Spot Welder TSP-1 User manual

Spot Welder

ModelS tSp-1/tSp-2/tbW

Spotwelder

Spot Welder

Spot Welder

MACHINerY

dIVISIoN

Spotwelder

oWNer’S

MANUAl

Owner’s Manual for

TSP1:

SN# 21809 and below

TSP2:

SN# 30897 and below

TBW:

SN# 41001 and below

Approx:

July ‘13 and earlier

INTRODUCTION

ELECTRICAL INSTALLATION

WIRING CONNECTIONS

CONTROL SCREW ADJUSTMENT

ELECTRIC TIMERS

INSTALLATION OF ARMS

TBW HI-LO SWITCH

Duro Dyne Spot Welders have over 50 years of proven

reliability in shop environments. The latest models, TSP/

TBW, incorporate the established durability with a built

in solid state timer for weld accuracy and consistency.

Optional accessories such as water cooled arms and the

ST-2 Spotwelder Stand mean the TSP/TBW Spot Welders

can be customized for your special needs in producing a

top quality product.

To avoid unnecessary problems while using your TSP/TBW

Spot Welder, please read this instruction manual fully and

understand its contents completely.

IMPORTANT: Always follow manufacturer’s recommen-

dations for proper safety and handling procedures for all

materials used in conjunction with this machine as outlined

in Manufacturer’s Safety Data Sheet (MSDS) for each

product.

MODEL TSP-1 - 110V - Fuse for 25 amps

MODEL TSP-2 - 220V - Fuse for 15 amps

MODEL TBW - 220V - Fuse 25 amps

Connect the welder to a lightly loaded circuit supply line.

For best results: Use a separate line as voltage drops can

severely affect the efficiency of your welder.

Welders are normally supplied with a 3 prong polarized plug

to insure that the body of the welder is grounded. This is

a safety precaution which should be taken on all electrical

tools. In the event that you wish to use a plug other than

the one supplied, the following diagram shows the welder

connections:

white

black

connect

to power

green to

ground

The arms of your welder should be inserted as follows:

1. Loosen slightly the 1/4-20 Allen Head Cap Screw on

the side of the “nose piece.” Insert top arm (shorter

arm) all the way in, seat firmly and tighten screw.

2. Loosen slightly the 1/4-20 Allen Head Cap Screw on

the side of "lower arm mounting" (hole in side of front

body allows easy access). Insert lower arm deep

enough so that tips meet exactly when arms are

brought together. Tighten screw.

3. Recheck the alignment and readjust as necessary.

Located on the underside of the welder handle, towards the

back is a small, knurled screw. This screw determines the

point at which the welder is activated after the welding tips

are brought together against the metal. This switch control

screw should be adjusted as follows:

1. Place metal between welding tips. Squeeze handle,

applying moderate pressure to the welding tips.

Current should NOT yet be “ON.”

2. Loosen jam nut. Adjust switch screw up or down, as

the case may be, so that further pressure on the

handle will activate switch and apply current. Tighten

jam nut to lock adjustment.

3. This setting is changed only if the thickness of the

metal being welded is changed greatly, or to compen-

sate for the dressing of the tips.

NOTE: In some cases the range of switch adjustment

may not be sufficient for proper setting. To adjust for new

arms, remove the upper arm, place back end in a vise and

bend slightly in the direction necessary to allow for proper

adjustment.

All TSP and TBW welders are supplied with solid state

timers. The timer allows complete control of the welding

cycle to assure fast and quality welding on even very light

gauge steel. When properly adjusted the timer will eliminate

“burn through.”

The timer is adjustable from 1/10th to one (1) second. To

adjust, simply turn the knob on the back of the welder until

the desired time is set ( counterclockwise to decrease;

clockwise to increase).

When welding extremely light gauge metal the power of the

TBW may be too hot to avoid “burn through.” To “cool down”

the TBW, a Hi-Lo switch was installed. When welding light

gauge steel simply “flip” the Hi-Lo switch to Lo and adjust the

timer as usual. Be sure to change the switch to Hi when going

to heavy gauge or difficulty in welding will be experienced.

OPERATION OF THE WELDER

WELDING GALVANIZED METALS

It is suggested that before using the Spot Welder on regular

work, the operator should try welding pieces of scrap metal

similar to the production material in order to determine the

length of time it takes for proper fusion of the metals. The

heavier the thickness of metals to be welded, the longer the

timer must be on to perform a satisfactory weld.

Since the galvanized coating is a poor conductor of electricity,

it does not weld as readily as uncoated metal. The following

simple procedure is suggested when welding galvanized iron:

1. As soon as current is applied, tilt the work so that the

tips can “bite” into the coating. This will start the weld.

2. Keep handle depressed until weld cycle is complete. In

cases of metal which is rusty or has a heavy scale,

cleaning is recommended before welding.

In all cases, materials being welded should be clamped

together so it will not be necessary for the arms to pull

the material together.

