SPM intellinova compact INS06 Ex Owner's manual

Installation and Operation Instructions

INS06 Ex

blanc

SPM Instrument AB • Box 504 • SE-645 25 Strängnäs • Sweden Technical data subject to change without notice.

ISO 9001 certified. ©Copyright SPM 2022-11. 72086 B Rev.8

Additional information

71421 “Installation of Measuring Equipment” describes the installation of transducer lines

(transducers, matching units, cables etc). “

72260 “Condmaster®Ruby, Installation and system administration” describes how to install the

Condmaster Entity Server (CES) Service, Condmaster software installation and setup, etc.

72261 “Condmaster®Ruby User guide” describes how to set up measuring assignments, work with

the alarm list, evaluation functions, reports, etc.

72262 “CES Admin Portal User guide” describes license activation, management of databases,

users, user groups, system settings, etc.

Trademarks

Airius, CondID, Condmaster, DuoTech, EVAM, HD ENV, Intellinova, Leonova, Leonova Diamond, Leonova

Emerald, SPM and SPM HD are trademarks of SPM Instrument AB.

All other trademarks are the property of their respective owners.

Patents

www.spminstrument.com/patents

© Copyright SPM Instrument AB. ISO 9001 certified.

Contents

Installation Instructions

Safety Arrangements........................................ 2

Installation Precautions..................................... 3

System Description........................................... 4

Conformity with Standards............................... 4

Mechanical Installation ..................................... 5

System Unit – Overview.................................... 6

Electrical Installation......................................... 7

Cable Entries ................................................. 7

Selection of Cables........................................ 7

Power Supply................................................. 8

Intrinsic Safety Earth ...................................... 9

Network Connection...................................... 9

Connection to PC .......................................... 9

Bearing Monitoring ........................................ 11

Connection of Shock Pulse Transducers....... 11

Mounting TNC Connector 93022 ................ 12

Vibration Monitoring ..................................... 13

Connection of Vibration Transducers ........... 13

Connection to IS-earth................................. 13

Connection of Digital Inputs, DI/RPM............ 14

Connection of Analog Inputs, AI .................... 15

Connection of Digital Outputs, DO................ 16

SD Memory Card ............................................ 17

Configuration ................................................. 17

Wi-Fi Ethernet unit (Option) ........................... 18

Service and Maintenance................................ 19

Technical Specifications INS06 Ex .................. 20

Part Numbers ................................................. 21

Approved Spares and Accessories ................. 21

– 2 –

Safety Arrangements

Safety Arrangements

General

All persons performing installation or service on rotating

machines and electrical equipment should be authorised

and familiar with general safety rules and IEC symbols

as well as local requirements, rules and regulations. This

equipment must only be installed, used and maintained

by competent personnel. Such personnel shall have

undergone training, which included instruction on the

various types of protection and installation practices, the

relevant rules and regulations, and on the general princi-

ples of area classification. Appropriate refresher training

shall be given on a regular basis (See EN 60079-17).

The installation, use and maintenance of this equipment

must comply with the appropriate European, national and

local regulations, which may include reference to the IEC

standards IEC60079-14, IEC60079-17 and IEC60079-19.

In addition, particular industries or end users may have

specific requirements relating to the safety (or health)

and these requirements should also be met. Instructions

and specifications issued by the manufacturer must be

followed.

In case of doubt, the local management should be con-

sulted. SPM Instrument will not be responsible for any

accident caused by persons not observing these Safety

Precautions.

The explosion-proof Intellinova®Compact Ex units are

used for stationary installation in hazardous areas classi-

fied to EN 60079-10 as Zone 2 or Zone 22.

Do not leave this manual or any other object inside the

enclosure when the unit is in service.

Operate the explosion-proof Intellinova®Compact Ex

units only for their intended purpose when in an undam-

aged and clean condition, and only where the material of

the enclosure is compatible with the environment.

If assembly is not carried out correctly, it cannot be ensured

that the cabinet is a restricted breathing enclosure EPL “Ex

nR” and dust ignition protection by enclosure EPL “Ex tc”.

No modifications that are not expressly specified in this

Manual are allowed to the Intellinova®Compact Ex units.

Whenever work is done on the Intellinova®Compact Ex

units, the national safety and accident prevention regula-

tions and the safety instructions given in this Manual must

always be observed!

Disconnection

Before starting installation work on machines, make sure

that main power is off and will stay off until the work is

done. Do not simply pull the switch - remove the fuses,

lock the fuse box, put up warning signs. Check all termi-

nals to ensure that the equipment is voltage-free by using

a Ex-certified voltage tester.

Electrical Installation

Always read the instructions delivered with the equip-

ment before performing installation or service on elec-

tric equipment. If you are in doubt, please contact your

local SPM Instrument representative before installing

the equipment. Damage of the equipment caused by

incorrect installation is not covered by product warranty.

Before starting installation work, make sure that the

main power switch is in off position and will stay off until

the work is done. Check that all terminals, marked with

protective earth IEC symbol, are properly connected to

the protective earthing conductor of the building instal-

lation wiring. In some countries, the term "protective

grounding" is used instead of "protective earthing".

Earth and ground are used synonymously in this instal-

lation instruction. Choose installation tools that are safe

and suitable for its working environment. Electrical risks

can sometimes be eliminated by using air, hydraulic or

handpowered tools. These are especially useful in harsh

conditions.

System Components

To ensure optimum safety for user and environment,

only original system components available from SPM

Instrument should be used. When using non-original

components, the compliance with EU directive with re-

spect to electric safety, EMC, ATEX and machine safety

is not guaranteed by SPM Instrument.

Reapplying Power

For human safety, ensure that the electrical equipment

or installation is electrically safe. Before starting the

machine, make sure that all protection covers on the

machine are mounted and secured. Perform periodic

pressure testing to ensure enclosure is not leaking.

Symbols

Protective

earth

ATEX and UKEX certified

electrical equipment for

explosive atmospheres.

EU certified

equipment

Rotating

parts

Risk for electric

shock

Caution

Intrinsic safety

earth

– 3 –

Installation Precautions

For installation and operation, the rules of generally

accepted engineering practice, the provisions of EN

60079-14: 'Electrical installations design, selection and

erection', EN 60079-17: 'Electrical installations inspec-

tion and maintenance' and the instructions set out in

this Manual must be observed.

Installation of Measuring Units and Measuring Terminals

The explosion-proof Intellinova®Compact Ex units must

be installed at carefully selected locations where they

cannot be damaged by mobile equipment such as pallet

and forklift trucks.

Measuring units and terminals should be located in a

protected position assigned by the local management.

The units shall be easily accessible for undisturbed

measurements and service. The measuring equipment

should be intended and specified for use in existing

environment. It is important that you read the operating

instructions completely and follow all safety precau-

tions before operating the measuring units. Electrical

connections and wiring should be performed only by

suitably trained personnel.

Specific Condition of Use

The following conditions relate to safe installation and/

or use of the equipment:

• A warning label must be shown, stating “WARNING

– Do not open, maintain or service in an area where

explosive atmosphere may be present”

• A warning label must be shown, stating “WARNING –

Ensure door is correctly tightened when closed”

Work Regulations

All personnel should be provided with the local work

regulation before any work is commenced. It is impor-

tant that parts of metal, rubber and plastics are dumped

in special containers. Such parts can cause bad accidents

and production disturbances if dropped on the wrong

place. From an environmental point of view, wrapping

materials should be collected so as not to cause dam-

age. Precautions should also be taken when drilling,

tapering and grinding to avoid chips and grindings

causing accidents and production disturbances.

Inspection and Acceptance

Inspection of transducer positioning, connections, ca-

ble laying, TMU installations and strapping should take

place after finished installation.

After completed installation, the restricted breathing

properties should be checked according to “Periodic

pressure testing”.

The installation should be inspected and accepted when

in compliance with EN60079-14.

