SPM intellinova parallel MB INS MB 4V Owner's manual

INSMB4V

Installation and

Operation Instructions

Trademarks

Airius, CondID, Condmaster, DuoTech, EVAM, HD ENV, Intellinova, Leonova, Leonova Diamond, Leonova Emerald, SPM

and SPM HD are trademarks of SPM Instrument AB.

All other trademarks are the property of their respective owners.

Patent

www.spminstrument.com/patents

© Copyright SPM Instrument AB. ISO 9001 certified.

SPM Instrument AB • Box 504 • SE-645 25 Strängnäs • Sweden Technical data subject to change without notice.

ISO 9001 certified. © Copyright SPM 2020-09. 72123 B Rev.1

– 1 – 72123 B

Intellinova Parallel INSMB4V

Contents

Safety Arrangements.................................................2

Installation Precautions..............................................2

Introduction...............................................................3

Technical Overview .................................................... 3

Mechanical Installation ..............................................3

Electrical Installation.................................................. 4

Commissioning Procedure.........................................4

Electrical Connections ...............................................4

Operating Instructions............................................... 5

Measurements ...........................................................6

Alarm .........................................................................7

Digital Inputs/Outputs and RPM Inputs.................... 8

Configuration for Offline Mode ................................. 9

Configuration for Online Mode .................................9

Scheduled Service ..................................................... 9

Troubleshooting......................................................... 9

Replacement and On-site Repair ............................... 9

Upgrade of Firmware................................................. 9

Decommissioning and Removal................................. 9

Functional Test......................................................... 10

Test Procedure......................................................... 10

Extended Functional Test ........................................ 10

Offline Configuration Software................................ 11

Channel Configuration............................................. 13

Save the Configuration File ..................................... 17

Open a Saved Configuration File............................. 17

Send the Configuration File to the Parallel Unit ...... 17

Receive the Configuration File from the Unit .......... 17

Upgrade of Firmware............................................... 18

Technical Specifications ........................................... 20

Accessories.............................................................. 20

Abbreviations and Technical Terms.......................... 20

APPLICATION EXAMPLE - Pumps ........................... 21

Measuring Assignments Overview ...................... 22

Measuring Assignments for Offline Mode........... 23

Modbus Register for Measuring Results ............. 35

Extracting Time Signals and Spectrums ............. 36

Measuring Assignments for Online Mode ........... 37

APPENDIX A – Register Specification ..................... 38

Installation and Operation Instructions

– 2 – 72123 B

Intellinova Parallel INSMB4V

Safety Arrangements

1. Safety Arrangements

1:1. General

All persons performing installation or service on rotating

machines and electrical equipment should be authorised

and familiar with general safety rules and IEC symbols as

well as local requirements, rules and regulations. In case

of doubt the local management should be consulted.

SPM will not be responsible for any accident caused

by persons not observing these Safety Arrangements.

1:2. Disconnection

Before starting installation work on machines, make sure

that main power is off and will stay off until the work is

done. Do not simply pull the switch - remove the fuses,

lock the fuse box, put up warning signs. Check all ter-

minals to ensure that the equipment is voltage free by

using a voltage tester.

1:3. Electrical Installation

Always read the instructions delivered with the equip-

ment before performing installation or service on electric

equipment. If you are in doubt, please contact your lo-

cal SPM representative before installing the equipment.

Damage of the equipment caused by incorrect installa-

tion is not covered by product warranty. Before starting

installation work, make sure that the main power switch

is in off position and will stay off until the work is done.

Check that all terminals, marked with protective earth

IEC symbol, are properly connected to the protective

earthing conductor of the building installation wiring. In

some countries, the term "protective grounding" is used

instead of "protective earthing". Earth and ground are

used synonymously in this installation instruction. Choose

installation tools that are safe and suitable for its working

environment. Electrical risks can sometimes be eliminated

by using air, hydraulic or handpowered tools. These are

especially useful in harsh conditions.

1:4. System Components

To ensure optimum safety for user and environment, only

original system components available from SPM should

be used. When using non-original components, the com-

pliance with EU directive with respect to electric safety,

EMC and machine safety is not guaranteed by SPM.

1:5. Reapplying Power

For human safety, ensure the electrical equipment or in-

stallation is electrically safe. Before starting the machine,

make sure that all protection covers on the machine are

mounted and secured.

2. Installation Precautions

2:1 Installation of Measuring Units and

Measuring Terminals

Measuring units and terminals should be located in a

protected position assigned by the local management.

The units shall be easily accessible for undisturbed

measurements and service. Signal cables should not be

located close to power supply cables. The measuring

equipment should be intended and specified for use in

existing environment.

It is important that you read the operating instructions

completely and follow all safety precautions before

operating the measuring units. Electrical connections

and wiring should be performed only by suitably trained

personnel.

2:2 Work Regulations

All personnel should be provided with the local work

regulation before any work is commenced.

It is important that parts of metal, rubber and plastics

are dumped in special containers. Such parts can cause

bad accidents and production disturbances if dropped

on the wrong place. From an environmental point of

view, wrapping materials should be collected so as not

to cause damage.

Precautions should also be taken when drilling, tapering

and grinding to avoid chips and grindings causing ac-

cidents and production disturbances.

2:3 Inspection and Acceptance

Inspection of transducer positioning, connections, cable

laying and strapping should take place after finished

installation. The cables should be marked in accord-

ance with agreement with the local contact. Inspection

protocol in accordance with the local regulations should

be used.

