Spotnails DSP103020 User manual

DSP103020

AIR DRIVE PLIER

OPERATION and MAINTENANCE MANUAL

WARNING

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS

MANUAL, TO UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND

INSTRUCTIONS. EEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE

REFERENCE. IF YOU HAVE ANY QUESTIONS, CONTACT YOUR DISTRIBUTOR.

2

INTRODUCTION

The SP50 is a precision-built tool; designed for high speed, high volume stapling. These tools

will deliver efficient, dependable service when used correctly and with care. As with any fine

power tool, for best performance the manufacturer’s instructions must be followed. Please

study this manual before operating the tool and understand the safety warnings and cautions.

The instructions on installation, operation and maintenance should be read carefully, and the

manual kept for reference. NOTE: Additional safety measures may be required because of your

particular application of the tool. Contact your distributor with any questions concerning the

tool and its use.

INDEX

Safety Instructions ..............................................................................................................2

Air Supply and Connections ..............................................................................................2

Loading Tool ........................................................................................................................3

Operation..............................................................................................................................3

Maintaining the Tool............................................................................................................3

Loading the SP50 Series Stapling Plier.............................................................................5

Replace Driver Piston or Driver .........................................................................................8

Replace Anvil .......................................................................................................................9

Replace Driver Guide ..........................................................................................................10

Replace Pusher or Spring...................................................................................................11

Parts List ..............................................................................................................................12

Exploded View of Tool.........................................................................................................13

SAFETY INSTRUCTIONS

WARNING EYE PROTETION which conforms to ANSI specifications and provides

protection against flying particles both from the FRONT and SIDE should

ALWAYS be worn by the operator and others in the work area when loading,

operating or servicing this tool. Eye protection is required to guard against

flying fasteners and debris, which could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye

protection equipment must conform to the requirements of the American

National Standards Institute, ANSI Z87.1-1989 and provide both frontal and side

protection. NOTE: Non-side shielded spectacles and face shields alone do not

provide adequate protection.

WARNING CAUTION: ADDITIONAL SAFETY PROTECTION will be required in some

environments. For example, the working area may include exposure to noise

level which can lead to hearing damage. The employer and user must ensure

that any necessary hearing protection is provided and used by the operator and

others in the work area. Some environments will require the use of head

protection equipment. When required, the employer and user must ensure that

head protection conforming to ANSI Z89.1 1986 is used.

AIR SUPPLY AND CONNECTIONS

WARNING Do not used oxygen, combustible gases, or bottle gases as a power source for

this tool as tool may explode, possibly causing injury.

WARNING Do not use supply sources which can potentially exceed 200 P.S.I.G as tool may

burst possibly causing injury.

WARNING The connector on the tool must not hold pressure when air supply is

disconnected. If a wrong fitting is used, the tool can remain charge with air after

disconnecting and thus will be able to drive a fastener even after the air line is

disconnected possibly causing injury.

3

WARNING Do not pull trigger or depress contact arm while connected to the air supply as

the tool may cycle, possibly causing injury.

WARNING Always disconnect air supply:

1.) Before making adjustments;

2.) When servicing the tool;

3.) When Clearing a jam;

4.) When tool is not in use;

5.) When moving to a different work area, as accidental actuation may occur,

possibly causing injury.

LOADING TOOL

WARNING When loading tool; 1.) Never place a hand or any part of body in fastener

discharge area of tool; 2.) Never point tool at anyone; 3.) Do not pull the trigger

or depress the trip as accidental actuation may occur, possibly causing injury.

OPERATION

WARNING Always handle the tool with care; 1.) Never engage in horseplay; 2.) Never pull

the trigger unless nose is directed toward the work; 3.) Keep others a safe

distance from the tool while tool is in operation as accidental actuation may

occur, possibly causing injury.

WARNING The operator must not hold the trigger pulled on contact arm tools except during

fastening operation as serious injury could result if the trip accidentally

contacted someone or something, causing the tool to cycle.

WARNING Keep hands and body away from the discharge area of the tool. A contact arm

tool may bounce from the recoil of driving a fastener and an unwanted second

fastener may be driven possibly causing injury.

WARNING Check operation of the contact arm mechanism frequently. Do not use the tool if

the arm is not working correctly as accidental driving of a fastener may result.

Do not interfere with the proper operation of the contact arm mechanism.

WARNING Do not drive fasteners on top of other fasteners or with the tool at an overly

steep angle as this may cause deflection of fasteners which could cause injury.

MAINTAINING THE TOOL

WARNING When working on air tools note the warnings in this manual and use extra care

when evaluating problem tools.

