Spitznas 5 1212 0010 User manual

Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 1 of 10

Pneumatic

Reciprocating Saw

Type 5 1212 0010

5 1212 0050

5 1213 0010

Tech. Doc. No. 504

Illustration can differ from the original

Operation and

Maintenance Manual

Pneumatic Reciprocating Saw

5 1212 0010, 0050 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 2 of 10

TECHNICAL SPECIFICATION

Type 5 1212 0010, 050 5 1213 0010

Operating pressure 6 bar 6 bar

Motor output 1.1 kW 1.1 kW

Stroke number (under load) 330 1/min. 330 1/min.

Stroke of saw blade 60 mm 60 mm

Air consumption 1.45 m³/min. 1.45 m³/min.

Air connection R ¾” male R ¾” male

Operating pressure 6 bar 6 bar

Weight approx. 6.4 kg 10.65 kg

Cutting capacity for pipes Ø 530 mm Ø 530 mm

Cutting capacity for profiles 290 mm 290 mm

Vibration level at free speed < 2.5 m/s² < 2.5 m/s²

Noise level at 1 m distance 84 dB (A) 84 dB (A)

Pneumatic Reciprocating Saw

5 1212 0010, 0050 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 3 of 10

SAFETY INSTRUCTIONS

Any power tool can be dangerous.

Please follow these simple procedures.

They are for your protection.

Wear goggles ( chips – risk of injury)

Wear gloves (cutting damages by sharp edged work pieces)

Wear safety shoes

Wear protective clothing

Remove rings, watches, ties etc. that could be torn by the machine.

Dress properly. Do not wear loose clothing or jewellery, it can be caught in

moving parts.

Follow the general current and appropriate Accident Prevention and Safety

Procedures.

Never work under the influence of alcohol, drugs or stronger medication.

Always make sure that you have a safe foothold.

Maintain a proper footing and balance at all time. Never work with the machine

while standing on a ladder or leaning against a scaffold.

Secure the working place well. Use clamps or a vice to fix the work piece. This is

safer than using hands and clears both hands for operating the machine.

Hold the machine tight during operation.

Keep your working area clean and uncluttered.

Keep children away and avoid other persons to come into contact with the

machine.

Switch off the machine if it stops - for any reason - to avoid the unexpected

starting in uncontrolled condition.

Pneumatic Reciprocating Saw

5 1212 0010, 0050 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 4 of 10

Do not operate the tool if it is damaged, improperly adjusted or not completely

and correctly assembled.

Check air hose for damage.

Work with oleiferous air only.

Avoid sparks in hazardous environment - created by the saw blade. Always flush

material and saw blade for cooling with sufficient water during working.

Do not employ machines by excessive force. Their performance is better and

safer, if they work at the prescribed speed.

Check damaged parts.

Before using the machine, damaged parts or protective devices should be

carefully checked to make sure they work soundly and fulfil the designated

function. Check alignment, connections and attachment of moving parts. Also

check if parts are broken. Parts or protective devices that are damaged should, if

nothing else is mentioned in these operating instructions, only be exchanged or

repaired by qualified personnel. The same applies to defective switches and

valve triggers. If the machine cannot be switched on or off with the valve trigger,

it should not be used.

The use of other accessories, or other additional items than recommended in

these operating instructions, may include the risk of bodily injury.

Only operate the tool after a thorough training or under supervision of a trainer.

Never exceed the maximum operation pressure.

Follow the valid national provisions in the country of application.

ATTENTION! Never use the flexible hose as a lifting handle!

Use

Intended Use

Skilled personnel only is allowed to operate the machine.

The machine (reciprocating saw) serves for cutting (shortening, cutting off to length) of different

materials and profiles. Mainly the saw will be used fixed in a clamping device that is corresponding

to the intended purpose.

But cutting without clamping device is also possible!

Improper Use

Any use deviating from the intended use as described is considered to be improper use.

Working without personal protection equipment.

Pneumatic Reciprocating Saw

5 1212 0010, 0050 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 5 of 10

Danger Zones

Operational

condition

----------------

Life phase

Normal function Malfunction Improper use Expected use

Transport Transport of the

machine in an

inoperable

condition

Drop of the

machine

Transport of the

machine in an

operable

condition

unknown

Start-up

Operation

Operating the

machine with

designated

device

unknown unknown Working without

device

Machine only

works with

actuated valve

Machine runs

without actuated

valve

Switch is blocked

in actuated

condition

unknownOperation

Machine moves

the tool

Tool blocks unknown unknown

Maintenance Operation at a

maintenance unit

Breakdown of the

machine

unknown unknown

BEDIENUNGSANLEITUNG

General

Our pneumatic saw is designed for a service pressure of 4 to 6 bar. The pneumatic reciprocating

saw is only used in conjunction with a clamping device. For this purpose the ground- in receiving

bolt of the clamping device is placed in the cross hole in gear casing cover and fixed by means of

the locking device. Firmly clamped work-piece will yield a clean cut and will reduce saw blade

damage. The selection of the clamping device and of the saw blade depends on the type and size

of the work-piece. The saw blade must be cooled and/ or lubricated with lubricant or oil.

