Spirent communications SPT-N11U User manual

SPT-N11U and SPT-N12U Installation Instructions |1

P/N 71-008728 Rev A, August 2019

SPT-N11U and SPT-N12U Chassis

Installation Instructions

This document is intended to guide you to a safe and successful installation of the Spirent

SPT-N11U or SPT-N12U mainframe chassis.

In this document...

• Certifications and Standards . . . . 4

• Introduction . . . . 7

• Site Selection . . . . 7

• Technical Specifications . . . . 8

• Powering the System . . . . 15

•RackMountingtheSPT-N11U/SPT-N12U . . . . 10

• Related Documentation . . . . 17

• How to Contact Us . . . . 18

SPT-N11U and SPT-N12U Chassis Installation Instructions

2|SPT-N11U and SPT-N12U Installation Instructions P/N 71-008728 Rev A, August 2019

Copyright

© 2019 Spirent Communications, Inc. All Rights Reserved.

All of the company names and/or brand names and/or product names referred to in this

document, in particular, the name “Spirent” and its logo device, are either registered

trademarks or trademarks of Spirent plc and its subsidiaries, pending registration in

accordance with relevant national laws. All other registered trademarks or trademarks are

the property of their respective owners. The information contained in this document is

subject to change without notice and does not represent a commitment on the part of

Spirent Communications. The information in this document is believed to be accurate and

reliable, however, Spirent Communications assumes no responsibility or liability for any

errors or inaccuracies that may appear in the document.

Limited Warranty

Spirent Communications, Inc. (“Spirent”) warrants that its Products will conform to the

description on the face of order, that it will convey good title thereto, and that the Product

will be delivered free from any lawful security interest or other lien or encumbrance.

Spirent further warrants to Customer that hardware which it supplies and the tangible

media on which it supplies software will be free from significant defects in materials and

workmanship for a period of twelve (12) months, except as otherwise noted, from the date

of delivery (the “Hardware Warranty Period”), under normal use and conditions.

To the extent the Product is or contains software (“Software”), Spirent also warrants that,

if properly used by Customer in accordance with the Software License Agreement, the

Software which it supplies will operate in material conformity with the specifications

supplied by Spirent for such Software for a period of ninety (90) days from the date of

delivery (the “Software Warranty Period”). The “Product Warranty Period” shall mean the

Hardware Warranty Period or the Software Warranty Period, as applicable. Spirent does

not warrant that the functions contained in the Software will meet a specific requirement

or that the operation will be uninterrupted or error free. Spirent shall have no warranty

obligations whatsoever with respect to any Software which has been modified in any

manner by Customer or any third party.

Defective Products and Software under warranty shall be, at Spirent's discretion, repaired

or replaced or a credit issued to Customer's account for an amount equal to the price paid

for such Product provided that: (a) such Product is returned to Spirent after first obtaining

a return authorization number and shipping instructions, freight prepaid, to Spirent's

location in the United States; (b) Customer provides a written explanation of the defect or

Software failure claimed by Customer; and (c) the claimed defect actually exists and was

not caused by neglect, accident, misuse, improper installation, improper repair, fire, flood,

lightning, power surges, earthquake, or alteration. Spirent will ship repaired Products to

Customer, freight prepaid, based on reasonable best efforts after the receipt of defective

Products. Except as otherwise stated, any claim on account of defective materials or for

any other cause whatsoever will conclusively be deemed waived by Customer unless

written notice thereof is given to Spirent within the Warranty Period. Spirent reserves the

right to change the warranty and service policy set forth above at any time, after

reasonable notice and without liability to Customer.

SPT-N11U and SPT-N12U Chassis Installation Instructions

SPT-N11U and SPT-N12U Installation Instructions |3

P/N 71-008728 Rev A, August 2019

TO THE EXTENT PERMITTED BY APPLICABLE LAW, ALL IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY, NONINFRINGEMENT AND FITNESS FOR A PARTICULAR

PURPOSE, ARE HEREBY EXCLUDED, AND THE LIABILITY OF SPIRENT, IF

ANY, FOR DAMAGE RELATING TO ANY ALLEGEDLY DEFECTIVE PRODUCT

SHALL BE LIMITED TO THE ACTUAL PRICE PAID BY THE CUSTOMER FOR

SUCH PRODUCT. THE PROVISIONS SET FORTH ABOVE STATE SPIRENT'S

ENTIRE RESPONSIBILITY AND CUSTOMER'S SOLE AND EXCLUSIVE REMEDY

WITH RESPECT TO ANY BREACH OF ANY WARRANTY.

