Spitznas 2 3055 0010 User manual

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 1 of 16

Hydraulic

Drill

Type 2 3055 0010

Illustration can differ from the original

Operation and

Maintenance Manual

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 2 of 16

TECHNICAL SPECIFICATION

Drill Holder MK 3

Nominal Pressure 140 bar

Free speed / Speed under load 280/ 230 1/min

Torque 60 Nm at

150 bar and 280 1/ min

Fluid Hydraulic oil

Weight 8.5 kg

Connection/ Quick-lock coupling M 18 x 1.5

ID of hose DN10

Oil filtering ISO-Purity Degree 18/13

Power 1.6 kW

Noise level at 1 m distance 85.2 db(A)

Vibration level

Sand-lime brick

Medium hard concrete

3.4 m/s²

15.8 m/s²

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 3 of 16

SAFETY INSTRUCTIONS

ATTENION: Your own safety and the safety of the people near by depend on the careful and

appropriate operation of the drill. Before using it, make yourself familiar with the operation of the

drill and remove unnecessary people from the work area. Read all operation and maintenance

instructions before starting the operation. The drill is designed for special applications only.

We therefore thoroughly recommend not modifying and/ or using it for improper applications.

Before operating the drill, make yourself familiar with the following safety instructions:

1. Keep the work area clean and uncluttered.

2. Keep children away from the drill or the work area.

3. Proper Clothing

Do not wear clothes, which are too tight or too loose. This can constrain your movement,

resp. can be caught by the drill. This applies for jewellery as well.

4. Protect your head and hear, eyes and ears, hands and feet.

Wear a helmet, goggles and ear protection. Protect your hands with non-slipping gloves.

Safety shoes protect your feet. Disconnect the machine from the main supply after finishing

the work (avoidance of unexpected starting in uncontrolled condition).

5. Switch off the machine before laying it aside (shut valve). Disconnect machine from

power supply after finishing the work (avoid unintentional starting).

6. Stay alert

Fatigue leads to carelessness and accidents. Never work under the influence of alcohol,

drugs or stronger medication.

7. Safe working

If the drill rod jams, the torque rises immediately. Always be prepared fort his and hold the

handles tight. Ensure safe foothold and good balance.

The machine is operated by hand and stops at a torque of approx. 40- 45 Nm.

8. Avoid unintended starting

Never carry the drill with the motor running.

9. Follow the general current and appropriate Accident Prevention and Safety

Procedures.

10. Storage

At longer down times (a few days) rinse the motor with hydraulic oil.

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 4 of 16

OPERATION INSTRUCTIONS

The capacity of the machine is designed for a diameter of 48 mm and a depth of 12 m in coal and

stone with medium hardness.

The drill is operated with hydraulic oil. When feeding the drill from the system, it must be

considered that the machine is not operated at a bigger pressure as specified.

Pressure reducing valves have to be applied, otherwise the machine will be damaged or

destructed.

