Sportig E30 User manual

1

Owner’s Manual

Retain this owner’s manual for future reference

Read and follow all instructions in this owner’s manual

Version A

1

Thank you

Thanks for purchasing this product.The product will help you exercise your muscles in

the correct way and to improve your fitness – and all this in a familiar environment.

Precautions

WARNING: This elliptical trainer has been designed and constructed to provide maximum

safety. Nevertheless, certain precautions should be taken when using exercise equipment.

Read the whole manual before assembling and using the elliptical trainer. The following

safety precautions should also be observed:

◆It is the responsibility of the owner to ensure that all users of the elliptical trainer are

adequately informed of all precautions. Use the elliptical trainers only as described

in this manual.

◆Keep children and pets away from this equipment at all times. DO NOT leave them

unsupervised in the room where this elliptical trainer is kept.

◆Please make sure that the elliptical trainer has been assembled properly and all the

screws are locked .

◆Place the elliptical trainer on a level surface, with at least 1.0 m of clearance on each

side of elliptical trainer. To protect the floor or carpet from damage, please place a

mat under the elliptical trainer.

◆Keep the elliptical trainer indoors,without moisture and dust.Maintain the using

place ventilation. Do not use it in the airless place.

◆Don’t put any sharp things around the elliptical trainer.

◆Wear proper clothes while exercising; do not wear loose clothes that could be

tripped on the elliptical trainer.Always wear athletic shoes for foot protection while

exercising.

◆Do not use this product if you are over 150kg.Please choose our other series of

elliptical trainers.

◆Do not put your hands on the moving parts to prevent injures.

◆Keep your pedaling speed in control.

◆If you find your elliptical trainer works not normal, do not use it immediately.

◆No more than one person should use the elliptical trainer at the same time.

◆If you feel pain or dizziness while exercising, stop exercising and askfor adoctor.

2

Safety notice

When you are remedial or have below symptoms, after discussing with your doctor, then

could use this elliptical trainer.

1. Waist paining now and leg, waist, neck hurt before, legs, waist, neck and hand numbly

please do not use.

2. Have anamorphic arthritis, rheumatic and gout.

3. Have osteoporosis and other abnormality.

4. Have perfunctory system obstacle (heart disease, blood obstacle, hypertension).

5. Have breathobstacle.

6. Using the manpower pulse adjust machine or insert into the bodymachine.

7. Havesarcomata.

8. Have thrombus or othersymptoms.

9. Have diabetes or be caused by diabetes feelingobstacle.

10. Have skintrauma.

11. Hyperpyrexia caused by sick(38 ℃or over 38 ℃).

12. Abnormal back bone or back bonebending.

13. Pregnant orcatamenia.

14. Feel physical abnormality, need convalesce.

15. Body condition is not verywell.

16. The aim is tohealing.

17. Except the upper symptoms, feel other physical abnormality.

----Maybe cause the accident or the poor body condition.

Before beginning any exercise program, please consult your physician. This is especially

important for person who are over thirty five years old ,pregnant or with no experience of

excersice or have any health problem.To reduce the risk of serious injury, read all above

important precautions and instructions in this manual and all warnings on your elliptical

trainer before using.

3

Technical information:

PRODUCT NO. E30

DIMENSION Unfold:1660×720×1580mm

MAX LOAD 150KG

SPEED RATIO 10.3

FLYWHEEL Double magnetic way,Φ280/9kg

RESISTANCE 1-32

STRIDE LENGTH 420×200

*WE RESERVE THE RIGHT TO AMEND THE PRODUCT WITHOUT PRIOR NOTICE.

3URGXFWLQVWUXFWLRQ

+DQGOHEDU

&RQVROH

+DQGOHSXOVH

%RWWOHKROGHU

0DLQIUDPH

8SSHUXSULJKWSRVW

:KHHO

)URQWVWDELOL]HU

3HGDO

5HDUVWDELOL]HU

4

Screw bag list

NO. NAME SPECIFICATION QTY

26 Allen C.K.S. half thread screw M10×70×20 4

28 Flat washer Φ10 4

31 Flat washer Φ8.5×Φ20×t1.5 4

34 Philips pan head full thread screw M4×10 16

36 Flat washer Φ62

38 Philips C.K.S. self-tapping screw ST4×16 2

101 Philips C.K.S. self-tapping screw ST4×12 4

L shape wrench 5×40×100 1

33 M4×16-2

34 M4×10-16

38 ST4×16-2

37 M6× 15-2

35 Φ 10×45× M6×20-2

26 M10×70×20-4

27 Φ10-4 28 Φ10-4

36 Φ6-2 31 Φ8.5*F20*t1.5-4

L5S-A

L5-B

L6

29 M8*20-4

101 ST4×12-4

E30

103 Φ17-2

5

L shape wrench 6×66×140 1

NO. NAME SPECIFICATION QTY

27 Spring washer Φ10 4

29 Allen pan head full thread screw M8×20 4

33 Philips pan head full thread screw M4×16 2

35 Allen C.K.S. hollow screw Φ10×45×M6×20 2

37 Allen C.K.S. full thread screw M6×15 2

103 Curve elastic washer Φ17 2

L shape wrench 5×80×80S(with philips)