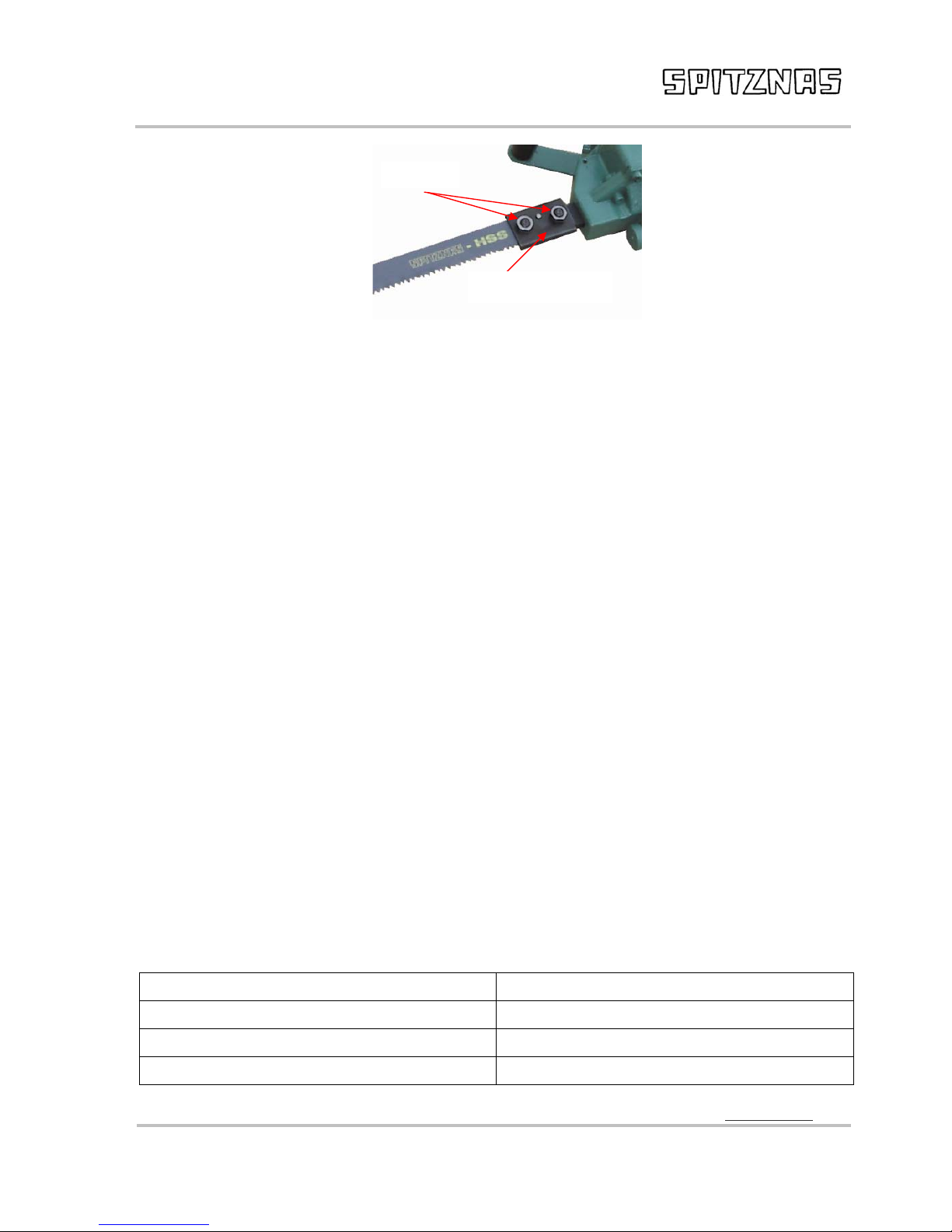

Cutting

- Check oil level and fill up oiler, if neccessary.

- Equip saw with the appropriate saw blade. For this loosen two nuts, take away the pressure

plate and put in the saw blade. Mount the pressure plate and fix it to the saw blade by

tightening the nuts.

Pneumatic Reciprocating Saw

5 1212 0010, 0050 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 6 of 10

- Connect pneumatic hose. (Before connecting, it is recommended to blow out the hose and

thus remove impurities).

- Actuate valve and press sensor button. (Only after pressing the sensor button, the channel

is opened. When the valve is closed, the sensor shuts as well. When the valve is opened

again, the sensor button has to be pressed again as well.)

