1

Contents

Introduction ............................................................................................. 4

Condition-based maintenance ........................................................................... 4

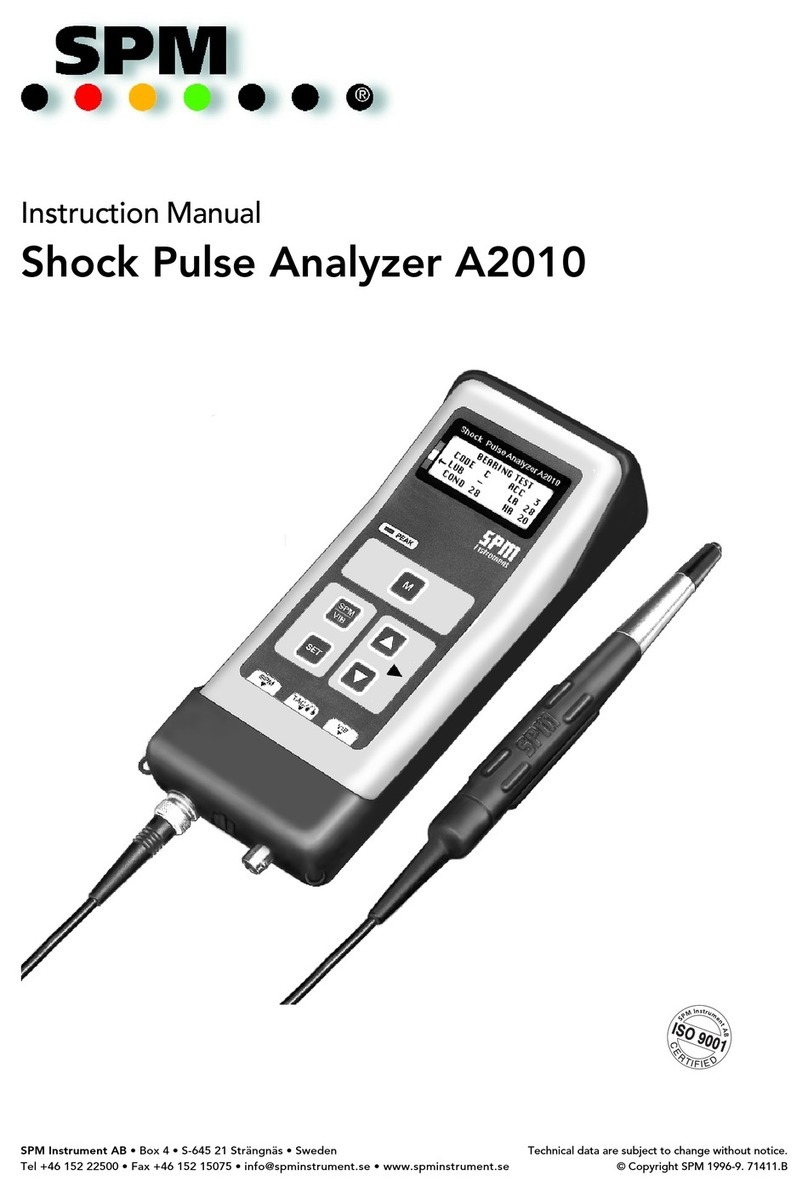

Instrument overview ............................................................................... 5

Instrument parts................................................................................................. 5

General description ........................................................................................... 5

Displays and icons.............................................................................................. 6

Battery .............................................................................................................. 9

Start up............................................................................................................ 10

Settings ................................................................................................... 11

Default settings................................................................................................ 11

Using external sensors ..................................................................................... 17

Sensors with magnets (option)......................................................................... 17

Bias voltage ..................................................................................................... 18

Vibration severity measurement .......................................................... 19

Vibration parameters ACC, VEL, DISP ............................................................. 19

Built-in sensor with probe................................................................................ 20

Measuring points ............................................................................................. 20

Measurement ................................................................................ 21

Recording readings for follow-up .................................................................... 22

Storing measurement results .......................................................................... 23

Spectrum analysis .......................................................................... 24

Spectrum display ............................................................................................. 24

Zoom ............................................................................................................... 24

RPM, manual input........................................................................................... 25

Adding markers for harmonics......................................................................... 25

Time signal analysis ....................................................................... 26

Time signal display........................................................................................... 26

Zoom ............................................................................................................... 26

ISO 2372 ....................................................................................... 27

Evaluation of machine condition...................................................................... 27

Definition of machine classes according to ISO 2372 ...................................... 28

ISO 10816 ..................................................................................... 29

ISO 10816 Part 2.............................................................................................. 29

ISO 10816 Part 3.............................................................................................. 30

ISO 10816 Part 4.............................................................................................. 31

Technical specifications .................................................................. 32

VibChecker VC200/250.................................................................................... 32

Accessories ...................................................................................................... 32

Maintenance and calibration .......................................................... 33

Maintenance .................................................................................................... 33

Calibration ...................................................................................................... 33

Warranty .......................................................................................................... 33