Spring Well SPRW-UV4-2 User manual

Operaon & Installaon Instrucons

UV4

Series

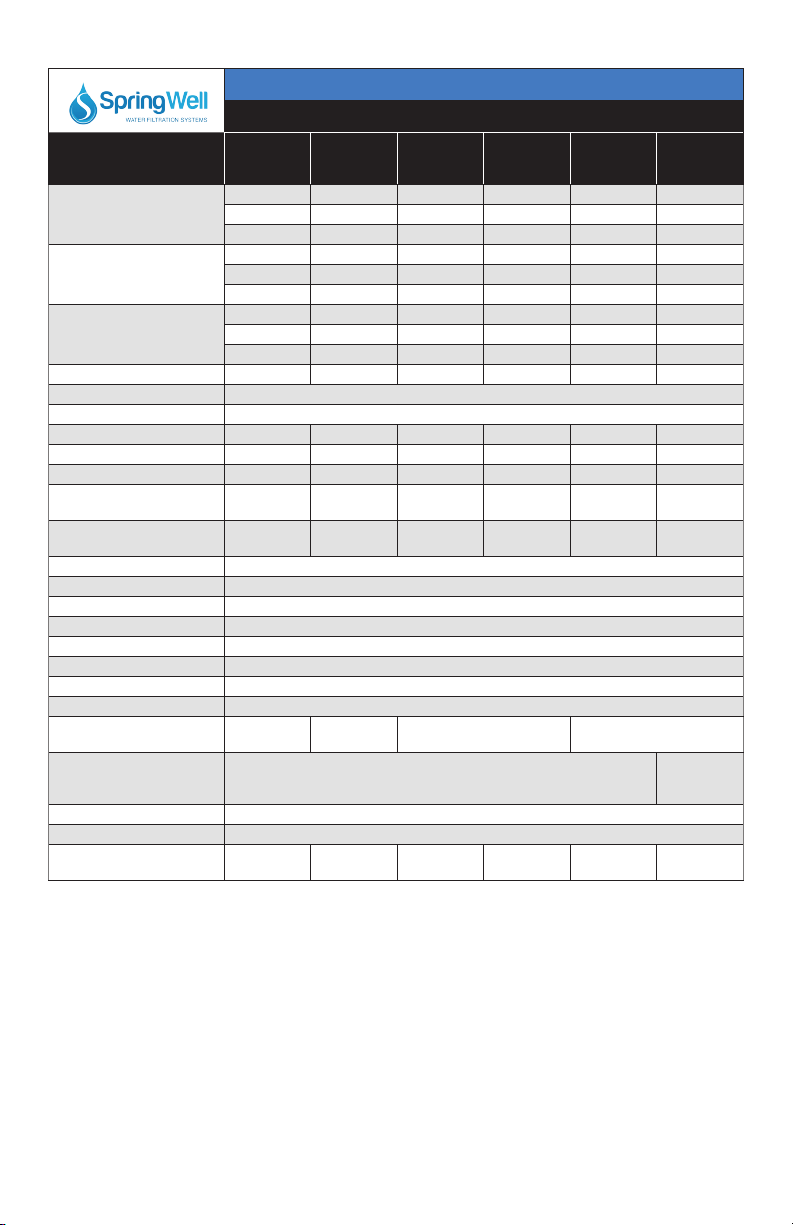

SpringWell - Standard Systems

System Rated Flow System Rated Flow

SPRW-UV4-2

SPRW-UV5-2

SPRW-UV6-2

2 gpm

SPRW-UV4-5C

SPRW-UV5-5C

SPRW-UV6-5C

5 gpm

SPRW-UV4-3

SPRW-UV5-3

SPRW-UV6-3

3 gpm

SPRW-UV4-10C

SPRW-UV5-10C

SPRW-UV6-10C

10 gpm

SPRW-UV4-6

SPRW-UV5-6

SPRW-UV6-6

6 gpm

SPRW-UV4-15C

SPRW-UV5-15C

SPRW-UV6-15C

15 gpm

SPRW-UV4-11

SPRW-UV5-11

SPRW-UV6-11

11 gpm

SPRW-UV4-25C

SPRW-UV5-25C

SPRW-UV6-25C

25 gpm

SPRW-UV4-15

SPRW-UV5-15

SPRW-UV6-15

15 gpm

SPRW-UV4-40C

SPRW-UV5-40C

SPRW-UV6-40C

40 gpm

SPRW-UV4-21

SPRW-UV5-21

SPRW-UV6-21

21 gpm

UV5/6

Series

UV4-C

Series

UV5/6-C

Series

2|Page

Congratulaons on purchasing this

ultraviolet disinfecon system.

