Split-fire 4003 User manual

Thank You for Purchasing a Split-fire 4003

Woodchipper!

We appreciate having you as our customer and wish you many

years of safe and satisfactory operation with your machine.

SPLIT-FIRE SALES INC.

285633 Airport Road

Norwich, ON N0J 1P0

Canada

1-877-548-3473 / 519-468-3647

Please share a google review about your

Split-Fire experience

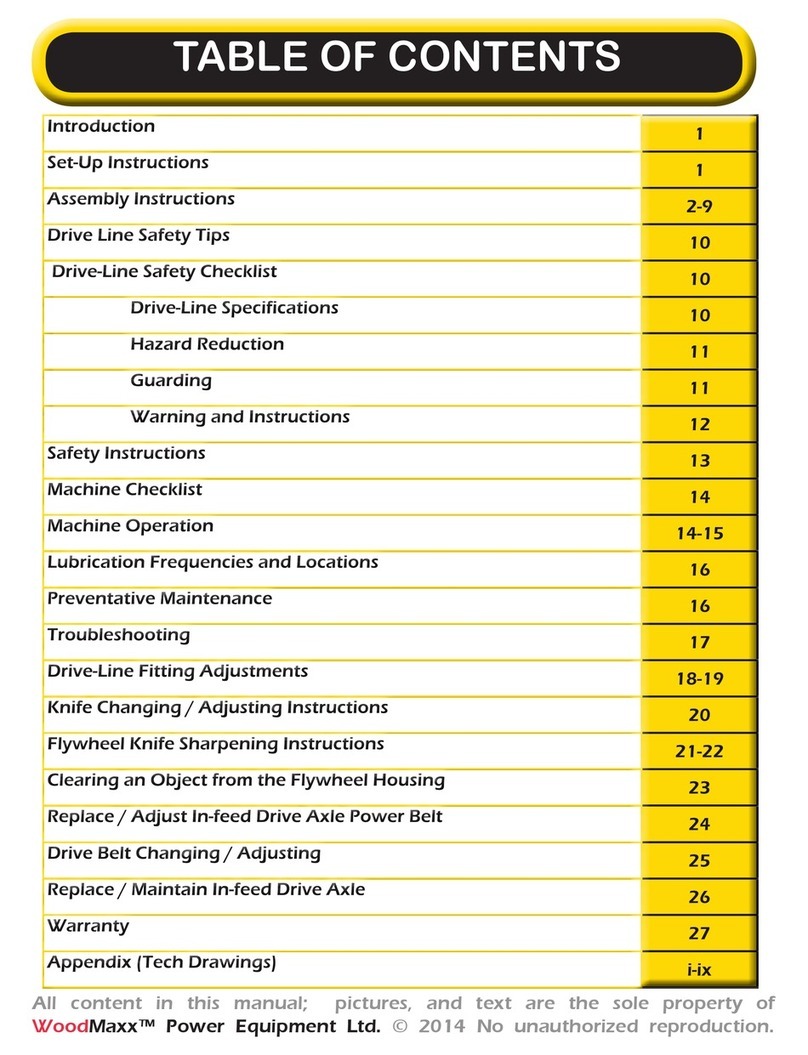

Contents

1. Introduction ................................................................................................................................................................. 4

1.1 How to use your Owner’s Manual........................................................................................................................ 4

1.2 Product Identification .......................................................................................................................................... 6

1.3 Warranty.............................................................................................................................................................. 8

2. Safety ........................................................................................................................................................................... 9

2.1 Safety Labels ........................................................................................................................................................ 9

2.2 Wood Handling Safety.........................................................................................................................................16

2.3 Operation Safety .................................................................................................................................................17

2.4 Worksite Safety...................................................................................................................................................19

2.5 Option Safety / Operation ...................................................................................................................................20

2.51 Rear Hitch ...................................................................................................................................................20

3. Chipping Capacity........................................................................................................................................................21

4. Operation....................................................................................................................................................................22

4.1 Before Operation ................................................................................................................................................22

4.2 Three Point Hitch Chipper Setup .........................................................................................................................24

4.21 Emergency Stop Configuration .........................................................................................................27

4.22 Infeed and Outfeed Clocking.......................................................................................................................29

4.3 After Operation...................................................................................................................................................30

4.4 Operation Troubleshooting.................................................................................................................................31

5. Maintenance ...............................................................................................................................................................33

5.1 Woodchipper Maintenance.................................................................................................................................33

5.11 Blades / Rotor Maintenance........................................................................................................................33

5.12 Rotor Maintenance .....................................................................................................................................34

5.13 Anvil Maintenance ......................................................................................................................................34

5.14 Bearing Maintenance ..................................................................................................................................35

