Spotnails SFN19 User manual

Operating Manual

--SFN19 Flooring Coil Nailer--

NOTE: Please read and fully understand the instructions in this

manual before operating the pneumatic power tool. Carefully read

through this OPERATOR'S MANUAL to ensure efficient, safe

operation. It is recommended that the Manual be kept readily

available as an important reference when using this tool.

IMPORTANT INFORMATION

WARNING: The warnings, cautions and instructions discussed in this

instruction manual cannot cover all possible conditions and situations that

may occur. It must be understood by the operator that common sense and

caution are factors which cannot be built into this product but must be

supplied by the operator.

When using the tool, basic safety precautions should always be followed to reduce the risk

of personal injury and damage to equipment.

Read and understand tool labels and operating instructions, safety precautions and

warnings in this manual before operating or maintaining this nailer.

Failure to follow warnings could result in DEATH or SERIOUS INJURY.

Most accidents that result from the operation and maintenance of nailers are caused by the

failure to observe basic safety rules or precautions. An accident can often be avoided by

recognizing a potentially hazardous situation before it occurs and by observing appropriate

safety procedures.

Basic safety precautions are outlined in the "SAFETY" section of this manual and in the

sections, which contain the operation and maintenance instructions. Hazards that must be

avoided to prevent bodily injury or tool damage are identified as DANGERS or WARNINGS

on the nailer and in this manual.

Never allow the nailer to be operated by children or individuals who have not reviewed this

manual.

OPERATE THE NAILER ACCORDING TO THIS MANUAL.

WARNING!

Always follow the tool manufacturer's safety and

maintenance instructions.

Always wear appropriate safety glasses & ear protection

when operating or servicing tools.

Always disconnect the air supply from the tool and empty

the magazine when servicing tools.

SAVE THIS MANUAL

FOR FUTURE REFERENCE!

WARNING:

The operating instructions shall draw attention to the following

a) Only those fasteners listed in the operating instructions may be used in the fastener

driving tools;

NOTE: The fastener driving tool and the fasteners listed in the operating instructions must

be seen as one unit system in terms of technical safety.

b) Only the main energy and the lubricants listed in the operating instructions may be used;

c) Fastener driving tools marked with an inverted equilateral triangle standing on one point

may only be used with an effective safety yoke;

d) Fastener driving tools equipped with contact actuation or continuous contact actuation,

marked with the symbol “Do not use on scaffoldings, ladders”, shall not be used for specific

application for example:

when changing one driving location to another involves the use of scaffoldings, stairs,

ladders, or ladder alike constructions, e.g. roof laths, closing boxes or crates, fitting

transportation safety systems e.g. on vehicles and wagons;

e) For the maintenance of fastener driving tools, only spare parts specified by the

manufacturer or his authorized representative shall be used;

f) Repairs shall be carried out only by agents authorized by the manufacturer or by other

specialists, having due regard to the information given in the operating instructions;

NOTE: Specialists are those who, as a result of professional training or experience, have

sufficient expertise in the field of fastener driving tools and sufficient familiarity with relevant

governmental industrial protection provisions, accident prevention regulations, directives

and generally recognized technical regulations (e.g. CEN- and CENELEC-standards), to be

able to assess the safe working condition of fastener driving tools.

g) Stands for mounting the fastener driving tools to a support for example a work table,

shall be designed and constructed by the stand manufacturer, in such a way that the

fastener driving tool can be safely fixed for the intended use, thus for example avoiding

damage, distortion or displacement.

Additional instructions for fastener driving tools operated by compressed air

a) Fastener driving tools operated by compressed air shall only be connected to

compressed air lines where the maximum allowable pressure cannot be exceeded by a

factor of more than 10%, which can for example be achieved by a pressure reduction valve

which includes a downstream safety valve;

b) When using fastener driving tools operated by compressed air, particular attention must

be paid to avoid exceeding the maximum allowable pressure;

c) Fastener driving tools operated by compressed air should only be operated at the lowest

pressure required for the work process at hand, in order to prevent unnecessarily high

noise levels, increased wear and resulting failures;

d) Hazards caused by fire and explosion when using oxygen or combustible gases for

operating compressed air operated fastener driving tools.

SAFETY INFORMATION

WARNING:

BEFORE USING THE TOOL, READ CAREFULLY AND UNDERSTAND THE

FOLLOWING SAFETY INSTRUCTIONS.FAILURE TO FOLLOW WARNING

COULD RESULT IN DEATH OR SERIOUS INJURY.

1. WEAR SAFETY GLASSES OR GOGGLES.

Danger to the eyes always exists due to the possibility of dust being blown up by

the exhausted air or of a fastener flying up due to the improper handling of the

tool. For these reasons, safety glasses or goggles shall always be worn when

operating the tool. The employer and/or user must ensure that proper eye protection is

worn. The employer is responsible to enforce the use of eye protection equipment by the

tool operator and all other personnel in the work area. NOTE: Non-side shielded spectacles

and face shields alone do not provide adequate protection.