By purchasing a SpringWell UV Disinfecon system, you are

receiving not only a high quality product but also peace of

mind. Protecng your water supply with a UV system gives you

reassurance that your family will have access to safe drinking

water throughout your enre home with no chance of

microbiological contaminaon. This is a chemical free process

which is simple in its concept and eecve in its abilies to

inacvate microorganisms present in the water supply. Simple

maintenance, connuous disinfecon and ulmately safe

water, SpringWell Water Filtraon Systems makes it that easy.

3|Page

TABLE OF CONTENTS

Safety Consideraons ......................................................................................................... 4

Before You Begin ................................................................................................................ 4

Water Quality Parameters .................................................................................................. 5

Assembly ............................................................................................................................ 6

System Sizing ...................................................................................................................... 8

Locaon .............................................................................................................................. 8

Installaon ......................................................................................................................... 9

System Disinfecon .......................................................................................................... 11

Cleaning the Quartz Sleeve .............................................................................................. 11

Cleaning the UV Sensor .................................................................................................... 12

Operaon ......................................................................................................................... 13

UV4 Controllers ...................................................................................................... 13

UV5 & UV6 Controllers .......................................................................................... 13

UV5 & UV6 Power-up Sequence ............................................................................ 13

UV5 Operaonal Screens ....................................................................................... 14

UV6 Operaonal Screens ....................................................................................... 14

Lamp Countdown Sequence .................................................................................. 15

System Service Suggested ...................................................................................... 16

Lamp Replacement (UV4 systems) ........................................................................ 16

Lamp Replacement (UV5 & UV6 systems) ............................................................. 16

QR Codes ............................................................................................................... 16

System Troubleshoong......................................................................................... 17

Temperature Management Devices ................................................................................. 18

Expansion Modules .......................................................................................................... 19

Standard Output System Specicaons ........................................................................... 20

High Output System Specicaons ................................................................................... 21

Limited Warranty Statement ............................................................................................ 22

Warranty Registraon ...................................................................................................... 23

4|Page

Safety Consideraons

Although your UV system has been manufactured to the highest safety standards, care must be

followed when operang and/or maintaining your system.

1. Before servicing this equipment, disconnect the power cord from the electrical outlet.

2. Energy given o by the UV lamp is harmful to your eyes and skin. NEVER look directly

at an illuminated UV lamp without adequate eye protecon and always protect your skin

from direct exposure to the UV light.

3. For complete disinfecon, use ONLY genuine replacement parts.

4. Do not operate the unit if it has any damaged or missing components.

5. To avoid possible electrical shock, use only with a properly grounded electrical outlet.

6. Never perform any maintenance to the system unless you are comfortable in doing so.

Contact the manufacturer for service instrucons if required.

7. Do not use this system for any purpose other than what it was intended for. Misuse of this

system could potenally cause harm to the user or others.

8. Your system is intended to be installed indoors and away from leaking plumbing. DO NOT

plug the unit in if the system or any of the components are wet.

9. The disinfecon system should be directly installed into a ground fault circuit interrupter

(GFCI). If the use of an extension cord is required, the cord must be manufactured with a

minimum of 16 gauge wire and care should be taken to avoid potenal tripping hazards.

10. We recommend that a licensed plumber or cered technician install the system.

Before You Begin

The following will be needed for installing the UV system:

Tools

• Pipe cuer, hacksaw or other specialized tools required to cut into your exisng

plumbing (e.g. if you have PEX piping)

• Soldering tools (torch, ux, emery cloth and solder)

• Wrench (for ghtening ngs)

Other Materials

• Inlet/outlet connecons

• Teon™ tape

5|Page

Water Quality Parameters

UV disinfecon is extremely eecve against microorganisms but only if the UV light can pass

through the water it needs to treat. This means that the quality of your water is very important

in order to ensure complete disinfecon.

Treated water should be tested for at the least the parameters listed below. If the water

exceeds the listed parameters SpringWell strongly recommends that appropriate pretreatment

equipment be installed (equipment required will depend on parameters being treated):

Hardness: <7 gpg (120 mg/L) – if hardness level is 7 gpg or slightly below the

quartz sleeve must be cleaned periodically in order to ensure e-

cient UV penetraon; if above the water must be soened.

Iron (Fe): <0.3 ppm (0.3 mg/L)

Manganese (Mn): <0.05 ppm (0.05 mg/L)

Turbidity: < 1 NTU

Tannins (organics): <0.1 ppm (0.1 mg/L)

UVT (transmiance): >85% (Please contact SpringWell if water has a UVT that is less than

80% for pre-treatment recommendaons)

You can have your water tested at a private analycal laboratory or by your local dealer. It is

always recommended to install pre-ltraon of at least 5 microns prior to a UV disinfecon

system.

