Spitznas 2 1362 0010 User manual

Original-Betriebsanleitung, erstellt: 13.07.18

213620010_BA_en_Version_01.doc

Pneumatic

Drill

Type 2 1362 0010

ATEX Tool

Illustration can differ from the original

Translation of the original manual,

compiled: 01.09.21

Techn. Doc. No. 251

Operation

and Maintenance Manual

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 1 of 30

Directory

Page

Signal Word and Symbol Definition

2

Technical Specification

3

Use

3

Product Description

4

Scope of delivery

4

Identification

5

Installation

6

Startup

7-13

Operation

14-16

Accessoires

17-20

Basic Safety Instructions

21

Employer‘s Obligations

21

Operator‘s Obligations

21

Explanation of Symbols for Protective Equipment and for Accident Prevention

22

Safety Instructions for avoiding Safety Hazards

23-26

Service and Maintenance

27-28

Disassembly –Re-assembly

28

Storage

28

Disposal

28

Environmental Regulations

28

Troubleshooting

29

Warranty and Liability

29

Declaration of Conformity

30

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 2 of 30

Signal Word and Symbol Definition

The signal words and symbols used in the technical documentation (safety instructions, operating booklet,

etc.) have the following meaning:

WARNING –Read the operation and maintenance manual

It is imperative to familiarize with this operation and maintenance manual and its safety

instructions before starting your SPITZNAS machine. Stick to the operating processes and

avoid accidents due to improper use of the machine.

This symbol has

the following

meaning:

DANGER –Indicates an immediate danger, which causes serious injuries to any person

or even death, if not avoided.

WARNING –Indicates a threatening danger, which can cause serious injuries to any

person or even death, if not avoided.

CAUTION –Indicates a danger or unsafe procedure which can cause injuries to any

person or material damages, if not avoided.

NOTICE –Indicates a potentially dangerous situation which can cause damage to the

product or its surroundings, if not avoided.

WARNING –explosive atmosphere

Air and flammable substances can mix and result in an explosive atmosphere. In areas

exposed to explosion hazards, supplementary instructions and directives apply. Observe

the safety instructions of the employer as well.

WARNING –explosive material

Caution should be exercised when working with explosive material or in its surrounding

area.

PROHIBITION –No naked flame, fire, or ignition source and no smoking

Prevent from fire and explosion hazards, which can be caused by naked flame, open

ignition source or by smoking.

Eating and drinking forbidden –The prohibition sign forbids the consumption of food.

REQUIREMENT –Observe the instruction

Ensure that the operation process is adhered to and avoid accidents and expensive break

down times due to improper use of machines, devices and tools.

By using the mandatory sign you refer to the adherence of operation instructions.

This symbol has

the following

meaning:

NOTICE –Gives recommendations and important hints for handling the product

IMPORTANT –Indicates application advice and other particularly useful information.

REMARK:

In each case the used symbol does not replace the safety text. The text must always be read fully. In some

cases other symbols will be used with the signal words.

WARNING

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 3 of 30

Technical Specification

Operating pressure

6 bar

Power

1 kW

Free speed step 1, 2, 3, 4

450, 650, 850, 1000 1/min

Rotation direction

reversible

Drill chuck

up to 13 mm

Drilling in steel

max. 30 mm

Thread cutting

max. M12

Air consumption

1.15 m3/min

Air connection

R ¼" female

Weight

3.7 kg

Length with drill chuck

approx. 230 mm

Sound pressure level LpA(1)

84 dB (A)

Sound power level LWA

95 dB (A)

Vibration (2)

< 2.5 m/s²

ATEX Classification

II 2G Ex h IIB T5 Gb

(1) Remark: Measurement acc. to DIN EN ISO 15744

(2) Remark: Measurement acc. to DIN EN ISO 28927-5

Measurement uncertainty K: 3 dB (A)

Measurement uncertainty K: 1.5 m/s2

The performance specifications are guide values only, they depend basically on the application, the

working pressure and the accessories used.

Intended Use

SPITZNAS machines are designed for industrial use only.

Only trained, skilled personnel are allowed to operate the machine. The drill serves for drilling:

Wood, plastic, non-ferrous metal, cast iron, steel and stainless steel

It can be applied for:

Chemical industry / refineries, nuclear industry, body construction and ship building industry, construction.

