SPORTident BS Series User manual

Battery exchange in BSF7 and BSF8 stations

V1.1 22.09.2015

Battery exchange in BSF7 and BSF8 stations

All BSx7 and BSx8 control stations are equipped with high quality lithium batteries. The continuous

current in standby mode is extremely small.To avoid problems with the cable connector the batteries

of these control stations are soldered directly to the electronic board. The battery exchange requires

technical equipment and skills. Please read the following instructions to learn how the battery

exchange can be realized successfully.

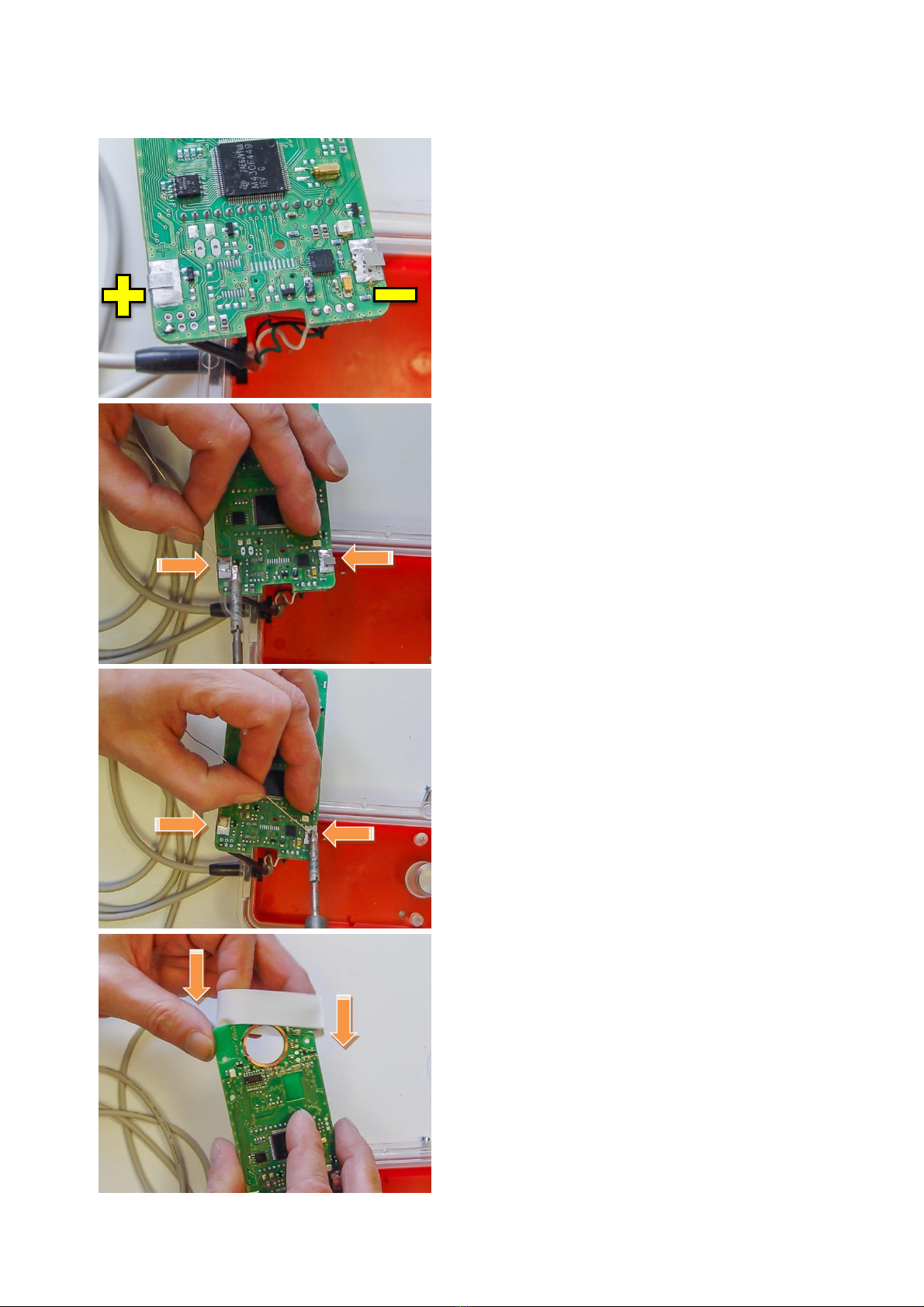

BSx7 battery exchange

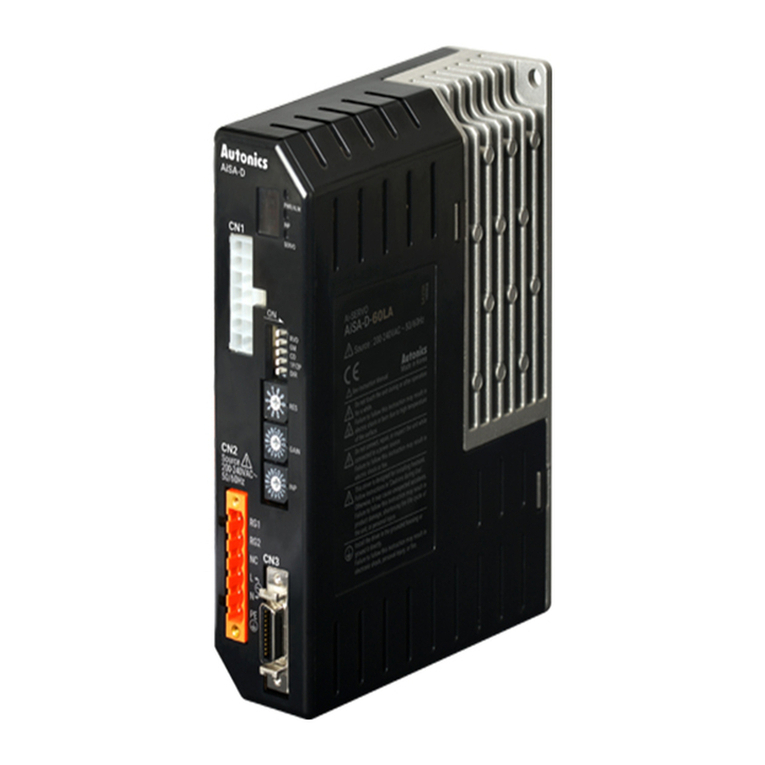

Remove the 4 screws with a screwdriver.

Take care of the nuts falling off at the back

side.

The box is tightly sealed. Take a blunt knife or

a flat screwdriver to open the box carefully.