Installation Precautions

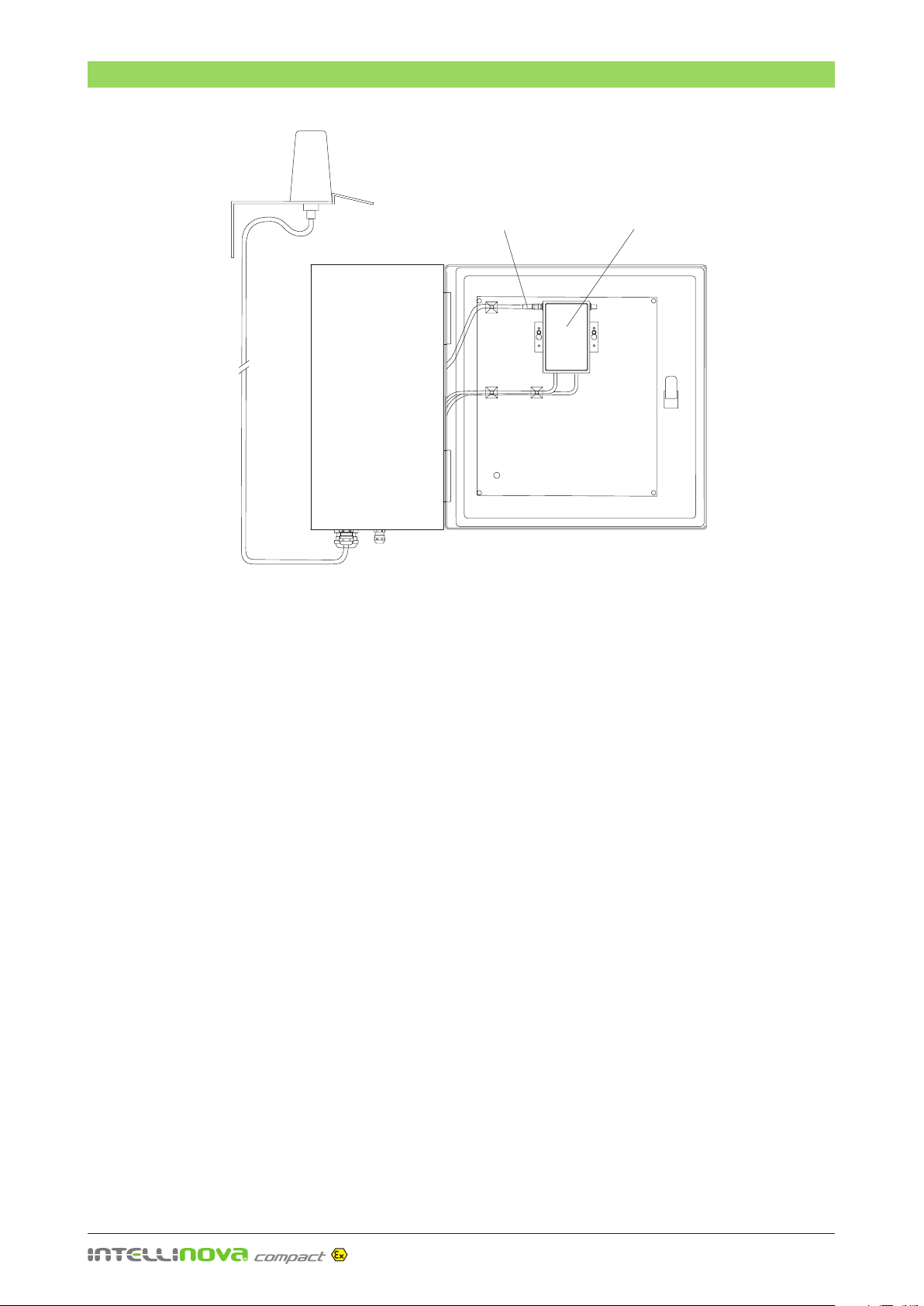

Installation in Hazardous environments

The Intellinova®Compact Ex unit meets the requirement

to be installed in safe or Ex zone 2/22. Sensors installed

in Ex zone 0/20 and 1/21 is connected to the Intellinova®

Compact Ex unit with Ex interfaces. A typical hazardous

installation is exemplified as illustration below.

Read the entire instruction manual

before the products are put into use!

– 4 –

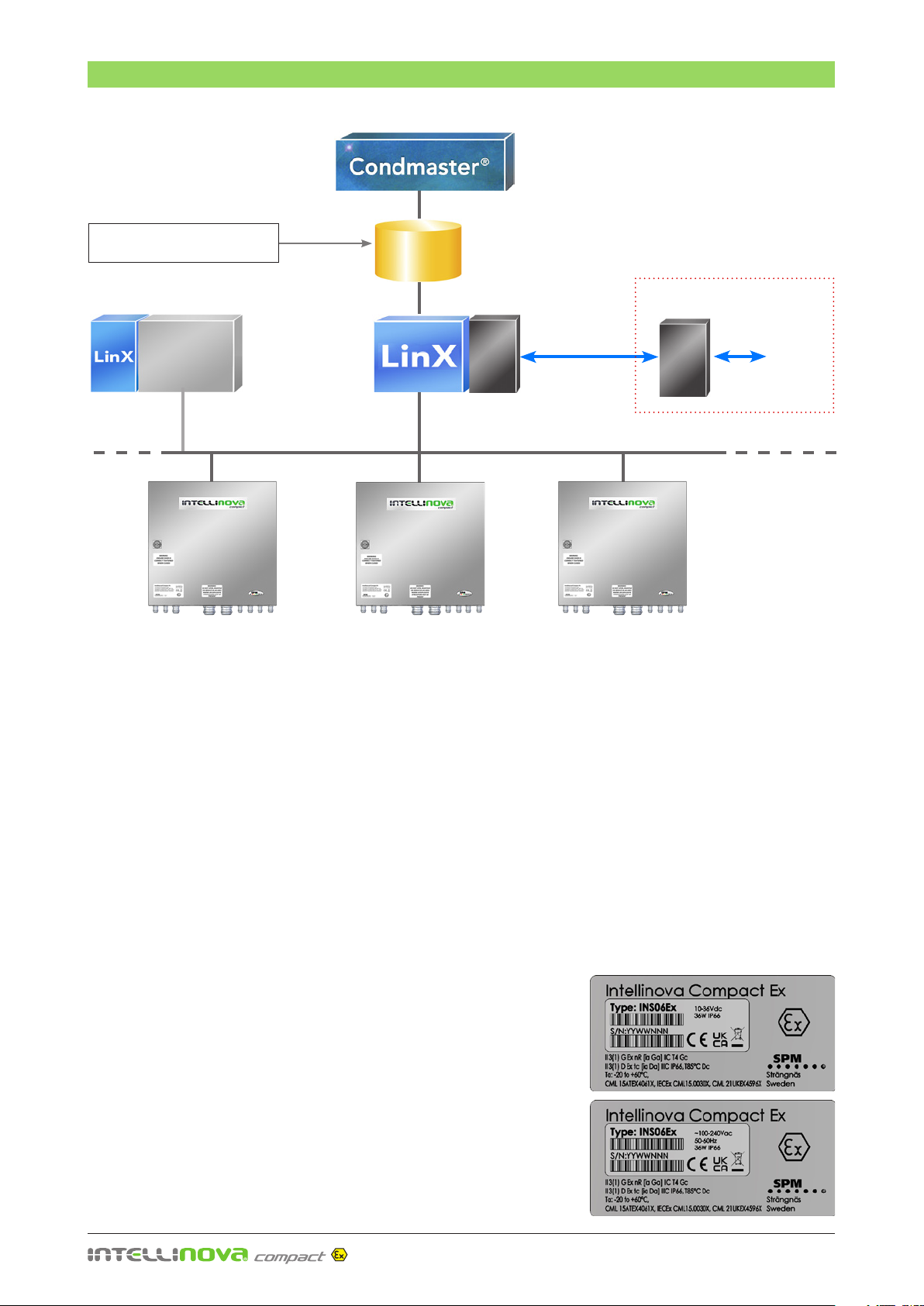

System Description

System Description

The Intellinova®Compact Ex system is a permanently

installed, online machine condition monitoring sys-

tem. It is handled by the comprehensive software

Condmaster®Ruby or Condmaster®Nova, which controls

the system, collects, stores, and evaluates the measuring

results. Via Ethernet, the Intellinova system is connected

to a computer with the software Condmaster®, and the

communication program LinX. The measuring assign-

ments are set up in Condmaster®and LinX transmits the

measuring assignments to and reads the result file from

the Intellinova System Unit. Measuring results are stored

in a historical database. System functionality and trans-

ducer lines are automatically monitored for malfunctions.

The core of the system is the SPM Instrument software,

Condmaster®, which receives the measuring results from

all SPM Instrument devices for evaluation and presenta-

tion. Based on extensive empirical data, international

standards and machine statistics, the evaluation result is

an easy-to-understand color code, highlighting potential

trouble spots. By calibrating and adjusting limit values,

the automatic evaluation process can be tuned with great

precision to get an immediate, reliable diagnosis. Intel-

linova implements OPC™ Data Access, through which

process control data can be transferred seamlessly to and

from any data source, such as DCS or SCADA systems,

PLCs, databases, gauges, spreadsheets etc. to any OPC

compliant application. Intellinova®Compact Ex is robustly

designed in every aspect, made for harsh and potentially

explosive environments and long-term use.

Conformity with Standards

The explosion-proof Intellinova®Compact Ex units meet

the requirements of EN 60079-0, EN 60079-15 and EN

60079-31. They have been developed, manufactured

and tested in accordance with ISO 9001 and EN ISO/

IEC 80079-34.

Existing SPM online systems

System Unit 1

Data base

Service laptop

Process

Control

System

Ethernet

Data Access

Customer systems

Ethernet/

SD card

System Unit 2 System Unit 3

OPC

Client/

Server

FSS

Field Support

Software

OPC

Client/

Server

– 5 –

Installation with mounting braces (SPM 81524)

Mechanical Installation

Mechanical Installation

Mounting

The Intellinova®Compact Ex units have an industrial cabi-

net designed for wall mounting. It should be mounted

vertically with 4 bolts through the 8 mm holes in mount-

ing braces as shown in the figure. Use mounting bolts

with material quality Stainless Steel recommended to

DIN912, ISO4762.

The Intellinova®Compact Ex unit shall be mounted in a

way that allows access to the test port.

Environment

The cabinet is made of stainless steel and has silicone

gaskets (IP66). Environmental limitations are according

to the technical specification. The electrical environment

must be suitable for data cables.