2. EAR PROTECTION MAY BE REQUIRED IN SOME ENVIRONMENTS.

As the working condition may include exposure to high noise levels which can

lead to hearing damage, the employer and user should ensure that any

necessary hearing protection is provided and used by the operator and others in

the work area.

3. DO NOT USE ANY POWER SOURCE EXCEPT AN AIR COMPRESSOR.

The tool is designed to operate on compressed air. Do not operate the tool on

any other high pressure gas, combustible gases (e.g. Oxygen, acetylene, etc.)

since there is the danger of an explosion. For this reason, do notuse anything

other than compressed air.

4. OPERATE WITHIN THE PROPER AIR PRESSURE RANGE.

The tool is designed to operate within an air pressure range of 70 psi

to100 psi (5 to 7 bar). The pressure should be adjusted to the type of

the work being fastened. The tool shall never be operated when the

operating pressure exceeds 120 psi. (8.3 bar).

5. DO NOT OPERATE THE TOOL NEAR A FLAMMABLE SUBSTANCE.

Never operate the tool near a flammable substance (e.g., thinner, gasoline,

etc.). Volatile fumes from these substances could be drawn into the

compressor and compressed together with the air and this could result in an

explosion.

6. DO NOT USE THE WRONG FITTINGS.

The connector on the tool must not hold pressure when air supply is disconnected. If a

wrong fitting is used, the tool can remain charged with air after disconnecting and thus will

be able to drive a fastener even after the line of air is disconnected, possibly causing injury.

7. DISCONNECT THE AIR SUPPLY AND EMPTY THE MAGAZINE WHEN THE TOOL IS

NOT IN USE.

Always disconnect the air supply from the tool and empty the magazine when operation has

been completed or suspended, when unattended, moving to a different work area,

adjusting, disassembling, or repairing the tool, and when clearing a jammed fastener.

8. INSPECT SCREW TIGHTNESS.

Loose or improperly installed screws or bolts cause accidents and tool damage when the

tool is put into operation. Inspect to confirm that all screws and bolts are tight and properly

installed prior to operating the tool.

9. DO NOT TOUCH THE TRIGGER UNLESS YOUR INTEND TO DRIVER A FASTENER.

Whenever the air supply is connected to the tool, never touch the trigger unless you intend

to drive a fastener into the work. It is dangerous to walk around carrying the tool with the

trigger pulled, and this and similar actions should be avoided.

10. NEVER POINT THE DISCHARGE OUTLET TOWARD YOURSELF AND

PERSONNEL.

If the discharge outlet is pointed toward people, serious accidents may be caused when

misfiring. Be sure the discharge outlet is not pointed toward people when connecting and

disconnecting the hose. Loading and not loading the fasteners or similar operations.

11. USE SPECIFIED FASTENERS.

The use of fasteners other than specified fasteners will cause the tool malfunction. Be sure

to use only specified fasteners when operating the tool.

12. PLACE THE DISCHARGE OUTLET TO THE WORK PROPERLY.

Failure to place the discharge outlet of the nose in a proper manner can result in a fastener

flying up and is extremely dangerous.

13. KEEP HANDS AND BODY AWAY FROM THE DISCHARGE OUTLET

When loading and using the tool, never place a hand or any part of body in fastener

discharge area of the tool. It is very dangerous to hit the hands or body by mistake.

14. DO NOT DRIVE FASTENERS CLOSE TO THE EDGE AND CORNER OF THE WORK

AND THIN MATERIAL

The work piece is likely to split and the fastener could fly and hit someone.

15. DO NOT DRIVE FASTENERS ON THE TOP OF OTHER FASTENERS.

Driving fasteners of the top of other fasteners may cause deflection fasteners which could

cause injury.

16. REMOVING THE FASTENERS AFTER COMPLETING OPERATION

If fasteners are left in the magazine after the completion of operation, there is the danger of

a serious accident occurring prior to the resumption of operation, should the tool be handled

carelessly, or when connecting the air removes all fitting. For this reason, always move the

fasteners away which remaining in the magazine after completion of the operation.

17. CHECK OPERATION OF THE CONTACT TRIP MECHANISM FREQUENTLY IN

CASE OF USING A CONTACT TRIP TYPE TOOL

Do not use the tool if the trip is not working correctly as accidental driving of a fastener may

result. Do not interfere with the proper operation of the contact trip mechanism.

18. WHEN USING THE TOOL OUTSIDE OR ELEVATED PLACE.

When fastening roofs or similar slanted surface, start fastening at the lower part and

gradually work your way up. Fastening backward is dangerous as you may lose your foot

place. Secure the hose at a point close to the area you are going to driver fasteners.

Accidents may be caused due to the hose being pulled inadvertently or getting caught.

19. NEVER USE THE TOOL IF ANY PORTION OF THE TOOL CONTROLS (e.g.,

TRIGGER, CONTACT ARM) IS INOPERABLE DISCONNECTED, ALTERED OR NOT

WORKING PROPERLY.