5.15 Gearbox Maintenance.................................................................................................................................35

5.16 PTO Shaft Maintenance...............................................................................................................................36

5.17 Belt Maintenance........................................................................................................................................36

5.18 Latch Maintenance......................................................................................................................................38

5.19 Torque Spec Chart.......................................................................................................................................39

6. Storing Your Woodchipper..........................................................................................................................................40

7. Checklists ....................................................................................................................................................................41

Safe Feeding Checklist.....................................................................................................................................................42

Machine Operator Safety Instructions ............................................................................................................................43

Parts Breakdown.............................................................................................................................................................46

4003 Woodchipper

Introduction Owners Manual

5

1. Introduction

1.1 How to use your Owner’s Manual

This owner’s manual is a very important part of your new machine

and should remain a permanent part of it. If the machine is sold, the

operator’s manual must go with it.

By reading the operator’s manual you will help yourself and others

avoid unnecessary personal injury and/or damage to the machine

and will also allow you to perform maintenance to keep your machine

operating properly. The information recorded in this manual will help

you use this machine safely and effectively. Once you know how to

operate the machine correctly and safely, you can train others to

operate the machine as well.

If your machine has been ordered with any options or attachments,

please refer to the option safety section of the individual operator’s

manual that is included with that specific accessory.

The machine that is used in this manual for illustration may differ

slightly from your model. It will be similar enough to help you

understand our instructions.

Throughout this manual the terms “Left Hand” and “Right Hand” will

be used. These sides are determined when standing in front of the 3-

Point Hitch pickup, as if you are the tractor. The “Information Plate”

side of the chipper is the right side. Also “Back” and “Front” will be

used. On the 4003 woodchipper the “Front” refers to the 3PT Hitch

pickup location. So, the information plate would be located on the

front right of the 4003 woodchipper.

Your machine has been tested and inspected to pass quality control

at Split-fire’s Manufacturing facility to ensure good performance prior

to leaving the factory.

4003 Woodchipper

Owners Manual Introduction

5

While reading the manual, important messages are used to bring the

operator’s attention where there may be safety concerns relating to

machine damage and important servicing information. Please read

all these messages to avoid personal injury and machine damage.

The three main messages will start with:

WARNING!!!: which suggests, a strong chance of personal

injury or death to the operator or bystanders if procedures are

ignored.

IMPORTANT: which suggests, a strong chance of potential

damage to the machine may occur if procedures are ignored.

NOTE: suggests to the operator, General information given to

help the operator to operate or service the machine.

4003 Woodchipper

Owners Manual Introduction

6

1.2 Product Identification

If you ever need to contact your dealer or the manufacturer for parts

or questions regarding the operation or servicing of the machine, it is

important to have the model number as well as all the necessary

identification numbers. Using the sample pictures on page 7 you can

find the necessary numbers to complete the spaces below.

Date of Purchase:

______________________

Dealer Name:

___________________________________________

Dealer Phone Number:

______________________

Frame Serial Number: ( XX XX XX )

______________________

4003 Woodchipper

Owners Manual Introduction

7

Frame Serial Number

4003 Woodchipper

Safety Owners Manual

9

1.3 Warranty

Split-Fire Sales Inc. guarantees the original purchaser of any new

Split-Fire machine, that the same is free of defects in workmanship or

materials that may cause performance failure, subject to the

condition’s hereafter.

Split-fire must be contacted before the problem on the machine has

been fixed. Split-fire will diagnose the problem and authorize any

warranty work that will be allowed. If Split-fire does not authorize or

parts are not sent from Split-Fire, warranty will not be applicable.

This guarantee is limited to a period of one year from the date of

purchase. Replacement of any defective part is free of charge FOB

Split-Fire Sales Inc. If Split-Fire requires the parts to be returned to

Split-Fire, Split-Fire will pay for return shipping.

This guarantee does not apply to engines or other parts that are

manufactured and guaranteed by the manufacturer thereof, nor does

this apply with respect to any part or product that:

1. has original parts removed or otherwise altered without

specific authorization beforehand from Split-Fire Sales Inc.

2. has had placed upon or attached to it, any part or product not

sold or approved by Split-Fire Sales Inc.

3. has been damaged or is not used in conformity with the

applicable instruction for the machine.

4. has not been properly adjusted or maintained by the owner.

5. has been adjusted or altered to increase the performance of

the machine.

This guarantee is in lieu of, and excluded all other guarantees and

conditions of merchantability and fitness for a purpose. Acceptance

of a Split-Fire Sales product constitutes an agreement that Split-fire

Sales shall have no liability for any special or consequential damage.

4003 Woodchipper

Owners Manual Safety

10

2. Safety

2.1 Safety Labels

The machine safety labels shown in the section below are very

important. They are placed in areas on the machine that draw the

attention of the operator to potential safety hazards on the machine.