380

380

210

410

434

326

10

340

344

XX

– 6 –

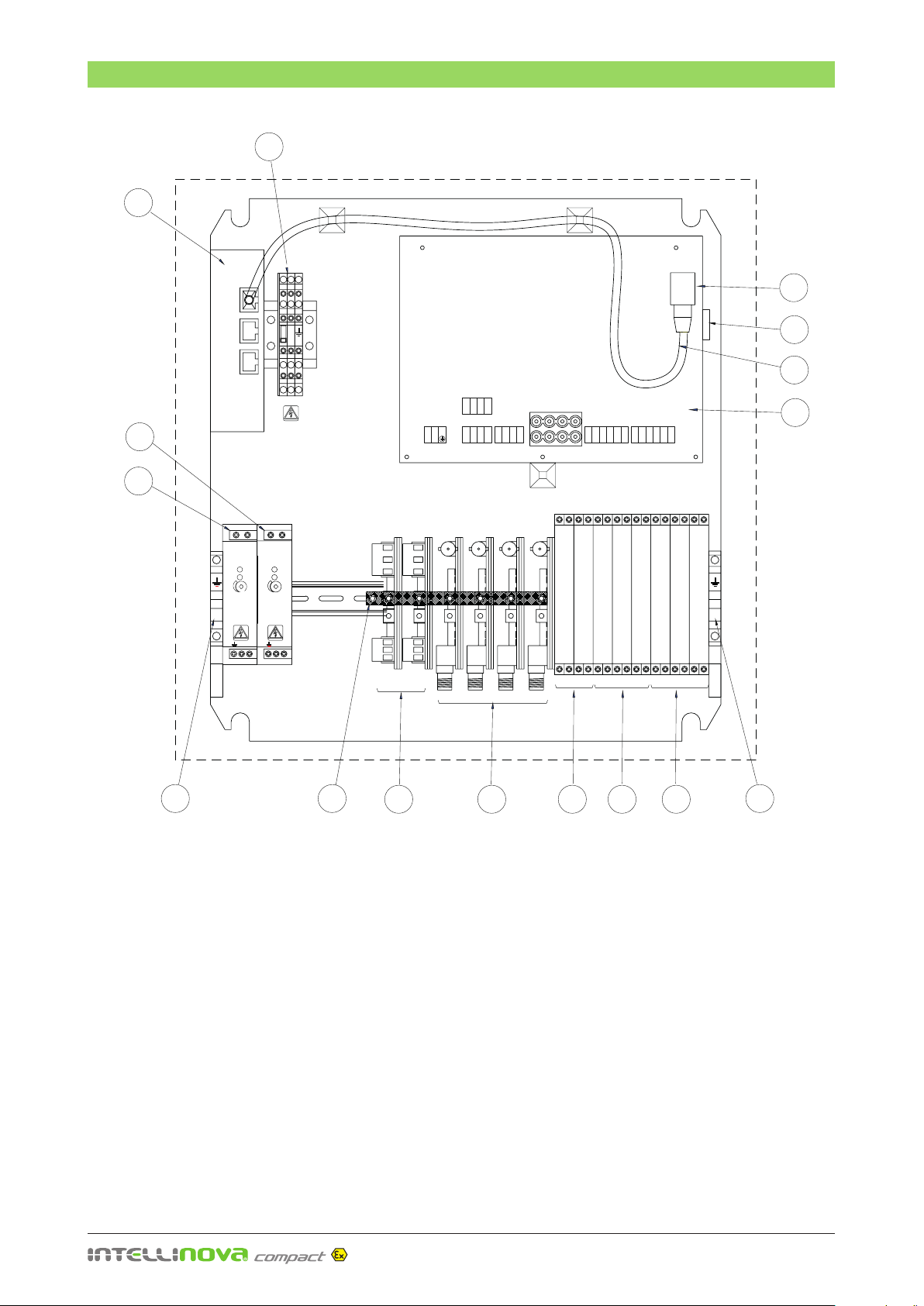

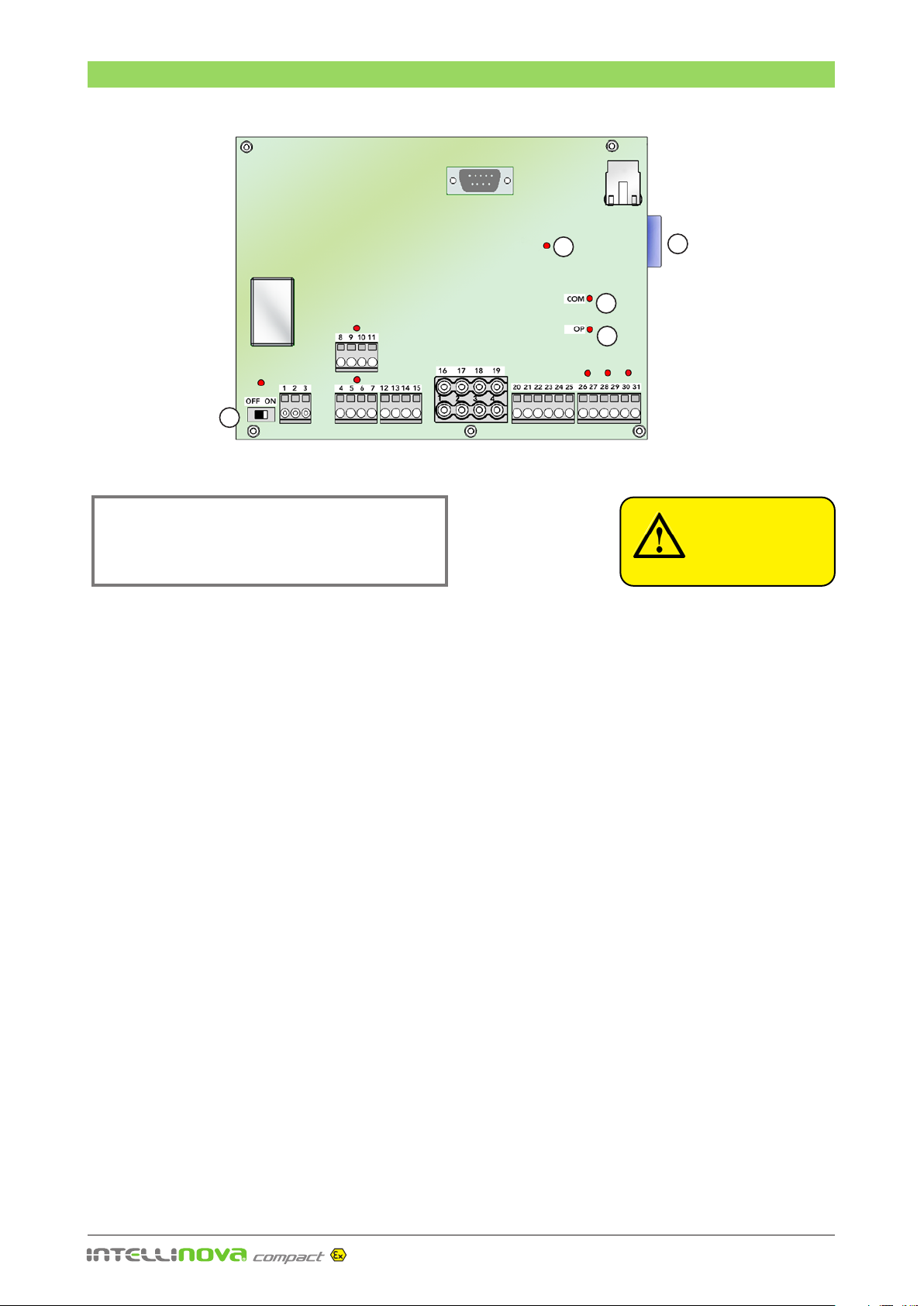

System Unit – Overview

IS-EARTH

IS-EARTH

14

2

10987

13

4

6

5

1

3

11 12

12

15

+ -

+ -

V- V+

V- V+

24 VDC/0.75A

24 VDC/0.75A

LO

LO

ON

ON

Vout ADJ.

Vout ADJ.

100-240 VAC

100-240 VAC

0.5A

0.5A

47-63Hz

47-63Hz

N

N

L

L

1

1

2

2

3

3

4

4

5

5

6

6

7

7

12

12

13

13

14

14

15

15

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

8

8

9

9

10

10

11

11

16

16

17

17

18

18

19

19

V- V+

V- V+

12 VDC/0.75A

12 VDC/0.75A

LO

LO

ON

ON

Vout ADJ.

Vout ADJ.

100-240 VAC

100-240 VAC

0.5A

0.5A

47-63Hz

47-63Hz

N

N

L

L

N

N

L1

L1

1 Circuit board

2 Ethernet connector

3 SD memory card

4 Power supply terminal blocks

5 Power supply unit 12V DC

6 Power supply unit 24V DC, Option

7 VIB transducer Ex interface

8 SPM transducer Ex interface

9 RPM/DI sensor Ex interface

10 Analog in (AI) Ex interface. Special order only.

11 Digital out (DO) Ex interface. Special order only.

12 IS-earth terminal blocks

13. Earth rail

14 Ethernet switch, Option

15. Internal Ethernet cable, Option

System Unit – Overview

– 7 –

Electrical Installation

Test Port

A

A

B

B

C

C

D

D

E

E

E

E

F

F

G

G

BOTTOM VIEW

PE Earth screw

Cable Entries

For type “Ex nR” and “Ex tc” explosion-proof Intellinova®

System units, only those cable and conductor entries and

plugs that possess an EC type-examination certificate

(Category 3 G or 3 D) issued by a European Notified Body

as per European Standards EN 60079-0, EN 60079-7, EN

60079-15 and EN 60079-31 may be used.

The cable and conductor glands must be installed to

prevent self-loosening and to ensure permanent sealing

of the cable and conductor entry points.

The spacing between the cable glands is such that a

torque wrench can be used to secure the gland bodies

in the enclosure wall and to tighten the seals around the

cables.

Intrinsically safe circuits must enter and leave the enclo-

sure via separate cable glands that are specially marked

with a light blue color.

If any cable and conductor glands are not used or are no

longer needed, the holes and redundant gland bodies

must be blanked off with suitable blind plugs or caps.

The cabinet has the following cable glands:

A. One cable gland M20 x1.5 for power supply cable,

cable diameter 6 to 12 mm.

B. Three cable glands M16 x1.5 for digital in DI/RPM

cables, cable diameter 4.5 to 10 mm.

C. Two cable glands of type M25 x1.6 for up to four

measuring cables each with diameter 4.5 to 6 mm.

D. One cable gland of type M16x1.5 for a standard

Ethernet cable with cable diameter 4.5 to 10 mm.

E. Two cable glands of type M16 x1.5 for Intrinsic

Safety Earth, cable diameter 4.5 to 10 mm.

Tighten torque

Cable gland

size

Connection thread

(Nm)

Pressing nut

(Nm)

M16x1.5 2.5 3.75

M20x1.5 3.3 3.75

M25x1.5 3.3 3.75

F. Markings for additional six cable glands intended

for digital/analog signal cables and extra Ethernet

cables. Holes have to be drilled if needed for the

installation. Drill the holes in the punch marks and

mount cable glands of type M20 x1.5 or M16 x1.5.

G. Cable gland not intended to be used as cable en-

try. This cable gland is intended to be used as test

port, see “Periodic Pressure Testing” on page 19.