20. NEVER ACTUATE THE TOOL INTO FREE SPACE.

This will avoid any hazard caused by free flying fasteners and excessive strain on the tool.

21. ALWAYS ASSUME THAT THE TOOL CONTAINS FASTENERS.

22. DO NOT USE ON SCAFFOLDING LADDERS.

The tool shall not be used for specific application for example:

•When changing one driving location to another involves the use of

scaffoldings, stairs, ladders, or

•Ladder alike constructions, e.g. roof laths,

•Closing boxes or crates,

•Fitting transportation safety systems e.g. on vehicles and wagons.

TECHNICAL DATA

Type of tool

SFN19 Construction Coil Nailer

Dimensions

11-1/8”X4-1/4”X10-1/8”

248mmX108mmX260mm

Weight (without fasteners)

1.60kgs (3.50lbs.)

Actuation mode

Contact/Single-sequential actuation

Magazine capacity

200 nails (plastic sheet collated nails)

Maximum allowable pressure

120psi (8.3bar)

Recommended pressure range

70psi to 100psi (5bar to 7bar)

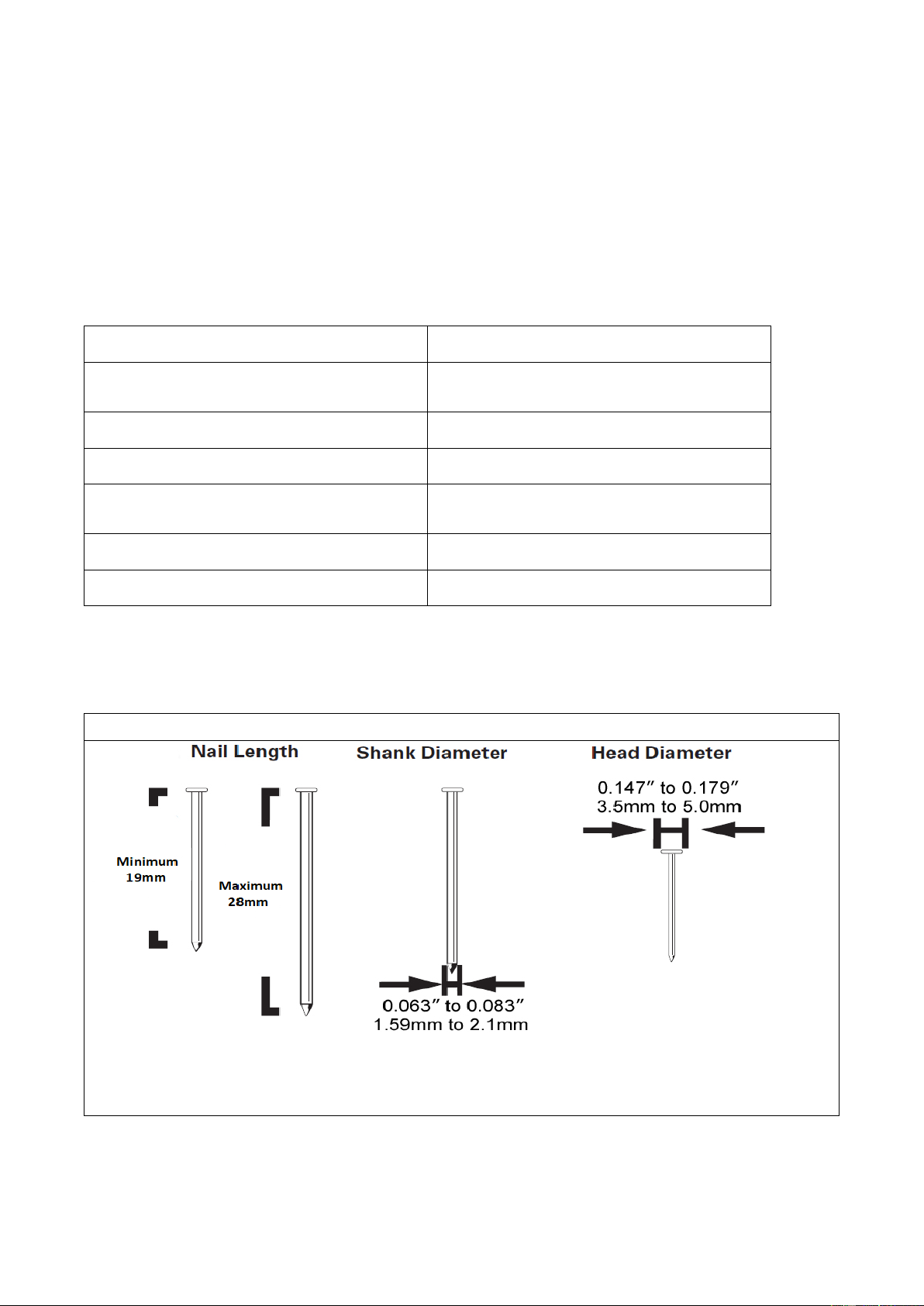

Fasteners

Only the nail sizes shown in the table below can be driven with this nailer.