6

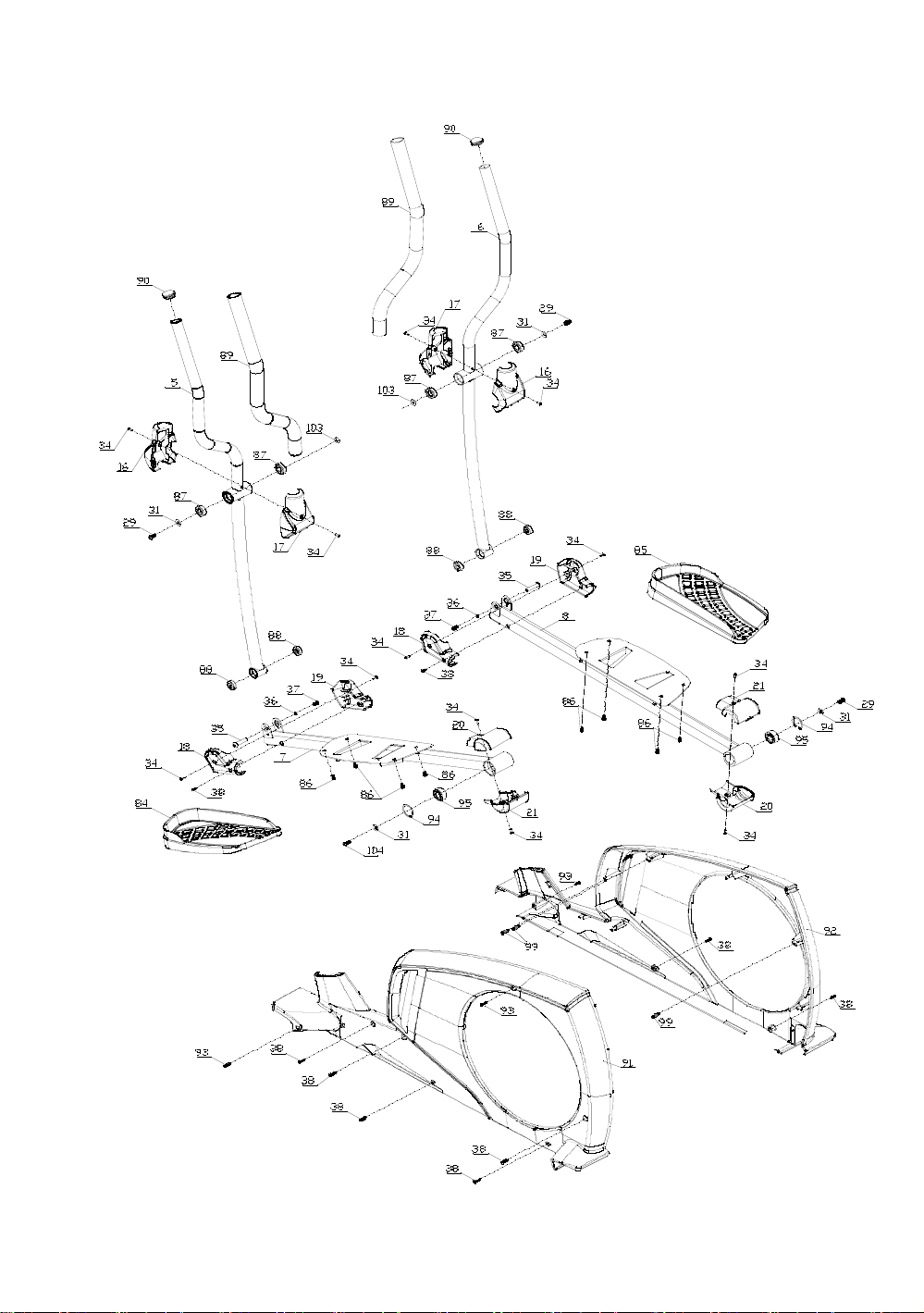

ASSEMBLY INSTRUCTIONS

Step 1:

1. Attach the front stabilizer (2) to the main frame (1) with curved washer(28), spring

washer(27) and Allen C.K.S. half thread screw(26).

Step 2:

1. Attach the rear stabilizer (3) to the main frame (1) with curved washer(28), spring

washer(27) and Allen C.K.S. half thread screw(26)

7

Step 3:

1. Connect motor communication wire(11) and upright post communication wire(12).

2. Attach upper upright post(4) to the main frame(1). Lock Allen flat head set-bolt (39)

preinstalled on the main frame, to fixed upright post. after that,cover back the Hole

Plug(102).

Attention: the two screws of the upright post should be locked in turn until the riser is firmly

locked. When finished tightening one screw, then start on the other screw in turn until

tightened the upright post.

8

Step 4:

1. Assemble of Body arm L/R, First, lubricate both ends of the axis,set the curve washer

(103) to the both side of the Axle (25). Then assemble Bodyarm-L(5) to the left of

Axle(25). Bodyarm-R(6) to the right of Axle(25). Lock with flat washer(31) and Allen

C.K.S. full thread screw(29).

2. Assemble Body arm cover (17) and Body arm cover (16) to the Body arm-left(5) with

Phillips pan head full thread screw(34).

