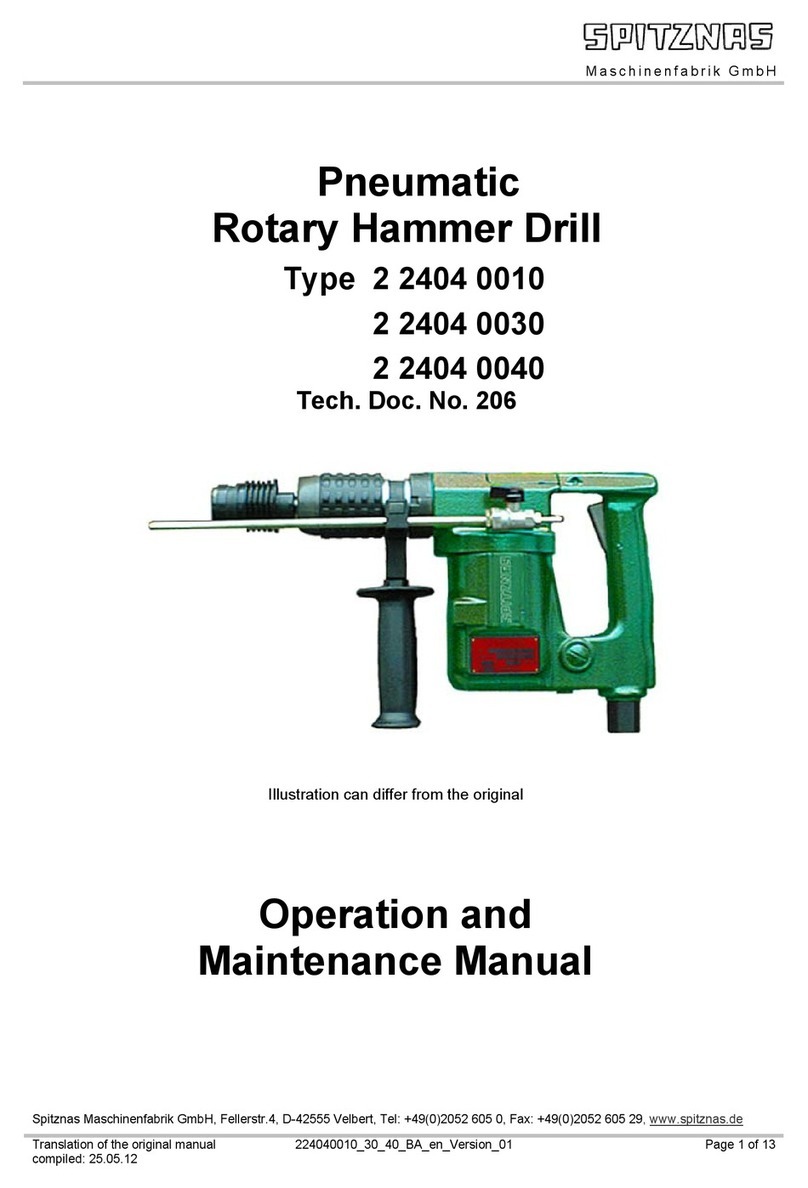

Spitznas 2 1330 0010 User manual

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 1 of 25

PNEUMATIC

MAGNETIC DRILLING MACHINE

Type 2 1330 0010 / 0030

Tech. Doc. No. 201

Illustration can differ from the original

Operation and

Maintenance Manual

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 2 of 25

GENERAL INSTRUCTIONS

Before using the machine, please read these instructions

Remove the unit from its case along with the accessories and check that all parts are included; the

box should contain:

•Drilling unit

•Accessory pack containing:

- Safety chain & carbine hook

- Allen key SW 2,5 for wear strip adjustment

- Allen key SW 4 for arbor. (This is for fitting cutters)

•Oil bottle with plastic hose

•This operating instructions

This pneumatic machine is designed for an operating pressure of 4 to 6 bar (60 to 90 PSI). Service

life and performance of the machine are determined by:

•Degree of air purity

•Lubrication and maintenance

Blow the air hose clear before connecting it to the machine. Install dirt and water separator

upstream of the machine, if it is not possible to prevent the formation of rust and water

condensation in the air distribution lines.

Use always acid- and resin-free SAE 5 W to SAE 10 W oil. Thick flowing oil will clog the vanes and

affect the start-up and performance of the machine. Only proper maintenance can ensure constant

performance, reduction in wear and thus, a decrease in operating costs and an increase in service

life. We therefore highly recommend to install service units upstream of the machine. Observe the

comments in the information sheet "Maintenance of Pneumatic Tools". In winter or when using

very moist air, an antifreeze lubricant, such as "BP-Energol AX“, "Kilfrost“ or "Kompranol N74"

should be used.