15°Flat plastic sheet collated nails

NAILER CONNECTION AND OPERATION

NOTE: The information contained in this manual is designed to assist you in the safe

operation of the nailer. Some illustrations in this Manual may show details or attachments

that are different from those on your nailer.

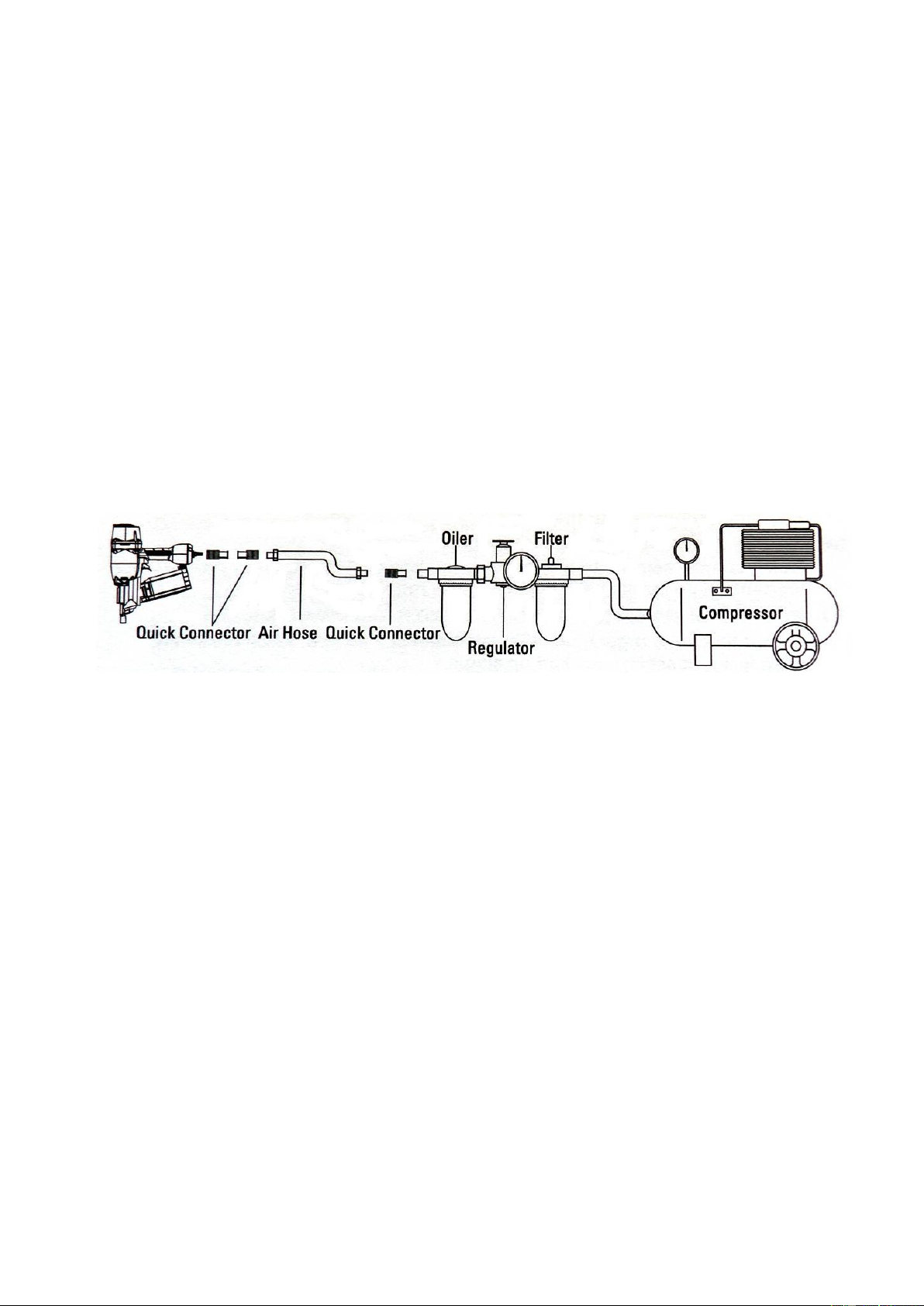

Air Supply, Connections and Operating Pressure

Read section titled SAFETY. Make sure of the following before operation: Air Supply

Power Source (Compressor)

•Use only clean, dry, regulated compressed air as a power source.

•NEVER use oxygen or other bottled gases, as an explosion may occur.

•Use suitable air compressors used to supply compressed air to this tool.

•Moisture or oil in the air compressor may accelerate wear and corrosion in the

tools.

•Drain daily.

Connections

1. Fittings

Install a female coupling to the hose. The female coupling will connect to the quick release

that fits the tool.

2. Filter-Regulator-Lubricator

•NEVER connect the tool to pressure which potentially exceeds 120psi.

•Filter-regulator-lubricator units supply an optimum condition for the tool and extend

the tool life. These units should always be used.

Filter

•The filter removes moisture and dirt from compressed air.