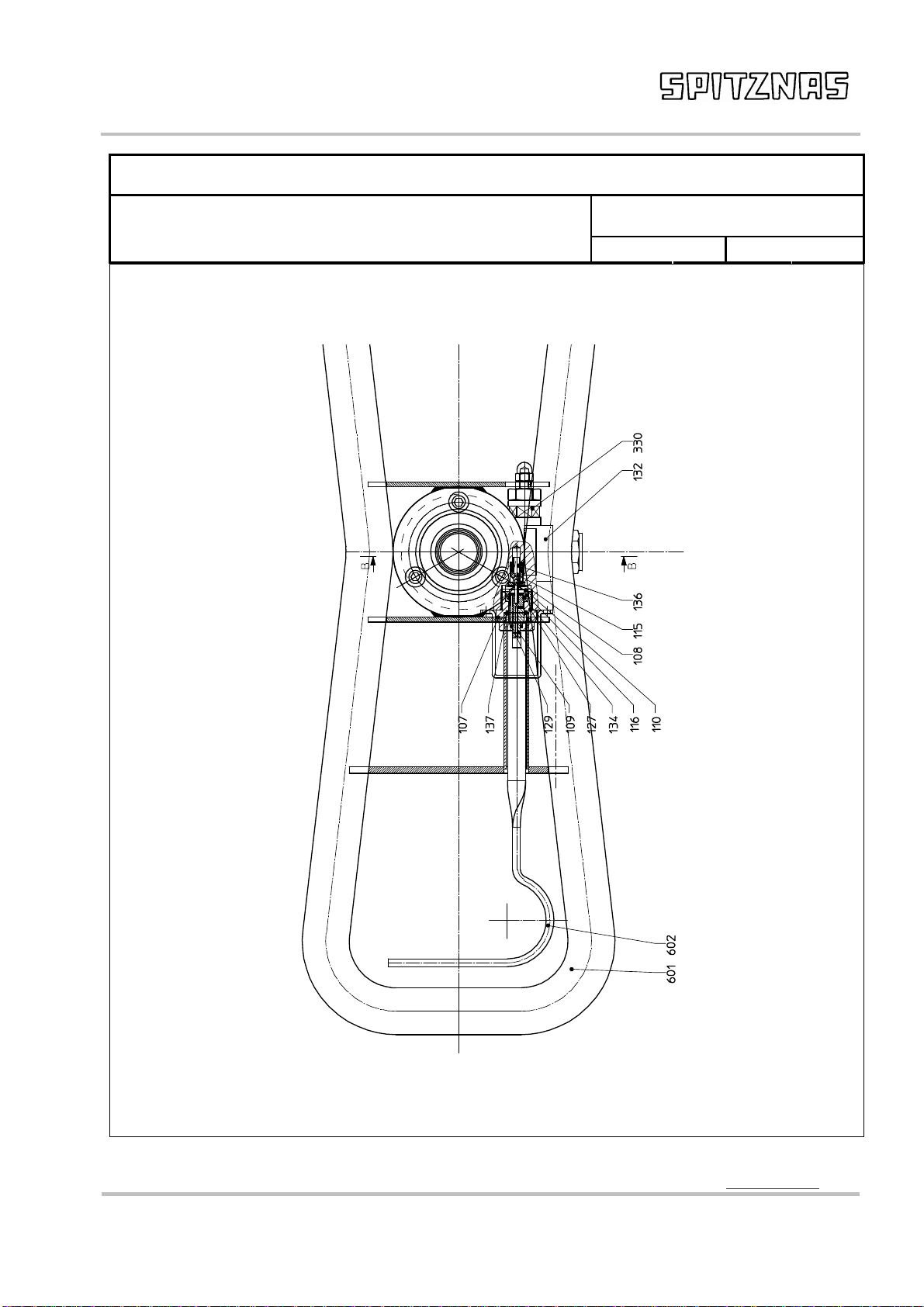

Fig. 2 Main Elements

1. Handle

2. Drive

3. Actuating Lever

4. Pressure supply „P”

5. Tank connection „T”

6. Overload valve

7. Drill holder

Connect the machine to the main supply according to fig. 3. Install the main valve (Fig. 3, item 7) in

the supply line, this allows locking the supply, e. g. when the system is modified.

Fig. 3 Switch Diagram

1. Drive

2. Actuating Lever

3. Return Valve

4. Overload Valve

5. Screen

6. Quick-lock coupling

7. Pressure hose

8. Tank hose

9, 10 Cut off cock

3

7

2

1

6 4

5

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 5 of 16

Drilling

•Install the tool at the machine.

•Hydraulic lines. Attention: Pay attention to the correct order of the hoses.

First tank hose “T” (see switch diagram fig. 2).

•Cool the drill with water

•Actuate valve and start the drill-/ reaming up work.

After finishing the drill work

•Release actuating lever (2)

•Shut main valve (9), shortly press actuating lever (2), release rest pressure and

disconnect hoses. First pressure hose „P“ – fig. 3.

•Take out drill tool.

•Clean retainer seat

Maintenance

Keep the tool clean

•Only regular maintenance ensures a constant capacity of the tool.

•During the use of the hydraulic drill pay attention ot the following:

oCleanness of the oil.

oAppropriate dirt protection of the lines and the connections of the drill.

oClean the drill after each job and protect it against corrosion with a light protection

oil.

oAt longer down time (a few days), rinse the drive with hydraulic oil.