OPERATING PRESSURE

WARNING

The operating pressure of the SP50 series plier is To prevent accidental

36 to 55 p.s.i (3.9kg/cm²). Tool wear will be greatly firing, disconnection air

increased if excessive pressure is used. supply:

炽before making

adjustments

炽when servicing the tool

炽when clearing jams

炽when tool is not in use

4

SETTING THE CORRECT PRESSURE

WARNING

The air equipments will vary, depending on the Do not use oxygen or

material to be stapled and the staple size. Do not combustible gases as a

use more air pressure than is required to drive the power sources which can

staple in the specific job. To determine best setting, potentially exceed 200

start at low pressure and increase pressure until drive P.S.I as tool may explode.

is satisfactory. Using excess pressure increases tool

wear on the plier and wastes compressed air.

WARNING

QUICK DISCONNECT FITTINGS

NOTE:The air supply

Install a free –flow connector plug on the nailer. system must be capable

Thread is 1/4” N.P.T. of maintaining the

Install a connector socket on the air hose. For required air pressure at

best performance, fitting should have minimum the tool when it is

inside dia. of .190”(4.8mm). operated at its highest

cycle speed. Inadequate

air supply will result in a

loss of power and

inconsistent driving after

the first cycle when the

tool is operated in high

speed bursts.

Always attach a

free-flow-connector plug to the

plier. If a wrong fitting is used,

the tool can remain charged

with air after disconnecting,

and thus will be able to cycle

even after the air line is

unplugged.

REGULATORS

Most air supply equipment will produce pressures NOTE: Air compressors used

that exceed the SP50’s maximum operating pressure, to supply compressed air to

55 p.s.i (3.9kg/cm²). A pressure regulator is required this plier should comply with

to control the operating pressure. The flow capacity the requirements of the

must be sufficient for the air usage at the installation. American National Standards

Institute Standard B19.3-1972,

Safety Standard for

HOSES

Compressors for Process

Air supply equipment should have a 85 p.s.i. Industries.

(6.0 kg/cm²) working pressure rating (or 150 percent

of the maximum pressure that could be produced in NOTE: Make sure air lines

the air system.) and fittings are clean before

connecting.

AIR CONSUMPTION

The SP50 requires 1.75 cubic feet per minute of free air to operate at the rate of 100 staples

per minute, at 55 p.s.i.

Take the actual rate at which the plier will be run to determine the amount of air required.

For instance, if your staple usage averages 50 staples per minute, you need 50% of the

7.75c.f.m. which is required for running at 100 staples per minute.

5

LOADING THE SP50 SERIES STAPLING PLIER

WARNING EYE PROTECTION which conforms to ANSI specifications and provides

protection against flying particles both from the FRONT and SIDE should

ALWAYS be worn by the operator and others in the work area when loading,

operating or servicing this tool. Eye protection is Required to guard against

flying fasteners and debris, which could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye

protection equipment must conform to the requirements of the American

National Standards Institute, ANSI Z87.1-1989 and provide both frontal and side

protection.

NOTE: Non-side shielded spectacles and face shields alone do not provide

adequate protection.

WARNING TO PREVENT ACCIDENTAL INJURIES:

炽Never place a hand or any other part of the body in nail discharge area of tool

while the air supply is connected.

炽Never point the tool at anyone else.

炽Never engage in horseplay.

炽Never pull the trigger unless nose is directly towards the work.

炽Always handle the tool with care.

炽Do not pull the trigger or depress the trip mechanism while loading the tool.