If at any time the stickers are removed, or come off, contact your

dealer or the manufacturer immediately for replacement decals.

The operator’s manual explains the potential safety hazards in detail

associated to each decal. Special attention should be kept for these

recommendations. They are outlined for your safety.

The Emergency Stop switch is a safety system that is in an easy

access point to stop the woodchipper in case of an emergency. The

emergency switch is situated at the top of the 3-point hitch pick-up for

easy access. When connected as outlined later in the manual this

switch will stop your tractors engine, and in turn the chipper.

4003 Wood Chipper

Safety Owners Manual

11

This sticker is located in the infeed chute. Do not remove or modify

safety guards on this machine or serious injury or death may occur.

Safety guards have been put in place for safe operation and must not

be removed at any time during operation.

This sticker is located in the infeed chute. Do not put hands, arms,

feet, legs or any body part in the infeed chute. If material needs to be

pushed down to engage the chipping blades use a forked push stick.

This will allow you to push the material into the blades without risk of

injury or harm.

4003 Woodchipper

Owners Manual Safety

11

This sticker is located in the infeed chute. It states the requirement of

eye protection, and a full-face shield is recommended. Wood flyouts

may occur and the correct PPE will ensure that the operator is safe.

This sticker is located on the chip deflector on the back of the

machine. When chipping wood, chips will be discharged out of the

discharge chute at high rate of speed. Angle the discharge chute

toward the ground to control the chips, and do not walk through the

stream of chips while operating the machine.

4003 Woodchipper

Owners Manual Safety

12

This sticker is located on the safety switch on the lower infeed chute.

Safety switches have been located in areas to maintain safe

operation. Do not tamper, modify or remove any safety switches on

this chipper.

This sticker is located behind the infeed chute latches. When

operating the machine, only remove the infeed chute after the

emergency stop has been actuated, the engine is switched off, and

after both the engine and the chipping rotor have come to a full stop.

4003 Woodchipper

Owners Manual Safety

13

This sticker is located on the discharge chute. When operating the

machine, at no time put hands or any body part into discharge chute.

If hands or any body part are inserted into the discharge chute during

operation, serious injury or death may occur. If the woodchipper is

jammed, the woodchipper must have come to a complete stop, the

emergency stop must be activated (down) and the tractor must be

switched off. Then any debris in the discharge chute can be removed

safely.

4003 Woodchipper

Owners Manual Safety

14

This sticker is located on the back of the infeed chute. This sticker is

a visual pre-run checklist for operators to study before they operate

the machine. Even after reading the owners manual, this pre-run

checklist must be read to ensure the operator is wearing proper PPE

and understands safe operation.

4003 Woodchipper

Owners Manual Safety

15

This chipper uses a PTO Shaft. It is important to always follow PTO

shaft guidelines. Always verify that the PTO shaft is in good operating

condition, with the applicable plastic safety shroud. Always ensure

that the safety shroud is fastened appropriately via the 2 attachment

chains. If the PTO shaft is not in proper operating condition, the

chipper must not be used.

It is important to always be careful when working around a PTO Shaft

as entanglement can cause serious injury or death. Never remove

guarding. Never operate above 540 RPM.

4003 Woodchipper

Owners Manual Safety

16

2.2 Wood Handling Safety

It is important that the operator understand wood safety when

operating a woodchipper. A general understanding of wood chipping

practices will make the operation easier and safer.

When cutting trees and tree limbs always use the appropriate PPE

and correct tools. If the tree is large, get help to make the job easier

and safer. Stack the branches and sticks in an organized pile away

from muddy patches. Muddy branches and sticks could have dirt,

gravel and other foreign material stuck to them which could damage

the woodchipper. Always give the branches and sticks a quick visual

inspection before feeding into the chipper. Foreign material will

damage the woodchipper and could cause serious injury or death.

This 4003 chipper has been designed for a max capacity of 4”

diameter. If branches are larger than 4” diameter, utilize the oversize

sections as firewood. If the branches are 4” diameter and under, cut

the branches as follows:

✓Cut to a manageable length of no more than 6’ long.

✓If branches are twisted and curvy, it may be beneficial to cut the

branches into shorter lengths for ease of transportation and

feeding.

✓If the branches have large Y sections, these may need to be

trimmed to enable them to be fed into the chipper. Keep in mind,

any branches with a Y can be utilized as forked push sticks to

feed tough and stubborn material into the infeed chute.

✓A large armload of small sticks and leaves can be loaded into the

infeed chute. This type of material may need to be pushed in with

a forked push stick.

x Do not load branches with mud, dirt, nails, spikes, or foreign

material. This will cause damage to woodchipper and could cause

injury or death.