Replace wear parts –in particular the vanes- when necessary. The vanes are considered worn if

their width is less 7,2 mm.

IInstallation

dimensions

replace

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 3 of 25

SAFETY INSTRUCTIONS

Any power tool can be dangerous. Please follow these simple safety

procedures – they are for your protection.

•Regular maintenance is essential – check nuts, screws etc. for tightness

•Check air line for damage

•Make sure the unit is lubricated

•Never use blunt cutters

•Wear goggles and gloves

•Secure the unit with the safety chain before drilling

•Always disconnect air when changing cutters or working on the machine

•Remove rings, watches, ties etc. that could tangle in the moving parts

•Keep the unit and workpiece as clear of dirt and swarf as possible

WARNING! Never use the flexible hose as a lifting handle!

Your safety is in your hands! Keep these instructions!

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 4 of 25

PREPARATION

1. Insertion of pilot pin

The pilot pin is used to both center the cutter and to eject the slug on completion of the cut. It

has a flat side to allow the coolant to run down to reach the center of the cut where the heat is

greatest. Slide the pin through the hole in the center of the cutter shank.

2. Fitting the cutter

Lay the machine on its side, ensuring the set screws are accessible. Loosen both screws to

permit shank of the cutter to slide home in the arbor with the two flats aligned with the set

screws. Tighten the set screws in turn until the cutter is locked. Do not over-tighten the screws.

If a pilot pin is used, ensure that it slides freely in the cutter.

3. Clean any dirt or swarf from the base of the magnet and the workpiece with a gloved hand.

Mark the position of the hole by a center-punch. Place unit in correct position for drilling.

4. Place unit in correct position for drilling with the pilot over the center-punch. The magnet will

hold on all ferrous materials from a minimum of 6 mm (1/4") thickness.

5. Attach safety chain by looping it through the handle of the unit and around the workpiece or

other suitable anchor point, take up any slack in the chain and clip the hook through a

convenient link in the free end of the chain.

6. Check the air connection with a suitable supply (6 bar/90PSI, 64 SCFM/1,8 m3/min)

7. Connect the free end of the lubrication hose to the adapter of the motor.

DRILLING

1. Activate the magnet using the control lever.

2. Check magnet is holding to workpiece. Recheck the pilot is still centered on the hole position –

activating the magnet can sometimes cause the unit to move slightly from the center mark,

reposition if necessary.

3. Using the pressurized oil bottle add oil to the workpiece. Ensure only the correct cutting oil is

used, it has been formulated to speed cutting and enhance tool life.

4. Start the motor. Motor will not run unless magnet is activated. If for any reason the airflow is

interrupted, the switching system will leave the magnet on. The unit will switch itself to a drill off

position and will need to be switched back to drilling when the supply is re-connected.

5. Advance the cutter to the workpiece using light pressure until the cutter has broken the surface,

then increase the pressure until the motor is loaded and maintain even pressure right through

the cut. Too much pressure will not speed the cut, it will reduce the life of the cutter and may

cause damage to the motor. If the turnings become blue add more oil. At the end of the cut the

slug will be ejected, check before commencing the next hole. Make sure that no swarf collects

inside the cutter.

6. Stop motor, switch off magnet.

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 5 of 25

SPECIFICATIONS

Hole capacity with annular drills ∅2 1/16" , 2 1/16" depth ∅52 mm, 52 mm depth

Hole capacity with twist drills ∅3/16" to ½" ∅5 to 13 mm

Arbor size ¾" Weldonshaft 19 mm Weldonschaft

Air motor 1.6 H.P. 1200 W

Free speed

Load speed

400 RPM

200 RPM

400 1/min

200 1/min

Magnet force 1600 lbs. 8000 N

Air consumption 64 CFM 1,8 m3/min

Operating pressure 90 PSI 6 bar

Air connection G 3/8" Female R 3/8"