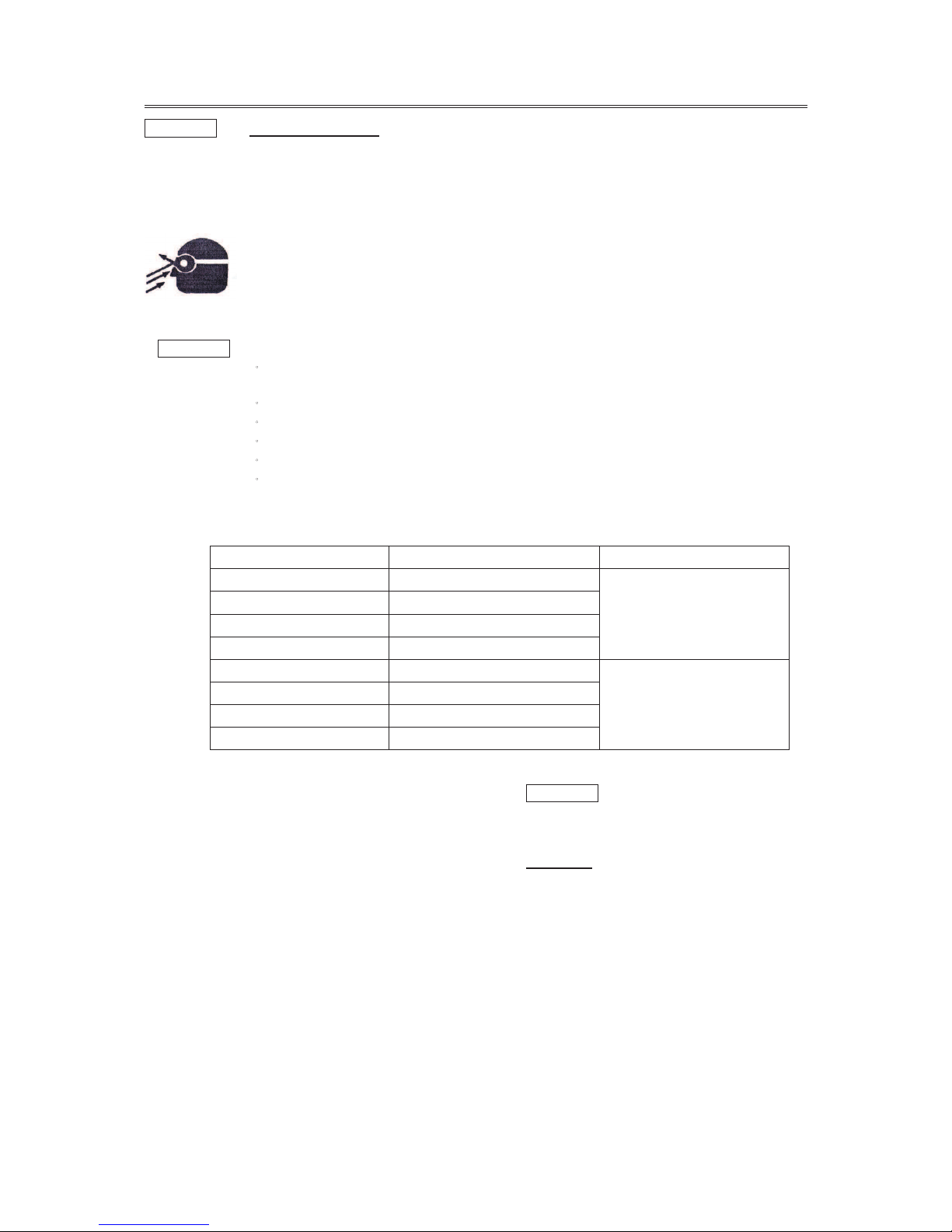

MODEL SP-50 SERIES AIR DRIVE PLIERS

MODEL ANVIL STAPLES

SP-50-10B-A ANVIL A SB103020

3/8” (9.5mm)

1/2”(12.7mm)

5/8”(15.8mm)

SP-50-10B-B ANVIL B

SP-50-10B-CL ANVIL CL

SP-50-10B-CR ANVIL CR

SP-50-5B-A ANVIL A SB5019

1/4” (6.3mm)

3/8” (9.5mm)

1/2” (12.7mm)

5/8” (15.8mm)

SP-50-5B-B ANVIL B

SP-50-5B-CL ANVIL CL

SP-50-5B-CR ANVIL CR

1)Open the Magazine: WARNING

Pull cover back until locked by detent pin. Disconnect the air supply before

making adjustments.

2)Load Staples:

Insert a stick of staple and push forward in CAUTION: Do not attempt to operate

the channel. this plier without material between the

Insert a second stick of staples. shuttle and clincher to avoid damaging

the driver tip.

3)Close magazine:

Push the lock release tab(located at front of

magazine cover) down and push the cover

forward until its locked by the detent pin.

FILTERS

Dirt and water in the air supply is a major cause of wear in air tools. A filter will help to get

best performance from this plier. The filter must have adequate flow capacity for the specific

installation. The filter has to be kept clean to be effective in cleaning the air. Consult the

filter manufacturer’s instructions on proper maintenance. Clean and empty the filter as

needed. A dirty and clogged filter will also cause a pressure drop, which can reduce the

pliers performance.

Table of contents

Other Spotnails Nail Gun manuals

Popular Nail Gun manuals by other brands

Metabo HPT

Metabo HPT NR 3675DD Instruction and safety manual

EXTOL PREMIUM

EXTOL PREMIUM 8894580 Translation of the original user manual

DeWalt

DeWalt XR Li-Ion DCN680D2 Original instructions

Performance Tool

Performance Tool M643 owner's manual

Hitachi

Hitachi VH650 - Fencing Nailer, Full Head instruction manual

Parkside

Parkside PET 25 B1 Operation and safety notes