6|Page

Assembly

Unpack the system and ensure all the components are included with the system. Your system is

shipped with the following components:

STANDARD OUTPUT

LAMP SYSTEMS

LAMP

KEY

CLAMPS

CONTROLLER

UV4 Systems

SPRW-UV-NE1

UV5 & UV6 Systems

SPRW-UV-N1

GLOW PLUG

300016 Complete Assembly

310026 Teon Plug

310040 O-Ring

390007 Brass Nut

UV SENSOR

SPRW-UV-NS1

UV5/6 series

“-02”, “-03”, “-06”, “-11”, “-15” series

SPRW-UV-NS2

“-21” series

GLAND NUT

320006

O-RING

300038

UV LAMP

SPRW-UV-210

SPRW-UV-290

SPRW-UV-470

SPRW-UV-820

SPRW-UV-850

SPRW-UV-999

SLEEVE SPRING

310039

QUARTZ SLEEVE

SPRW-UV-Q210

SPRW-UV-Q290

SPRW-UV-Q470

SPRW-UV-Q820

SPRW-UV-Q850

SPRW-UV-Q999

REACTOR

300083 “-02” series

300050 “-03” series

300052 “-06” series

300054 “-11” series

300061 “-15” series

300068 “-21” series

7|Page

HIGH OUTPUT

LAMP SYSTEMS

CONTROLLER

UV4-C Systems

SPRW-UV-HO-NE

UV5-C & UV6-C Systems

SPRW-UV-HO-N

GLOW PLUG

300016 Complete Assembly

310026 Teon Plug

310040 O-Ring

390007 Brass Nut

UV SENSOR

SPRW-UV-NS3

POWER CORD

260004 North American

260005 Euro

260006 Australian/New Zealand

260008 Brish

GLAND NUT

320006

O-RING

300038

UV LAMP

SPRW-UV-210HO “-05” series

SPRW-UV-330HO “-10” series

SPRW-UV-420HO “-15” series

SPRW-UV-600HO “-25” series

SPRW-UV-950HO “-40” series

SLEEVE SPRING

310039

QUARTZ SLEEVE

SPRW-UV-Q210 “-05” series

SPRW-UV-Q330 “-10” series

SPRW-UV-Q420 “-15” series

SPRW-UV-Q600 “-25” series

SPRW-UV-Q950 “-40” series

REACTOR

300062 “-05” series

300063 “-10” series

300064 “-15” series

300007 “-25” series

300009 “-40” series

LAMP

KEY

CLAMPS

8|Page

System Sizing

All UV systems are rated for a specic ow rate in water that meets the quality parameters on

page 5. PLEASE NOTE that increasing the ow above this rang or disinfecng water that does

not meet the quality parameters will decrease the dose and therefore compromise the micro-

organism inacvaon.

To determine ow rate follow these simple steps:

Be sure no water is being used in the home. Open a faucet or tap nearest the pressure system

and run unl the well pump starts. Close the faucet and using a second hand watch, record the

length of me in seconds unl the pump stops. This is known as the cycle me.

Then using a container of known volume, preferably in US Gallons, open the faucet or tap near-

est the pressure system and measure the amount of water drawn o unl the pump starts again.

Depending on the size of the container used, it is acceptable to turn the faucet on and o to

empty the container. This measurement is known as the draw down.

To calculate the pressure system ow rate divide the draw down by the cycle me and mulply

that by 60.

Draw Down__________÷ Cycle Time____________ x 60=__________Pumping Rate in USGPM

Locaon

For Point of Entry (POE) systems, choose a locaon where the main cold water line is accessible.

The system must be installed aer other water treatment equipment (soener or lters), but

before any branches (See Figure 1). For Point of Use (POU) systems, install the unit just before

the faucet. SpringWell recommends that a 5 micron lter be installed before the UV system for

a nal polishing step before the water is disinfected.