The tips supplied are made of a top grade copper and

will last a long time under normal conditions.

Since the “power” of the welder is reflected in the di-

ameter and cleanliness of the tips, it is recommended

that the tips be kept at a diameter of not greater than

1/8”. For best results, keep them at 3/32”. Tips should

be dressed by using a small mill file regularly. Keep them

clean and to correct diameter.

CARE OF THE TIPS

GENERAL MAINTENANCE

ACCESSSORIES

DURO DYNE WARRANTY

Threaded Cone Tips (MT-3): Type MT-3 tip removal is

simple, however, it is necessary to use the following

procedure in order to break copper oxide scale which

forms in the threads:

Place an open end wrench on the tip and hit the far end

of the wrench with a sharp blow of a hammer. This breaks

the bond, and the tip can easily be removed and replaced.

Taper Fit Tips (MT-1 & MT-2): Tap the part of the arm

in which the tip is inserted, to loosen the tip. It should

then drop out easily.

Other than the proper adjustment and care of the tips,

there is little maintenance of the welder except to:

1. Make sure the line cord is not cut or damaged.

2. Make sure the plug wiring is secure and proper.

3. Remove the arms periodically to clean any scale

with steel wool.

Water Cooled Arms

Most standard arm styles are available with the water-

cooling feature. These arms are especially useful where

the heat generated in the arms is objectionable. Water-

cooled arms allow for most efficient operation and longer

tip life.

Welder Stand

Model ST-2

Part# 9203

Allows all Duro Dyne

Portable Spotwelders to

be converted to stationary

type units.

SPOT WELDER PARTS LIST

Duro Dyne Machinery is manufactured by skilled mechanics,

utilizing the latest production techniques. Each unit has been

rigorously tested prior to packaging and shipment in order to

ensure trouble free operation.

Your Duro Dyne machine has a 90 day warranty against de-

fects in material. Any component found to be defective will

be repaired or replaced (at manufacturer’s discretion) at

no cost, if faulty component is returned freight prepaid to

the nearest Duro Dyne Service Department. Warranty does

not apply to expendable parts or repairs or service due to

improper maintenance or operation procedures.

Duro Dyne products have been engineered to maximize op-

erator safety. Unauthorized modification of this product will

void the warranty.

All warranty claims must be accompanied by serial number,

date of purchase and distributor purchased from.

For Service or Parts:

Welder Service Department

Duro Dyne Corporation

Bay Shore, N.Y. 11706

Phone: 631-249-9000

Fax: 631-249-8346

Give us the details of your problem. The answer is often simple,

and in most cases eliminates unnecessary repairs.

ITEM# DESCRIPTION

9210 TSP/TBW Front Body

9211 TSP Rear Body

9212 TBW Rear Body

9213 TSP/TBW Rear Body Cover

9214 TSP Carriage

9215 TBW Carriage

9216 TSP/TBW Nose Piece

9217 TSP/TBW Lower Arm Mounting

9218 TSP Handle

9219 TBW Handle

9220 TSP/TBW Switch Mounting Bracket

9221 TSP/TBW Handle Spring

9222 TSP/TBW Actuator Spring

9223 TSP Nylon Actuator

9224 TSP/TBW Micro Switch

9225 TSP/TBW Switch Control Screw

9226 TSP Timer 110 Volt

9227 TSP/TBW Potentiometer

9228 TSP-1 Weld Transformer

9229 TBW Weld Transformer

9230 TSP Line Cord 110 Volt

9231 TSP2/TBW Line Cord 220 Volt

9232 TBW Hi/Lo Switch

9233 TSP/TBW Filter Screen

9234 TSP-1 Primary

9235 TBW Primary

9236 TSP Secondary

9237 TBW Secondary

9238 TSP/TBW Pivot Bolt

9239 TSP2/TBW Timer 220 Volt

9240 Line Cord Retainer

9241 TBW Nylon Activator

9242 TSP-2 Weld Transformer

9243 TSP-2 Primary

The welder is operated

by means of a foot le-

ver. The welder may be

installed and removed

with ease.