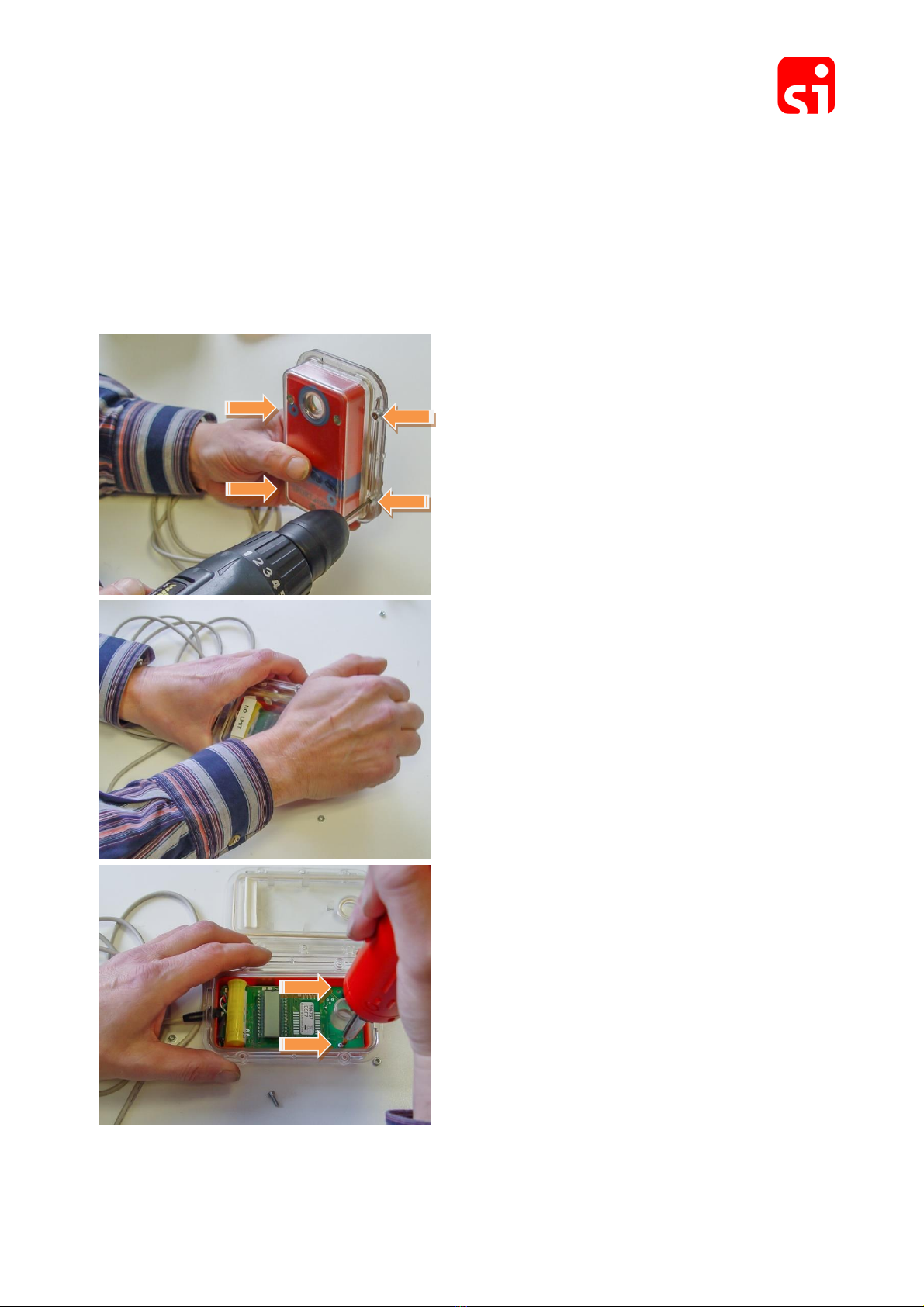

Remove the two screws that hold the board in

the housing. Lift the board with the hole first

and then move the board slightly out of the

housing. Take care of the cable if the station is

equipped with a cable output.

Battery exchange in BSF7 and BSF8 stations

V1.1 22.09.2015

Cut the shrink tube around the battery with a

side cutter. Be careful to not touch the board

electronics with the tool.

Desolder the battery contacts with a 40 to 60

Watts soldering iron. The temperature should

be between 350°C and 400°C,

because lead free tin solder was used.

Important! There is a risk of explosion when

the battery lugs are shorted. Please do not

forget to cut the soldering lugs from the battery

with a side cutter.

It is required to dispose of the batteries as

hazardous waste. Please bring them to a

collecting point or send them back to us.

Bend the soldering lugs of the new battery

around the board.

Battery exchange in BSF7 and BSF8 stations

V1.1 22.09.2015

Pay attention to the right polarity of the battery!

The green ring on the battery is the minus

pole, „+“ and „-“ are marked on the printed

circuit board.

To solder on the battery, additional tin solder is

necessary. Please use only lead-free tin

solder, we recommend alloy Sn 95.5 / Ag 3.8 /

Cu 0.7 with a diameter less than 1.0 mm.

While contacting the solder lugs to the solder

pads the station gets a reset signal and is

brought on-line with 2 beeps. Press down the

lugs with a spiky tweezer while soldering and

wait for the soldering pads to cool down until

you can safely touch them.

Slip the shrink tube over the stations board

starting from the top. Do not remove the cable

from the BSM7 station.