IEC symbols

Risk for electric shock Caution

Rotating parts Protective earth

– 3 – 72123 B

Intellinova Parallel INSMB4V

Introduction

The purpose of this document is to provide the user with

information about how to install and operate the Intel-

linova Parallel unit.

Technical Overview

The 4 channel vibration measuring unit measures differ-

ent parameters depending on what kind of transducers

are used. Typical vibration parameters are measured

when using a standard IEPE accelerometer. Shock pulse

parameters can be measured in addition to vibration

parameters when using a transducer of type DuoTech.

The following parameters can be measured using differ-

ent type of transducers:

Installation Procedure

Transducer Parameters

Standard IEPE ACC, VEL, DISP, HD ENV

DuoTech ACC, VEL, DISP, HD ENV

HDm/HDc, LR/HR HD

The 4 channels are running in parallel which enables a

high rate of measuring results.

The unit can operate in two different modes: Online or

Offline. In Online mode the unit operates as a MODBUS

RTU and responds to commands from the MODBUS Mas-

ter. The selector switches on the front define the address.

The unit can respond to commands that:

• configures the operation of the unit

• requests the results from vibration measurements.

In Offline mode the selector switches defines the con-

figuration that the unit should operate in. The user can

configure the unit to operate in many different ways

by first creating a configuration file in a PC and then

transferring the file to the unit. By changing the selec-

tor switches the unit automatically changes from one

configuration to another.

A software tool, PRO230, is available to use for con-

figuration of the unit for offline operation. See chapter

“Software” for more info.

Information about the registers when it operates as a

MODBUS RTU is described in "Appendix A" in the end

of this manual.

Mechanical Installation

The INSMB4V unit is designed to be mounted on a DIN

rail. Do not mount on a rail that is exposed to excessive

vibration, max level of vibration is 5 mm/s. The unit is

recommended to be mounted inside an enclosure with

IP not less than 54.

DIN rail

mounting

– 4 – 72123 B

Intellinova Parallel INSMB4V

Electrical Installation

Make the external connections in the following order:

• Connect a functional earth to GND.

• Connect the vibration transducers using a shielded

twisted pair cable to the VIB unit for channel 1, 2,

3 and 4. The transducers should be of type IEPE.

Installation of transducer line is described in manual

71421B "Installation of Measuring Equipment".

• Connect the RPM probes that can be of type NPN

or PNP.

• Connect the power cables that supply a voltage in

the range 15-36 Vdc.

• Switch on the power. The S LED should flash green

after the startup process.

Commissioning Procedure

A functional test is recommended to be performed the

first time the unit is taken into operation after having

been installed according to the instructions. See section

"Functional test" for how it is performed.

Installation Procedure

DIO6–

DIO6+

DIO5–

DIO5+

DIO4–

DIO4+

DIO3–

DIO3+

DIO2–

DIO2+

DIO1–

DIO1+

VIB4gnd

VIB4–

VIB4+

VIB3gnd

VIB3–

VIB3+

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

0V

+24Vdc

RPM2pupd

RPM2–

RPM2+

Vdcint+

RPM1pupd

RPM1–

RPM1+

GND

RS485 A

RS485 B

VIB1gnd

VIB1–

VIB1+

VIB2gnd

VIB2–

VIB2+

Electrical Connections

0V /+24 Vdc Voltage supply, 15-36 Vdc

RPMXpupd Used for proximity switch of type PNP

or NPN

RPMX+,

RPMX–

Positive and negative terminal of

RPMX where X = channel

Vdcint+ Power supply to external RPM sensor

and Digital input

GND Ground

RS485A

RS485B

Positive terminal of RS485

Negative terminal of RS485

VIBXgnd Ground connection for the shield of

the cable, internally connected to GND

VIBX+,

VIBX–

Positive and negative terminal of Vi-

bration Input no. X where X = channel

DIOX+,

DIOX–

Positive and negative terminal of Digi-

tal Input no. X where X = 1-6

– 5 – 72123 B

Intellinova Parallel INSMB4V

Operating Instructions

User Interface

The front panel of INSMB4V unit has the following fea-

tures:

• Three selector switches named SETTINGS

• One push button named KEY

• One connector named COM

• One BNC connector named OUT

• One LED named S (Status)

• Four LEDs named CHANNEL (1, 2, 3, 4)

SETTINGS

These selector switches are used to put the unit in a

state where it performs a specified task according to the

list below.

• SETTINGS=000: Not used.

• SETTINGS=001-032: Used in Online mode when

the unit is operating as a MODBUS RTU.

• SETTINGS=033-098: Not to be used

• SETTINGS=099: Used when the unit should receive

a configuration file from a PC connected to COM.

• SETTINGS=100-899 Used in Offline mode where

the configuration file defines the configuration of

the unit.

• SETTINGS=900-997: Not used.

• SETTINGS=998: Used for test of DIO.

• SETTINGS=999: To be used when the firmware of

the unit should be upgraded.

CHANNEL

The four LEDs show the status of the four channels. The

different states are shown as:

• No light: The channel has not been initiated or no

active measurement.

• Constant green: The channel has been initiated,

measurements are running, the results are below

the alarm level and the Bias Test has passed.

• Constant yellow: Alarm state. Measurements are

running and the latest result or a previous result

was above the yellow alarm limit.

• Constant red: Alarm state. Measurements are run-

ning and the latest result or a previous result was

above the red alarm limit.