3. Same as above way to assemble Body arm cover (17) and Body arm cover (16) to

the Body arm-right(6)

Coated lubricate

oil

Coated lubricate

oil

9

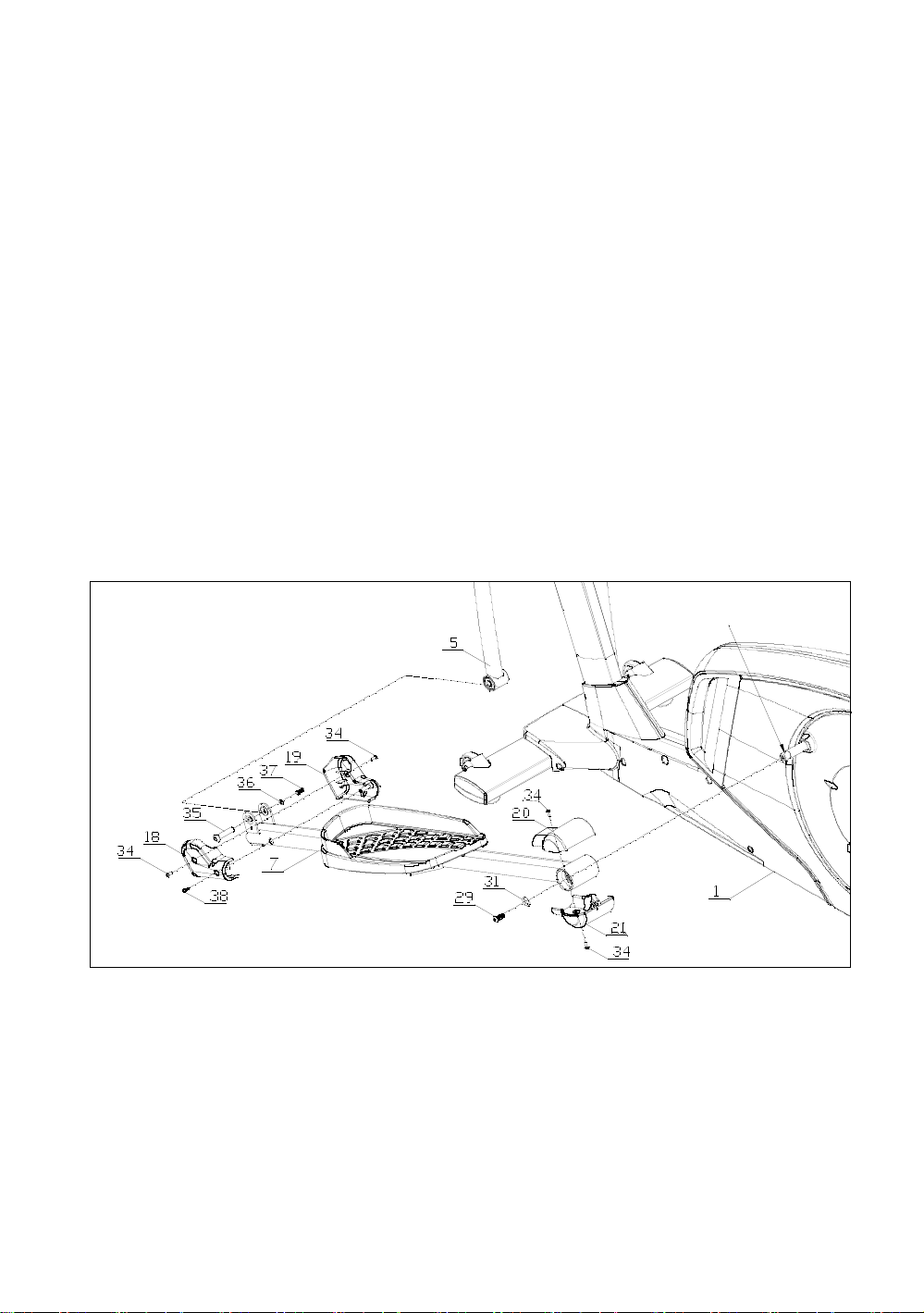

Step 5:

1.First, lubricate both ends of the axis, then Attach the axle sleeve of left rear pedal

supporter (7) to the axle of main frame(1) with Flat washer (31) and Allen C.K.S. half

thread screw (29).

2.Attach the axle sleeve of left front pedal supporter(7)to left body arm(5)with Allen

C.K.S. hollow screw(35), flat washer(36) and Allen C.K.S. full thread screw(37).

3.Attach the rear cover of pedal supporter(20/21) to left pedal supporter(7) with Philips

pan head full thread screw(34). Attach the front cover of pedal supporter(18/19) to left

pedal supporter(7) with Philips pan head full thread screw(3 and Philips C.K.S. self-

tappingscrew(38).