9219 TBW Handle

9218 TSP Handle

9225 Switch Control Screw

9221 Handle Spring

9223 Nylon Actuator

9241-TBW

9213 Rear Body Cover

9227 Potentiometer

9240 Line Cord Retainer

9226 Timer 110 Volts

9239 Timer 220 Volts

9224 Micro Switch

9211 Rear Body TSP

9212 TBW

9220 Switch Mounting Bracket

Complete Transformer

9228 TSP-1

9242 TSP-2

9229 TBW

9216 Nose Piece

9210 Front Body

Carriage

9214 TSP

9215 TBW

Secondary

9236 TSP

9237 TBW

9217 Lower

Arm Mounting

9238 Pivot Bolt

9232 TBW Switch (Hi-Lo)

Line Cord

9230 TSP-1 110 Volts

9231 TSP-2/TBW 220 Volts

9222 Actuator Spring

9233 Filter Screen

TBW Primary

Shown (4 wires) 9235 TBW

(2 wires) 9234 TSP-1

(2 wires) 9243 TSP-2

17385 Pot Knob

PARTS LOCATION

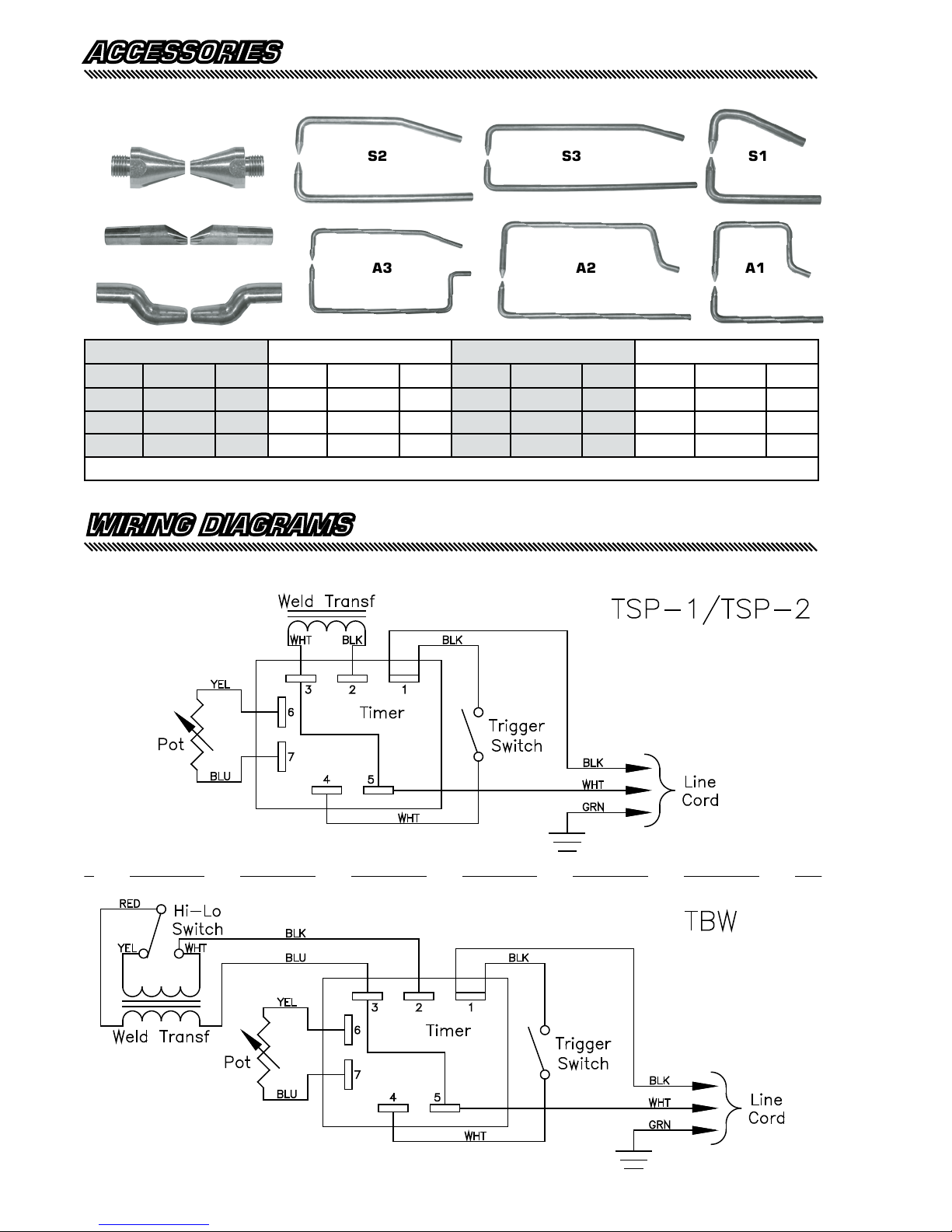

ACCESSORIES

TIPS STANDARD ARMS

MT3

ITEM# 9018

MT1

ITEM# 9019

MT2

ITEM# 9020

S2 S1

A3 A2 A1

S3

STANDARD WATER COOLED STANDARD WATER COOLED

Length Descrip. Item# Length Descrip. Item# Length Descrip. Item# Length Descrip. Item#

6” S-1 9012 6” A-1 9015

12” S-2 9013 12” S-2-W 9022 15” A-2 9016 15” A-2-W 9026

18” S-3 9014 18” S-3-W 9023 18” A-3 9017 18” A-3-W 9027

*NOTE: Dimensions reflect arms in closed position.

WIRING DIAGRAMS

Spotwelder

Spotwelder

®

MACHINERY DIVISION

© 2012 Duro Dyne Corporation

Printed in USA 05/2012

BI009401

®

This manual suits for next models

2

Table of contents