• Flashing red: Bias error or a measurement error.

• Flashing yellow: DSP Time out.

• All four LEDs flashing red: The value of SETTINGS is

not a valid value for measurement.

KEY

This push button can be used in two modes:

• An alarm can be reset by pushing the KEY twice if

an alarm has been generated and the configuration

of alarm reset is set to Manual.

• By pushing KEY the LEDs CHANNEL indicates which

channel is connected to the BNC connector OUT.

This works when the unit is in normal operation and

the user would like to use an external instrument to

perform a measurement from the BNC connector

OUT. Push twice to move to next channel.

Note: The measurements via the BNC connector

OUT operate independently from other measure-

ments.

S

The LED S shows the overall status of the unit. The dif-

ferent states are shown as:

• Green slow flashing: The unit is operating normally.

• Green fast flashing: The unit is communicating over

either the COM port or the RS485 port.

COM

This 4 pole connector is used to connect a PC to the unit

by using the communication cable SPM 15484. The SPM

software PRO230 is used in these cases:

• When the configuration file is to be transferred from

a PC to the unit (SETTINGS=099).

• When the firmware of the DSP is to be upgraded

(SETTINGS=099).

• When the firmware of the Host processor is to be

upgraded (SETTINGS=999).

See chapter “Software” and chapter "Upgrade of Firm-

ware" later in this manual for more information.

OUT

The BNC connector is used when an external instrument

is used to measure from any of the four channels. The

incoming signals are buffered before connected to OUT.

See also KEY.

Operating Instructions

– 6 – 72123 B

Intellinova Parallel INSMB4V

Measurements

Measurements

The unit measures the following parameters:

• ACC

• VEL

• DISP

• HD ENV

• SPM HDm/HDc

• SPM LR/HR HD

The unit also measures a time waveform and calculates

a frequency spectrum from this. The spectrum is used

to calculate the symptoms where a symptom is the rms

value of all frequencies included in the definition of

the symptom. Three symptoms can be created which

are based on up to 9 frequency bands defined by the

user. Each frequency band consists of a low and a high

frequency limit, and the band consist of all frequencies

within the range.

The unit can be configured to use a fixed RPM or to use

order tracking. With a fixed RPM the sampling frequency

is constant and based on the selected frequency range.

If a RPM signal is available order tracking can be used.

Using order tracking means that the number of samples

per revolution is constant which implies that the sampling

frequency varies when the RPM varies.

All measured parameters and symptoms are also stored

as a CMA parameter (CMA=cumulative moving average)

where the results are weighted in an exponential manner

to create a moving average. The user defines the factor

that controls how fast the cma reacts to a change in the

input signal.

Illustration of the Cumulative Moving Average (CMA) and how it reacts to a

step change of the input signal.

Illustration of CMA

– 7 – 72123 B

Intellinova Parallel INSMB4V

Alarm

Alarm levels

The vibration parameters (ACC, VEL and DISP) and the

SPM parameters (HDm/HDc, LR/HR) can generate an

alarm based on two alarm levels (red/yellow) defined

by the user. The symptoms and the Cumulative moving

average use one alarm level.

Alarm delay

The alarm can use a delay which can be of three types:

1. No delay

2. Delay based on time

3. Delay based on number of measurements

No delay: One single measurement above the alarm level

generates an alarm.

Delay based on time: If the time is set to e.g. 60 seconds

an alarm will be generated if all measurements made

during a time interval of 60 s are above the alarm level.

Delay based on number of measurements: If the num-

ber of measurements is set to e.g. 10, an alarm will be

generated if 10 consecutive measurements are above

the alarm level.

NOTE: The alarm delay setting is not unique for each

channel. When you have selected a type of alarm delay,

this setting is used by all 4 channels.

Resetting alarms

There are two ways to bring the unit back into a normal

state when an alarm has been generated.

Auto reset

The unit can be configured to use "Alarm auto reset"

which means that the unit will leave the alarm state when

a new measurement is below the alarm level.

Manual reset

The unit can also be configured to use "Alarm manual

reset" which means that the KEY button must be pushed

twice for the unit to leave the alarm state.

Alarm

– 8 – 72123 B

Intellinova Parallel INSMB4V

Digital Inputs/Outputs and RPM Inputs

The unit has 6 independent DIO (Digital Inputs / Outputs)

that the user can select to use as either an input or as

an output.

Any of the measured parameters can be linked to a Digi-

tal Output (DO) which is activated when an alarm is gen-

erated. The red and yellow alarm can use different DO

for the first measurement. The red and yellow alarm for

the second measurement (HDc or HR) uses the same DO.

Measurement A

(ACC, VEL, DISP, HDm, LR)

Measurement B

(HDc, HR)

Alarm

Red

Alarm Red A /

DO Red A

Alarm Red B /

DO B

Alarm

Yellow

Alarm Yellow A /

DO Yellow A

Alarm Yellow B /

DO B

An input channel can be linked to any of the 6 DIO and be

used as a Digital Input if the measurements on that channel

is to be controlled by an external equipment. A high (low)

input would enable (disable) the measurements.

Transfer characteristics for Digital Inputs:

Positive-going threshold voltage: typ 8 V, max 10 V

Negative-going threshold voltage: typ 4 V, min 2 V

The unit has two RPM inputs for standard RPM probes

of type NPN or PNP. Order tracking can be used when

a RPM sensor is connected.