Battery exchange in BSF7 and BSF8 stations

V1.1 22.09.2015

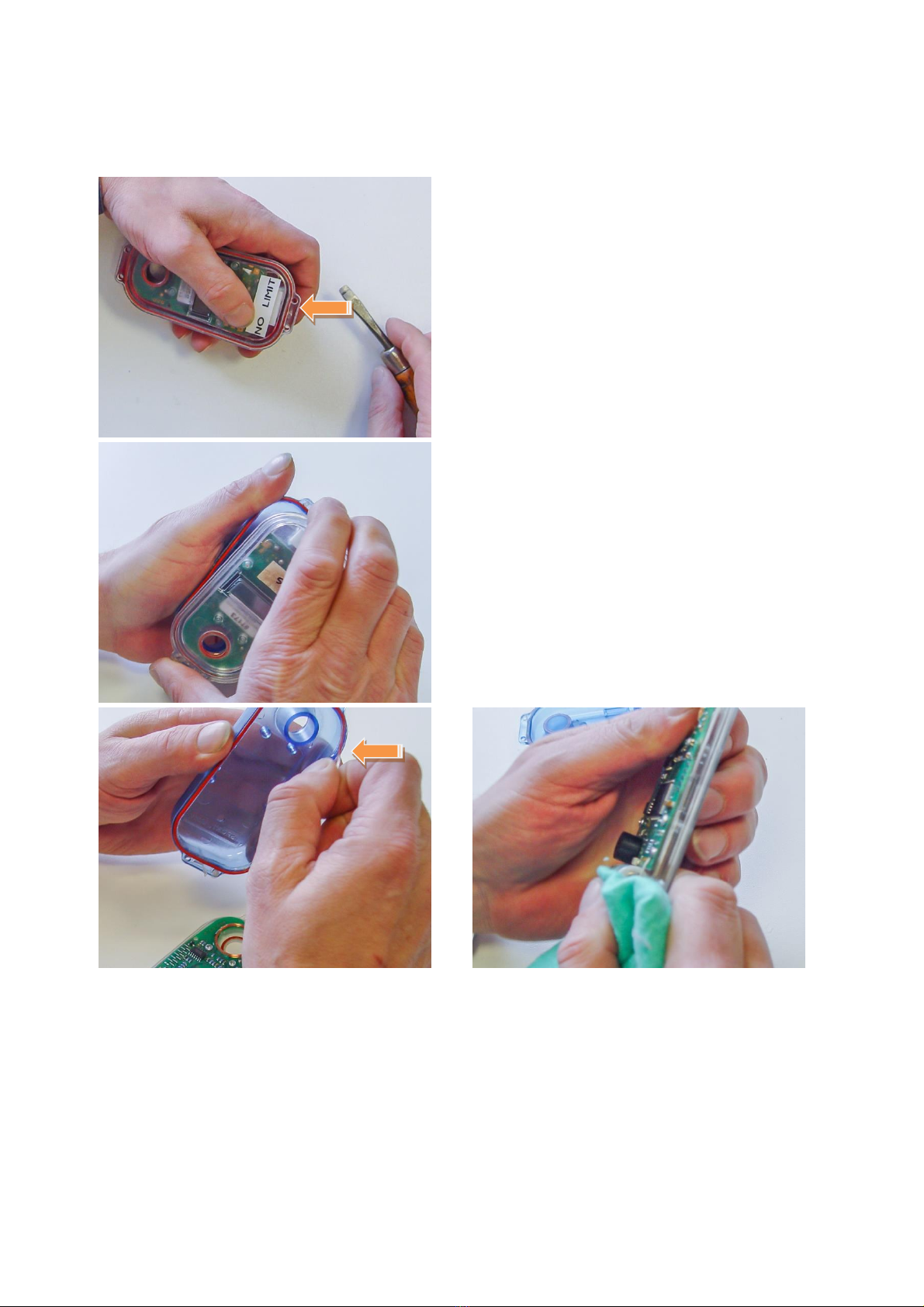

Put the shrink tube evenly over the battery as

shown in the picture. Start heating it up with a

heat gun at level 2. Move the board back and

forth over the heat gun for about one second

for each side.

A perfect result can be seen in the pictures. If

the shrink tube cracks, replace it and use a

new one.