•Keep the filter clean by maintaining regularly.

•Drain daily.

Regulator

•The regulator controls the operating pressure for safe operation of the tool.

•Inspect the regulator before operation to be sure it operates properly.

Tool Connection and Operation

Lubricator

•The lubricator supplies an oil mist to the tool.

•Inspect the lubricator before operation to be sure the supply of lubricant is adequate.

•If an inline lubricator is not used, a few drops of pneumatic oil will need to be added

to the tool inlet before each use.

3. Air Hose

Air hose must have a minimum working pressure rating of 180 psi.

Hose has a min. ID of 1/4"(ISO 7-1)

The supply hose should contain a fitting that will provide "quick disconnecting" from the

male plug on the tool.

Operating Pressure

•Recommended operating pressure range is 70 to 100 psi.

•Maximum permissible operating pressure is 120 psi.

•Select the operating pressure within this range for the best fastener performance.

The nail length and thickness and the hardness of the wood are factors in

determining what the pressure should be set at.

•Do not exceed this recommended operating pressure.

NOTE: Dirt and water in the air supply are major causes of wear in the tool.

An air filter will help to get the best performance and minimum wear from the tool. Frequent,

but not excessive, lubrication is required for the best performance. Pneumatic oil added

through the air line connection will lubricate the internal parts.

WARNING

NEVER connect nailer to pressure which potentially exceed

120psi.

DO NOT USE THE WRONG FITTING ON NAILER.

The nailer and air hose must have a hose coupling so that all

pressure is removed from the nailer when the coupling is

disconnected. The connector on the tool must not hold pressure

when the air supply is disconnected. If the wrong fitting is used,

the tool can remain charged with air after disconnecting and thus

will be able to drive a nail even after the air line is disconnected,

possibly causing injury.

DANGER

NEVER use oxygen or other bottled gases, as an

explosion may occur.

INSTRUCTION FOR OPERATION

1. Before operation

(1) Wear safety glasses & ear protection

(2) Do not connect the air supply

(3) Inspect screw tightness

(4) Check operation of the contact arm & trigger are moving smoothly

(5) Connect the air supply

(6) Check for air-leakage. (tool must have no air leaks.)

(7) Hold the tool with finger-off the trigger, then push the contact arm against the work-

surface. (the tool must not operate.)

(8) Hold the tool with contact arm free from work-piece and pull the trigger. (the tool must

not operate.)

2. Operation

Keep hands and body away from the nose piece when driving the fasteners to avoid injury.

Nail loading

(1) Disconnect the airline.

(2) Press LATCH (394539) to open DOOR (394571), then open MAGAZINE COVER

(394589).

(3) Adjust the height of NAIL SUPPORT (394592) according to nail length.

(4) Insert ALUMINUM DISC on top of nail support before loading 19mm nails.

(5) Place the first nail in the groove on FEED PAWL (394566).

(6) Close MAGAZINE COVER (394589), close DOOR (394571).

(7) Re-connect to airline.

Test operation

(1) Adjust the air pressure at 80psi. (5.5 bar) and connect the air supply.

(2) Without touching the trigger, depress the contact arm against the work-surface. Pull the

trigger. (the tool should fire the fastener.)

(3) With the tool off the work-surface, pull the trigger. Then depress the contact arm against

the work-surface. (the tool should fire the fastener.)

(4) Adjust the air pressure to the lowest possible setting according to the diameter and

length of fastener, also the hardness of work-surface.

MAINTENANCE AND INSPECTION

Read the section title SAFETY.

SERVICE AND REPAIRS

All quality tools will eventually require servicing or replacement of parts due to wear from

normal use. It is recommended that these operations should be performed by a

professional technician.

NOTE: The information contained in this Manual is designed to assist you in the safe

maintenance of the tool. Some illustrations in this Manual may show details or attachments

that are different from those on your nailer.

WARNING: Disconnect air hose and remove nails from nailer when:

•Carrying out maintenance and inspection

•Clearing a jam

Inspecting the magazine

1. DISCONNECT AIR HOSE.

2. Clean the magazine. Remove dust which may have accumulated in the magazine.

Clearing a jam

Remove a jammed nail in the following order:

1. DISCONNECT AIR HOSE.

2. Remove all nails.

3. Remove the jammed nail with a slotted head screwdriver or pin punch.

4. In case of frequent jams, contact a Spotnails stockist.

A qualified person should perform repair and maintenance

Periodic maintenance to be performed:

•Check that the piston bumper is operating normally. A damaged piston bumper may

cause damage to other components.

•Check o-rings for wear or damage. Damaged o-rings may affect overall

performance.

•Make sure all screws are secure. Loose screws may affect overall performance.

•When repairing a tool, make sure the internal parts are clean and lubricated.

Storing

•When not in use for an extended period, apply a thin coat of the lubricant to the steel

parts to avoid rust.

•The nailer should be stored in a warm and dry place when not in use. Do not store

the nailer in a cold weather environment.