Pressure Connection „P”

Tank Connection „T”

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 6 of 16

MAINTENANCE OF HYDRAULIC TOOLS

Only proper maintenance can ensure

constant performance, reduction in wear

and thus, a decrease in operating costs

and an increase in service life.

Our hydraulic tools are equipped for an

operating pressure of up to 100 bar.

Regulator setting for a lower operating

pressure is possible.

The tools should not run empty, because

this results in heat and higher wear of the

output section and the tool holder.

The hydraulic oil should be clean. This is

ensured by professional equipment.

Clean the connecting parts before

connecting the hydraulic hoses.

For an economic use of the hydraulic

tools the required sizes of pipe, fittings

and hoses have to be adjusted.

Proper greasing of the gear and the tool

heads is a must. See the operation

manual on this.

After finishing the work the tools have to

be cleaned and protected against

corrosion.

Visible grease nipples are provided for

regular lubrication of the gears with a

grease gun, or the gearboxes have a

long term greasing.

Note the following for grease lubrication:

Every 60 hours of operation check

striking mechanism, friction bearings and

antifriction bearings; if necessary, grease

them. Every 300 hours of operation

grease the gears and antifriction

bearings anew. In the case of impact

wrenches, use a grease gun to grease

the anvil guide before beginning daily

work, or every 6-8 hours.

All inner parts of the drive (tool holder

must be lubricated before storing for

longer periods of time in order to prevent

rusting. It is recommended to check the

vanes and bearings at regular intervals.

Store tools in dry rooms only.

Grease to be used:

In general: SAE 5 W to SAE 10

For impact wrenches without gear only SAE 5 W

For saw chain greasing on chain saws:

Machine oil with adhesive additive, viscosity:

c ST 49-55’ (6,5-7,5 E)/ 50°C

- Examples-

GREASE (free of acids and resins) Multi-purpose greases for antifriction

and friction bearings and gears Special greases for high-speed miter gears

Designation in accord. with DIN 51502

Consistency class (DIN 51818)

Saponification type

Dripping point

Worked penetration

Temperature range

K L 2 k

2

Lithium

185 °C

265 to 295

-25°C to + 125°C

G 000 h

00

Sodium

145°C

400 bis 410

-25°C bis + 100°C

For the operation of the hydraulic motor we recommend high-class hydraulic oil, e. g. HLP 46,

depending on the case of operation (temperature).

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 7 of 16

Spare Parts and Accessories

Only original spare parts may be used. There is no warranty for damages and liability is

disclaimed, if non-original spare parts and accessories are used.

The repairing of the machine is allowed authorized expert companies only.

Problem, Cause, Remedy

Problem Cause Remedy

The drilling is not satisfactory,

though the motor is running

properly.

•Pressure of oil too low

•dull drill rod

•Screen at pressure supply

clogged

•Check supply unit

•Replace drill rod (new)