Be sure to not cover the LED at the back side

of the board.

Put the board carefully back in the case and

fasten the screws.

Clean the rubber ring with some alcohol and

apply silicone spray to ensure a proper sealing

of the rubber ring.

Close the case and fasten the screws. Use a

low gear level for the cordless screwdriver.

You need to reset the battery parameters,

check the settings and set the time of the

station with Config+ afterwards (see below).

Complete!

Battery exchange in BSF7 and BSF8 stations

V1.1 22.09.2015

BSF8 battery exchange

Open the box carefully with a short screwdriver

or a blunt knife.

Remove the big rubber ring and the silicone

remainders carefully.

Leave the small rubber ring untouched.

Battery exchange in BSF7 and BSF8 stations

V1.1 22.09.2015

Desolder the battery contacts with a 40 to 60

Watts soldering iron. The temperature should

be between 350°C and 400°C,

because lead free tin solder was used.

Important! There is a risk of explosion when

the battery lugs are shorted. Please do not

forget to cut the soldering lugs from the battery

with a side cutter.

It is required to dispose of the batteries as

hazardous waste. Please bring them to a

collecting point or send them back to us.

To bend the soldering lugs of the new battery,

use the gauge (article number 33370).

Pay attention to the right polarity of the battery!

The green ring on the battery is the minus

pole, „+“ and „-“ are marked on the printed

circuit board.

Battery exchange in BSF7 and BSF8 stations

V1.1 22.09.2015

To solder on the battery, additional tin solder is

necessary. Please use only lead-free tin

solder, we recommend alloy Sn 95.5 / Ag 3.8 /

Cu 0.7 with a diameter less than 1.0 mm.

While contacting the solder lugs to the solder

pads the station gets a reset signal and is

brought on-line with 2 beeps. Press down the

battery with a finger while soldering and wait

for the soldering pads to cool down until you

can safely touch them.

Put the big rubber ring in the groove of the

ground plate.

Press it inside with the special case (article

number 33360).

Cover the large rubber ring with a small

quantity of liquid silicone continually.

The small round rubber ring is not covered with

silicone and must not be touched.

We strongly recommend to only use our

special electronics silicone as it does not

corrode the rubber sealing or plastic parts.

Battery exchange in BSF7 and BSF8 stations

V1.1 22.09.2015

Clench together the ground plate and the

upper part.

Put the station in a dry and warm place. It

takes 24 hours until the silicone is hardened.

Finally remove the excess silicone with a

plastic strip with a sharp edge. Do not use

metal tools to no damage the housing.

Clean up the station with a soft cloth.

Clean up the station with a soft cloth.

You need to reset the battery parameters,

check the settings and set the time of the

station with Config+ afterwards (see below).

Complete!