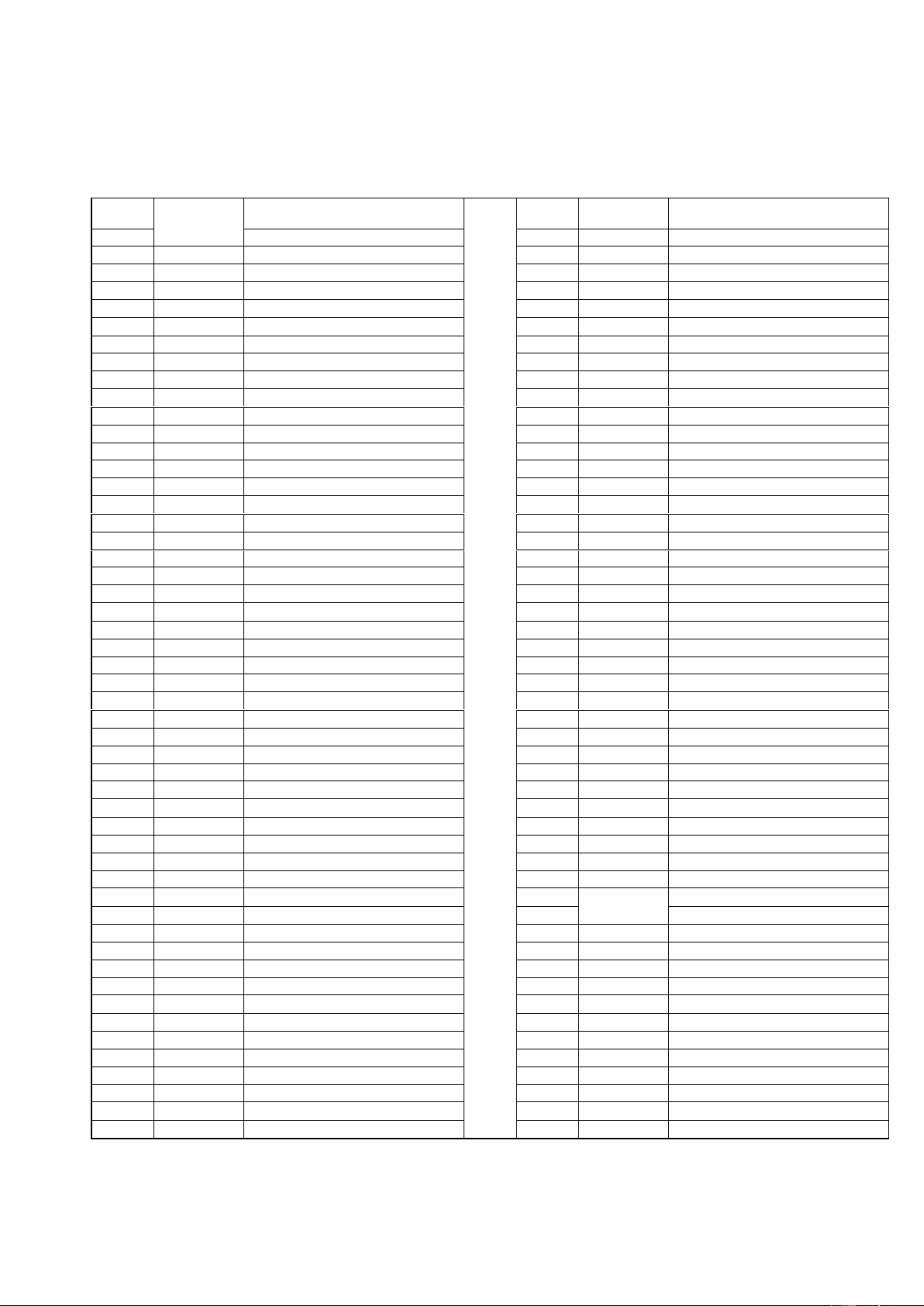

PARTS LIST-SFN19

NO.

CODE

Description

NO.

CODE

Description

1

394501

BOLT M6X20 (Loctite)

55

394555

TRIGGER STEM

2

394502

BUSHING

56

394556

O-RING 2.5X1.4

3

394503

EXHAUST COVER

57

394557

TRIGGER VALVE SPRING

4

394504

EXHAUST FILTER (A)

58

394558

O-RING 8.6X1.9

5

394505

EXHAUST FILTER (B)

59

394559

TRIGGER VALVE BUSHING

6

394506

BOLT M5X25

60

394560

O-RING 5.8X1.9

7

394507

CYLINDER CAP

61

394561

PIN CAP (B)

8

394508

GASKET

62

394562

STEP PIN

9

394509

BACK BUMPER

63

394563

FEED SPRING

10

394510

EXHAUST SEAL

64

394564

CHECK TOE

11

394511

COMPRESSION SPRING

65

394565

PIN CAP (A)