Safety Precautions

Warning: Calls attention to operating procedures or practices that should be followed to

avoid bodily injury or damage to equipment.

Caution: Reflects conditions that could cause product damage or data loss.

Note: Describes limitations on the use of the equipment or procedure.

Equipment Noise Level

Warning: The SPT-N11U/SPT-N12U is designed for operation in an unattended room

(e.g., datacom or telecom equipment room). The system can generate noise levels up to

90.7 dB (A-weighted sound power level, LWA as measured per ISO 3741 Sound Power

Noise Measurement), and appropriate ear protection should be worn when working in

proximity to the chassis. Please contact your employer or local health and safety agencies

for specific guidelines for your working environment.

No User-Serviceable Parts

Warning: No user-serviceable parts inside. Do not open.

Waarschuwing: Er zijn geen door de gebruiker te vervangen onderdelen. Niet openen.

Attention: Aucune pièce se trouvant à l'intérieur ne peut être réparée ou remplacée par

l'utilisateur. Ne pas ouvrir.

Calibration

At the time of manufacture, all components manufactured by Spirent Communications are

calibrated in accordance with applicable procedures. Spirent Communications equipment

is calibrated using national standards, consensus standards, and ratio-type measurements

based on self-calibration techniques. By design, the equipment has no user adjustments

and does not require further calibration. Products are calibrated within the published

environmental specifications for the products. At the time of shipment, this Spirent

Communications product met its published operating specifications.

Unpacking

Before opening the product carton, examine it for damage. If damage is not visible,

unpack the carton and check contents for damage. Save all packing materials. If damage is

SPT-N11U and SPT-N12U Chassis Installation Instructions

Certifications and Standards

4|SPT-N11U and SPT-N12U Installation Instructions P/N 71-008728 Rev A, August 2019

noted, forward an immediate request to the delivering carrier to perform an inspection and

prepare a damage report. Save the container and packing material until contents are

verified or in case the equipment will be transported at a later date.

Report the nature and extent of damage to Spirent Communications Customer Support so

that action can be initiated to repair or replace damaged items or instructions can be

provided for returning items.

The responsibility of the manufacturer ends with delivery to the first carrier. All claims for

loss, damage, or nondelivery must be made against the delivering carrier within

10 calendar days of receipt of shipment.

Important: The SPT-N11U/SPT-N12U weighs over 100 lbs and will require at least four

people to move and install it. The preferred method is to install it using an IT equipment

lift designed for heavy network equipment.

Open the packaging carefully and save all packaging materials. Safely shipping the SPT-

N11U/SPT-N12U requires the use of the included pallet, custom-fit foam, and shipping

box. Set these materials aside for future use. Set aside the accessories and power supplies.

These will be needed later. Carefully lift the chassis out of the box using the side and front

handles and securely place it on a level and stable surface.

Damaged or Missing Equipment

If any equipment is damaged or missing, call (800) 774-7368 or (818) 676-2616

(international) for technical support. Registered users may also access the Spirent

Communications support website at https://support.spirent.com. You may also email