Battery exchange in BSF7 and BSF8 stations

V1.1 22.09.2015

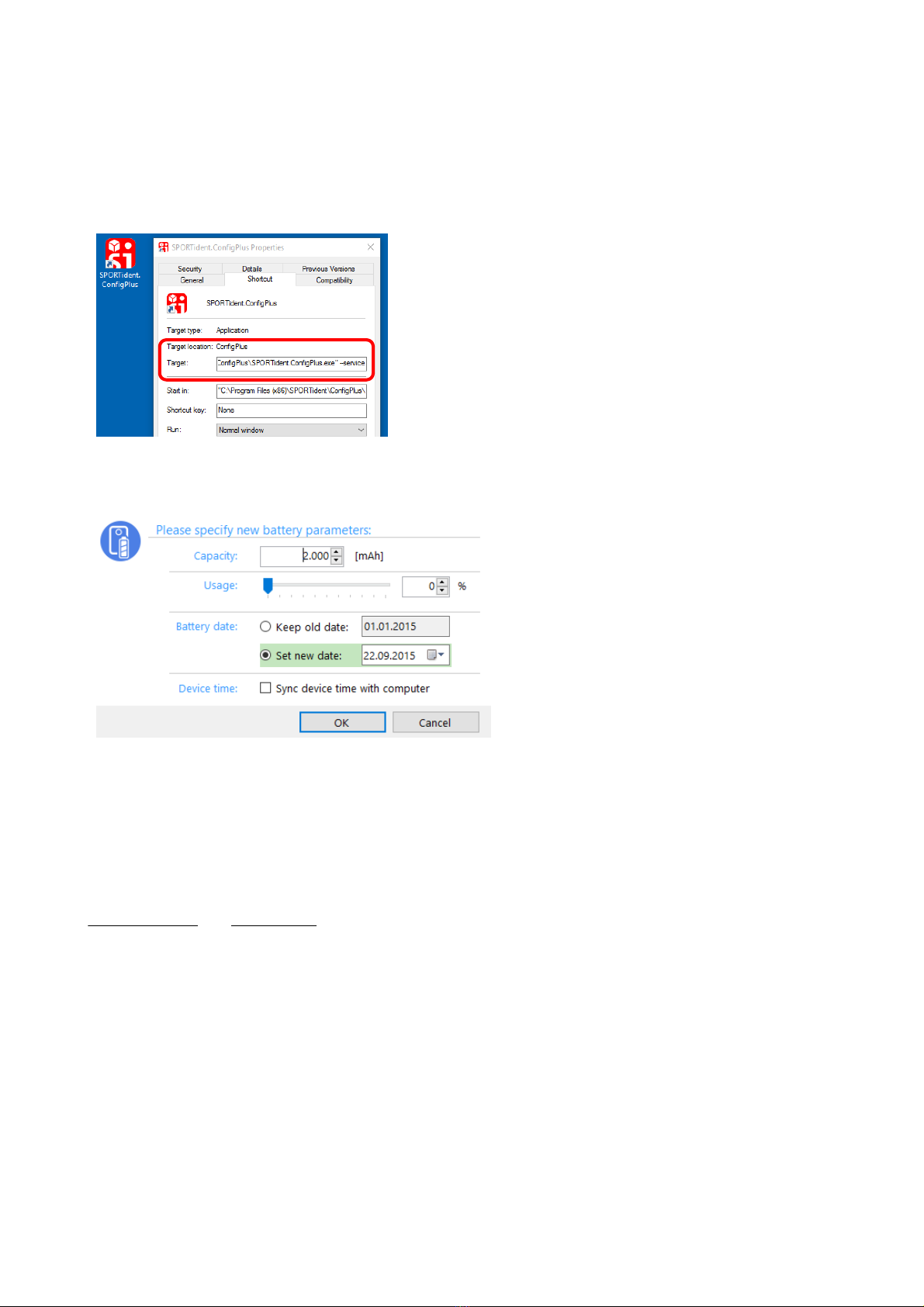

Writing new battery parameters to the station

To write the battery change date and to reset the consumption counter in the station, you need to

enable the service mode in Config+. You can use the shortcut on your Desktop to do this.

1. Right click on the shortcut and bring up the

properties dialog.

2. In the text box “Target:” scroll to the most right

position and

append a “ --service” after the last quote

character.

3. The last few characters should look like this:

\SPORTident.ConfigPlus.exe" --service.

4. Confirm the changes with OK.

Now start up Config+ by clicking on the Desktop icon.

1. First select your device connection

and choose direct or remote

depending on which device battery

to have changed.

2. Read/verify the device settings and

correct if required.

3. In the menu “Service” select the

sub menu “New device battery…”.

4. In the upcoming dialog select the

desired parameters.

Usually you want to change the

usage counter and the battery

date.

5. Click OK to apply the settings.

Repair material

Article number

Description

33310

Battery lithium 2000 mAh / AA (BSF7), lithium batteries will be

shipped in the original packaging unit of 30 pieces

33320

Battery lithium 1000 mAh / 1/2 AA(BSF8), lithium batteries will be

shipped in the original packaging unit of 30 pieces

33330

Flexible O-ring seals BS8 (1 piece each)

33341

Liquid Silicone (60 ml for approx. 60 pcs.)

33350

Shrink tubing for battery (BSF7)

33360

Special case for press the O-ring seals in the BSF8 case

33370

Gauge for bending the 1/2 AAbattery cable

This manual suits for next models

2