12

394512

HEAD VALVE PISTON

66

394566

FEED PAWL

13

394513

O-RING 40X2.65

67

394567

SPRING

14

394514

BUMPER

68

394568

FEED PAWL PIN

15

394515

O-RING 51.5X2.65

69

394569

DOOR PIN

16

394516

CYLINDER RING

70

394570

NOSE

17

394517

O-RING 38.7X3.55

71

394571

DOOR

18

394518

CYLINDER

72

394572

CHECK PAWL PIN

19

394519

O-RING 38.7X2.65

73

394573

CHECK PAWL

20

394520

CYLINDER COLLAR

74

394574

CHECK PAWL SPRING

21

394521

BODY

75

394575

GUARD COVER

22

394522

HANDLE GRIP

76

394576

ROLL PIN 3X20

23

394523

DOWEL PN

77

394577

LATCH

24

394524

TRIGGER BRACKET

78

394578

LATCH SPRING

25

394525

SPRING

79

394579

O-RING 9X1.8

26

394526

ADJUSTER BUTTON

80

394580

FEED PISTON

27

394527

CONTACT PLATE

81

394581

O-RING 17X2.65

28

394528

TRIGGER

82

394582

FEED PISTON SPRING

29

394529

ROLL PIN 3X30

83

394583

FEED PISTON BUMPER

30

394530

PIN CAP

84

394584

FEED PISTON CAP

31

394531

STEP PIN

85

394585

SNAP RING

32

394532

O-RING 3.55X1.8

86

394586

END CAP SEAL

33

394533

BOLT M6X22 (Loctite)

87

394587

END CAP

34

394534

SAFETY UPPER

88

394588

BOLT M5X22

35

394535

SPRING

89

394589

MAGAZINE COVER

36

394536

SAFETY UPPER GUIDE

90

394590

SPRING HOLDER (A)

38

394538

ADJUSTER DIAL

91

394591

MAGAZINE SPRING

39

394539

SAFETY GUIDE

92

394592

NAIL SUPPORT PLATE

40

394540

ADJUSTER

93

394593

SPRING HOLDER (B)

41

394541

O-RING 5.15X1.8

94

394594

MAGAZINE

42

394542

SNAP RING 4

95

394595

BOLT M5X35

44

394543

SAFETY

96

394596

NUT M5 (Nylock)