Cable gland torque moment to be followed

Selection of Cables

Use only cables and conductors that meet the following

minimum requirements:

• Made of thermoplastic, thermosetting or elasto-

meric materials

• Exceptionally firm and circular

• Only extruded embedding material between the

individual cores

• No hygroscopic fillers used

• Cables currently fulfil IEC 60079-14

SPM Instrument can supply sensor cables that fulfil re-

quirements of testing according to IEC 60079-14.

– 8 –

Electrical Installation

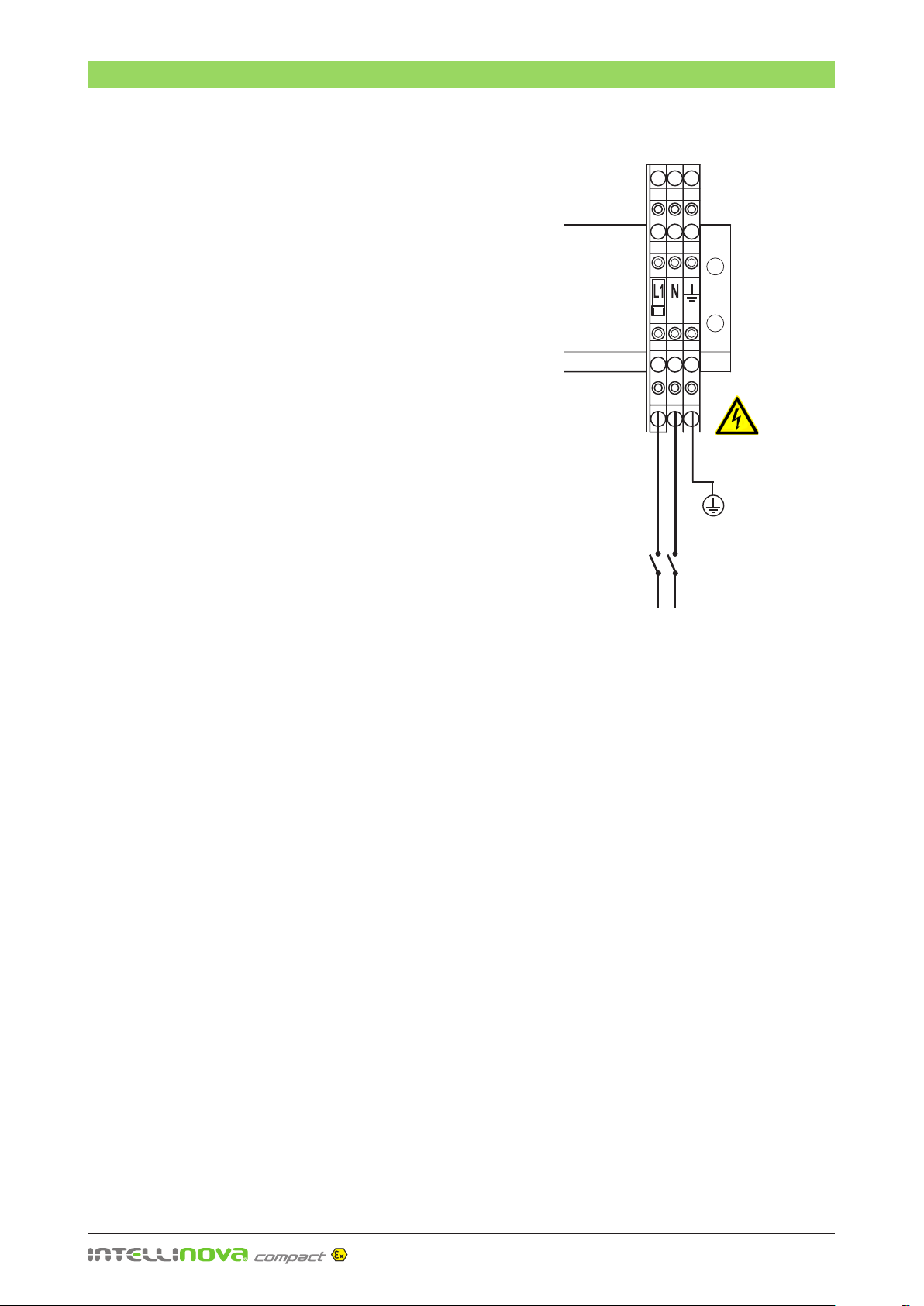

Power Supply

The intrinsically safe circuits and Ex i components installed in the

Intellinova®Compact Ex units, those electrical limits crucial to

intrinsic safety must be taken into account.

Signal cables should not be located close to power supply cables.

The System Unit is delivered with an internal power supply unit

(100-240 V AC/50-60 Hz, max. 10 A or 10-36 V DC, 25 W), internal

wiring and terminal blocks for mains power connection.

The supply power should come via an external main power switch,

from a power source with an even load (nominal voltage ± 10%, no

excessive transients). See the figure beside for connection to mains

power terminals. A switch or a circuit breaker must be included in

the installation. It shall be suitable located and easily reached. It

must also be marked with on/off and as the disconnecting device

for the Intellinova®Compact Ex.

Cords shall be rated for the maximum current for the equipment

and the cable used shall meet the requirements of IEC 60227 or

IEC 60245. Cords certified or approved by a recognized testing

authority are regarded as meeting these requirements.

• Make sure that the main power switch is in off position

and will stay off until the work is done. Lock the switch if

possible.

• Open the cable gland and guide the cable end through the

cable entry (A, see page 7).

• Prepare the cable and connect the conductors to the

terminal blocks.

• Tighten the inlet sealing nut with an open-ended 22 mm

spanner, see "Cable gland torque moment” on page 7.

Check that the System Unit is connected to protective earth,

marked with IEC symbol, and that protective earth (PE) is

properly connected to the protective earthing conductor of

the building installation wiring.

100-240 V AC,

50-60 Hz, max. 10 A

or 10-36 V DC, 25 W

L N

Protective

earth (PE)