•Clean the screen

Drill doesn’t start •Connections mixed-up

•Screen at pressure supply

clogged

•Connect correctly

•Clean the screen

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 8 of 16

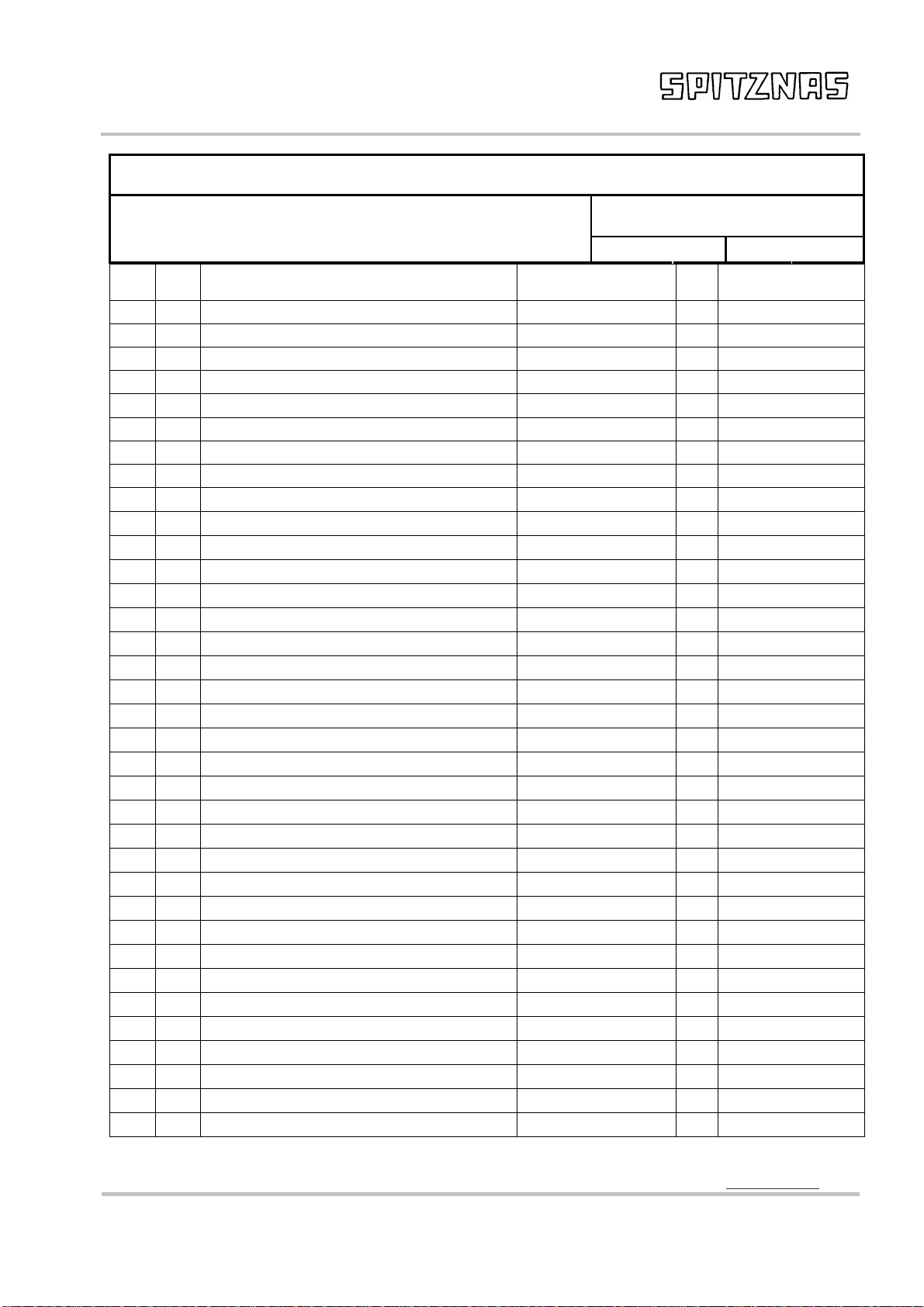

Spare Parts List

Description: Part and drawing number:

2 3055 0010

Hydraulic Drill

Item

Qty.

