IM-P113 -02 CMGT Issue 6

8

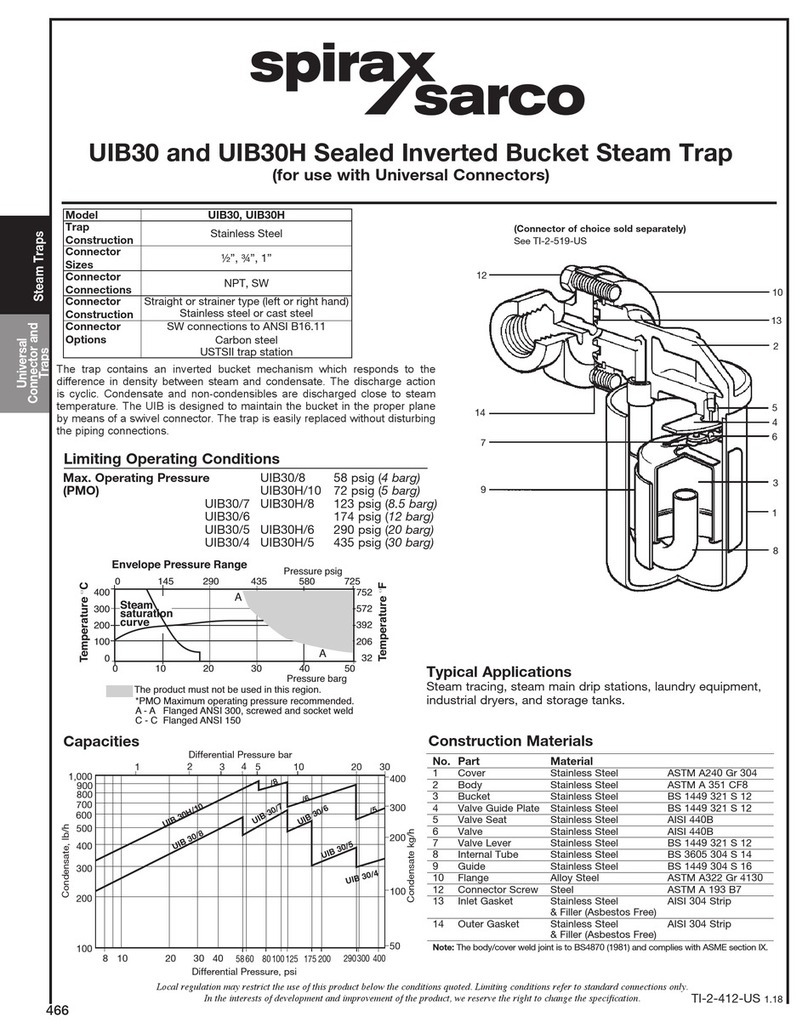

UIB30 and UIB30H Sealed Inverted Bucket Steam Traps for use with Pipeline Connectors

Note: Before actioning any installation observe the 'Safety information' in Section 1.

Referring to the Installation and Maintenance Instructions, name-plate and Technical Information Sheet,

check that the product is suitable for the intended installation:

3.1 Check materials, pressure and temperature and their maximum values. If the maximum operating limit

is included in the system to prevent overpressurisation.

3.2

3.3

appropriate, before installation on steam or other high temperature applications.

3.4 If the trap has been supplied with a drain plug and is to be replaced with a drain device, this should

13) and the drain plug

14).

3.5 The UIB can be installed on any pipeline connector. See separate Installation and Maintenance

Instructions for Spirax Sarco pipeline connectors (IM-P128-06, IM-P128-11 and IM-P128-13).

Ensure that both gaskets are clean and undamaged and that the transfer holes are clear. Place the

UIB body against the connector gasket face, ensuring that the trap itself is vertical so the bucket

always rises and falls in a vertical plain.

Ensuring the new connector screws supplied with the trap are used, apply a suitable amount of

anti-seize thread lubricant to the threads of the connector screws (10). Tighten the screws finger

tight until the mating gasket faces are in parallel, intimate contact. Tighten the screws evenly and

gradually to the recommended torque value (see Table 1). Open isolation valves slowly until normal

operating conditions are achieved.

3.6 Inverted bucket steam traps do not permit rapid release of air. On process applications, in particular,

this can lead to slow warm-up times and waterlogging of the steam space. A separate external air

trap. If it is below, and is leaking or left open, the waterseal could be blown away leading to steam

damage can be reduced by thermal insulation.

3.7 The inlet of the trap should be below the drain point of the plant being drained, so that a waterseal

can be maintained around the open end of the bucket. When installed in a horizontal pipeline a small

drop leg should precede the trap - typically 150 mm (6").

3.8 Where the trap discharges into a closed condensate return system or where there is a lift at the trap,

3.9 If the trap has to be installed at a higher point than the drainage point, then a small bore riser into

internal waterseal.

3.10 If the trap is installed on a superheated steam system application, then a non return valve should be

Priming of the trap with water may be required before commissioning.

3.11 Check for leaks.

Note 1:

at a temperature of 100 °C (212 °F).

Note 2: On all blast discharge steam traps check valves and sight glasses must be installed at least 1 metre

(3 ft) downstream of the trap.

3. Installation