46

394546

DIRVER BLADE

97

394597

MAGAZINE PIN

47

394547

PISTON

98

394598

NOSE CAP

48

394548

O-RING 30X3.55

100

3945100

O-RING 10X1.8

49

394549

SPRING

101

3945101

O-RING 6.3X1.8

50

394550

STRAIGHT PIN B3X15

102

51

394551

TRIGGER VALVE CAGE

103

52

394552

O-RING 18.3X2.65

104

3945104

PIN CAP C

53

394553

O-RING 11.8X2.65

P1

3945P1

DRIVER UNIT

54

394554

TRIGGER VALVE CAP

P2

3945P2

TRIGGER VALVE

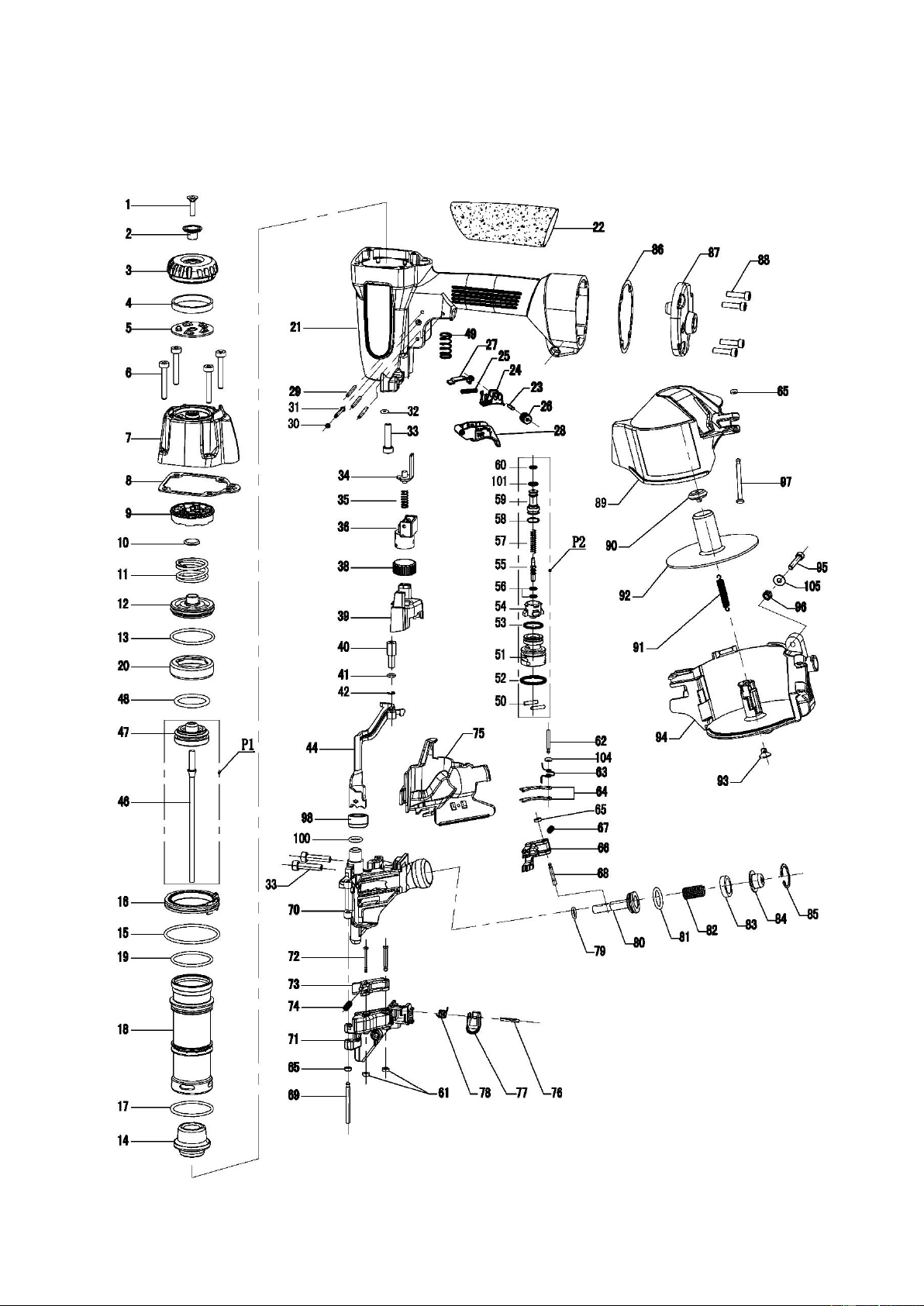

TOOL SCHEMATIC-SFN19

Table of contents

Other Spotnails Nail Gun manuals

Popular Nail Gun manuals by other brands

Paslode

Paslode CNW 70.2 operating instructions

Campbell Hausfeld

Campbell Hausfeld NB006750 operating instructions

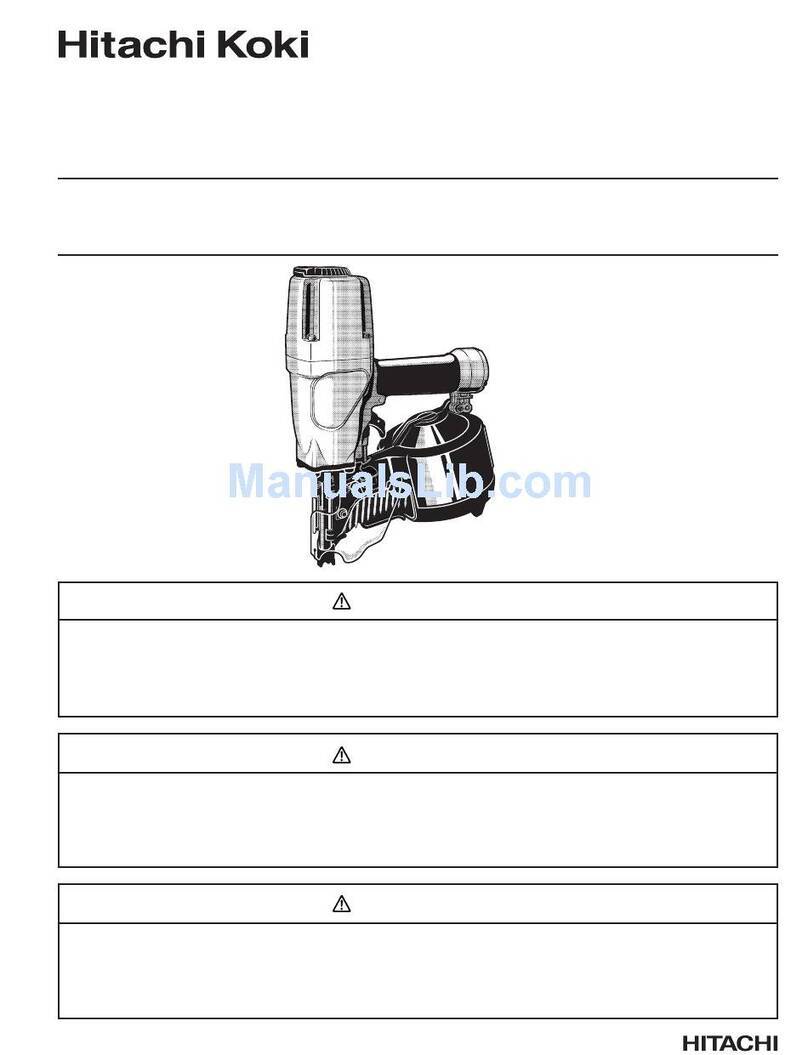

Hitachi Koki

Hitachi Koki NV75AG - 3" Utility Coil Nailer Instruction and safety manual

KMR

KMR 3522 Technical data spare parts

JETYD

JETYD j-Gun series Operation manual

Metabo HPT

Metabo HPT NP 50A Instruction and safety manual