Improper Use

Any use deviating from the intended use as described is considered to be improper use.

Working without personal protection equipment.

Using the machine in an inadmissible area.

Drilling self-flammable material.

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 4 of 30

Product Description

Fig. 1

1 Reverse slide

2 Valve trigger

3 Air connection

4 Exhaust

5 Speed regulator

6 Motor housing with pistol grip

7 Drill chuck key

8 Drill chuck

9 Gear housing

10 Second Handle

Scope of Delivery

Check, if the scope of delivery is complete:

1 Pneumatic Drill, 1 Operation and Maintenance Manual, 1 Carrying case and accessories, if applicable

4

6

2

3

5

7

8

9

1

10

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 5 of 30

Identification

Type sign Explanation of ATEX Identification

CE specification

Specification

acc. to 2014/34/EU

Address

Technical specification

ATEX Identification

Company name and Logo

Serial number (1. and 2. figure refer to the

year of manufacture/ following figures refer

to the series)

Type description

Machine group II

Explosive atmospheres

e. g. Industry

Category 2

Very high level of safety

High level of safety

Normal level of safety

1

2

3

Ex-Atmosphere G

Gas, vapor and mist

Marking according to

standard - Ex-Symbol

Ignition protection category h

Code letter h for all

non-electrical equipment

Explosion group IIB

e.g. Methane, Propane

e.g. Ethylene, Town gas

e.g. Hydrogene, Acethylene

IIA

IIB

IIC

Temperature class T

Surface limit temperature

450°C

300°C

200°C

135°C

100°C

85°C

T1

T2

T3

T4

T5

T6

Equipment Protection Level

Group II EPL Gb

Category 2 (usable in category 3 as well) explosion group IIB usable in explosion group IIA as well.

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 6 of 30

Installation

Requirements to the air supply

The pneumatic drill works optimally at an operating pressure of 6 bar, measured at the air inlet. The distance

from the air supply to the machine has to be adjusted to the application conditions on site.

We recommend installing an oiler or a maintenance unit upstream the machine for compressed air

preparation. Use acid and resin-free lubricating oil, like SAE 5W - SAE 10W.

Attention! Do not use viscous oil.

Use an antifreeze lubricant during winter time or when the compressed air is very moist, e.g.:

“Kilfrost”

or “Kompranol N74”.

The supplied compressed air has to be free of:

Foreign particles,

humidity.

Pay attention that all hoses:

Have a cross section being large enough,

do not have any restrictions or kinks,

are designed for a minimum operating pressure of 6 bar,

are replaced regularly at preventative maintenance,

have an oil resistant inner surface and an abrasion-resistant outer surface,

are proved and specified to be non-conductive when being used next to electric conductors.

Always use hoses, lubricating oil and antifreeze lubricants, which meet the local safety requirements for use

in areas exposed to explosion hazards.

Connecting the air supply to the pneumatic drill

Remove the locking cap from the air connection 3. Connect the pneumatic hose (not contained in the scope

of delivery).

Exhaust Air inlet

Fig.2

3

4

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 7 of 30

Startup

Assembly of the handle

Fix the second handle item 10 at the side (see fig. 3 and 4).

Fig. 3

Fig.4

Turn

10

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 8 of 30

Connection of the air supply

Sample application: Quick-coupling for the air connection

Screw-in nipple (not contained in the scope of delivery) (see fig. 5 and 6).

Fig. 5

Fig.6

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 9 of 30

Blow out the pneumatic hose before connecting the machine.

Never connect a pneumatic hose being under pressure (see safety instructions for prevention of hazards

caused by compressed air).

When connecting the machine, pay attention that the valve trigger 2 (see fig.7) is not actuated.

First connect the machine and then connect the compressed air supply.

Make a test run.

Fig. 7

2

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 10 of 30

Mounting the drill bit

When mounting the drill bit, ensure that the pneumatic hose ist not connected, respectively that the

pneumatic supply is deactivated. Depressurize the pneumatic drill and disconnect the pneumatic hose

(see fig. 8).

Fig. 8

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 11 of 30

Open the drill chuck item 8 by turning until the drill bit can be mounted. (see fig. 9 and 10).

Fig. 9 Fig. 10

Mount the drill bit (see fig.11).