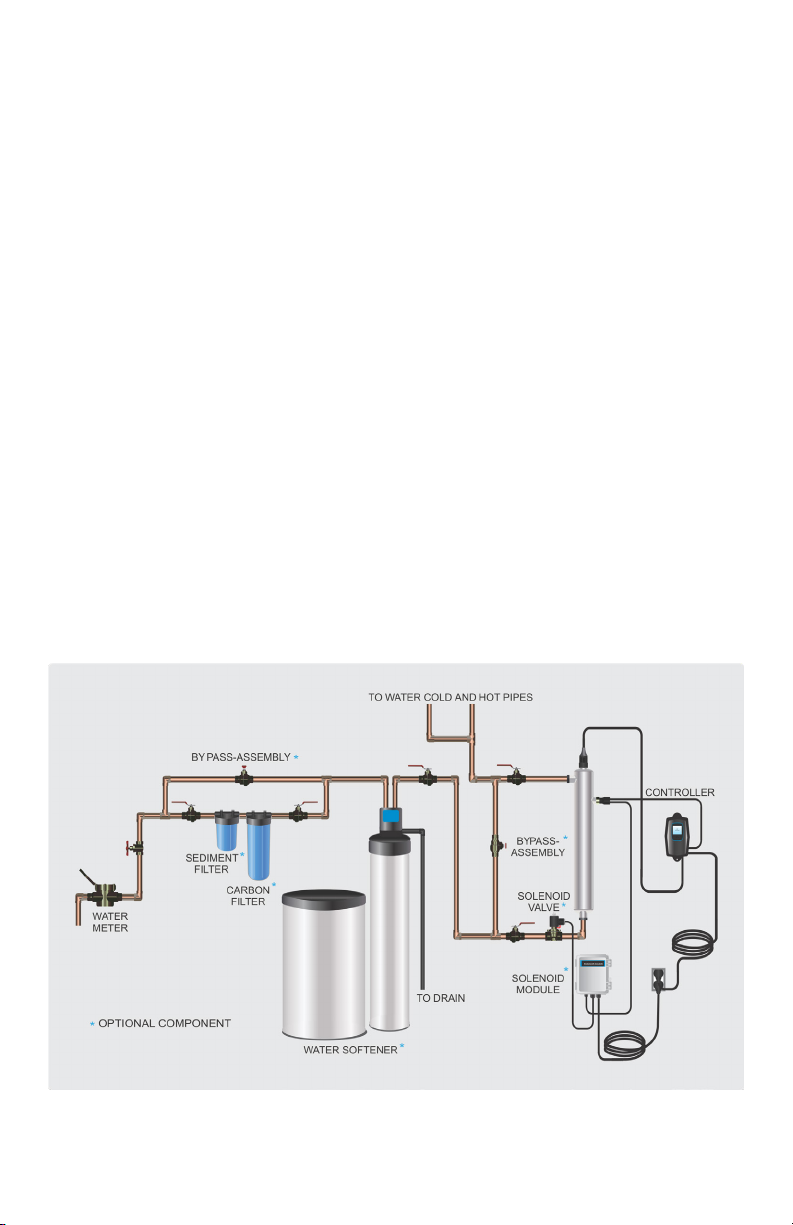

Figure 1. Recommended POE Installaon Locaon

9|Page

To facilitate lamp removal, ensure there is enough space at

the lamp connector end to safely remove the UV lamp and/

or quartz sleeve (See Figure 2). The controller will require

a ground fault circuit interrupter (GFCI or GFI) outlet and

should be mounted beside or above the reactor. PLEASE

NOTE: All UV disinfecon systems are intended for indoor

use only as they should not be exposed to the elements.

Installaon

Step 1: The reactor can be installed either horizontally or

vercally using the clamps provided. Vercal installaon is

the preferred method with the inlet at the boom (lamp

connecon at the top) as it allows any air that may be in the

lines to be easily purged from the system.

Step 2: The use of a by-pass assembly is recommended as

it will allow you to isolate the UV reactor. This will allow for

easier access in case maintenance is required (See Figure 3).

Step 3: Use the supplied fasteners to mount the UV

reactor to wood or drywall. If mounng to an alternate

material you will need to purchase the proper corresponding

fasteners.

Step 4: For water supplies where the maximum ow rate

is unknown, a ow restrictor is recommended so that the

rated ow of your parcular system is not exceeded. The

ow restrictor should be installed on the inlet port of the

reactor.

Step 5: It is recommended to have a licensed plumber

connect the UV reactor to the water supply and may be a

requirement depending on where you are located.

Step 6: Once the system has been plumbed in, gently

remove the quartz sleeve from its packaging being careful

not to touch the length with your hands. The use of coon

gloves is recommended for this procedure as oils from the

hands can leave residue on the sleeve and lamp which can

ulmately block the UV light from geng to the water.

Carefully slide the sleeve into the reactor unl you can feel

it hit the opposite end of the reactor. Align the sleeve so it

centered along the length of the reactor, then gently push it

in to lock it into the internal centering springs in the far side

of the reactor. CAUTION: Pushing too hard when the sleeve

is not aligned can damage the centering springs. Slide the o-

ring onto the sleeve unl it is bued up against the reactor.

Figure 2. Lamp

Removal Spacing

leave at least

an addional

reactor length

to facilitate

lamp and

sleeve removal

Note: Installaon of your disinfecon systems

shall comply with applicable provincial/state

& local regulaons.

Figure 3. By-pass

assembly

10|Page

Step 7: Hand ghten the provided gland nut over the quartz

sleeve onto the threaded end of the reactor. It has a posive

stop to prevent over-ghtening. A rm force may be required

to fully ghten the gland nut, but DO NOT USE TOOLS for this

step. Insert the provided stainless steel compression spring into

the quartz sleeve. The spring works with the lamp and lamp

connector to create the proper lamp alignment. PLEASE NOTE:

DO NOT install a UV lamp inside the quartz sleeve without the

sleeve spring in place.

Step 8: Install the UV sensor (ordered separately). Align the

at poron so it faces the gland nut end and matches up with

the half metal lip on the sensor port (see Figure 5). Insert the

sensor so it is fully seated and hand ghten the sensor nut.