Weight 42 lbs. 19 kg

Height x Width x Length 12 ¼" x 4" x 11 ½" 301 x 102 x 290 mm

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 6 of 25

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Magnetic base won't

hold effectively

Material being cut may be

too thin

Swarf or dirt under magnet

Irregularity on magnet

contact or workpiece

Attach an additional piece of metal under

workpiece where magnet will be located or

mechanically clamp magnetic base to

workpiece

Clean

Use extreme care, file imperfections flush to

surface

Cutter skips out of

center-punchmark at

initiation of cut

Magnetic base is not

holding effectively

Too much feed pressure at

start of cut

Cutter is dull, worn,

chipped or incorrectly

sharpened

Poor center-punchmark

Pilot not centered in

center-punchmark

Worn or bent pilot

Loose bolts on main

casting or loose slideway

adjusting setscrews

See above

Light pressure until a groove is cut. The

groove then serves as a stabilizer

Replace or resharpen

Improve center-punch

Replace

Adjust where necessary

Excessive drilling

pressure required

Incorrectly resharpened,

worn or chipped cutter

Coming down on swarf

lying on surface of

workpiece

Slideway needs

adjustment or lubrication

Swarf packed inside cutter

Resharpen or replace

Take care not to start a cut on swarf

Adjust set screws

Clear

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 7 of 25

PROBLEM CAUSE REMEDY

Excessive cutter

breakage

Steel swarf or dirt under

cutter

Incorrectly resharpened or

worn cutter

Cutter skipping

Slideway needs

adjustment

Cutter not attached tightly

to arbor

Insufficient use of cutting

oil or unsuitable type of oil

Remove cutter, clean thoroughly and

replace

Resharpen or replace

See above

Adjust

Retighten

Excessive cutter

wear

See above

Incorrectly resharpened

cutter

Insufficient or spasmodic

cutting pressure

Replace or resharpen

Use sufficient steady pressure to slow the

drill down. This will result in optimum

cutting speed

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 8 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 0010

Pneumatic- Magnetic Drilling Machine

Item Qty. Description Part and Drawing No. Remarks

1 Drive motor 2 1330 1000 see extra list

1 Valve, Assy. 2 1330 3000 see extra list

1 Housing Assy. 2 1330 6000 see extra list

1 Magnet, Assy. 2 1330 8000 see extra list

1 Pressure sprayer 9 4002 0020

1 Connection hose 9 3602 0650

1 Safety chain, Assy: 9 4902 0120

2 Straigbht screw fitting 9 2113 0370

1 Hexagon ball cock 9 2014 0900

608 1 Housing cover 2 1330 6070

615 4 Lens screw 9 1166 0170

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 9 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 0030