The RPM Inputs can also be used to start and stop a

measurement. An RPM value (RPM Low Limit) can be

set in the configuration of the unit so that a measure-

ment starts when the measured RPM exceeds the RPM

Low Limit.

The different channels can use a different RPM Low Limit.

The RPM Low Limit is compared to the RPM configuration

of the first assignment (out of 3) in each channel.

Digital Inputs/Outputs and RPM Inputs

3 4 5 6

3 4 5 6

27 28 29 30

24V

Connection of proximity switch (RPM2)

Connection of external relay (DIO1)

Digital

inputs/

outputs

RPM

inputs

– 9 – 72123 B

Intellinova Parallel INSMB4V

Configuration for Offline Mode

When the mechanical and electrical installation has been

done, the unit is ready to receive a configuration file if it

is to be operated in the offline mode. This file is a text

file that contains information about:

1) Which channels should be active

2) What measurements to execute

3) How to respond to a result from a measurement

4) How to respond if an alarm is generated

All this information is linked to a unique value of SET-

TINGS and the configuration file can contain up to 100

configurations which the user can select by changing the

value of SETTINGS on the front panel. If the SETTINGS

value is not found in the configuration file, the LEDs on

the front indicate this by flashing red.

See chapter "Software" for more info about how to create

the configuration file.

Configuration for Online Mode

When the selector switches have been set to a value of

SETTINGS=001-032, the unit will operate in online mode.

The unit should receive commands from a MODBUS Mas-

ter, e.g. a PLC. The commands should provide the same

information as stored in the configuration file used in offline

mode. In addition to this the unit also allows the MODBUS

Master to read registers where the measuring results are

stored. See "Appendix A - Register specification" in the

end of this manual for more information.

When the unit is restarted in online mode, the registers will

normally be 0 (default) and the user has to configure the

registers in a meaningful way to set the unit in a measuring

mode. But if the unit has a configuration file loaded and

this file contains a setting=100 the unit will read those

settings and starts to operate according to the settings

in this file. This can be useful for an operator who only

wants to read out the results when connecting the unit to

e.g. a PLC. In this way the software PRO230 can be useful

for a user who wants to operate the unit in online mode.

Communication parameters:

Bits per second: 19200

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

Configuration

Maintenance

Scheduled Service

A functional test is recommended to be performed with

an interval of three years.

Troubleshooting

If the unit is not operating correctly, first check that it

has been installed according to the instructions, then

perform a functional test. If the test fails the unit should

be returned to SPM Instrument for service.

Replacement and On-site Repair

All service of the unit that requires the unit to be opened

must be performed by SPM Instrument. Accessories like

transducers and cables may be replaced by the user.

Upgrade of Firmware

The unit is delivered with the latest firmware. If it would

be necessary to upgrade the firmware, this can be done

on site using a PC connected to the unit with communica-

tion cable (SPM 15484) connected to COM on the front

panel. With the selection switches in position 999, the

unit enters a state where it can receive new firmware. A

new firmware is transferred to the unit by using "PRO240

Intellinova Parallel Service Software".

See chapter"Upgrade of Firmware" later in this manual

for more information.

Decommissioning and Removal

If the unit is to be taken out of operation, the voltage

supply mustbe disconnected before disconnecting the

remaining cables. The unit can then be dismounted from

the DIN rail.

– 10 – 72123 B

Intellinova Parallel INSMB4V

Functional Test

Functional Test

The recommended functional test after installation is

done by simulating an alarm. Connect a transducer to

one of the VIB channels on the unit. The functional test

is normally done in offline mode where the transducer

vibration is simulated by hand. Correct operation of the

unit can be tested by changing the vibration level.

The test is intended to simulate a transducer amplitude

of the vibration signal above and below the alarm levels

of the unit. The correct response of the unit can be seen

on the LEDs indicating the status of each channel and

also by detecting the status of the digital outputs that

can be configured to be activated when an alarm state

is detected.

The functional test can be carried out with an offline

mode configuration made with the software PRO230.

The recommended setting during the test for channel

1 to 4 is:

• Measurement parameter VEL rms

• An alarm level is set at 1.0 mm/s

• DIO1 is activated at alarm

• Auto reset of alarm is used

Test Procedure

• Connect the vibration transducer to channel 1.

• Do not move the transducer.

• Verify that DIO1 = 0 and the LED on channel 1 is

green.

• Simulate a transducer vibration by shaking the

transducer by hand.

• Verify that DIO1 = 1 and the LED on channel 1 is

red.

• Do not move the transducer.

• Verify that DIO1 = 0 and the LED on channel 1 is

green.

• Repeat the above operations for channel 2, 3 and 4

if needed.