4. Install the Pedal supporter(R) (8)with same way.

Coated lubricate oil

10

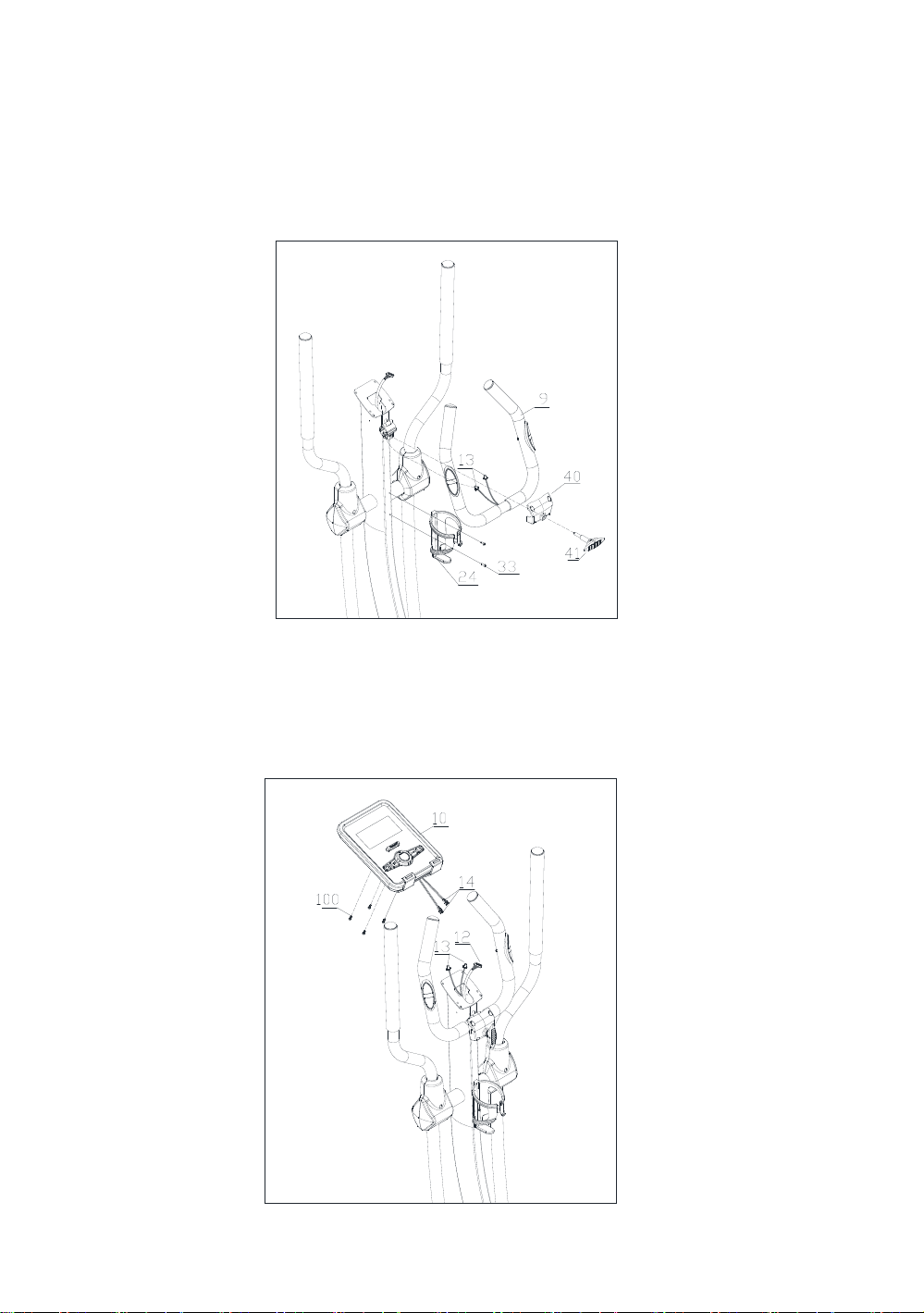

Step 6:

1. Fixed the handlebar (9). Through handle pulse connection wire(13) out of the upper

upright post(4). Then through T shape knob (41) out of the handlebar front cover (40).

Rotate inside. Notice: T shape don’t rotate tightly firstly.

2. Attach bottle holder(24) to upper upright post(4) with Philips pan head full thread

screw(33).