Fig. 11

Turn to open

8

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 12 of 30

Turn the drill chuck item 8 against the opening direction (see fig.12).

Fig. 12

Put the drill chuck key item 7 (see fig. 13) in the corresponding drillings of the drill chuck item 8 and tighten

the drill bit evenly.

Tighten

Fig. 13

When connecting the machine, ensure that the valve trigger item 2 (see fig. 13) is not actuated.

Never connect a pressurized pneumatic hose (see safety instructions for prevention of hazards caused by

pneumatic). First connect the machine and then the pneumatic supply.

Turn to shut

2

8

7

8

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 13 of 30

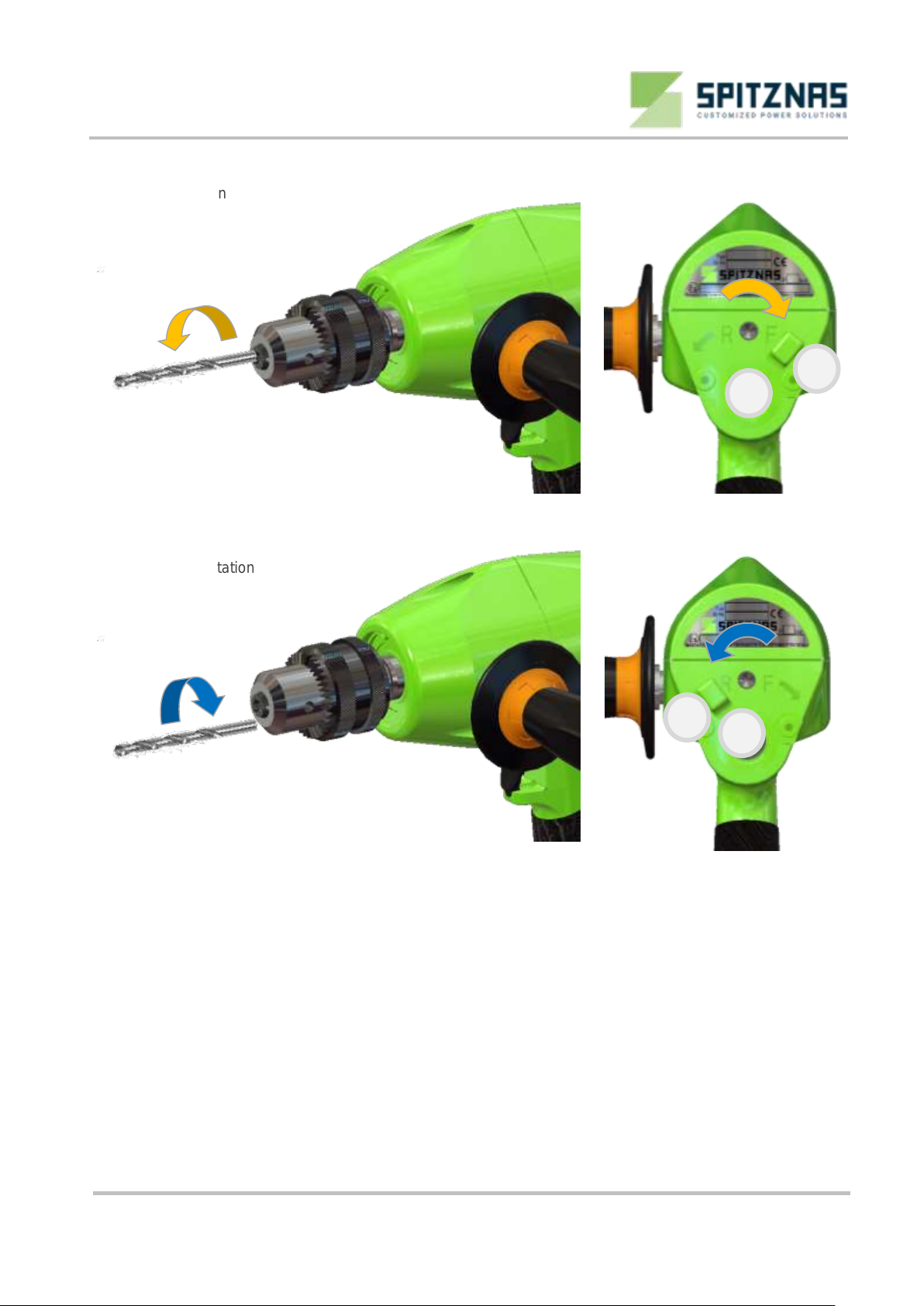

Adjusting the rotation direction

Clockwise rotation

Fig. 14 F„Forward“ for clockwise

rotation

Anti-clockwise rotation

Fig. 15 R „Reverse“ for anti-clockwise

rotation.