Step 9: The reactor is now ready for water ow. When all

plumbing connecons have been completed, slowly turn on the

water supply and check for leaks. Make sure the by-pass valves

are funconing properly and that the water is owing through

the reactor. The most common leak is from the o-ring not making

a proper seal on the reactor. For new installaons, review steps 6

and 7. For older systems drain the reactor, remove the o-ring, dry

it and reapply silicon grease. Reinstall the o-ring ensuring that it is

properly sealed against the reactor and check again for leaks.

Step 10: Mount the controller to the wall so it is above or

beside the reactor to ensure that no moisture can deposit

on any of the connecons (see Figure 1). Always mount the

controller vercally. For monitored systems, insert the sensor

connector into the IEP port located on the right side of the

controller (Figure 6). For the sensor to be recognized by the

controller, the controller power must be plugged in last. Do not

plug the controller power cord in before the last step.

Step 11: Always hold UV lamps by their ceramic ends, not by

the lamp quartz. Remove the lamp from its packaging. Again,

the use of coon gloves is recommended. Remove the lamp key

from the lamp’s connector and set it aside for the next step. Be

careful to not touch the key’s exposed contacts. Insert the UV

lamp into the reactor, being careful not to drop it.

Step 12: Install the lamp key into the controller (UV5 & UV6

systems only). The key always comes packaged with the lamp

and sits on the connector. With the key removed from the lamp,

orient it so the label is upright and facing you. The key will plug

into the lamp key port on the right side of the controller (Figure

7).

Figure 4. Quartz

Sleeve Installaon

Figure 5. UV Sensor

Installaon

Figure 6. IEP

Connecon

Figure 7. Lamp Key

Installaon

11|Page

Step 13: Plug the lamp connector into the lamp. Note the

keying for proper alignment (see Figure 8a, 8b). Insert the

lamp connector into the gland nut and turn the connector

approximately ¼ turn to lock the connector to the gland nut as

in Figure 9.

Step 14: Tighten the capve ground screw to the ground lug

on the UV reactor to ensure proper grounding(Figure 10).

Step 15: Your system is now ready to be plugged into the

appropriate GFCI protected outlet. Refer to the following

secon before any water is allowed to ow through the system.

System Disinfecon

With a new installaon, or any me the UV system is shut

down for service, without power, or is inoperave for any other

reason, the lines in the home or facility could be contaminated.

Use the following steps to fully disinfect the lines throughout

the enre home or facility.

Step 1: Check for and remove any “dead ends” in the lines

throughout the home as these can harbor bacteria. Plug in the

UV system and wait unl it is ready for operaon.

Step 2: Remove the lter cartridge from the last sump and ll

it with 1-2 cups of household bleach (most are 5.25% chlorine).

Replace the sump and slowly turn on the water supply.

Step 3: At a water outlet, run the water unl bleach can

be smelled. Repeat this for all faucets, toilets, shower heads,

refrigerators, outdoor taps, the washing machine, dishwasher,

etc. at the home or facility. Once nished, wait a minimum of 30

minutes before connuing.

Step 4: Reinstall the lter cartridge into the sump and ush

the chlorine soluon by opening all faucets unl chlorine can

no longer be detected. Your home has now been completely

disinfected with your UV system ready to inacvate any

microorganisms that enter the home.

Cleaning the Quartz Sleeve

Depending on the water quality, the quartz sleeve may require

periodic cleaning. At a minimum, the quartz sleeve should be

cleaned on an annual basis. The following steps outline a basic

cleaning procedure.

Step 1: If a by-pass assembly is installed, shut the inlet valve

o to prevent water ow through the system. Otherwise, turn

o main water inlet valve (and/or turn o the water pump).

Step 2: Disconnect power cord of UV system from electrical

outlet.

Figure 8a. Standard

Output UV Lamp

Connecon

Figure 8b. High Output

UV Lamp Connecon

Figure 9. Lamp

Connector

Figure 10. Ground

Screw Connecon

12|Page

Step 3: Release water pressure by opening a downstream faucet and then close the outlet

shut-o valve (if any). If there is no outlet shut-o valve, expect water to drain from the system

as the head pressure in the system will cause the water to ow back down.

Step 4: Remove the capve ground screw from the ground lug on the UV reactor.

Step 5: Remove the lamp connector from the reactor (gland nut) by pushing the lamp

connector in and turning it ¼ turn counter-clockwise. Disconnect the lamp connector from the

lamp. CAUTION: the lamp may be hot!

Step 6: Being careful to touch only the ceramic ends, remove the lamp out of the reactor.

Step 7: Unscrew the gland nut from the reactor exposing the end of the quartz sleeve.

Step 8: Remove the quartz sleeve and o-ring by gently twisng and pulling the quartz sleeve.