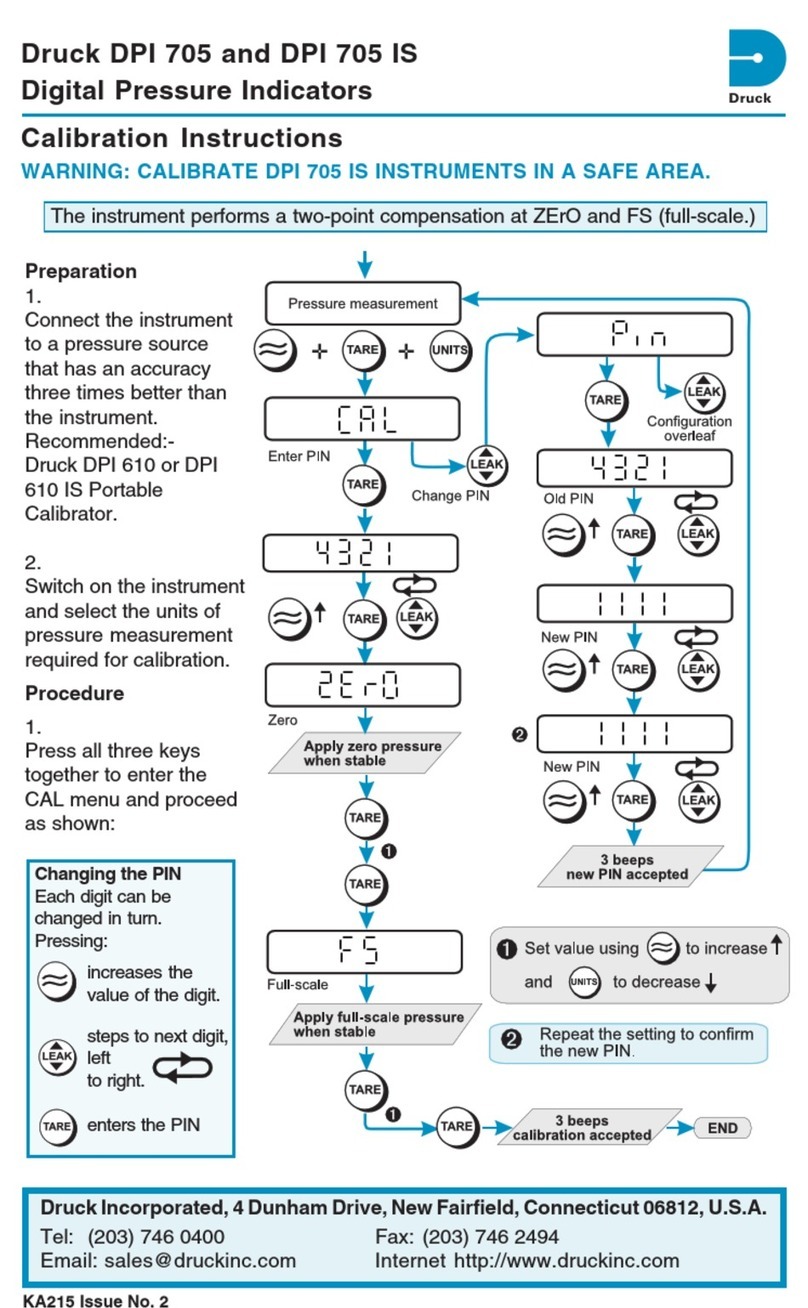

Extended Functional Test

The extended functional test is done by connecting Test

Generator STG-02 and Transducer Converter 17093 to

one of the VIB channels on the unit, see Figure 1. The

functional test is normally done in offline mode where

the STG-02 generates a well-defined vibration signal to

Figure 1: How to setup a functional test where STG-02 is

used as a signal source and 17093 as a transducer equiva-

lent feeding the signal to the measuring unit INSMB4V.

INSMB4V

Ch.2

Ch.1

17093

Ch.3

Ch.4

+24 Vdc

0V

STG-02

simulate real signals. Correct operation of the unit can be

tested by changing the amplitude of the vibration signal

above and below the alarm levels of the unit. The correct

response of the unit can be seen on the LEDs indicating

the status of each channel, and also by detecting the

status of the digital outputs that can be configured to be

activated when an alarm state is detected.

The functional test can be carried out with an offline

mode configuration made with the software PRO220. The

recommended setting for channel 1 to 4 is:

• An alarm level is set at 2.0 mm/s

• DIO1 is activated at alarm

• Auto reset of alarm is used.

Follow these steps in order to verify correct operation of

the measuring unit:

• Connect the STG-02 and 17093 to channel 1 as

shown in Figure 1.

• Set the STG-02 to generate a vibration signal of

VEL=1.8 mm/s at 80 Hz.

• Verify that DIO1 = 0.

• Increase VEL to 2.2 mm/s.

• Verify that DIO1 = 1 and that the LED on channel 1

is red.

• Decrease VEL to 1.8 mm/s.

• Verify that DIO1 = 0 and that the LED on channel 1

is green.

• Repeat the above operations for channel 2, 3 and 4.

– 11 – 72123 B

Intellinova Parallel INSMB4V

Offline Configuration Software

Assuming that the software PRO230 has already been installed, configuring the unit to measure in offline mode is done

as follows. Create the measurement configurations that are needed. Each configuration is linked to a unique value of

SETTINGS on the front panel of the unit. Up to 100 different configurations can be created. The configuration file is

transferred from a PC to the unit by using the communication cable SPM 15484.

1) Start the software and select INSMB4V (type of Parallel unit). To see help text, mark a parameter and press F1.

Software

SETUP (A)

Open the window 'General configuration' by clicking the Setup

button (A). These settings are made when starting the software

the first time and will be default when the software is restarted.

Communication

Serial port:

Shows selected serial port when cable 15484 is connected

to the PC.

Read timeout (ms):

Default 10000. Can be set 0-10000 ms.

Write timeout (ms):

Default 10000. Can be set 0-10000 ms.

All other settings are default and can not be changed.

Default information

Bias:

Min/Max (Volt): Default settings for the min and max values

of the transducer bias voltage.

Configuration file:

File Name: Select a default name of the text file in which the configurations are stored.

Miscellaneous:

Time out: The timeout used for the link between the Host and DSP processors. Min. value=30 seconds.