- Start cutting.

- Ensure appropriate cooling (water) of tool and working piece.

After finishing the sawing work

- Shut valve

- Shut compresse air supply and disconnect air hose..

- Take saw out of the device.

- Clean saw and retainer seat.

- Check oiler

Wartungsanweisung

Unsere Druckluftmotoren sind für einen Betriebsdruck von 4-6 bar ausgelegt.

Die Lebensdauer und die Leistung dieser Maschine werden maßgebend bestimmt durch:

a) den Reinheitsgrad der Luft

Vor Anschluss an die Maschine den Luftschlauch ausblasen.

Wenn sich im Leitungsnetz Rost bilden und Wasser absetzen kann, sind Schmutz- und

Wasserabscheider vorzuschalten.

b) die Schmierbedingungen und Wartung

Siehe „Wartung von Druckluft-Werkzeugen“

Die richtige Fettmenge ist mit Rücksicht auf gute Schmierung und geringer Erwärmung sehr

wichtig. Die in nachstehender Tabelle aufgeführten Fettmengen müssen eingehalten werden.

Grease Quantity in grams

In the crank casing 100

In the bevel gears 40

In the spur gears 30

Nuts

Pressure plate

Pneumatic Reciprocating Saw

5 1212 0010, 0050 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 7 of 10

Pneumatic Reciprocating Saw

5 1212 0010, 0050 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 8 of 10

Pneumatic Reciprocating Saw

5 1212 0010, 0050 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 9 of 10

Spare Parts and Accessories

Only original spare parts may be used. There is no warranty for damages and liability is

disclaimed, if non-original spare parts and accessories are used.

The repairing of the machine is allowed authorized expert companies only.

The accessories applicable with our machine are listed in our brochure.

Troubleshooting

Problem Cause Remedy

a Machine does not

start

Air not connected

Connect and open air line

b Machine rotates too

slowly

Operating pressure too low

Increase operating pressure (on the

machine ) to 6 bar

c Gearbox makes strong

noise

Contact authorized expert company

d Other problems Contact authorized expert company

D e c l a r a t i o n o f C o n f o r m i t y

as defined in the European Union Machine Directive 2006/42/ EC

for usable machines

We, the company

SPITZNAS Maschinenfabrik GmbH, Fellerstraße 4, 42555 Velbert– Langenberg,

declare, that the following product

Description: Pneumatic Reciprocating Saw

Model 5 1212 0010, 0050

complies with the provisions of the European Union Machine Directive 2006/42/ EC

and 94/9 EC (Atex 95 – group II, category 2, G c T5) and conforms to the following standards or

standardized documents: DIN EN ISO 12100

DIN 24063

DIN EN 1127

DIN EN 13463

According to section 8 (1) ii) of the directive 94/9/EC technical documentation is deposited under

reference No. 968/Ex-AB 323/03 at the following office:

TÜV Rheinland Industrie Service GmbH

Haumannplatz 4, 45130 Essen

(Registration No. 0035 for the scope of

the Directive 94/9/EC)

Name of the authorized person for documentation: Mr. Wolfgang Klare

Address of the authorized person for documentation: see manufacturer’s address

42555 Velbert, 04.04.11

Pneumatic Reciprocating Saw

5 1212 0010, 0050 Maschinenfabrik GmbH

Spitznas Maschinenfabrik GmbH, Fellerstr.4, D-42555 Velbert, Tel: +49(0)2052 605 0, Fax: +49(0)2052 605 29, www.spitznas.de

Translation of the original operation

manual, compiled: 04.04.11

51212_51213_BA_en_Version_00.DOC Page 10 of 10

D e c l a r a t i o n o f C o n f o r m i t y

as defined in the European Union Machine Directive 2006/42/ EC

for usable machines

We, the company

SPITZNAS Maschinenfabrik GmbH, Fellerstraße 4, 42555 Velbert– Langenberg,

declare, that the following product

Description: Pneumatic Reciprocating Saw

Model 5 1213 0010

complies with the provisions of the European Union Machine Directive 2006/42/ EC

and 94/9 EC (Atex 95 – group I, category M2, c T5) and conforms to the following standards or

standardized documents: DIN EN ISO 12100

DIN 24063

DIN EN 1127

DIN EN 13463

According to section 8 (1) ii) of the directive 94/9/EC technical documentation is deposited under

reference No. 968/Ex-AB 323/03 at the following office:

TÜV Rheinland Industrie Service GmbH

Haumannplatz 4, 45130 Essen

(Registration No. 0035 for the scope of

the Directive 94/9/EC)

Name of the authorized person for documentation: Mr. Wolfgang Klare

Address of the authorized person for documentation: see manufacturer’s address

42555 Velbert, 04.04.11

This manual suits for next models

2

Table of contents

Other Spitznas Saw manuals