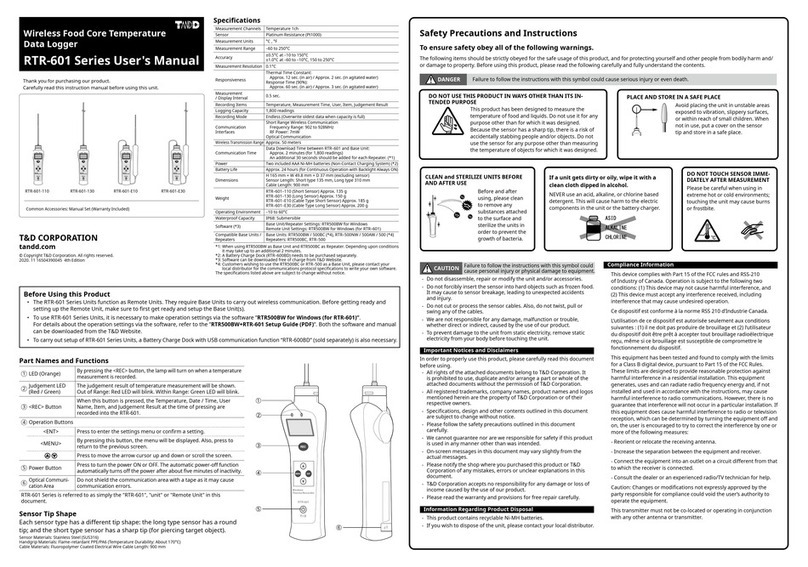

Splash Atlantis R10 User manual

R10 1st Stage

Service Manual

PATRIOT AS103

PATRIOT 1ST STAGE

Balanced Regulator 1ST STAGE

• Maximum working pressure 3500psi (232 bar)

• Low pressure port swivel assembly for versatile positioning

• Intermediate pressure output balanced piston

• 135-145PSI

• Four 3/8-24 UNF-2B intermediate pressure ports

• Two 7/16-20 UNF-2B high pressure port

• Chromium plated brass body

• Stainless steel springs

• Yoke or DIN

SPECIFICATIONS

PINNACLE AS-103

AIR FLOW 33 cu. ft. (935 liters/min). @ 1 atmosphere

INHALATION RESISTANCE 0.9” -2.0” (2.3 - 5.08 cm) w.c. @ 1 atmosphere

EXHALATION RESISTANCE 0.6” (1.52 cm) w.c. max. @ 1 atm.

RECOMMENDED LUBRICANT LTI Christo-Lube 111®

PINNACLE FIRST STAGE REGULATOR

TYPE balanced Piston Regulator - swivel

WEIGHT 2.1 lb.(.95 kg)

INTERSTAGE PRESSURE 135-145 psi (9.4-10 bar)

@ 3000 psi inlet (207 bar)

# LOW PRESSURE PORTS 4 (3/8”-24 UNF)

# HIGH PRESSURE PORTS 1 (7/16”-20 UNF)

MATERIALS Body -------- CDA-360 Brass

O-rings ----- Buna-N

Seat --------- TEFLON

ANNUAL SERVICE

REPLACEMENT PARTS:

790482

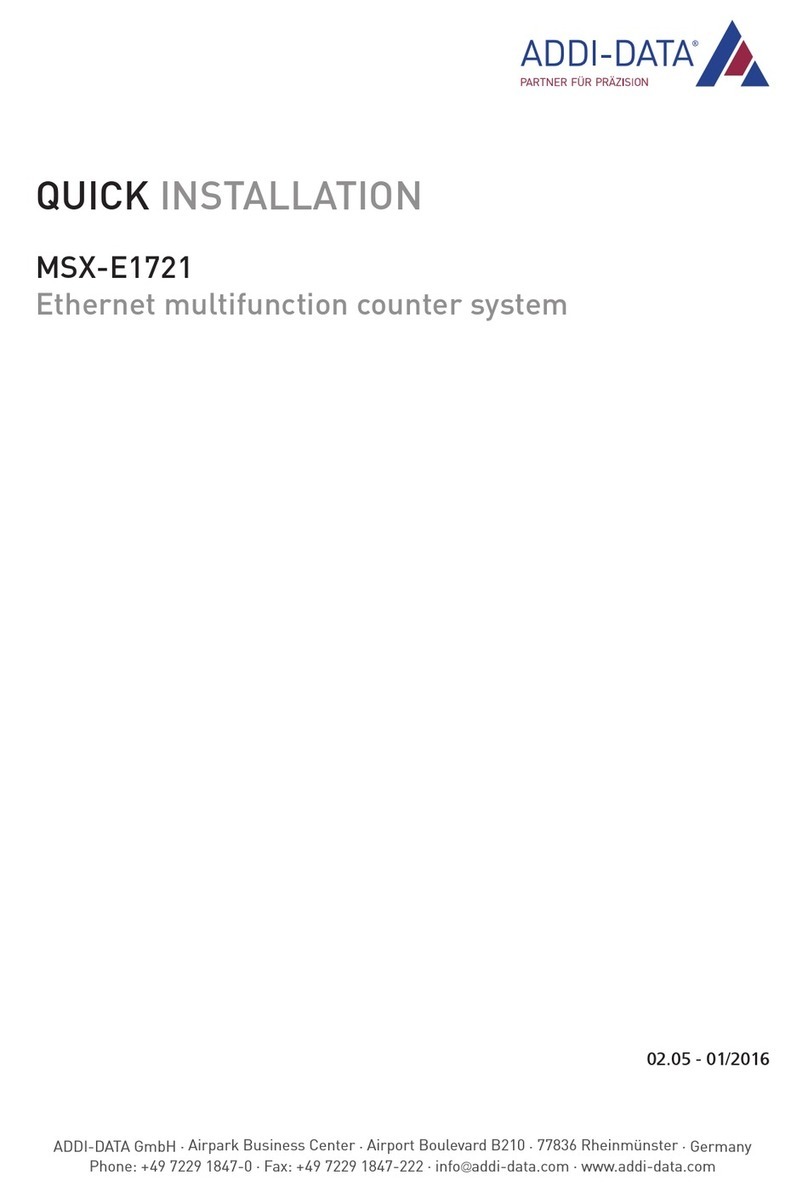

PATRIOT 1ST STAGE

Balanced Piston Regulator 1ST STAGE

‧ Maximum working pressure 3500psi(232 bar)