Certifications and Standards

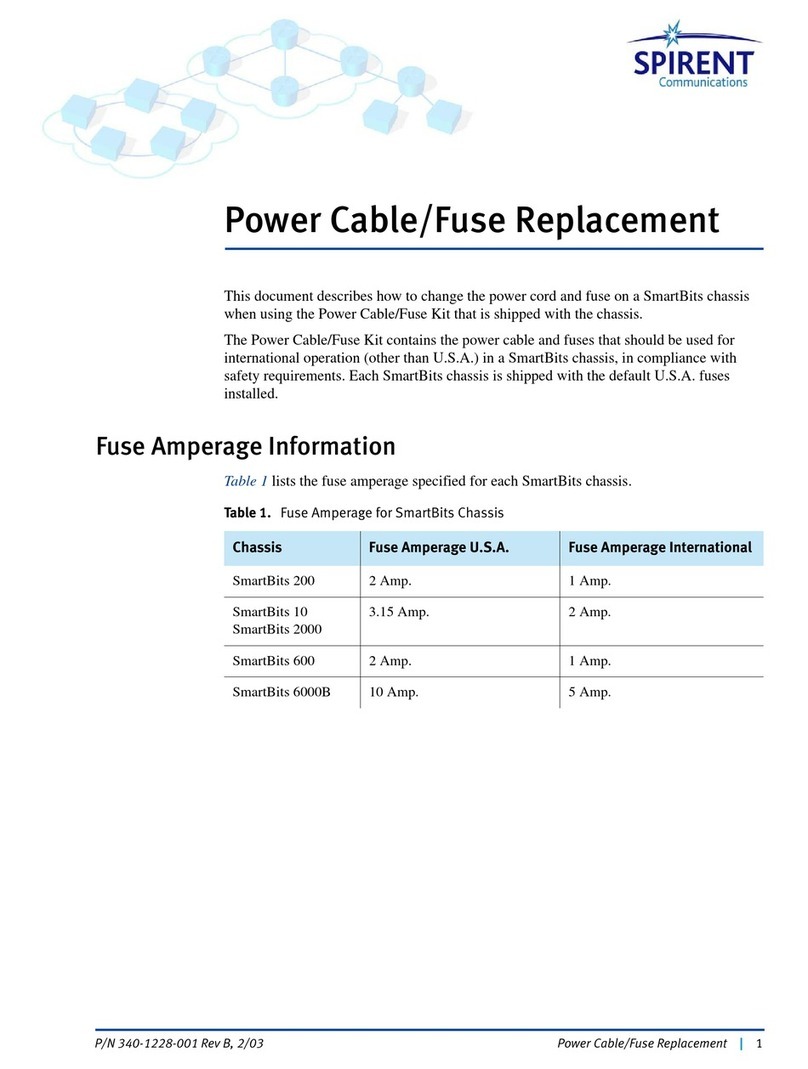

FCC

The SPT-N11U/SPT-N12U chassis complies with the limits for a Class A digital device in

accordance with Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when this equipment is operated in a

commercial environment. Operation is subject to the following two conditions:

•This device may not cause harmful interference.

•This device must accept any interference received, including interference that may

cause undesired operation.

This device generates, uses, and can radiate radio frequency energy if not installed and

used in accordance with the instructions in this manual. Operating this equipment in a

residential area is likely to cause harmful interference, and the customer will be required

to rectify the interference at his or her own expense. This product requires the use of

external shielded cables to maintain compliance pursuant to Part 15 of the FCC Rules.

SPT-N11U and SPT-N12U Chassis Installation Instructions

Certifications and Standards

SPT-N11U and SPT-N12U Installation Instructions |5

P/N 71-008728 Rev A, August 2019

CE

The CE symbol on the product label (on the back of the box) indicates this network

appliance is compliant with the EMC Directive and Low Voltage Directive of the

European Union. This product meets the following technical standards:

•EN 55022 — “Limits and Methods of Measurement of Radio Interference

Characteristics of Information Technology Equipment.”

•EN 55024 — “Limits and methods of measurement of immunity characteristics for

information technology equipment.”

•EN 60950 — “Safety of Information Technology Equipment.”

TUV

This product carries the cTUVus mark.

Key Points of cTUVus Certification:

•The cTUVus mark is accredited by OSHA (NRTL) for the U.S. and SCC for Canada.

•The cTUVus mark is recognized as equivalent to the UL and CSA marks by city,

county and state/provincial regulators throughout the U.S. and Canada.

•Safety testing conducted to applicable U.S. and Canadian standards and in most cases

can be combined with testing for other countries.

This manual suits for next models

1

Table of contents

Other Spirent communications Chassis manuals

Popular Chassis manuals by other brands

Overland Storage

Overland Storage SnapSAN S1000 Replacement instructions

Philips

Philips LC4.1E A Service manual

Supermicro

Supermicro SCF418 Series user manual

Supermicro

Supermicro SC823MTQ-R700LPB user manual

HP

HP A7503-S Product End-of-Life Disassembly Instructions

SilverStone

SilverStone RMS08 Series manual