Pneumatic- Magnetic Drilling Machine

Item Qty. Description Part and Drawing No. Remarks

1 Magnetic Drilling Machine 2 1330 0010 see extra list

1 Extended rack 2 1330 9000 see extra list

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 10 of 25

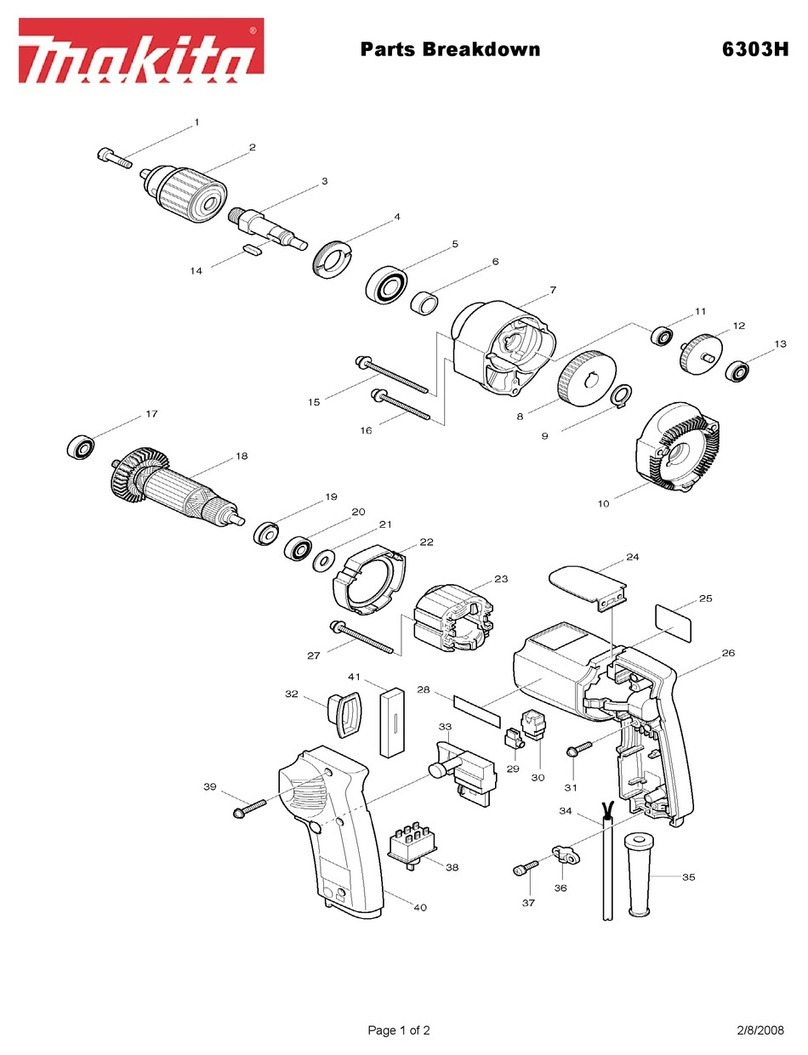

Spare Parts List

Description: Part and Drawing Number

2 1330 1000

Drive Motor

Item Qty. Description Part and Dratwing No. Remarks

101 1 Motor housing, Assy. 2 1330 1910 With item 102,118,

121,123,140,141,149

102 2 Insulator 2 1330 1700

103 4 Belleville spring 9 1801 0320

2 End plate, Assy. 3 8741 1940 * item 104-107

104 1 End plate, Assy. 3 8741 1110

105 1 Grooved ball bearing 9 1001 0370

106 1 Snap ring 9 1703 0040

107 1 Spacer 1 1001 1080

108 2 Cylinder bushing 5 6050 1020 *

109 2 Tensioning pin 9 1630 1060

110 2 Rotor 2 1330 1030 *

111 10 Vane 3 7666 1050 *

2 End plate, Assy. 7 1403 1930 * item 112-115

112 1 End plate 7 1403 1100

113 1 Grooved ball bearing 9 1001 0460

114 1 Snap ring 9 1703 0350

115 1 Spacer 1 3801 1080

116 2 Cover 2 1330 1150 *

117 2 O-Ring 9 1901 2380 *

118 1 Motor housing cover 2 1330 1130

119 1 Shaft sealing ring 9 1905 1390

120 1 Grooved ball bearing 9 1005 0350

121 4 Fillister-head screw 9 1110 3030

122 2 Insulator 9 3801 1030 *

123 1 Tensioning pin 9 1630 0560

2 Gearbox set 2 1330 4900 Item 130-137

130 1 Sprocket 2 1330 4020

131 1 Grooved ball bearing 9 1003 0340

132 1 Planetary wheel carrier 2 1330 4130

133 3 Planetary wheel 2 1330 4140

134 3 Planetary wheel bolt 9 1016 0340

135 1 Grooved ball bearing 9 1003 0340

136 3 Needle cage 9 1015 0950

137 6 Ring 2 1330 4150

138 2 Cover lid 2 1330 4100

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 11 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 1000

Drive Motor

Item Qty. Description Part and Dratwing No. Remarks

139 2 Snap ring 9 1703 0540

140 1 Bearing housing 2 1330 4210

141 2 Cylinder pin 9 1635 0070

142 1 Grooved ball bearing 9 1003 0450

143 1 Snap ring 9 1703 0130

1 Exhaust shaft, Assy. 2 1330 7920 Item 144-145 and

150-151

144 1 Exhaust shaft 2 1330 7020

145 2 Threaded pin 9 1140 5010

146 1 Feather key 9 1501 4060

147 1 Spur wheel 2 1330 4240

148 1 Snap ring 9 1702 0120

149 5 Fillister-head screw 9 1110 3090

150 1 Pressure piece 2 1330 7080

151 1 Pressure spring 9 1803 4180

152 1 Cylinder pin 9 1619 0150

153 1 Feather key 9 1501 3140

155 1 Tooth rack 2 1330 7050

156 2 Fillister-head screw 9 1110 4020

157 1 Plug nipple 9 2113 0370

158 1 Fillister- head screw 9 1110 4010

159 2 Washer 9 3302 0020

2 Washer 9 3331 1040

2 Washer 9 3331 1050

2 Washer 9 3331 1060

2 Washer 9 3331 2500

* Wear and tear parts to be stored in case of

Continuous operation!

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 12 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 1000

Drive Motor

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 13 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 3000

Valve, Assy.