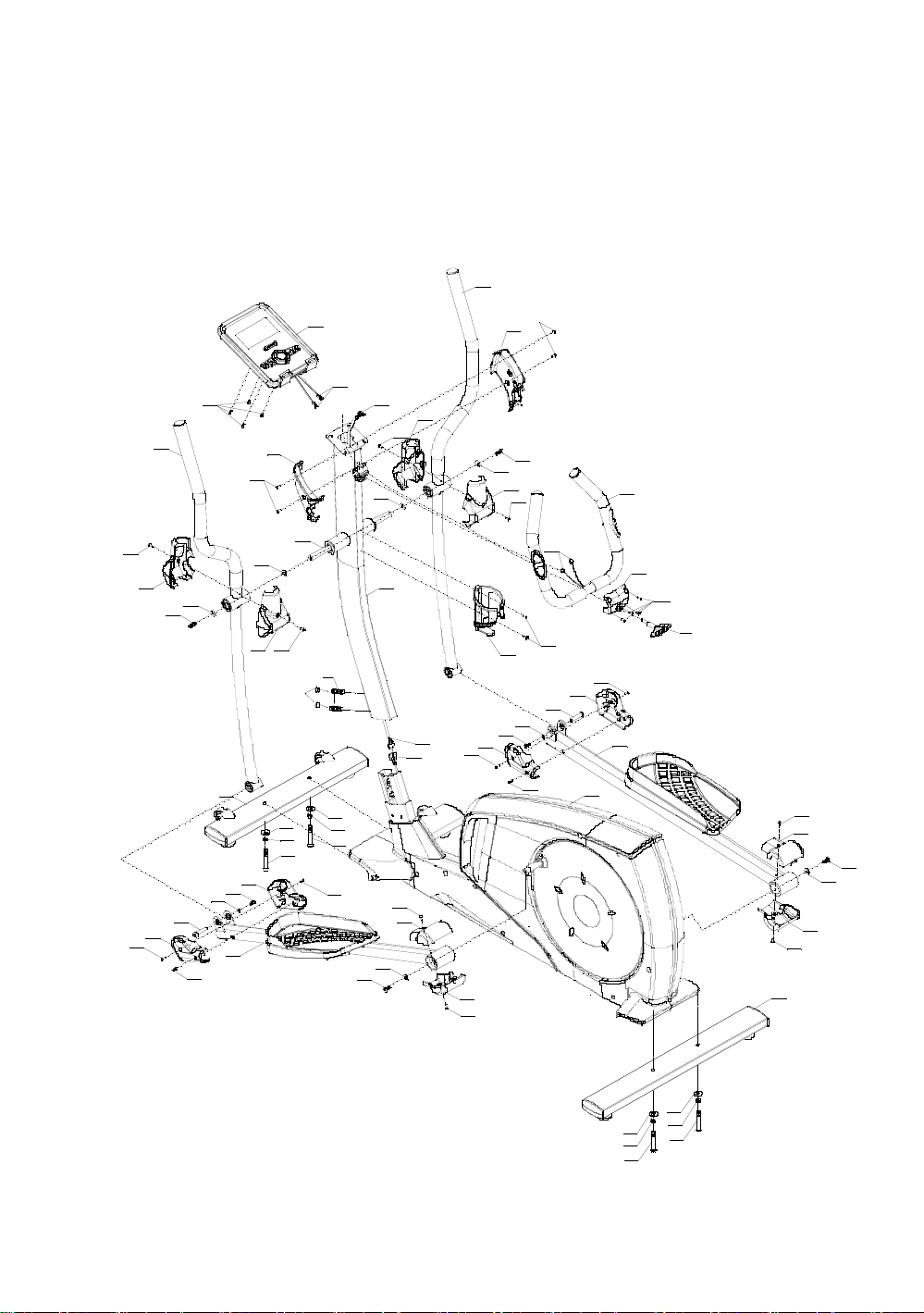

Step 7:

1.Connect console communication wire(12) with the interface of back console. Connect

handle pulse communication wire (13) with console outset(14).

2.Attach console(10) to upper upright post(4) with Philips C.K.S. full thread screw(100).

11

Step 8:

1. Attach handlebar cover –left (22) and right (23) to upper upright post (4) with Phillips

pan head full thread screw(34).

2. Lock the handlebar front cover (40) with Phillips C.K.S. self-tapping screw(101).

3. Adjust the Pulse tube to the suitable position. Rotate T shape knob.

Step 9:

1. Insert the power pugs into power hole as shown below. Assembling finished

12

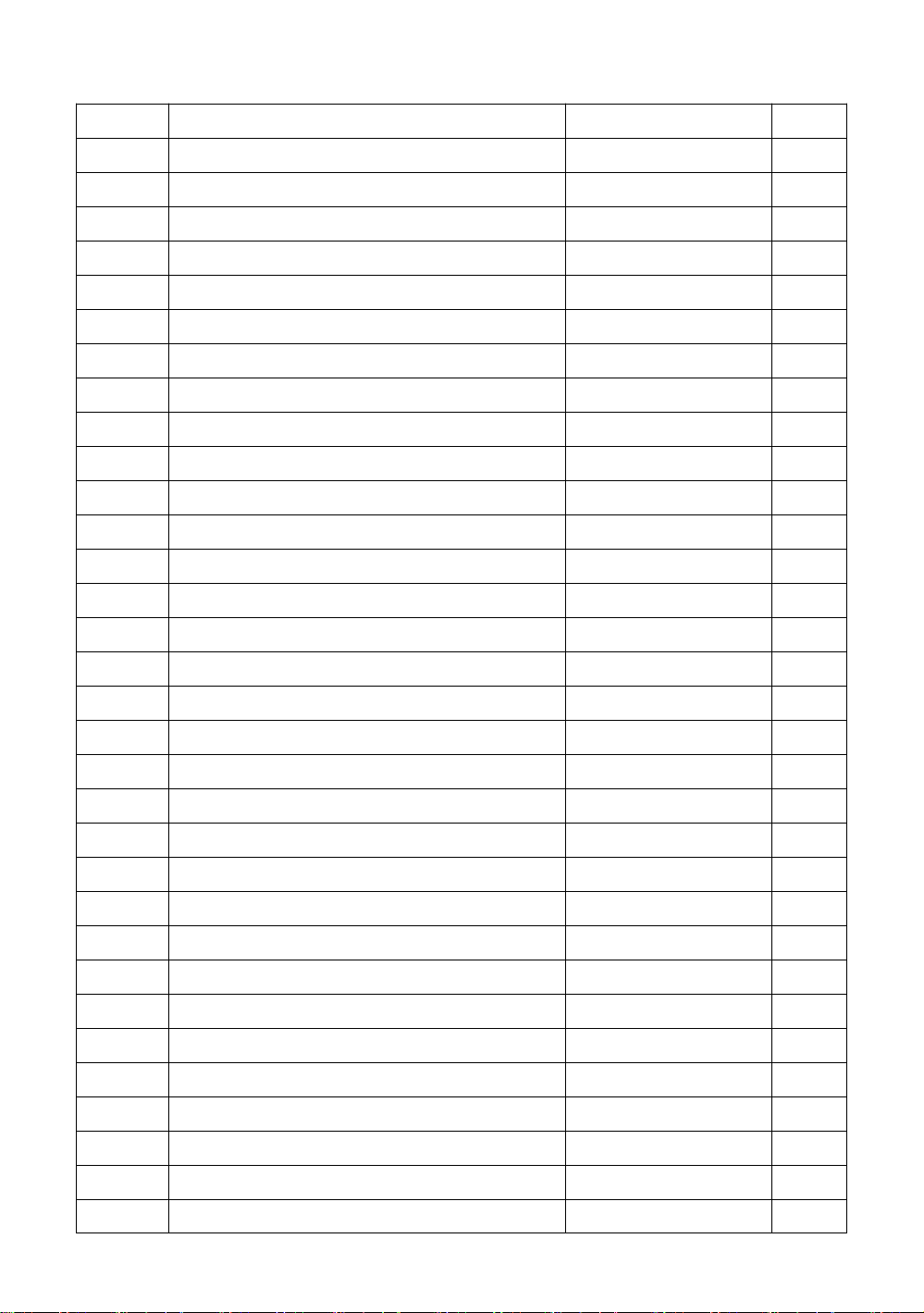

Half-drawing for assembly

4

12

25

31

29

17 34

16

34

29

31

16

34

34

9

13

100

10

14

35

36

37

18

34

19

38

34

20

31

21

29

34

37

36

35

19

18

34

34

38

34

21

34

20

31

29

8

21

3

5

6

12

11

17

34

7

33

24

34

22

34

23

28

27

26

28

27

26

28

27

26

28

27

26

101

40

41

39

103

103

102

13

Part List

NO. NAME SPECIFICATION QTY

1

Main frame 0.74 ㎡

1

2

Front stabilizer PT50×100×t1.5×600

1

3

Rear stabilizer PT50×100×t1.5×700

1

4

Upper Upright post 0.27 ㎡

1

5

Body arm(L) 0.161

1

6

Body arm(R) 0.161

1

7

Pedal supporter(L) 0.2 ㎡

1

8

Pedal supporter(R) 0.2 ㎡

1

9

Handlebars 0.085 ㎡

1

10 Console 5.5 " LCD/English

1

11 Motor communication wire L-550mm

1

12 Console communication wire L-1100mm

1

13 Handle pulse connection wire L-650mm

2

14 Console outset

2

16 Body arm cover 160.8×103×56

2

17 Body arm cover 160.8×103×45

2

18 Front pedal supporter cover 1 125.1×36.7×89.4

2

19 Front pedal supporter cover 2 125.1×39.7×89.4

2

20 Rear pedal supporter cover 1 107.7×103×34.5

2

21 Rear pedal supporter cover 2 107.7×103×37.5

2

22 Handlebar cover(L) 176.5×53.2×117.5

1

23 Handlebar cover(R) 176.5×53.2×117.5

1

24 Bottle holder Φ93×150

1

25 Axle Φ17×339.5

1

26 Allen C.K.S. half thread screw M10×70×20

4

27 Spring washer Φ10

4

28 Flat washer Φ10

4

29 Allen C.K.S. Full thread screw M8×20 4

31 Flat washer Φ8.5×Φ20×t1.5

4

33 Philips pan head full thread screw M4×16 2

34 Philips pan head full thread screw M4×10

16

35 Allen C.K.S. hollow screw Φ10×45×M6×20

2

14

36 Flat washer Φ6

2

37 Allen C.K.S. full thread screw M6×15

2

38 Philips C.K.S. self-tapping screw ST4×16 2

39 Allen flat head set-bolt M12×60

2

40 Handlebar front cover 89×73.5×35

1

41 T shape knob M8×30

1

100 Phillips C.K.S. full thread screw M5×10

4

101 Philips C.K.S. Self-tapping screw ST4×12