A

B

C

D

E

F

G

– 12 – 72123 B

Intellinova Parallel INSMB4V

GENERAL SETTINGS (B)

The following parameters can be set for the measuring unit:

Type of alarm:

No delay: An alarm will be generated when one measurement result

has exceeded the alarm level when No delay is selected.

Time based: An alarm will be generated when a measurement result

has exceeded the alarm level during a time interval greater than the

time given by the parameter Alarm delay.

No. of measurements: An alarm will be generated when a number of

measurement results (consecutive) has exceeded the alarm level as

many times as given by the parameter Alarm delay.

Alarm delay:

Has no function if Type of alarm = No delay. The unit of Alarm delay is seconds if type of alarm is Time based or

number of measurements if type of alarm is No. of measurements.

Auto reset:

An alarm is reset automatically if Auto reset = Yes. If Auto reset = No, a manual reset is required to reset the

alarm state. A manual reset is done by pressing the KEY button twice.

CMA Factor:

This factor defines how the CMA value is calculated. CMA is the Cumulative Moving Average which is a tech-

nique used for calculating an average value based on a sequence of results. The higher the CMA factor, the

slower the CMA response to a change of the input signal. CMA Factor = 1 means that the CMA value follows

without delay.

DO Logic:

DO Logic defines the logic used to control the Digital Outputs. When DO Logic=0 (default), the Digital Outputs

will be in a low state when there is no alarm and a high state when there is an alarm. When DO Logic=1 the

Digital Outputs will be in a high state when there is no alarm and a low state when there is an alarm.

SETTING (C)

Select a Setting value in the range 100-899 for the configuration. The

SETTINGS selector switches on the Parallel unit are then set to corre-

sponding value to perform the specified assignments according to the

configuration. Up to 100 configurations can be selected by changing

the Setting value.

Active Configurations:

After saving a configuration, it is listed under Active 'Configura-

tions'. To view or edit a configuration, mark it in the list.

All active configurations will be included in the configuration file

for download to the Parallel unit.

Copy an Active Configuration

Mark an active configuration in the list and click the button 'Copy setting'. Select a new value in the range 100-899 for

the new configuration where you want to paste the copy. Click the button 'Paste setting' and a new active configura-

tion is ready for modification. This saves time when the configurations are similar.

Software

– 13 – 72123 B

Intellinova Parallel INSMB4V

Channel Configuration (D)

Select the channel to be configured (1-4).

ASSIGNMENT (E)

Three assignments can be configured for each channel. Select

Assignment tab and click on the parameters to select settings.

Measurement

Technique:

Inactive: No measurement is performed for this assignment.

Acceleration: The measurement uses acceleration as amplitude unit. Each assignment generates one accelera-

tion rms value for the user defined frequency range. All other results such as symptoms values, time signal and

spectrum are expressed in the same unit.

Velocity: The measurement uses velocity as amplitude unit. Each assignment generates one velocity rms value

for the user defined frequency range. All other results such as symptoms values, time signal and spectrum are

expressed in the same unit.

Displacement: The measurement uses displacement as amplitude unit. Each assignment generates one displace-

ment rms value for the user defined frequency range. All other results such as symptoms values, time signal and

spectrum are expressed in the same unit.

HD ENV: The measurement uses the HD ENV technique where the user can select the filter to be used. The en-

veloping is applied on an acceleration signal. The measurement can also produce symptom values, time signal

and spectrum.

HDm/HDc: The measurement generates two results, HDm and HDc. The measurement can also produce symp-

tom values, time signal and spectrum.

LR/HR HD: The measurement generates two results, LR and HR. The measurement can also produce symptom

values, time signal and spectrum.

Type of sampling:

Order tracking: The sampling rate follows the RPM signal which means that the number of samples per revolu-

tion is constant. The sampling frequency is based on the value of Order selected by the user and the RPM signal.

Fixed Frequency: The sampling frequency is fixed and based on the frequency range selected by the user.

Alarm

Alarm Red A (VIB, HDm, LR):

The red alarm limit for vibration measurements (Acc, Vel, Disp, HD ENV) and shock pulse measurements HDm or

LR.

Alarm Yellow A (VIB, HDm, LR):

The yellow alarm limit for vibration measurements (Acc, Vel, Disp, HD ENV) and shock pulse measurements HDm

or LR.

Alarm A CMA (VIB, HDm, LR):

The alarm limit for the CMA (Cumulative Moving Average) of the vibration measurements (Acc, Vel, Disp, HD

ENV) and shock pulse measurements HDm or LR.

Alarm Red B (HDc, HR):

The red alarm limit for HDc or HR when measuring shock pulses.

Alarm Yellow B (HDc, HR):

The yellow alarm limit for HDc or HR when measuring shock pulses.

Alarm B CMA (HDc, HR):

The alarm limit for the CMA (Cumulative Moving Average) for HDc or HR when measuring shock pulses.

Software

E

D

– 14 – 72123 B

Intellinova Parallel INSMB4V

DO Alarm Red A:

Configures a DIO (1-6) as Digital Output. The output is activated if there is an alarm on Alarm Red A or AlarmA

CMA. Possible values are 0-6. The value 0 disables the activation of a Digital Output.

DO Alarm Yellow A:

Configures a DIO (1-6) as Digital Output. The output is activated if there is an alarm on Alarm Yellow A. Possible

values are 0-6. The value 0 disables the activation of a Digital Output.