‧ Low pressure port swivel assembly for

versatil e positioning

‧ Intermediate pressure output balanced piston

135-145PSI

‧ Four 3/8-24 UNF-2B intermediate pressure ports

‧ Two 7/16-20 UNF-2B high pressure ports

‧ Chromium plated brass body

‧ Stainless steel springs

‧ YOKE OR DIN

BALANCE PISTON 1ST STAGE REGULATOR PART LIST

NO ITEM NO DESCRIPTION Q'TY

1 0111 YOKE KNOB 1

2 0055 YOKE 1

3 0133 YOKE RETAINER 1

4 0113 FILTER 1

5 2-011-02 O-RING 1

6 0118 DUST CAP 1

7 0132 SADDLE 1

8 0261 MAIN HOUSING 1

9 2-010-02 O-RING 1

10 0131-02 WASHER - THINER 1

11 0135 MAIN SPRING 1

12 0131-02 WAHSER - THICKER 1

13 0136 PISTON 1

14 2-022-01 O-RING 1

15 0137 SWIVEL RETAINER 1

16 0143 SWIVEL WASHER 1

17 0262 CAP 1

18 2-019-01 O-RING 1

19 0139 LP PORT SWIVEL 1

20 3-903-01 O-RING 3

21 0109 LP PLUG 3

22 3-904-01 O-RING 2

23 0108 HP PLUG 2

24 0264 STYLE CAP 1

25 2-014-02 O-RING 1

26 0140 HP SEAT 1

27 0141 HP SEAT CAP 1

28 0114 DIN HOUSING 1

29 0116 DIN WHEEL KNOB 1

30 2-012-02 O-RING 1

31 0115 DIN RETAINER 1

32 2-112-02 O-RING 1

33 2-019-01 O-RING 1 DIN ONLY

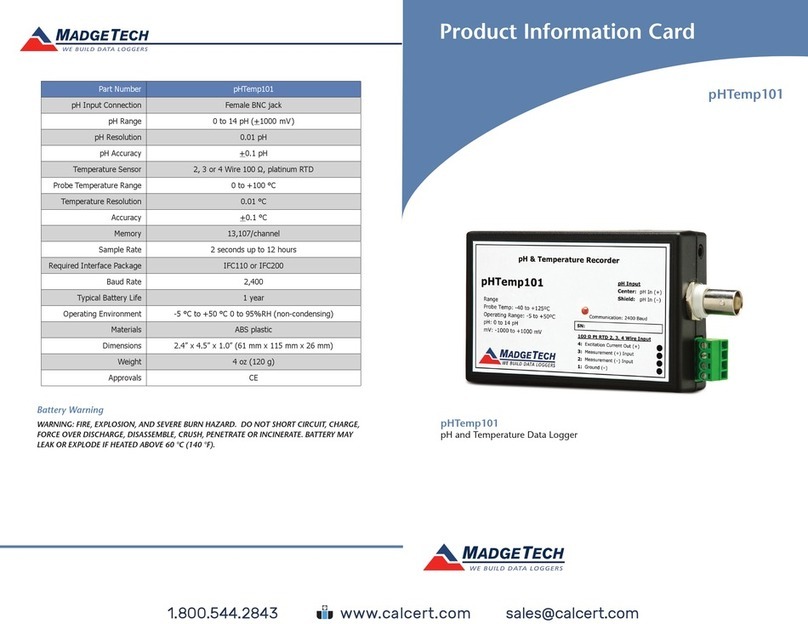

SERVICE KIT LIST 790482

NO PART NO DESCRIPTION Q'TY

9 2-010-02 O - RING 1 PISTON/BODY

14 2-022-01 O - RING 1 PISTON TOP

18 2-019-01 O - RING 1 CAP/LP PORT SWIVEL

20 3-903-01 O - RING 3 LP PORT OR ATLANTIS LP HOSE

22 3-904-01 O - RING 2 HP PORT OR ATLANTIS HP HOSE

25 2-014-02 O - RING 1 HP SEAT

26 0140 HP SEAT 1 STYLE SEAT /HP SEAT CAP

30 2-012-02 O - RING 1 DIN RETAINER INTERNAL

32 2-112-02 O - RING 1 DIN RETAINER EXTERNAL

33 2-019-01 O - RING 1 STYLE CAP / HP SEAT CAP

4 0113 FILTER 1

5 2-011-02 FILTER O-RING 1 FILTER

Torque Specications:

Description Item # Torque

Cap 16 120-140 in/lbs (13.56-15.82 N.M)

DIN HOUSING 21 16-18 ft/lb (21.70-24.41 N.M)

YOKE RETAINER 3 23-25 ft/lb (31.19-33.90 N.M)

DIN RETAINER 24 120-130 In/lb (13.56-14.69 N.M)

Port Plugs 18,20 35-40 In/lbs (3.96-4.52 N.M)

Hose inlet end 2-3 ft/lb (3-4 Nm)

Hose outlet end 2-3 ft/lb (3-4 Nm)

SERVICE PROCEDURES FOR THE AS-103

Before you begin disassembly of the regulator, test the rst and second stages for output

pressures and leakage. Pre-testing in this way will help the technician to pinpoint any specic

problems requiring repair.

SERVICE PROCEDURES FOR THE AS-103

The work area must be clean and well lit, with clean compressed air available to blow sand

and dirt from parts.