Step 9: Using a so, lint-free cloth or towel wipe the sleeve down using a commercial scale

cleaner (i.e. CLR® or LIME-A-WAY®). This removes scaling or iron deposits that may be on the

outside of the quartz sleeve. Be careful not to get any moisture or liquids inside of the sleeve.

Step 10: Dry the sleeve with separate cloth.

Step 11: Replace the o-ring and slide the sleeve back into the reactor following steps 7 and 8

from the installaon secon of the manual.

Cleaning the UV Sensor

Depending on the water quality, the UV sensor may require periodic cleaning. At a minimum,

the UV sensor should be cleaned on an annual basis. The following steps outline a basic cleaning

procedure.

Step 1: If a by-pass assembly is installed, shut the inlet valve o to prevent water ow through

the system. Otherwise, turn o main water inlet valve (and/or turn o the water pump).

Step 2: Disconnect power cord of UV system from electrical outlet.

Step 3: Release water pressure by opening a downstream faucet and then close the outlet

shut-o valve (if any). If there is no outlet shut-o valve, expect water to drain from the system

as the head pressure in the system will cause the water to ow back down.

Step 4: Place something under the reactor to catch any water that may come out of the

reactor during the removal of the UV sensor.

Step 5: Unscrew (counterclockwise) sensor nut from the reactor and pull the sensor slowly out

of the sensor port.

Step 6: Holding the sensor in your hand wipe the at poron (sensor face) of the sensor with

isopropyl alcohol using a clean lint-free cloth.

Step 7: Replace sensor following step 8 from the installaon secon of the manual.

13|Page

Operaon

UV systems come with a feature laden controller that incorporates both the lamp driver (ballast)

and control features in one water-ght case. Four main controllers are available (depending on

your model). All four models feature a power factor corrected, constant current lamp driver with

a universal power input.

Please Note: While the LED or display screen is red and the buzzer is sounding the water from

the system should NOT be consumed. If any water does pass through the system during this

period, please follow the disinfecon procedure as outlined in this manual before the water is

consumed. For UV4 and UV5 systems, even though they have a visual and audible warning built

into the controller, a green LED or status screen does not necessarily indicate that the water

coming from this system is in fact potable (safe to drink). These systems do not measure the level

of disinfecon; they simply measure the “on-o” status of the lamp. Please have your water

checked for microbiological contaminants on a regular basis.

UV4 Controllers

UV4

Series

UV4-C

Series

Simplisc in operaon, these systems feature a tri-

colour LED that indicang system status and a 4-digit

display to indicate lamp life remaining. Pressing the

buon will change the display to indicate total running

me. When the UV lamp is on and within its operang

age, the LED will be green. When the UV lamp is not on

or the lamp life has expired, the LED will be illuminated

red and an audible buzzer will be sounding. To remedy

this condion, the UV lamp must be replaced with a

new genuine SpringWell UV lamp.

UV5 & UV6 Controllers

UV5/6

Series

UV5/6-C

Series

A full colour LCD screen provides the user with a

detailed descripon of the system’s performance in

addion to providing any applicable fault messages

and system diagnoscs. The controllers used in both

the UV5 and UV6 are idencal. The dierence is that

the UV6 series of products includes a UV intensity

monitor. All UV5 and UV6 controllers include an

“innite expandability port” located on the right side

of the controller. Simply plug in an oponal UV sensor

module into the expandability port of a UV5 controller

and the system will now monitor the UV intensity of

the system!

UV5 and UV6 Power-up Sequence

On start up, the controller will run through a diagnosc start-up and the sequence will be

displayed as follows on the colour LCD:

14|Page

Next, the controller checks for and inializes any oponal modules that may be aached to the system.

Oponal Modules Check

- UV Sensor

- Solenoid

- 4-20 mA

- WIFI

- Remote Alarm

- Flow Meter

OR

A nal module screen is displayed showing which specic modules were inialized.

The controller then displays the lamp opmizaon screen for 60 seconds to allow the lamp to

reach its opmum output. Finally, a nal “start-up complete” screen is displayed. The system will

now be ready to disinfect water ow.

all detected modules lamp reaching max output successful start-up

UV5 Operaonal Screens

On systems without the UV monitor, the default screen shows the Home Screen. At any point

during operaon the user is able to scroll through the Home Screen, Lamp life remaining, QR

Code, Contact Info and Maintenance Parts screens by pressing the buon located on the front

of the controller.