DO Alarm B:

Configures a DIO (1-6) as Digital Output. The output is activated if there is an alarm on Alarm Red B, Alarm B CMA

or Alarm Yellow B. Possible values are 0-6. The value 0 disables the activation of a Digital Output.

Miscellaneous

Shaft diameter (mm):

Used together with RPM for calculating the HDi value, which

is a normalization factor subtracted from the measured “raw”

value. Normalization makes the shock pulse values independ-

ent of bearing size and RPM.

SEF ( 0 - 10):

Symptom Enhancement Factor is used to vary the “strength” of

the symptom enhancer algorithms. A higher factor will improve

the signal to noise ratio but the measuring time will increase; a

low factor will result in less clear spectrums but the measuring

time will be decreased. SEF=0 means no Symptom Enhancement.

TSA (2 - 999)

Time Synchronized Averaging is an average technique where

each measurement starts on the edge of the RPM signal. Any

signals not synchronized with the RPM signal will be attenu-

ated when the measurement is averaged in the time domain.

TSA=0 means No Time Synchronized Averaging.

RPM

When Type of sampling is set to Fixed Frequency, the only RPM pa-

rameter that needs to be defined is Speed (Channel, Factor, Pulses

per revolution, Max Dev are inactive in this state).

Speed:

Used when the RPM of the application is fixed.

Channel:

The channel used by the RPM sensor, RPM1 or RPM2.

Factor:

Used to convert the RPM result when the RPM sensor is measuring a different speed, e.g. on the other side of a

gearbox.

Pulses per revolution:

The number of pulses per revolution generated by the RPM sensor.

Max Dev %:

The maximum deviation (in %) of the RPM signal allowed during a measurement. A measurement error will result

if the RPM signal variation exceeds this value.

Also see RPM Low Limit by the settings for Transducer and DIO/RPM. The RPM Low Limit setting can be used for start-

ing and stopping measurements using RPM.

Software

– 15 – 72123 B

Intellinova Parallel INSMB4V

Spectrum

Lines:

The number of lines used in the spectrum. The more lines

the better the resolution of the spectrum, but the time of the

measurement is proportional to the number of lines.

Orders:

This value sets the upper limit of the spectrum when Type of

sampling = Order tracking. If Orders=100, it means that all

signals with a frequency up to RPM x100 will be included in the

spectrum.

HD Envelope filter:

The measurement uses the envelope technique where the user

can select a filter to be used. The enveloping is applied on an

acceleration signal.

Low Frequency limit:

Defines the low frequency limit (Hz) of the measurement.

High Frequency limit:

Defines the high frequency limit (Hz) of the measurement.

Used when Type of sampling = Fixed RPM.

SYMPTOM BAND (F)

For each assignment the user can define three symptoms.

Set Symptom to 'True' to active it.

Define the Symptom Bands you need, max. 10 in total

spread over the three symptoms. Each band is defined by an

upper and a lower frequency limit, in Hz or in orders when

Order tracking is used. The upper frequency limit must be

higher than the lower limit. Press 'Add' to save the symptom

band. Pressing 'Delete All' will delete all symptom bands.

Each assignment uses its own settings for symptoms. Mark

a symptom to view its symptom bands.

Symptom Alarm

Limit:

The alarm limit for the symptom.

Limit CMA:

The alarm limit for the CMA (Cumulative Moving Aver-

age) for the symptom.

DO Alarm:

Configures the alarm to a Digital Output. Possible values are 0-6 where 0 disables the function.

Software

– 16 – 72123 B

Intellinova Parallel INSMB4V

TRANSDUCER AND DIO/RPM (G)

DIO/RPM

Input:

Configures a DIO (1-6) as a Digital Input and let this signal

controls the measurement. A high (low) signal enables

(disables) the measurement. Possible values are 0-6 where

Input=0 enables the measurement all the time.

RPM Low Limit:

RPM Low Limit is a parameter used to run measurements

only when the RPM > RPM Low Limit. If RPM < RPM Low

Limit, the measurements will not start and the LED will

be black. Each channel has three assignments which

may have different RPM configurations (Speed, Channel,

Factor, Pulses per revolution, Max Dev). Please note that

RPM Low Limit is compared to the RPM as configured in

the first assignment.

Status Out:

Configures a DIO as Digital Output. The signal goes high if there is a Bias error or a measurement error. Possible

values are 0-6 where Status Out=0 disables the function.

Transducer

Bias max:

The max value of the Bias voltage (V). A Bias error will be produced if the measured bias voltage > Bias max.

Typical value for Bias max. is 16.

Bias min:

The min value of the Bias voltage (V). A Bias error will be produced if the measured bias voltage < Bias min.

Typical value for Bias min. is 5.

Sensitivity:

The sensitivity of the transducer expressed in mV/m/s2. The individual value for the transducer is given on the

calibration chart. Default value is 10.

Copy a Channel Configuration

Click the button 'Copy Ch.' to copy the active channel. Select the

channel where you want to paste the copy and click the button 'Paste

Ch'. This saves time if the channel configurations are similar.

– 17 – 72123 B

Intellinova Parallel INSMB4V

Send the Configuration File to the Parallel Unit

If the unit is to be operated in offline mode, the configuration file must be

downloaded to the Intellinova Parallel unit. Follow these steps in order to

download the configuration file.