Main power switch

or circuit-breaker

– 9 –

Electrical Installation

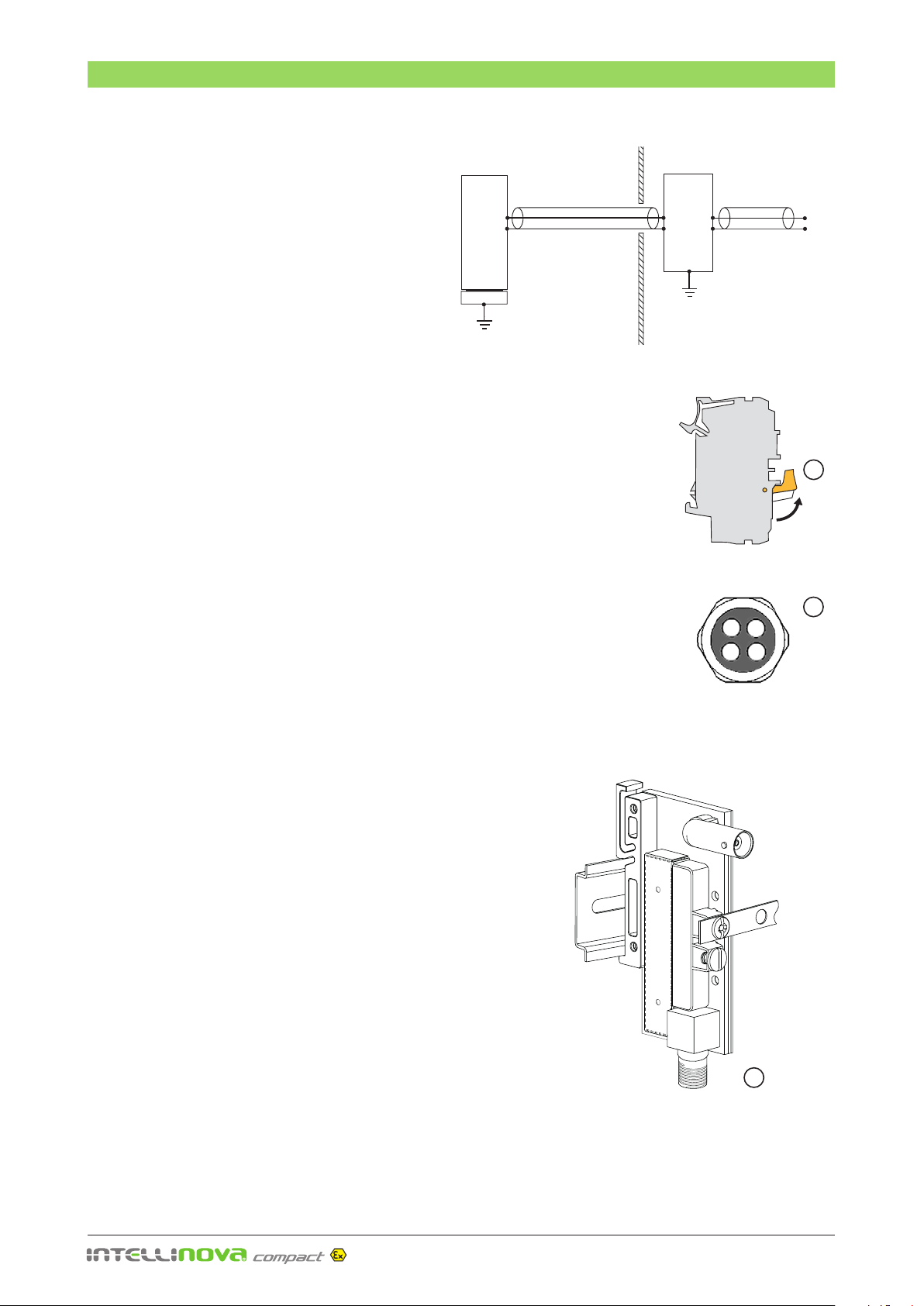

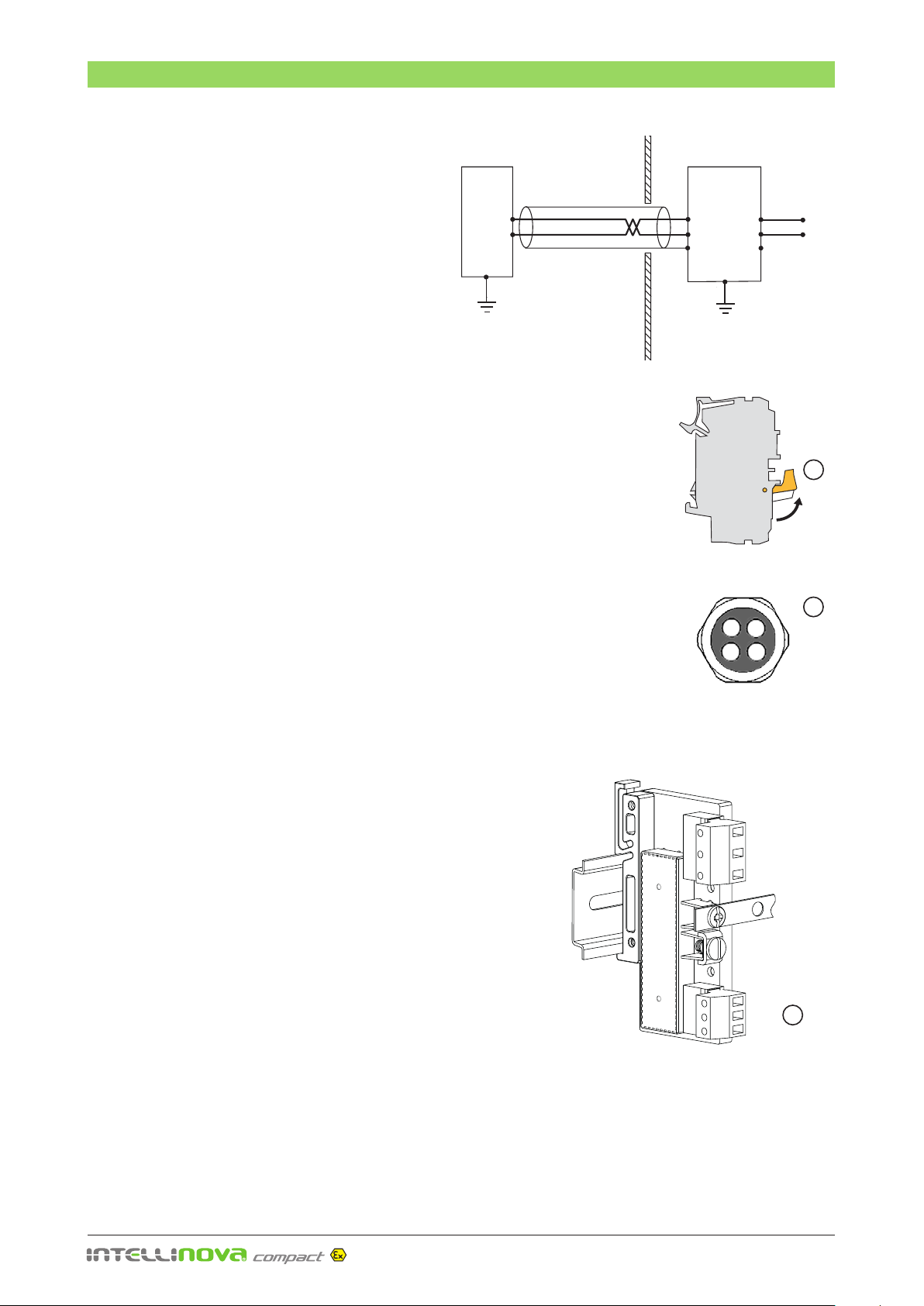

Intrinsic Safety Earth

From the standpoint of intrinsic safety Ex i, insulation must be

made between the equipotential IS-earth bonding conductors

and the PE conductors in the installation. The IS-earth bonding

conductor is regarded as a passive conducting element that fulfils

the required separation conditions with a 500 V insulation test.

The PE conductor, however, is at a certain potential in the event

of a fault, and is regarded as an active, non-intrinsically safe ele-

ment. To fulfil requirement in the ATEX and UKEX directives, the

IS-earth and the PE should be separated.

The minimum cross section of the associated IS-earth protection

conductor is 4 mm².

Network Connection

The System Unit is connected via an RJ45 connector to standard

Ethernet in a LAN network. A shielded network cable should be

used. Consult the responsible network technician prior to con-

necting Intellinova®Compact Ex units to the PC network.

As an option, the Intellinova®Compact Ex units can be equipped

with a network switch to distribute Ethernet to several Intellinova®

Compact Ex units.

• Open the M16 cable gland (D) and guide the cable

through the inlet.

• Mount an RJ45 connector plug on the cable.

• Connect the plug to the RJ45 connector on the circuit

board (pos.2 in the figure on page 6). If an Ethernet switch

(option) is included, connect the LAN network to the switch

(pos. 14 on page 6).

• Tighten the inlet sealing nut with an open-ended 19 mm

spanner, see "Cable gland torque moment” on page 7.

Connection to PC

A PC can be connected to the System Unit via the RJ45 connector

by using a shielded cross-over cable. For communication and set

up the software FSS (Field Service Software) must be installed

and running on the PC.

PE earth

on cabinet

IS-earth terminals

Resistance meter or band

integrity monitor connection

during Earth continuity test

Loop

resistance

<2Ω

Earthing an installation with two conductors

and providing resistance test facilities

D

D

Test Port

– 10 –

Electrical Installation

3

5

1

4

98

2

Power Digital Vibration Bearing Analog Digital

supply inputs monitoring monitoring inputs outputs

6

7

Installations

Electrical signals between safe zone/zone 2 or 22 to

hazardous areas zone 0/20 and 1/21, sensors and out-

puts must be connected to the Intelinova®Compact Ex

thru included Ex interfaces (Ex interface).

All electrical installations located in hazardous zone are

made on the Ex interfaces (Ex interfaces).

The external Ethernet network cable is connected to the

RJ45 connector (3) or if included the Ethernet switch.

When all electrical connections are made, the unit can be

started with the ON/OFF button (1) on the circuit board.

A red LED indicator (2) is lit when power is on.

Status LED Indicators

The circuit board has red status indicators. The LED in-

dicator, OP (4), will alight when the unit is in operational

mode, which means that the power is on and all measur-

ing circuits are running. The indicator, COM (5), is blinking

when the unit communicates via Ethernet.

The red status indicators (6) will alight when the digital

inputs DI/RPM are active and the indicators (7) will alight

when the digital outputs DO are active.

SD Memory Card

The System Unit is equipped with an SD memory card

(8) for data buffering and back-up. This card is also used

for initializing and setup of the System Unit. Reading and

writing to the card is shown by a red LED indicator (9).

Newer remove the SD memory card when power is on.

Digital Inputs

The digital inputs DI/RPM are generally used for speed

measuring with RPM transducers. Two RPM transducers

can be connected and linked to measuring assignments

set up in Condmaster.

Digital Outputs

The unit has three digital outputs DO, for connection

to PLC or via external relays to machine stop, external

warning lamp, etc.

Analog Inputs

The System Unit has three channels for continuous moni-

toring of analog signals AI and measures current from 0

to 20 mA. Measuring units, range, quantities, alarm limits,

etc. are set up in Condmaster.

– 11 –

J1 J2

J3, J4

Bearing Monitoring

Connection of Shock Pulse Transducers

Shock pulse transducers are connected to the TNC connectors on the

Ex interfaces. See the figures for proper connections.

The cabinet has two cable entries M25x1.5 (1) with rubber insert for

up to 4 measuring cables each, cable diameter 4.5 to 6 mm (IP68).

Unused holes should be sealed with supplied plugs.

Intellinova®Compact Ex INS06Ex units can be delivered fully equipped

with four Ex interfaces for bearing monitoring. If Intellinova®Compact

Ex units are ordered with less than four channels the system can be

updated on site with additional Ex interfaces. Contact SPM Instrument

for update kit including modification instruction.

• Make sure that the System Unit is in power off position.

• Disconnect the power supply by switching off the terminal block

marked L1. Lift the jumper bar (1) as shown in the figure.

• Remove the blanking plug on the M25 cable gland (2) and guide

the cable end through the cable entry.

• Cut the cable and mount TNC connector 93022, see next page.

• Screw the TNC connector firmly into respectively Ex interface (3),

designation SPM1 to SPM4.

• Seal eventually unused inlet holes with supplied plugs and

tighten the gland sealing nuts with an open-ended 33 mm

spanner, see "Cable gland torque moment” on page 7.

• Switch on the terminal block marked L1 by pushing in the jumper

bar (1).

• Perform periodic pressure test according to "Service and Main-

tenance" to check that the enclosure is properly sealed, see

page 19.

Coaxial

cable

2

Shock Pulse

Transducer with

Isolation Foot

Explosive Area Inside nR Enclosure

Ex interface

to circuit

board

Machine

ground

IS-earth

1

3

to circuit

board

TNC input

connector

SPM Transducer Ex interface

17301

rail for

IS-earth

Bearing Monitoring

The System Unit INS06Ex has four channels for con-

tinuous monitoring of bearing condition. It meas-

ures shock pulses according to the SPM®HD method

or the LR/HR HD method. All measuring parameters

such as measuring time, alarm limits, alarm delay,

etc. are set up in the software Condmaster Ruby.

The bearing monitoring channels are connected to

shock pulse transducers of type SPM 44000 Ex via

coaxial cables. The transducers must be fitted with

isolation foot 15862.

Connection to IS-earth

Shock pulse transducers of type 44000 Ex fitted with isolation foot

15862 are isolated from machine ground. The cable shield is con-

nected via the Ex interface to the IS-earth rail inside the system unit.