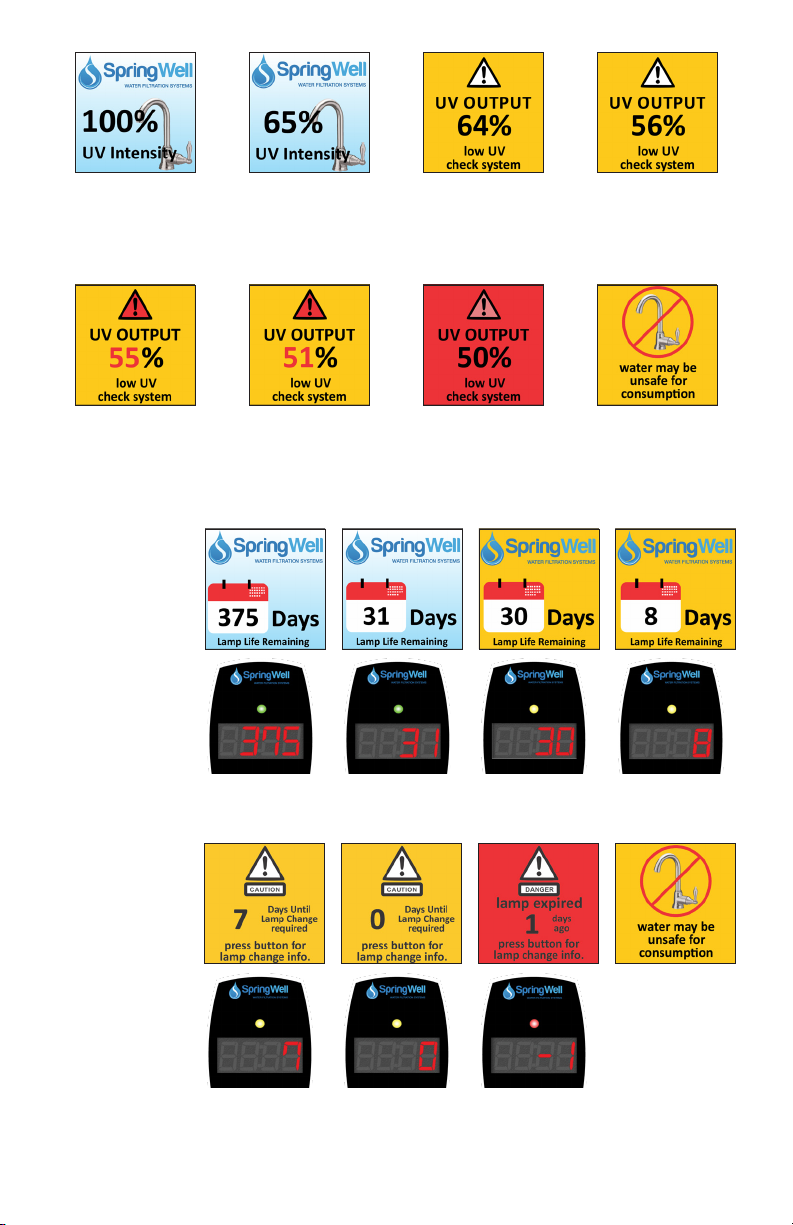

UV6 Operaonal Screens

On systems with the UV monitor, the system will display the same screens as on the UV5 except the

UV Intensity replaces the home screen. The UV Intensity screen displays the level of UV light detected

by the sensor. UV intensity can be aected by poor water quality, scaling on the quartz sleeve and/or

sensor, lamp failure or lamp expiring. The following screens show the UV Intensity dropping.

15|Page

Below 56%, the numbers and warning sign turn red and an audible chirp is given by the ballast

every 15 seconds. Below 51%, the screen is solid red and a constant audible alarm is given. This

alternates with a screen indicang “water may be unsafe for consumpon”. With the solenoid

module, the controller de-acvates the solenoid valve, shung o all water ow.

audible chirp every

15 seconds

audible chirp every

15 seconds

constant audible

alarm

cycles with red low

UV screen

Lamp Countdown Sequence

The system counts down the number of days unl a lamp change is required.

UV5

UV6

UV4

At thirty days remaining, the LED or display screen will change to a yellow cauon indicator. At

seven days remaining, the system will addionally repeat an audible chirp. Past the zero day

threshold, the LED or display screen changes to solid red with a connuous buzzer.

UV5

UV6

UV4

At any point during this sequence, the audible chirp or alarm can be deferred for seven days

by holding the controller buon down for a period of ve seconds. The number of deferrals

16|Page

used will be displayed as below. Once the deferral expires, the alarm will sound once again. The

deferral can be repeated up to three mes. PLEASE NOTE: At any point aer lamp expiraon,

the water may be unsafe for consumpon and should not be consumed without another form

of disinfecon.

System Service Suggested

UV5 & UV6 controllers will display the System Service Suggested Screen

every 6 months to remind consumers to maintain both their UV and other

preltraon. This will serve as a prompt only and will not put the system

into alarm. To clear this condion simply press the buon located below

the screen.

Lamp Replacement (UV4 systems)

Aer the lamp is expired, it must be replaced with the same part number as indicated by the

label on the reactor. Begin replacing the lamp by unplugging the power for the controller, then

refer to Installaon (page 11) for instrucons on installing the new lamp. To reset the mer in

the controller, rmly hold down the buon on the controller for 10 seconds. The controller will

read “rSt3”, “rSt2”, “rSt1” and then beep. The buon can now be released, the lamp countdown

mer has been reset.