1) Connect a PC to the unit by using a USB to UART cable (SPM 15484)

connected to the COM port on the front panel of the Parallel unit. This

requires the PC to have the correct drivers installed. See document 72093B

"Installing drivers for cable 15484".

2) Set SETTINGS= 099 on the front panel of the unit.

3) Download the configuration file to the unit by clicking on “Send File”.

This requires the PC to be connected to the unit. Select file to send and

press 'Open'. The LED S indicates that a transfer is ongoing by flashing

rapidly.

4) When the LED S returns to flashing slowly, the transfer is complete.

5) Set SETTINGS to the measurement configuration to be performed (e.g. 101). The LEDs of the four channels will

go flashing rapidly if SETTINGS is set to a value not defined in the configuration file. The same LEDs go into a

non flashing state when SETTINGS is set to a value that is defined in the configuration file.

6) When the unit is in a normal operating state the four LED shows the status of each channel.

Receive the Configuration File from the Parallel Unit

A configuration file can be transferred back from a Parallel unit to a PC for further editing. Follow these steps in order

to receive the configuration file.

1) Connect a PC to the unit by using a USB to UART cable (SPM 15484) connected to the COM port on the front panel

of the Parallel unit. This requires the PC to have the correct drivers installed. See document 72093B "Installing

drivers for cable 15484".

2) Set SETTINGS= 099 on the front panel of the unit.

3) Transfer the configuration file to the PC by clicking on “Receive File”. Input a suitable name and select the folder

where to save the file. The LED S indicates that a transfer is ongoing by flashing rapidly.

4) When the LED S returns to flashing slowly, the transfer is complete.

Software

DIO6–

DIO6+

DIO5–

DIO5+

DIO4–

DIO4+

DIO3–

DIO3+

DIO2–

DIO2+

DIO1–

DIO1+

VIB4gnd

VIB4–

VIB4+

VIB3gnd

VIB3–

VIB3+

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

0V

+24Vdc

RPM2pupd

RPM2–

RPM2+

Vdcint+

RPM1pupd

RPM1–

RPM1+

GND

RS485 A

RS485 B

VIB1gnd

VIB1–

VIB1+

VIB2gnd

VIB2–

VIB2+

Save the Configuration File

Save the configuration file by clicking the 'Save File' button. This creates

a text file (.txt) with the default file name set under 'Setup/General

configuration/Default'. You can input a suitable name and select the

folder where to save the file.

Open a Saved Configuration File

You can open and edit a saved file by clicking 'Open file'. Select the configuration file on the PC and press 'Open'.

When a file is opened its name is shown on the bottom line in program window.

– 18 – 72123 B

Intellinova Parallel INSMB4V

Upgrade of Firmware

The unit uses two processors, a Host processor and a DSP (Digital Signal Processor). First update the firmware for the

Host processor, then the firmware for the DSP. If you are updating the DSP you can do this without updating the Host

processor. The following equipment and software are needed in order to upgrade the different firmware.

• USB to UART cable, SPM 15484.

• Document 72093B "Installing drivers for cable SPM15484".

• Software PIC32UBL.

• Software PRO240 Parallel Service Software

• The file for firmware upgrade of the Host processor (INSMB4V_30xxx.hex).

• The files for firmware upgrade of the DSP (P109_dsp_spi_100proc.bin and machineguard.txt).

Latest version of firmware can be found on: http://www.spminstrument.com/Downloads/SPM-Software/

Upgrade of Firmware

Upgrade of firmware for Host processor

Follow these steps in order to upgrade the firmware. A possible problem when following these steps is that a time out

can be activated if the steps are carried out with an unnecessary delay between them. In that case the steps just have

to be repeated without a delay between them.

1) Make sure you have the correct drivers installed on a PC in order to use the USB to UART cable (SPM 15484).

Use document 72093 if the drivers need to be installed.

2) Connect the USB to UART cable to a USB port of the PC and to the COM port of the SPM Measuring unit.

3) Connect 24 Vdc to the SPM Measuring unit.

4) Set SETTINGS=999 on the front of the SPM Measuring unit.

5) Push KEY once and verify that the S LED starts to flash twice repeatedly.

6) Start the software PIC32UBL

7) Select the correct COM Port for the USB to UART cable. The com port should be listed as “Silicon Labs CP210x

USB to UART Bridge” in the Windows Device Manager.

8) Set the Baud Rate to 115200.

9) Click the Connect button and verify that you receive “Device connected” in the message field.

10) Click the Load Hex File button and select the file 'INSMB4V_30xxx.hex'.. Verify that you receive “Hex file

loaded successfully” in the message field.

11) Click the Erase button and wait until two “Flash Erased” appears in the message field.

12) Click the Program button and wait until “Program Completed” appears in the message field.

13) Click the Verify button and wait until “Verification Successful” appears in the message field.

14) Click the Disconnect button and wait until “Device Disconnected” appears in the message field.

15) Upgrade firmware for DSP, see next page.

The user interface used for upgrade of the firmware for the Host processor. The

messages shown in the message field is the result of a successful data transfer.

Table of contents

Other SPM Measuring Instrument manuals

SPM

SPM intellinova compact INS06 Ex Owner's manual

SPM

SPM Machine Guard MG4-REF11A User manual

SPM

SPM VibChecker User manual

SPM

SPM VIB-11 User manual

SPM

SPM leonova emerald User manual

SPM

SPM Intellinova Compact User manual

SPM

SPM A2010 User manual

SPM

SPM VibChecker User manual

SPM

SPM Vibrameter VIB-11B User manual