J1

J2

J3, J4

– 12 –

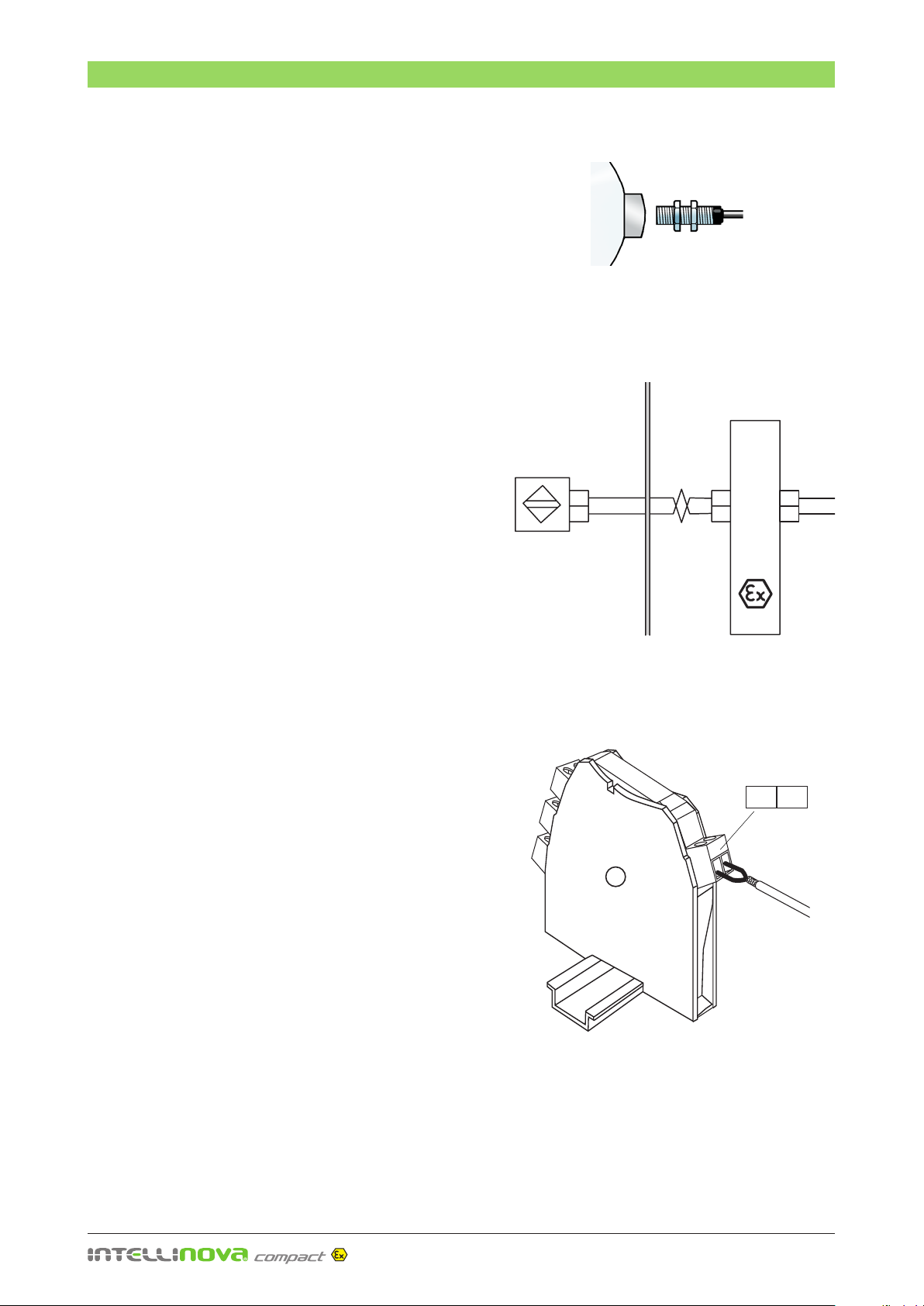

Mounting TNC Connector 93022

With the cutting tool SPM 81052, a cable is stripped as

follows:

•Cut the cable end with a sharp knife. Push the cutting

tool slide to 5. Put the cable into the tool, with the

end towards the SPM label, level with the centre of

the outer groove.

•Close the tool. Push the slide one step at a time to 1,

rotating the tool several turns for each step. Push the

slide to 5, open the tool, take out the cable.

•Remove the cut-off parts. The two outer bits should

come off easily, exposing 4.5 mm of the inner conduc-

tor and 3.5 mm of the dielectric.

•Slice lengthwise through the remaining bit of insula-

tion, peel it off. Do not damage the braid.

The cut through the insulation should not quite reach the

braid. If two or more strands are cut off the inner conductor,

the pin will not hold when crimped on.

Mount connector 93022 as follows:

•Slide the metal ferrule A onto the cable. With 4 mm

cables, also push the neoprene tube over the cable.

This is best done before stripping the cable.

•Push the contact pin B over the inner conductor and

against the dielectric, with all strands of the inner con-

ductor inside the contact pin. Crimp on the contact

pin.

•Splay out the braid with a conical movement of the

cable end. Push the crimp spigot C under the braid

until the contact pin engages. All strands of the braid

must be on the outside of the spigot.

•Slide the neoprene tube (if used) and ferrule over the

braid and against the connector body. Crimp twice,

first close to the connector body, then again at the

end of the ferrule.

SPM 82166

SPM 81052

Cables with 4 mm diameter

Bearing Monitoring

– 13 –

Vibration Monitoring

2

B

A

J1

1

2

3

J2

1

2

3

–

+

J3, J4

Vibration

Transducer

Explosive Area Inside nR Enclosure

Ex

interface

Shielded TP cable to circuit

board

Machine

ground IS-earth

Connection of Vibration Transducers

Vibration transducers are connected to the input terminals on the Ex inter-

faces. See the figures for proper connections.

Recommended transducers are SPM Instrument SLD200 series transduc-

ers with voltage output.

The optimum cable to use for permanently installed vibration transducers

is a shielded twisted pair. Around the outside of this twisted pair is the

shield. A braided shield is the optimum type of shielding, as it has slightly

better low-frequency shielding capabilities over a foil type of shield. Foil

is often used where RF shielding is necessary.

The cabinet has two cable entries M25x1.5 (1) with rubber insert for up

to 4 measuring cables each, cable diameter 4.5 to 6 mm (IP68). Unused

holes should be sealed with supplied plugs.

Intellinova®Compact Ex INS06Ex units can be delivered fully equipped

with Ex interfaces for two vibration channels. If Intellinova®Compact Ex

units are ordered with less than two channels the system can be updated

on site with additional Ex interfaces. Contact SPM Instrument for update

kit including modification instruction.

• Make sure that the System Unit is in power off position.

• Disconnect the power supply by switching off the terminal block

marked L1. Lift the jumper bar (1) as shown in the figure.

• Remove the blanking plug on the M25 cable gland (2) and guide

the cable end through the cable entry.

• Cut and prepare the conductors.

• Connect the conductors firmly into respectively Ex interface (3),

designation VIB1 and VIB2. Tighten the contact screws.

• Seal eventually unused inlet holes with supplied plugs and tighten

the gland sealing nuts with an open-ended 33 mm spanner, see

"Cable gland torque moment” on page 7.

• Switch on the terminal block marked L1 by pushing in the jumper

bar (1).

• Perform periodic pressure test according to "Service and Mainte-

nance" to check that the enclosure is properly sealed, see page 19.

Vibration Monitoring

The System Unit has 2 channels for continuous

vibration monitoring. It supports broadband vibration

measurement, both ISO 2372 and ISO 10816, plus

FFT with symptoms and EVAM (Evaluated Vibration

Analysis Method). All measuring parameters such

as measuring technique, measuring time, alarm

limits, alarm delay etc. are set up in the software

Condmaster®.

1

to circuit

board

VIB Transducer Ex interface

17310

rail for

IS-earth

Connection to IS-earth

Vibration transducers of type SLD are isolated from machine ground. The cable shield shall be connected in one end

only to the IS-earth rail inside the system unit. The IS-earth terminal on the Ex interface is to be used.

3

input

connector

J1:3

J1:2

J1:1

J4

J3

J2:3

J2:2

J2:1

– 14 –

Digital Inputs

Connection of Digital Inputs, DI/RPM

The digital inputs DI/RPM can be used for the connection

of RPM sensors (inductive proximity switches) for speed

measuring. Inductive proximity switches of type NAMUR (DIN

EN 60947-5-6) can be connected to include Ex interfaces.

Recommended inductive proximity switch of type NAMUR

is SPM Instrument part number 90576 or 90577.

A pulse is generated when a metallic object, normally the

shaft key, passes the proximity switch. The number of pulses

per revolution can be specified in Condmaster. One pulse

per revolution is normal.

The proximity switch is mounted close to a rotating machine

part. Adjust the gap between the transducer and the key in

accordance with the manufacturer's instructions. NB. Key

with sharp edges should be rounded as the edges will often

cause two pulses instead of one.

Intellinova®Compact Ex INS06Ex can be delivered fully

equipped with Ex interfaces for two DI channels. Intellinova®

Compact Ex units ordered with less than two channels can be

updated on site with additional Ex interfaces. Contact SPM

Instrument for update kit including modification instructions.

• Make sure that the System Unit is in power off position.

• Open one of the M16x1.5 cable entries (D, see page 7)

and guide the cable end through the cable entry.

• Cut and prepare the conductors.

• Connect the conductors firmly into respectively Ex

interface, designation DI1 to DI2. Tighten the contact

screws.

• Seal unused cable entries with a blanking plug and

tighten the gland nuts with an open-ended 14 mm

spanner, see "Cable gland torque moment” on page 7.

• Perform periodic pressure test according to "Service

and Maintenance" on page 19 to check that the en-

closure is properly sealed.

A red status indicator on the circuit board, next to the termi-

nal block, lights when a DI/RPM channel is active.