Item Qty. Description Part and Dratwing No. Remarks

301 1 Valve housing 2 1330 3010

302 1 Pressure rod 2 1330 3040

303 1 Locking cover 2 1330 3120

304 1 Valve piston 2 1330 3020

305 1 Adjusting piston, Assy. 2 1330 3990

306 1 Pressure plate 2 1330 3070

308 1 Pressure piston 2 1330 3080

309 1 Spiral pin 9 1642 0040

310 2 Steel ball 9 1017 0200

311 2 Pressure spring 9 1803 4320

312 2 Threaded pin 9 1140 4030

313 1 O-Ring 9 1901 3180

314 2 Adjusting screw 9 1147 4010

315 6 O-Ring 9 1901 3020

316 2 Plug nipple 9 2113 0340

318 1 Connection piece 9 2113 0350

319 1 Angle connection 9 2113 0360

320 1 Snap ring 9 1703 0080

321 1 O-Ring 9 1901 2550

322 1 Tensioning pin 9 1630 1060

323 1 Pressure spring 9 1803 2600

325 1 Pressure spring 9 1803 2160

326 1 O-Ring 9 1901 6320

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 14 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 3000

Valve, Assy.

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 15 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 6000

Housing, Assy.

Item Qty. Description Part and Dratwing No. Remarks

601 1 Housing 2 1330 6010

602 1 Shift - fork 2 1330 3050

603 1 Shaft 2 1330 3060

604 1 Leber 2 1330 3030

605 1 Feed shaft 2 1330 6040

606 1 Lock washer 2 1330 6060

607 2 Guide 2 1330 6050

609 1 End cap 2 1330 6100

610 3 Handle 9 3902 0360

611 1 Pneumatic hose, Assy. 9 3606 0350

612 1 Hose 9 3602 0630

613 1 Threaded pin 9 1146 2040

614

.1 1 Hose 9 3602 0680

614

.2 1 Hose 9 3602 0620

616 4 Fillister-head screw 9 1110 3100

617 1 Tensioning sleeve 9 1630 0590

618 2 Bearing bushing 9 1029 0720

619 2 Adjusting washer 0,3 9 3331 1550

619 2 Adjusting washer0,1 9 3331 1560

620 1 Fillister-head screw 9 1110 5110

621 1 Washer 9 3302 0040

622 2 Fillister-head screw 9 1112 4070

623 1 Pressure piece 9 1810 0060

624 2 Connection piece 9 2113 0340

625 2 Fillister-head screw 9 1110 3110

626 2 Tensioning sleeve 9 1630 0240

627 1 Pressure strip 2 1330 6080

628 5 Threaded pin 9 1146 3050

629 5 Hexagonal nut 9 1210 0120

630 1 Adapter 2 1330 6090

631 1 Connection piece 9 2113 0350

632 1 Plug nipple 9 2115 0100

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 16 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 6000

Housing, Assy.

Item Qty. Description Part and Dratwing No. Remarks

634 1 Adjusting screw 9 1147 4050

635 1 Reducing piece 2 1330 6110

636 1 Cover 2 1330 9360

637 2 Locking screw 9 1171 9230

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 17 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 6000

Housing, Assy.

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 18 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 8000

Magnet, Assy.

Item Qty. Description Part and Dratwing No. Remarks

801 1 Magnet housing, Assy. 2 1330 8980

802 1 Magnet insert kpl. 2 1330 8990

803 1 Piston 2 1330 2130

804 1 Sealing ring 2 1330 2120

805 1 Quad.-Ring 9 1913 0030

806 1 Rack sealing 9 1911 0620

807 1 O-Ring 9 1901 2430

808 1 Snap ring 9 1703 0300

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 19 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 8000

Magnet, Assy.

Pneumatic Magnetic Drilling Machine

2 1330 0010 / 0030 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Compiled: 27.01.10 213300010_30_en_Version_02.doc Page 20 of 25

Spare Parts List

Description: Part and Drawing Number

2 1330 9000

Extended Rack

Item Qty. Description Part and Dratwing No. Remarks

1 1 Prism 2 1330 6120

2 1 Shim 2 1330 6130

3 3 Fillister-head screw 9 1112 4010

4 1 Clamp bolt 9 3902 0370

5 1 Hose 9 3606 0360

This manual suits for next models

1

Table of contents

Other Spitznas Drill manuals

Popular Drill manuals by other brands

101 Sampling Solutions

101 Sampling Solutions 2100R Operation & maintenance manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN STM 26 user manual

Fieldmann

Fieldmann FDV 2005-E manual

Scantool

Scantool COMPACT 75 Safety instructions and operator's manual

XTT

XTT XLT-DRL1801 user manual

Gude

Gude BS 18 Translation of the original instructions