Prior to starting work

Check:

That the drill bit is properly tightened in the drill chuck,

That the pneumatic hose is properly connected,

That the rotation direction is adjusted with the reverse slide item 1 and the speed stage is correctly

adjusted with the speed regulator item 5 (see fig. 14 and 15).

Start the machine by actuating the valve trigger item 2 and start operating. The drill bit has to be cooled with

water in order to avoid sparks.

After finishing the work

Release valve trigger.

Shut the pneumatic supply, disconnect the pneumatic hose.

Dismount the drill bit, if necessary.

1

1

5

5

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 14 of 30

Operation

Replacing the drill bit

Shut the pneumatic supply and secure against unintentional starting. Depressurize the pneumatic drill and

disconnect the pneumatic hose. Wear protective gloves when replacing the drill bit, as the drill bit and the

drill chuck can strongly heat up during longer operation. Put the drill chuck key item 7 (see fig. 16) in the

corresponding drillings of the drill chuck item 8 and undo the drill bit.

Undo

Fig. 16

Open the drill chuck item 8 by turning and take the drill bit out of the drill chuck (see fig. 17 and 18).

Fig. 17 Fig. 18

Mount the drill bit (see fig. 19).

Fig. 19

Turn to open

8

2

7

8

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 15 of 30

Turn the drill chuck item 8 against the opening direction (see fig. 20).

Fig. 20

Put the drill chuck key item 7 (see fig. 21) in the corresponding drillings of the drill chuck key item 8 and

tighten the drill bit evenly.

Tighten

Fig. 21

Actuate the pneumatic supply.

Adjust the rotation direction (see „Adjusting the rotation direction“ on page 13) and start drilling.

Turn to shut

2

8

7

8

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 16 of 30

Second handle

The second handle item 10 can be mounted at two positions.

Undo the second handle item 10 (see fig. 22 and 23) .

Fig. 22 Fig. 23

Mount the second handle item 9 at the opposite side (see fig. 24 and 25).

Fig. 24 Fig. 25

10

10

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 17 of 30

Accessories

Mount the quick-release chuck

SPITZNAS part no.: 9 2902 0040

Shut the pneumatic supply and disconnect the pneumatic hose from the pneumatic drill. Wear protective

gloves when replacing the drill chuck to avoid injuries.

Open the drill chuck item 8 by turning. (see fig. 26).

Fig. 26

Put the hexagon screw driver SW 5 through the drill chuck item 8 on the socket head

screw (see fig. 27 and 28).

Fig. 27 Fig. 28

Turn the hexagon screw driver SW 5 until the drill chuck item 8 becomes loose and pull it from the shaft

(see fig. 29 and 30) .

Fig. 29 Fig. 30

Turn to open

8

Undo by turning

8

8

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 18 of 30

Tighten the socket head screw and put the quick-release chuck onto the shaft (see fig. 31 and 32).

Fig. 31 Fig. 32

Disassembling the quick-release chuck

SPITZNAS part no. 9 2902 0040

Put a wedge with the pneumatic drill on a support. Put a second wedge on the top and drive the quick-

release chuck off the shaft by slightly hammering. (see fig 33 to 36).

Fig. 33 Fig. 34

Fig. 35 Fig. 36

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Pneumatic Drill

2 1362 0010

Translation of the original manual,

compiled: 01.09.21

213620010_BA_en_Version_01.doc

Page 19 of 30

Mounting the exhaust connection

SPITZNAS part no.: 6 1034 9100

Fig. 37

A Exhaust connection with hose nozzle

B Hose nozzle for air supply

A

B

B.V.Technisch Bureau Duspra Amersfoortseweg 24-14 3951 LB Maarn The Netherlands

Table of contents

Other Spitznas Drill manuals