Description Part and

drawing no. Remarks

101

1 Motor housing 2 3053 1010

102

1 Drive 5 6075 1990

102.1

1 Rim of the gear 5 6075 1020

102.2

1 Rotor 5 6075 1030

102.3

10 Sprocket 5 6075 1050

102.4

2 Control plate 5 6075 1150

103

1 Drive shaft 2 3053 1040

104

1 End plate 2 3053 1120

105

1 Pressure screw 5 6075 1130

106

1 Pressure plate 2 3051 1140

107

1 Locking screw 2 3051 3050

108

1 Valve seat 5 6067 3070

109

1 Valve piston, Assy. 5 6067 3040

110

1 Pressure piece 5 6067 3020

112

1 Pin 5 6067 1160

113

1 Plug 5 6067 1170

114

2 Connecting nipple 2 3055 3810

115

1 Valve plate 2 3051 3140

116

1 O-Ring 9 1901 2340

117

1 Grooved ball bearing 9 1004 0450

118

1 Grooved ball bearing 9 1003 0520

119

1 Steel ball 9 1017 0060

120

1 Snap ring 9 1702 0140

121

1 Snap ring 9 1703 0150

122

1 O-Ring 9 1921 5080

123

1 Supporting ring 9 1919 0230

124

2 O-ring 9 1901 3610

125

1 O-ring 9 1921 1570

126

1 O-ring 9 1901 3280

127

1 O-ring 9 1921 6000

128

2 O-ring 9 1921 2640

129

1 O-ring 9 1901 2080

130

6 Bearing needle 9 1019 0170

131

1 O-ring 9 1901 3500

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 9 of 16

Spare Parts List

Description: Part and drawing number:

2 3055 0010

Hydraulic Drill

Item

Qty.

Description Part and

drawing no. Remarks

132

1 Locking screw 9 1174 0010

133

3 Fillister-head screw 9 1110 5100

134

1 O-ring 9 1901 2560

135

1 Radial shaft sealing ring 9 1905 0080

136

1 Pressure spring 9 1803 5130

137

1 O-ring 9 1901 3450

138

1 Water screen 5 6067 5010

139

1 O-ring 9 1901 3020

140

1 Supporting ring for o-ring 9 1919 0390

330

1 Pressure limiting valve 2 3051 3300 Pos. 331-346

331

1 Valve housing 2 3051 3310

332

1 Screw 2 3051 3320

333

1 Pressure pin 2 3051 3330

334

1 Spring plate, Assy. 2 3051 3340

336

1 Slide 2 3051 3360

337

1 Nut 9 1208 0080

338

1 Adjusting screw 9 1147 4080

339

1 Hexagonal nut 9 1203 0040

340

1 Pressure spring 9 1803 5000

341

1 O-ring 9 1901 3410

342

1 O-ring 9 1921 1450

343

1 Supporting ring for o-ring 9 1919 0300

344

1 O-ring 9 1901 2780

345

1 O-ring 9 1901 2560

346

1 Supporting ring for o-ring 9 1919 0280

141

1 Spacing ring 2 3053 1080

142

1 Guide bushing 2 3052 3850

143

1 Valve plate 2 3052 3860

144

1 Valve seat 2 3052 3870

145

1 O-ring 9 1901 2400

146

1 Pressure spring 9 1803 2640

148

1 Thread pin 9 1140 5010

149

2 Snap ring 9 1914 0260

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 10 of 16

Spare Parts List

Description: Part and drawing number:

2 3055 0010

Hydraulic Drill

Item

Qty.