Connection of NAMUR sensor to DI/RPM Interface

Inductive proximity switch

DI/RPM

Interface

21

4.24.1

BN

BU

4.24.1

NAMUR

sensor

Explosive Area Inside nR Enclosure

to circuit

board

1

4.1 4.2

– 15 –

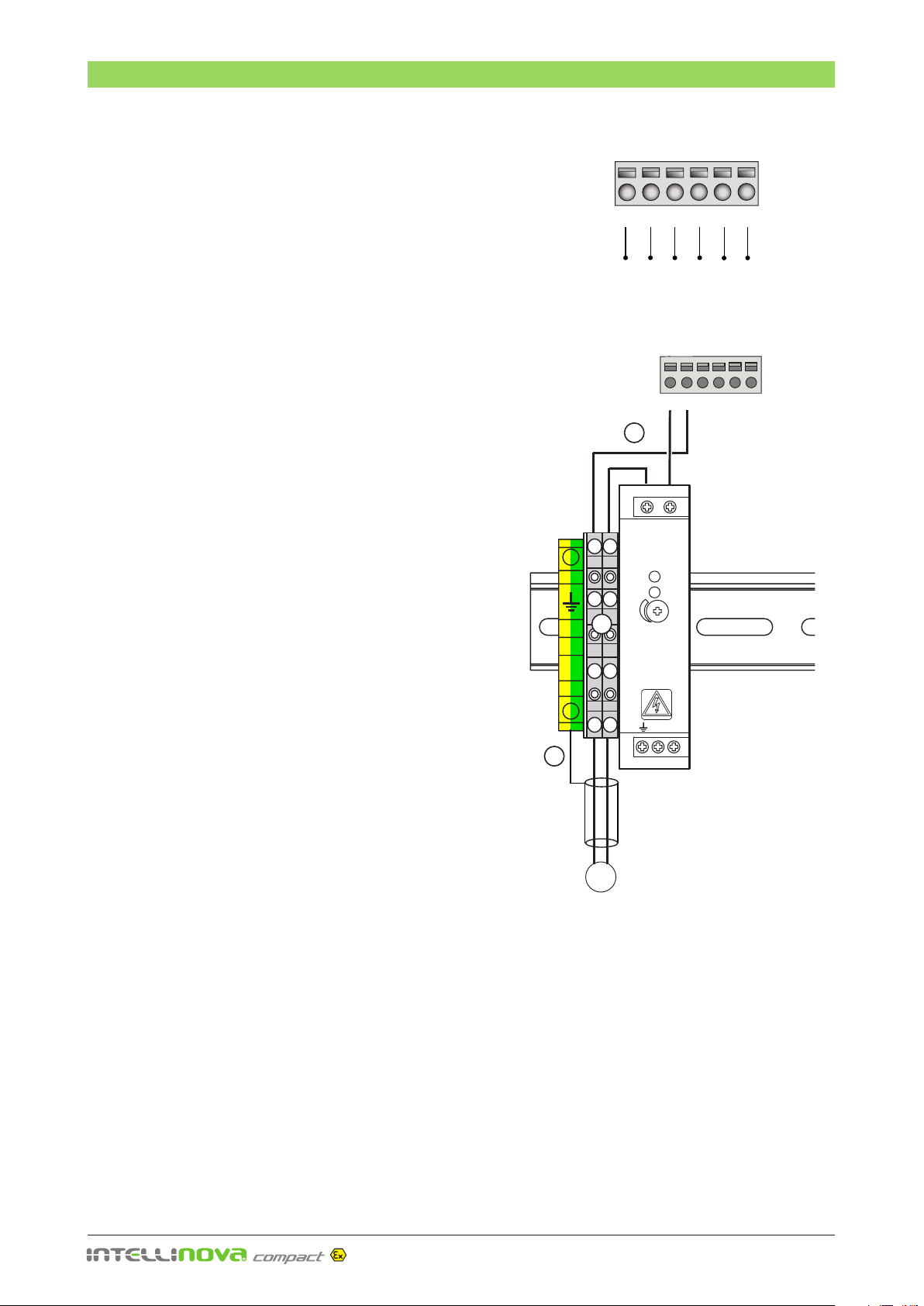

Analog Inputs

V- V+

24 VDC/0.75A

LO

ON

Vout ADJ.

100-240 VAC

0.5A

47-63Hz

NL

Connection of Analog Inputs, AI

The System Unit has three channels for continuous moni-

toring of analog signals and measures current from 0 to

20 mA. Measuring units, range, quantities, alarm limits

etc. are set up in Condmaster®.

Connection of analog sensors located in hazardous

areas zone 0 and 1

If Analog sensor is located in Ex hazardous zone 0/20

or 1/21, the Intellinova®System units need to be or-

dered as special. The actual type of sensor intended to

be used must be specified at the time of ordering the

Intellinova®System unit, so that suitable Ex interfaces can

be included.

Connection of analog sensor in safe zone

The cable length may be up to max. 100 m. A 100-ohm

shunt resistor is used for current measurement.

The push-in terminal blocks on the circuit board are

marked with numbers:

AI channel 1 + 20

– 21

AI channel 2 + 22

– 23

AI channel 3 + 24

– 25

Holes for additional cable entries intended for signal ca-

bles to the analog inputs have to be drilled. Drill the holes

in the punch marks on the enclosure with maximum 0.5

mm larger diameter than the cable gland. Cable glands

of type “Ex e” or “Ex t” with suitable size for the cables

must be used. The maximum cable gland size is M20 x1,5.

• Make sure that the system unit is in power off position.

• Disconnect the system unit from the mains power

source. Check with a voltage tester to ensure that the

unit is voltage-free.

• Mount terminal blocks (option SPM Instrument 93380)

on the DIN rail (1).

• Drill holes and mount suitable Ex cable glands on the

enclosure.

• Tighten the inlet sealing nuts. The tightening torques

must be followed by the appropriate manual.

• Open the cable gland and guide the sensor cable

through the inlet.

• Prepare the end of the sensor cable and push the

conductors firmly into respectively terminal.

• When using a shielded cable, connect the shield to

the protective earth terminal block (2) via a short

cable soldered on the shield. The shield should not

be connected to the sensor end.

Analog inputs on circuit board

+ – 4–20mA

Sensor

Protective

earth rail

• Tighten the inlet sealing nut. The tightening torques

must be followed by the appropriate manual.

• Cut and prepare internal single conductor cables as

shown in the figure above (3). Push the cables firmly into

respectively terminal and tighten the contact screws.

• Secure the cables with cable ties mounted on the cable

tie mounting bases.

• Connect the mains power source and switch on the

System Unit with the ON/OFF button.

• Perform periodic pressure test according to "Service

and Maintenance" on page 19 to check that the

enclosure is properly sealed.

1

3

2

20 21 22 23 24 25

+ – + – + –

Ch.1 Ch.2 Ch.3

+ – + – + –

AI

– 16 –

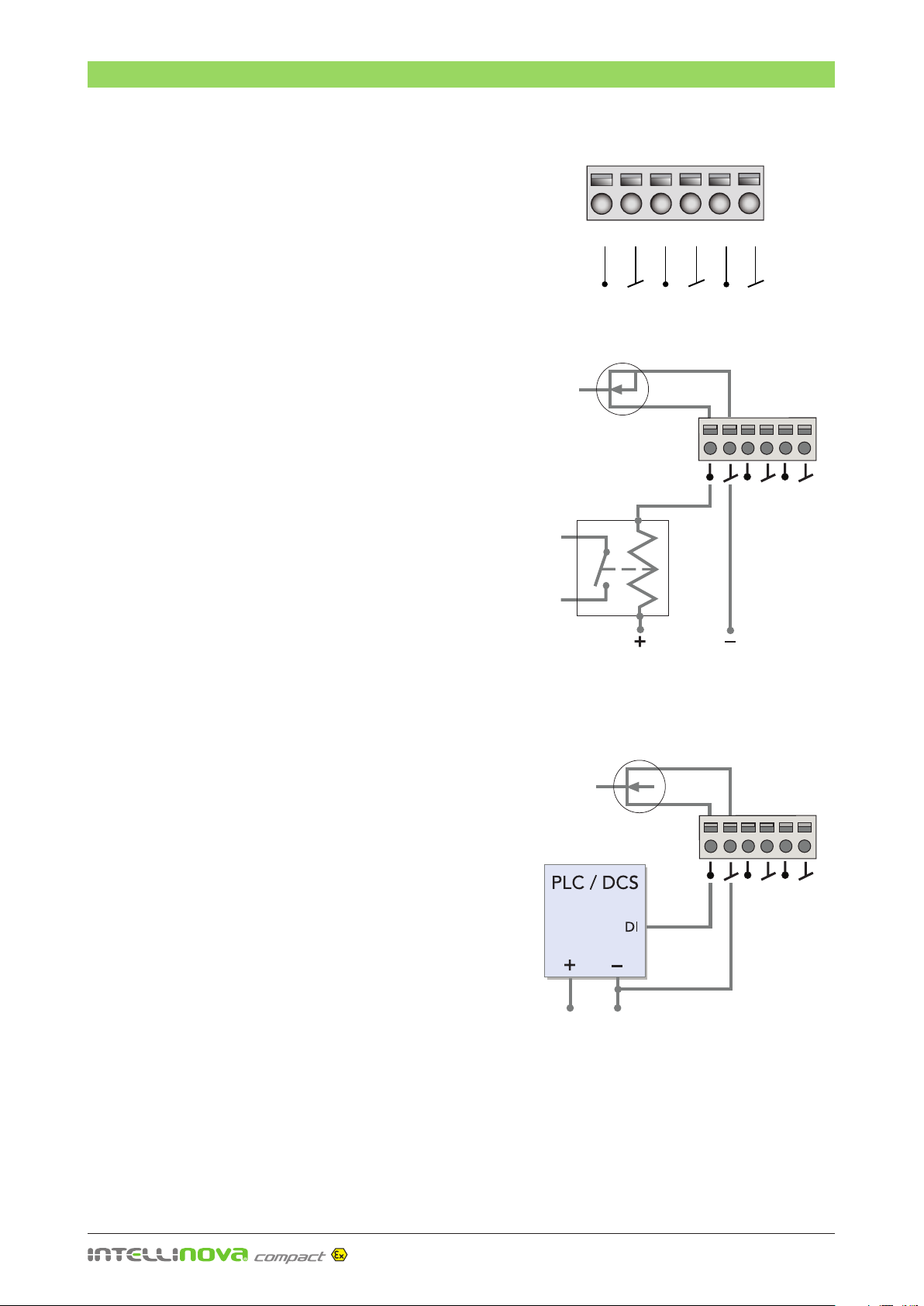

Connection of Digital Outputs, DO

The digital outputs DO can be connected to a PLC/ DCS or

via optional external relays to machine stop, external warning

lamp, etc. The output circuit must not exceed 1 A, 36 V DC.

