitted to

these traps. This option provides a steam lock release (SLR) feature in addition to the standard air vent.

Note: The steam lock release and bimetallic air vent cannot be used in conjunction with each other.

Alternative arrangements may be available. For further information please contact Spirax Sarco.

The top of the cover can be drilled and tapped 3/8" BSP or NPT for the purpose of fitting a balance line

if requested at the point of order.

The bottom of the cover can be drilled and tapped 3/8" BSP or NPT for the purpose of fitting a drain

cock if requested at the point of order.

Standards

This product fully complies with the requirements of the EU Pressure Equipment Directive/UK Pressure

Equipment (Safety) Regulations and carries the mark when so required.

Certification

This product is available with a manufacturers’ Typical Test Report. Certification to EN 10204 3.1 can

be supplied at extra cost for the FT44 , FT46 and the FT47.

Note: All certification / inspection requirements must be stated at the time of order placement.

Note: For further product data see the following sections and Technical Information Sheets:

Product Material Section TI reference + Capacities

FT43

DN25 - DN50 Cast iron Section 2.2 TI-S02-21

DN80 - DN100 Cast iron Section 2.2 TI-S02-22

FT44

DN15 - DN50 Carbon steel Section 2.3 TI-S02-14

DN80 - DN100 Carbon steel Section 2.3 TI-S02-23

FT46 DN15 - DN50 Stainless steel Section 2.4 TI-P143-01

FT47 DN15 - DN50 SG iron Section 2.5 TI-P142-01 and TI-S02-36

2. General product information