Description Part and

drawing no. Remarks

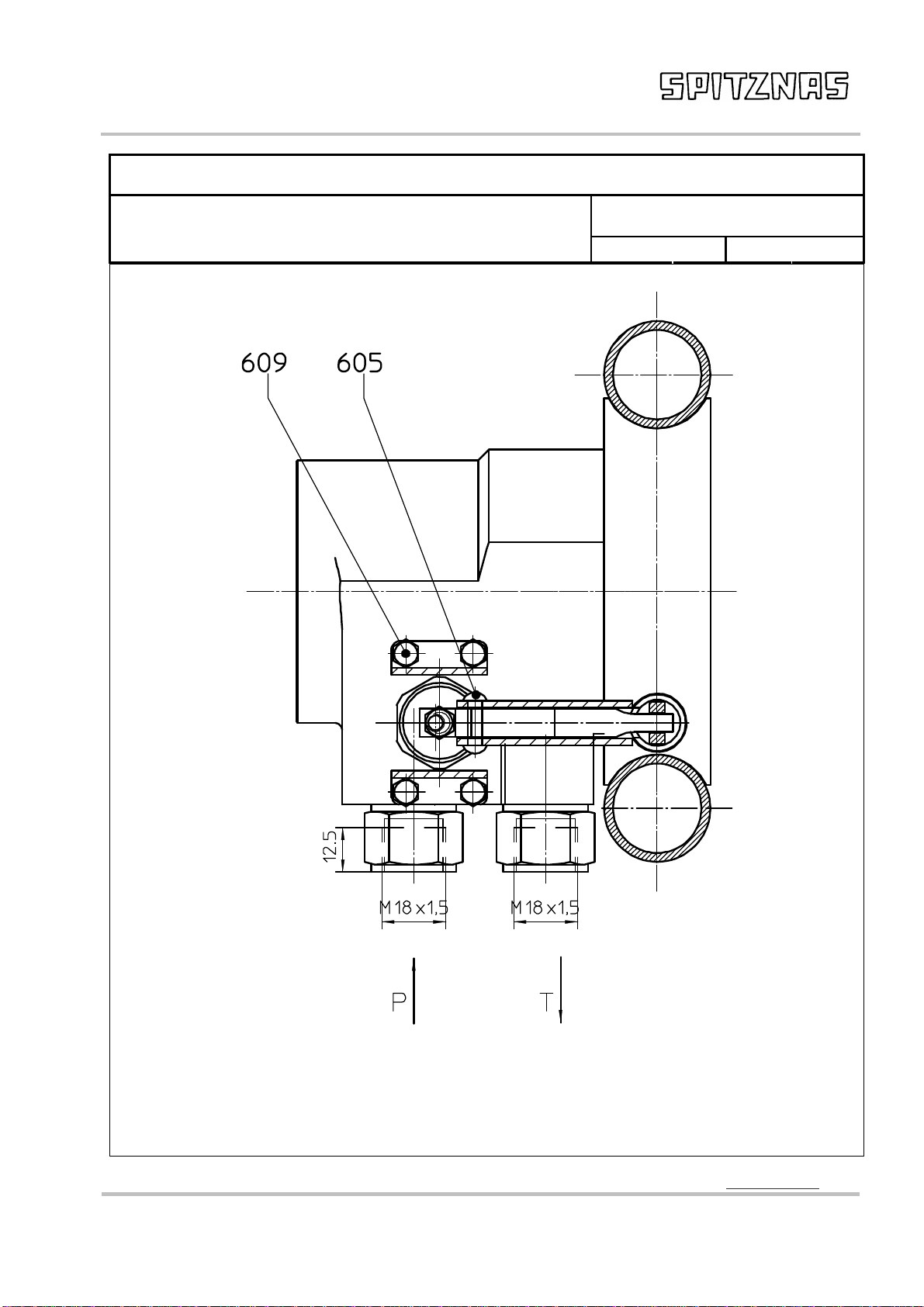

601

1 Handle, assy. 2 3053 6010

602

1 Tension rod 2 3053 6090

603

1 Hexagonal screw 9 1107 3080

604

1 Hexagonal nut 9 1209 0070

605

1 Half-round rivet 9 1603 0150

606

1 Valve lever 2 3053 6100

608

1 Protection 2 3053 6110

609

4 Fillister-head screw 9 1107 2010

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 11 of 16

Spare Parts List

Description: Part and drawing number:

2 3055 0010

Hydraulic Drill

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 12 of 16

Spare Parts List

Description: Part and drawing number:

2 3055 0010

Hydraulic Drill

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 13 of 16

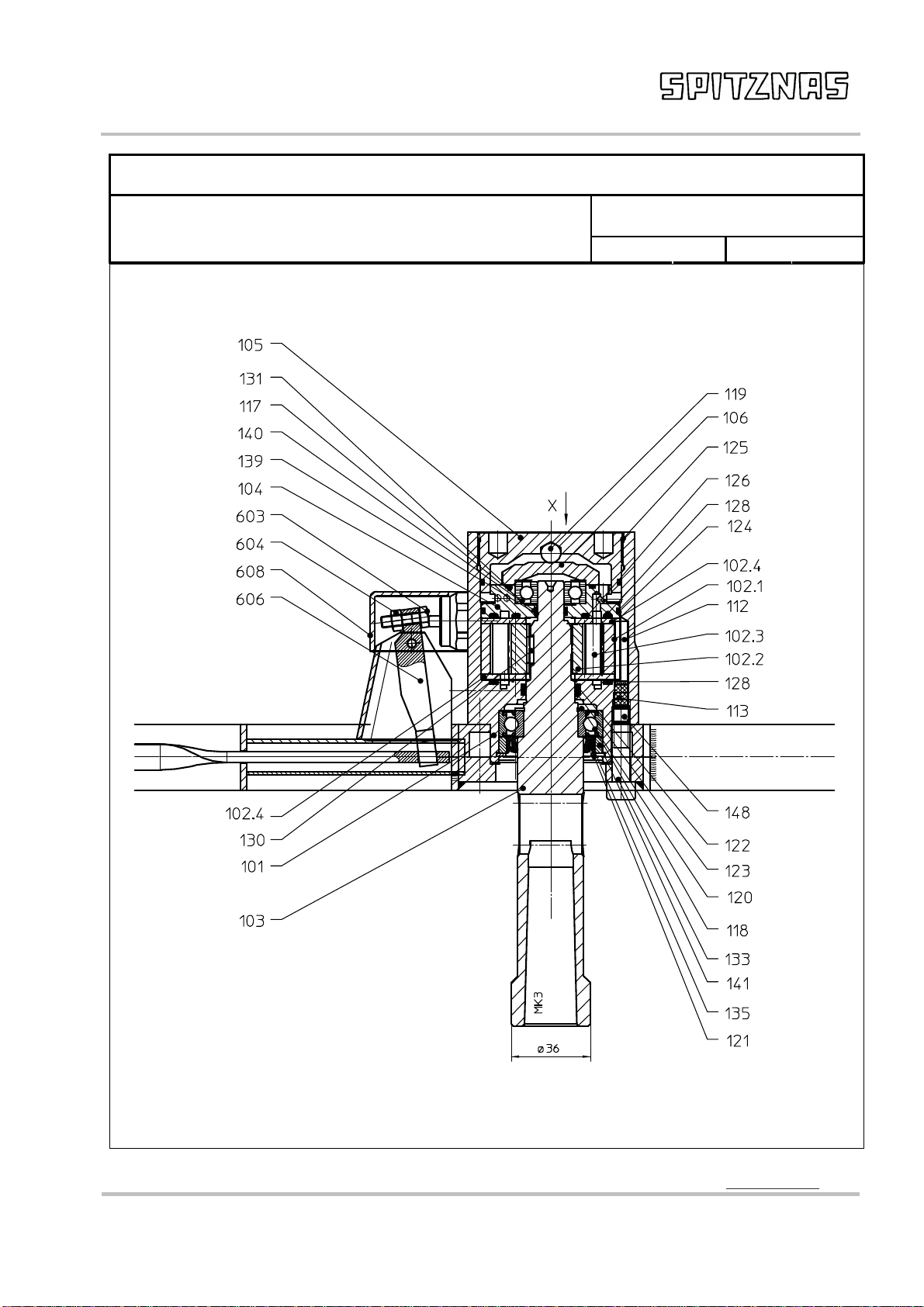

Spare Parts List

Benennung: Part and drawing number:

2 3055 0010

Hydraulic Drill

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 14 of 16

Spare Parts List

Benennung: Part and drawing number:

2 3055 0010

Hydraulic Drill

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 15 of 16

Spare Parts List

Benennung: Part and drawing number:

2 3055 0010

Hydraulic Drill

Item 331 – 346 Pressure Limiting Valve

Hydraulic Drill

2 3055 0010

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29

, www.spitznas.de

Translation of the original manual,

compiled: 14.02.11 230550010_en_Version_01 Page 16 of 16

D e c l a r a t i o n o f C o n f o r m i t y

as defined in the European Union Machine Directive 2006/42/ EC

for usable machines

We, the company

SPITZNAS Maschinenfabrik GmbH, Fellerstraße 4, 42555 Velbert– Langenberg,

declare that the following product

Description: Hydraulic Drill

Model 2 3055 0010

complies with the provisions of the European Union Machine Directive 2006/42/ EC,

and conforms to the following standards or standardized documents:

DIN EN ISO 12100

DIN 24063

Name of the authorized person for documentation: Mr. Wolfgang Klare

Address of the authorized person for documentation: see manufacturer’s address

42555 Velbert, 24.11.10

Table of contents

Other Spitznas Drill manuals