The circuit is normally open.

Connection of digital output located in hazardous

area zone 0 and 1.

If Digital Output is connected to equipment located in Ex

hazardous zone 0/20 or 1/21, Intellinova®System units need

to be ordered as special. The actual type of equipment

intended to be used must be specified at the time of order

of the Intellinova®System units, so that a suitable IS barrier

can be installed.

Connection of digital output located in safe zone.

The push-in terminal blocks on the circuit board are marked

with numbers:

DO channel 1 38

39

DO channel 2 40

41

DO channel 3 42

43

Holes for additional cable entries intended for signal cables

to the digital outputs have to be drilled. Drill holes in the

punch marks on the enclosure with max. 0.5 mm larger di-

ameter than the cable gland. Cable glands of type “Exe”

or “Ex t” with suitable size for the cable must be used. The

maximum cable gland size is M20x1.5.

• Make sure that the System Unit is in power off position.

• Drill holes and mount suitable Ex cable entries on the

flange.

• Tighten the gland nut. The tightening torque must be

followed by the appropriate manual.

• Open the cable gland and guide the cable end through

the inlet.

• Push the conductors firmly into respectively terminal.

• Tighten the inlet sealing nut. The tightening torque

must be followed by the appropriate manual.

• Perform periodic pressure test according to "Service

and Maintenance" on page 19 to check that the

enclosure is properly sealed.

A red status indicator on the circuit board, next to the termi-

nal block, lights when a DO channel is active.

Digital Outputs

Connection to PLC/DCS (DO 1)

Power Supply

Max.1A,

36 V DC

Relay

Max.1A,

36 V DC

Digital outputs on circuit board

38 39 40 41 42 43

DO1 DO2 DO3

Connection to optional external relay (DO 1)

– 17 –

Configurating Intellinova

SD Memory Card

The System Unit has a built-in SD (Secure Digital) card

reader for 2 GB SD cards (1). The supplied card has been

formatted and can be used immediately.

The SD card is used for the configuration of the System

Unit and establish communication between the unit and

the LinX server, storing measurement task files and buffer-

ing measurement data in case of network malfunctions. It

is also used in situations where Intellinova is used offline,

e.g. onboard ships. A computer with the communication

software LinX and the Field Service Software, FSS, may

be used to load task files from the database onto the SD

card and download measuring results to Condmaster.

This card must not be removed when the System Unit

is in use.

Configuration

Configuration of the System Unit is done in FSS, the

graphical user interface to LinX (also used for field service

and support). LinX is the communication software han-

dling all messages between the Condmaster database

and the Intellinova System Units.

The SD card has to be loaded with necessary setup files

to establish communication between the System Unit

and the LinX server. The SD card is connected to the LinX

computer and the setup is done in FSS. The setup files

are saved to the SD card so that if communication has

been lost, the buffered data will later find its way to the

LinX server.

Before starting the System Unit, all mechanical and elec-

trical installations must be done.

• Place the configured SD card in the SD card reader

(1). Push the card in as far as it will go into the slot

with the contact area facing in and with the chipped

corner on the right side.

• Start up the System Unit with the ON/OFF button

(2). The red LED (3) indicates reading and writing to

the card.

• The COM indicator (4) will blink when the System

Unit communicates with the LinX computer.

• The OP indicator (5) will light when the measuring

circuits are operating.

NB: See the software instruction 'Installing

Condmaster® Ruby" (72094B) with detailed step

by step instructions how to setup the Commander

Unit in the Field Service Software, FSS.

CAUTION

Never remove

the SD card when

power is on

SD card

5

2

4

1

3

– 18 –

Wi-Fi Ethernet unit

Omni-directional

antenna with

5 m cable Antenna connected

to 'MAIN'

Technical Specifications IND01Ex

Fonctions Ethernet wireless Wi-Fi bridge, bridge router, access Point, repeater (WDS) & virtual cable

Format Universal mounting box (wall and Din Rai)

Dimensions L:103 x W:67 x H:24 mm

Support MODBUS/TCP, PROFINET & Ethernet/IP wireless gateway

Maximum Speed 108 Mbps

Ethernet link 100 Base Tx (RJ45) 10/100 compatible

Radio link Triband wireless Wi-Fi IEEE 802.11a/b/g/h & Super AG

Frequency range 2.4 / 5 / 5.4 GHz

Radio Modem (AD HOC) Bridge mode

Rapid roaming < 50 mS

Antenna connectors RP-SMA

Nominal range 300m, open field (with built-in antennas)

Security WPA-PSK, WPA2-PSK, WEP 64/128 bits, IEEE 802.1X (RADIUS) MAC addresses filtering

SSID broadcast control

Number of Wi-Fi clients 30 (in AP mode)

Administration Web browser SNMP, ACKSYS NDM

Power supply +9VDC to +48VDC, 3-point PHOENIX connector

Power consumption 3.5W typical

The option IND01Ex includes a wireless Ethernet unit

mounted on the cabinet lid and internal wiring. An ex-

ternal omni-directional antenna and a 5 m antenna cable

are included.

The System Unit is connected via a 10/100 Ethernet

switch on the Wi-Fi Ethernet unit. For configuration of

the Wi-Fi unit, see the user guide from the manufacturer

(ACKSYS DTUS061).

WirFi Ethernet Unit (Option)

Inside of the lid

Table of contents

Other SPM Measuring Instrument manuals

SPM

SPM VibChecker User manual

SPM

SPM Machine Guard MG4-REF11A User manual

SPM

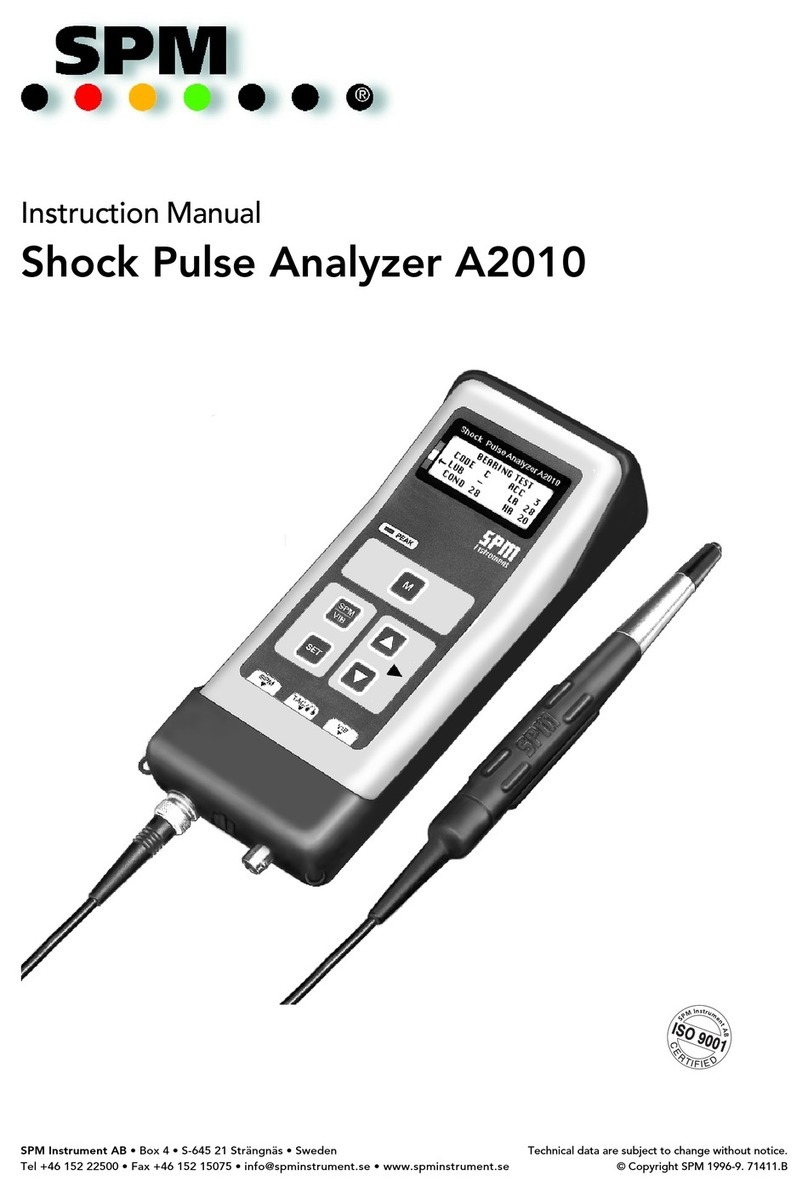

SPM A2010 User manual

SPM

SPM intellinova parallel MB INS MB 4V Owner's manual

SPM

SPM Vibrameter VIB-11B User manual

SPM

SPM VibChecker User manual

SPM

SPM Intellinova Compact User manual

SPM

SPM leonova emerald User manual

SPM

SPM VIB-11 User manual

Popular Measuring Instrument manuals by other brands

Steiner

Steiner M830r LRF instruction manual

Black & Decker

Black & Decker ATM100 instruction manual

SATO KEIRYOKI

SATO KEIRYOKI PC-5400TRH instruction manual

Graytechnos

Graytechnos photom MiNi 219 instruction manual

Analog Technologies

Analog Technologies ALDD28V5A401 quick start guide

Abaxis

Abaxis Piccolo Xpress AB-801-110-0000 Quick reference guide