4

102 Hole Plug Φ15

2

103 Curve washer Φ17

2

15

Drawing for assembly

16

17

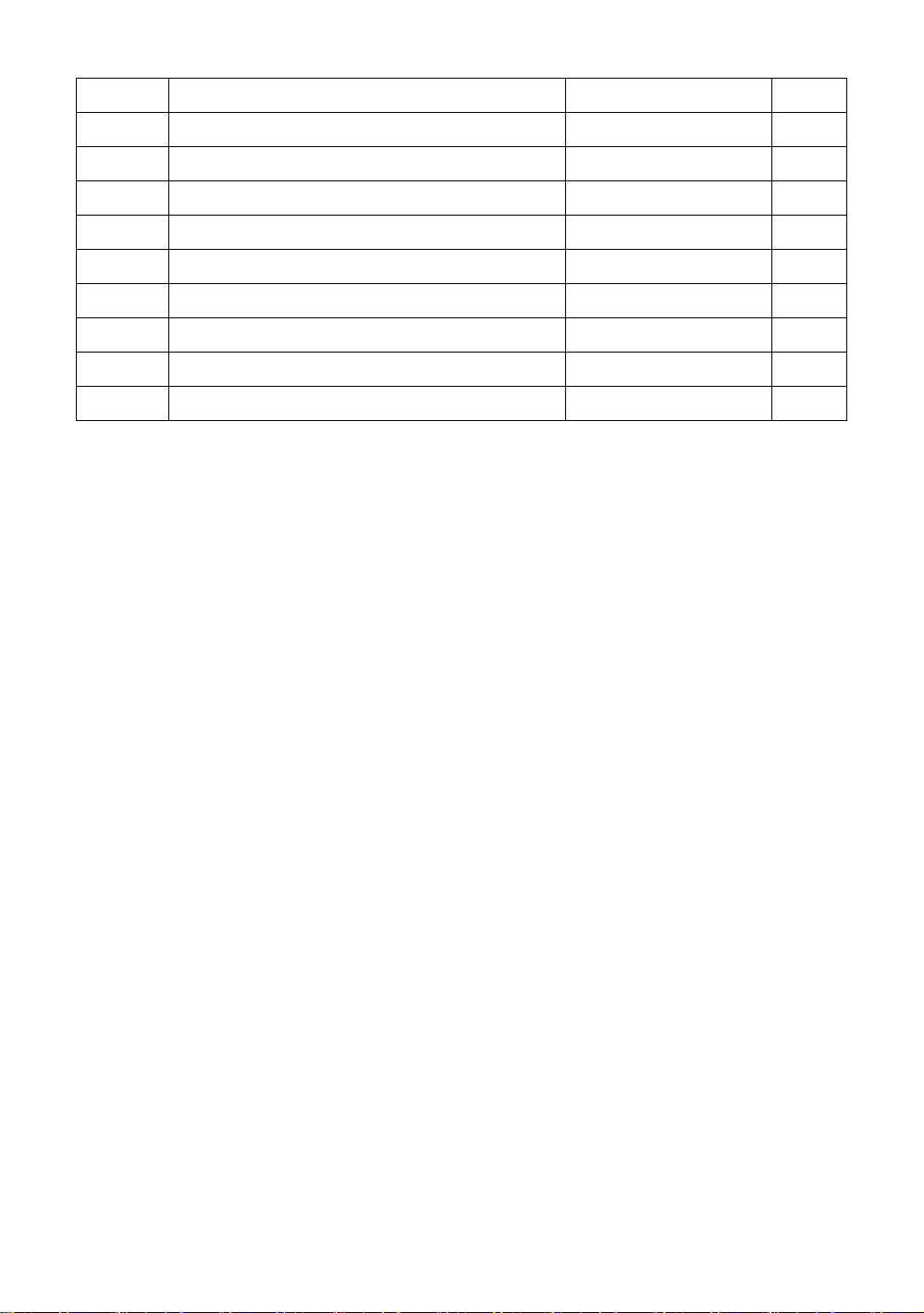

Part list

NO. NAME SPECIFICATION QTY

1

Main frame 0.74m2

1

2

Front stabilizer PT50×100×t1.5×600

1

3

Rear stabilizer PT50×100×t1.5×700

1

4

Upper Upright post 0.27m2

1

5

Body arm(L) 0.161m2

1

6

Body arm(R) 0.161m2

1

7

Pedal supporter(L) 0.2m2

1

8

Pedal supporter(R) 0.2m2

1

9

Handlebars 0.085m2

1

10 Console 5.5 " LCD/English

1

11 Motor communication wire L-550mm

1

12 Console communication wire L-1100mm

1

13 Handle pulse connection wire L-650mm

2

14 Console outset

2

15 Power adapter 240V

1

16 Body arm cover 160.8×103×56

2

17 Body arm cover 160.8×103×45

2

18 Front pedal supporter cover 1 125.1×36.7×89.4

2

19 Front pedal supporter cover 2 125.1×39.7×89.4

2

20 Rear pedal supporter cover 1 107.7×103×34.5

2

21 Rear pedal supporter cover 2 107.7×103×37.5

2

22 Handlebar cover(L) 176.5×53.2×117.5

1

23 Handlebar cover(R) 176.5×53.2×117.5

1

24 Bottle holder Φ93×150

1

25 Axis Φ17×339.5

1

26 Allen C.K.S. half thread screw M10×70×20

4

27 Spring washer Φ10

4

28 Flat washer Φ10

4

29 Allen C.K.S. Full thread screw M8×20 9

30 Spring washer Φ8

4

18

31 Flat washer Φ8.5×Φ20×t1.5

6

32 Hex self-locking nut M10

3

33 Philips pan head full thread screw M4×16 2

34 Philips pan head full thread screw M4×10

16

35 Allen C.K.S. hollow screw Φ10×45×M6×20

2

36 Flat washer Φ6

2

37 Allen C.K.S. full thread screw M6×15

6

38 Philips C.K.S. self-tapping screw ST4×16 17

39 Allen flat head set-bolt M12×60

2

40 Handlebar front cover 89×73.5×35

1

41 T shape knob M8×30

1

42 Turntable Φ466.6×24.1

2

43 Turntable rubber buckle Φ12.4×13 12

44 Phillips C.K.S. Tail cutting self-tapping screw ST4×10 12

45 Crank square iron

2

46 Hex half thread screw M10×55×20

2

47 Hex full thread screw M4×20

2

48 Flat key 5×5×15

2

49 Allen countersunk head full thread screw M6×15

2

50 Flat washer Φ8×Φ30×t3.0

2

51 Fixed idler wheel