Safe operation with clean branches and sticks will allow for safe and

effective operation of the machine.

4003 Woodchipper

Owners Manual Safety

17

2.3 Operation Safety

Carefully read and understand all the instructions pertaining to the

woodchipper in the operator’s manual before operating your new

machine. Anyone who operates or services this machine must read

the owner’s manual first. If any doubt or question arises about the

safe and/or correct method of performing anything in this manual,

contact our representatives at the Split-Fire head office.

Avoid accidents by being alert and recognizing potential hazards. Not

all possible circumstances can be anticipated in this manual. Keep

your woodchipper and work area safe for yourself and others. Proper

PPE , care and safety are your responsibility.

NOTE! This 4003 chipper must never be used indoors or in a

unventilated area. Your tractor’s engine will produce harmful carbon

monoxide that can seriously injure or kill.

x Never allow untrained persons to operate or service this

woodchipper.

x Never let persons under the age of 18 operate this woodchipper.

✓The owner is responsible for accidents and injuries to themselves

and/or other persons operating their machine. If others are

permitted to use this machine it is the responsibility of the owner

to train and supervise users.

✓New users may operate this machine in a clear, unobstructed

area under the supervision of an experienced operator, only after

they have read and understand the owner’s manual.

✓Only allow responsible adults who have read the owner’s manual

and are familiar with the controls to operate the woodchipper.

✓Inspect your machine each time before use. Special attention

should be taken that all components are in place, damaged or

missing parts are replaced, and that all the safety decals

4003 Woodchipper

Owners Manual Safety

18

highlighted in the safety labels section are in place and visible on

the machine.

✓Only one person may operate the machine at any time. More than

one operator greatly increases the chance of personal injury or

death.

x Never leave machine unattended while running.

x Never operate the machine when under the influence of alcohol

or drugs.

x Do not alter, add accessories, or attachements to your

woodchipper without the approval of the manufacturer. Doing so

without the manufacturer’s approval WILL VOID THE

WARRANTY. If attachments have been added with approval of

the manufacturer, be sure to keep safety labels visible.

✓Your machine is designed to chip wood only! Stones, metal,

gravel, and other foreign objects will cause damage to the

machine and will increase the chance of personal injury or death.

✓Always wear proper PPE before working on the worksite and

before starting and operating your 4003 woodchipper. Proper

PPE must include, but not limited to –Eye Protection, Ear

Protection, Foot Protection, Hand Protection.

4003 Woodchipper

Safety Owners Manual

19

2.4 Worksite Safety

Worksite safety is very important for operator safety. A clean

organized worksite will allow the operator to work safely and

effectively.

✓Keep area around the woodchipper clear from tall grass, debris,

tools, and large pieces or wood at all times.

✓Operate woodchipper on a dry level surface only.

x Do not operate machine when distracted by others. Keep children

and pets at least 50 feet away from the work area to protect them

from possible injuries. Keep other distractions such as electronic

devices, cell phones, etc. away.

✓Only use machine during daylight hours. Use of this machine

without proper lighting can lead to personal injury or death.

✓Protect yourself at all times while operating your machine. Safety

glasses, a wood working face mask, hand protection, steel-toed

boots and ear protection must be worn at all times.

✓The operator must wear fitted clothing at all time. Loose clothing

can increase the risk of injury or possible death.

x Do not transport this machine while the PTO is engaged. This

may cause permanent damage to your woodchipper.

✓Always disconnect the PTO shaft when the woodchipper is being

serviced.

4003 Woodchipper

Owners Manual Safety

20

2.5 Option Safety / Operation

2.51 Rear Hitch

The rear hitch is an option that allows the user to tow a utility trailer

behind the woodchipper. This option is for off-road use only!! If

installation is not completed by a Split-Fire technician, follow the

instruction manual associated with the option.

Rear Hitch Safety

- Do NOT use for on-road use

- Do NOT tow machinery / trailers faster than 40 km/h

- Do NOT tow machinery / trailers with a tongue weight over

200 lbs.

- Do NOT tow machinery / trailers with a gross weight over

800 lbs.

Rear Hitch Operation

The rear hitch is a static option that allows the user to tow

machinery / trailers behind the woodchipper. This option is for off-

road use only!! The rear hitch option does not affect woodchipper

operation in any way. The rear hitch option has a max tongue

weight capacity of 160 lbs. It is important that when chipping, the

machinery / trailer be either turned away from the discharge chute

or unhooked from the woodchipper for both operator safety and

damage prevention. The rear hitch can either be used as a farm

style hitch or can be fitted with a 2” ball for ease of use with any

utility trailer.

Table of contents

Other Split-fire Chipper manuals