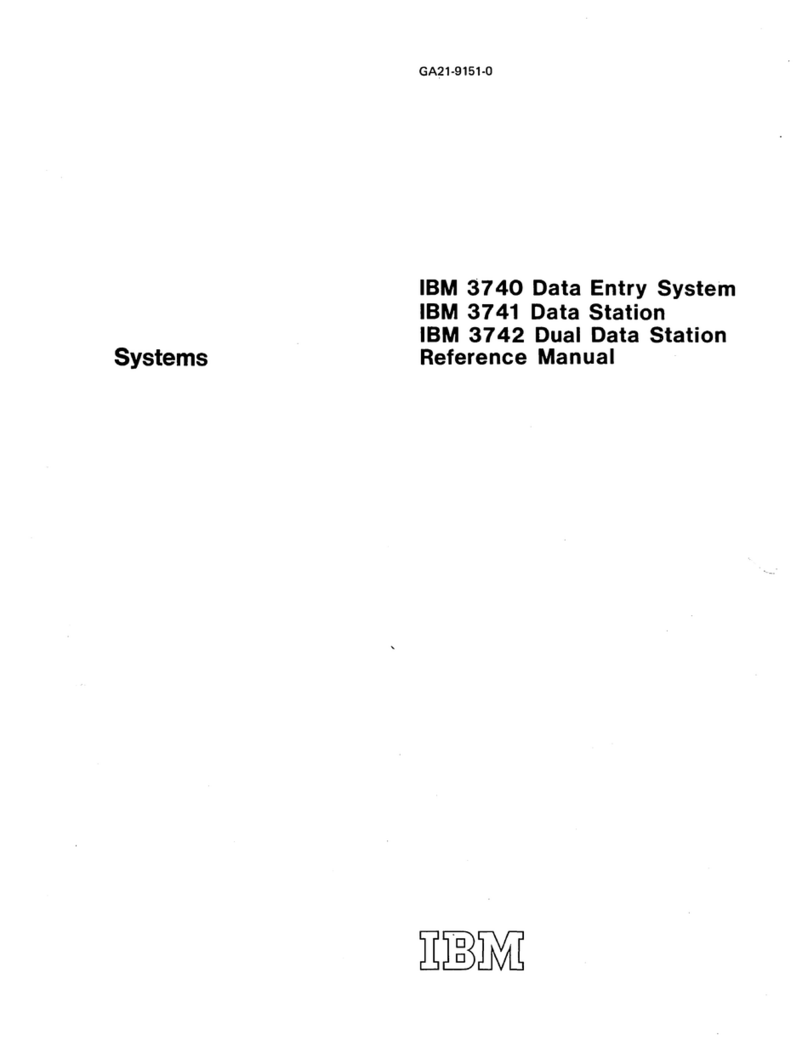

PATRIOT 1ST STAGE ANNUAL SERVICE KIT

HANDLE BAR

6" & 8" ADJUSTABLE WRENCH HOSE

4MM HEX BIT SOCKET ALLEN KEY = PORT PLUGS

PIN SPANNER RING SPANNER = CAP

1/4" HEX BIT SOCKET ALLEN KEY = HP SEAT RETAINER

8MM HEX BIT SOCKET ALLEN KEY = SWIVEL SEAT RETAINER

1.7MM DRILL BIT = SEAT

PISTON BULLET

1" HEX SOCKET

TORSION BAR

SOCKET WRENCH

TORQUE WRENCH 035 NM

INTERMEDIATE PRESSURE TESTING GAUGE

SILICONE GREASE

CHRISTO LUBE

0'RING PICKS

SOAPY SPRAY

YOKE ASSEMBLY

}

Use the 6” and 8” adjustable wrenches to loosen the hose nut from the PORT of the 1st

stage. Remove the hose assembly from the second stage.

Inspect the hose assembly for any cuts or cracks, especially on the hose at the metal

ferrules. Blow the interior bores of the hoses.

Replace the hose assembly if any cuts or cracks are found. Remove and discard the O-rings

from each end of the hose. Clean, rinse, and blow-dry the interior bores of the hoses. Replace

the hoses if necessary.

Put the body into the xture block or clamp carefully in a soft-jawed bench vise. Use 1" HEX

SOCKET to loosen and remove the yoke retainer (3) , the dust cap (6) and saddle (7).

Remove the yoke knob assembly (1) from the yoke (2). remove the inlet lter (4) and the lter

O-ring (5).

Use a 4MM HEX BIT SOCKET to remove all port plugs (21, 23) from the body. Discard the

port plug O-rings. (20, 22)

Screw the STAINLESS HANDLE BAR into the HP port. Put the body into the xture block or

on the table. Use the PIN SPANNER to remove the Cap (17) from the Body (8).

Remove any Spacer(s) (10, 12), the Spring (11) and the Piston (13) from the Cap. Remove

and discard the O-rings (14) from the piston. Remove and discard the O-rings (9) from the

body. Whenever possible, try to remove the O-rings by pinching them with the ngers and

rolling them out of the groove.

WARNING

If a sharp pick is used to remove the O-rings, it should be made from soft brass, not steel. ANY

scratches left in the groove when removing O-rings will cause leaks (bubbling out of the Cap

ambient pressure ports) and the piston or body will have to be replaced to stop these leaks.

Put the body into the xture block again with the hp seat cap (27) facing up. Use a 1/4" HEX

BIT SOCKET to remove the seat cap (27).

Remove the Seat (26) from the seat cap (27) by pushing it out with a 1.70MM DRILL BIT or

pneumatic pressure with air. Place one end of the drill bit on a at hard surface. Lower the

large end of the seat cap over the drill bit until the at end of the drill bit rests against the

back side of the Seat. Push the seat cap rmly down straight on the drill bit, until the seat is

pushed out of the seat cap. Discard the old Seat.

Remove the o-ring (25) from the body (8). Remove the o-ring (33) and style cap (24).

Screw the STAINLESS HANDLE BAR into the lp port swivel. Use an 8mm BIT SOCKET to

remove the swivel retainer (15) and swivel washer (16) .Remove and discard the o-ring (18)

from the cap (17).

Table of contents

Other Splash Data Logger manuals