1

52 Idler adjustment connecting shaft Φ15×30

1

53 Hex nut M8

2

54 Hex locking nut M8

7

55 Idler wheel Φ38×22

1

56 Circlip for shaft Φ10

1

57 End cap 45×90×t1.5

4

58 Feet pad Φ49×22×M10×26

4

59 Wheel Φ54.5×23.5

2

60 Allen C.K.S. hollow screw Φ8×33×M6×15

2

61 Hex full thread screw M5×60

1

62 Hex nut M5

2

63 Deep groove ball bearing 6004-2RS

2

19

64 Fixed magnetic induction

1

65 Philips washer head end-cutting self-tapping screw ST4×12

1

66 Crank axle sleeve 1 Φ25×Φ20.1×4.6

1

67 Crank axle sleeve 3 Φ40×Φ20.1×7.7

1

68 Crank axle Φ20×115

1

69 Belt pulley Φ308×22

1

70 Crank axle sleeve 2 Φ25×Φ20.1×10.2

1

71 Fixed magnet set

1

72 Magnetic control fixed axle Φ12×50

1

73 Brake tension spring Φ11.5×Φ1.2×13

1

74 Magnet motor

1

75 Double flywheel Φ280/9KG

1

76 Motor belt 540PJ6

1

77 Brake line

1

78 Rail plastic cap Φ42.5×30

2

79 Handle pulse

2

80 Philips C.K.S. self-tapping screw ST4×20

2

81 Pipe plug Φ28×t1.5

2

82 Foam grip Φ32×t3.0×480

2

83 Circlip for shaft Φ12

2

84 Pedal(L) 406×187×74

1

85 Pedal(R) 406×187×74

1

86 Allen C.K.S. full thread screw M6×12

8

87 Deep groove ball bearing 6003-2RS

4

88 Deep groove ball bearing 6200-2RS

4

89 Foam grip Φ36×t3.0×720

2

90 Pipe plug Φ32×t1.5

2

91 Motor cover(L) 1291.1×72×616.2

1

92 Motor cover(R) 1291.1×75.9×616.2

1

93 Philips C.K.S. Self-tapping screw ST4×25

2

94 Circlip for holes Φ40

2

95 Self-aligning ball bearing 2203-2RS

2

96 Hex full thread screw M8×120

1

97 Power communication wire

1

20

Table of contents

Other Sportig Exercise Bike manuals

Popular Exercise Bike manuals by other brands

Sunny Health & Fitness

Sunny Health & Fitness SF-B121021 user manual

Monark

Monark 827E instruction manual

Stamina

Stamina 1310 owner's manual

American Fitness

American Fitness SPR-BK1072A owner's manual

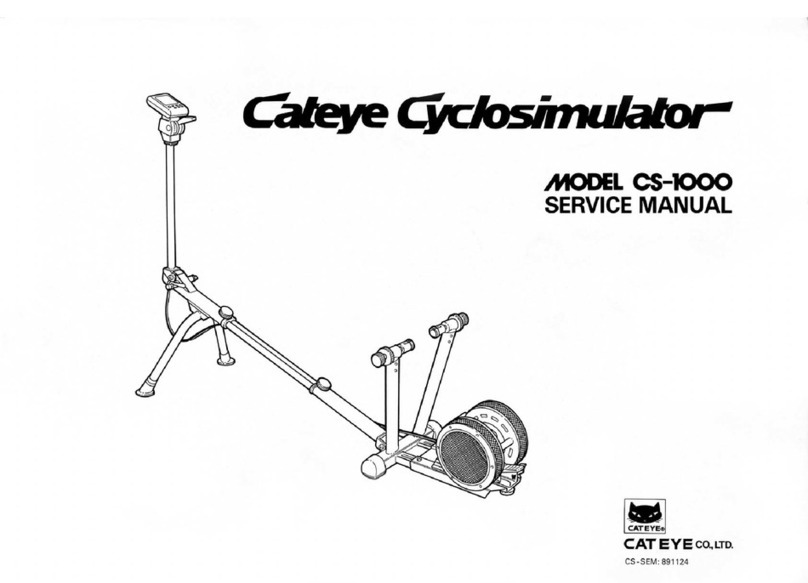

Cateye

Cateye CS-1000 (CYCLO SIMULATOR) Service manual

BH FITNESS

BH FITNESS H9158H Instructions for assembly and use