Lamp Replacement (UV5 & UV6 systems)

Aer the lamp is expired, it must be replaced with the same part number as indicated on the

Maintenance Parts screen or on the label on the reactor. With the system powered down,

remove and discard the lamp key from the controller. The replacement lamp is packaged with

a lamp key on the connector at the end of the lamp. Remove the key from the lamp and place

it in the controller. Refer to Installaon (page 11) for instrucons on installing the new lamp.

QR Codes (UV5 & UV6 systems)

QR codes store a link to a specic page on our website. Users with a camera

phone equipped with the correct reader applicaon can scan the image

of the QR code and over a wireless network connect to a SpringWell web

page in the phone’s browser. The QR webpage has informaon on how to

purchase replacement components as well as a helpful video directory on

system servicing (i.e. How to change a UV lamp or quartz sleeve). To access

the QR code on the controller, press the control buon unl the QR code

screen appears.

17|Page

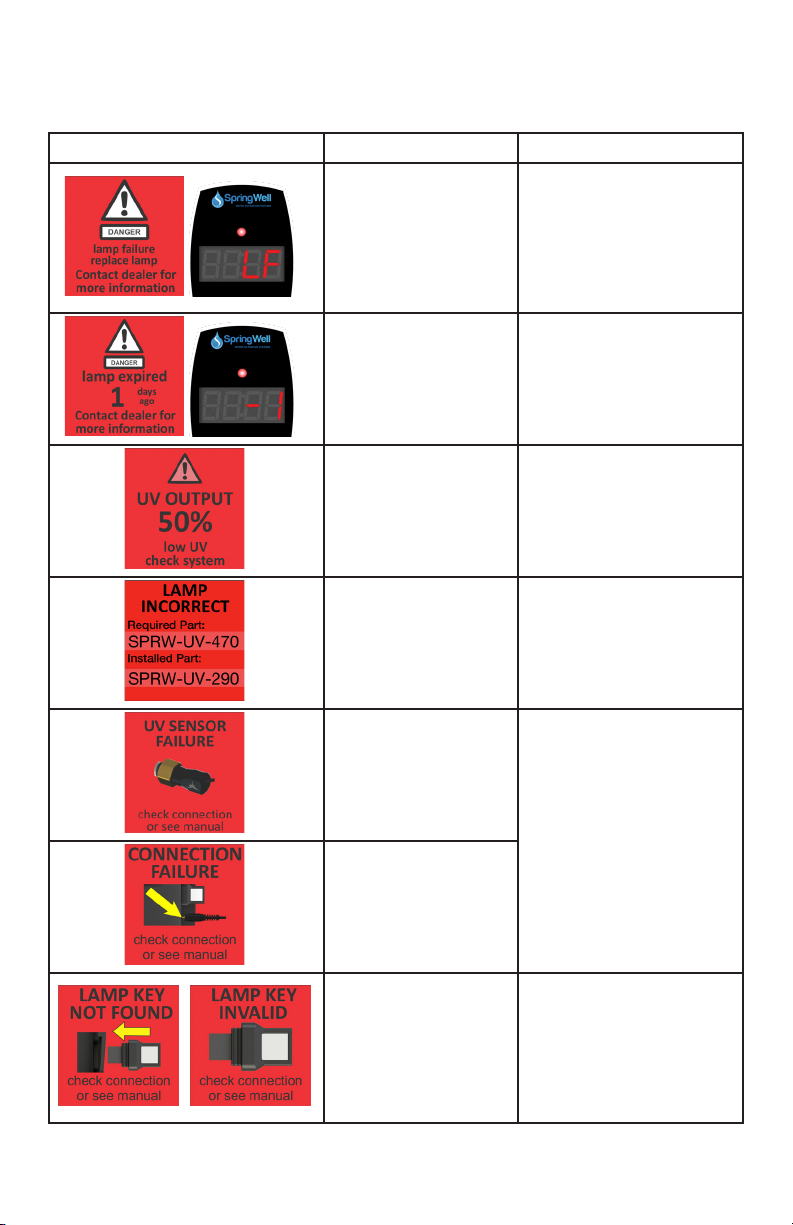

System Troubleshoong

Hard Alarms: The following give a constant audible alarm. If present, the solenoid valve is closed,

and the 4-20, remote alarm and WiFi modules transmit the alarm.

System Display Problem Resoluon

The system has detected

a problem with the

lamp.

Reset lamp protecon circuit

-unplug unit for 10 seconds.

Replace the lamp with the

part as indicated on the

silver label on the reactor or

on the Maintenance parts

screen.

Although the lamp is

powered and visibly

illuminated, due to the

lamp’s age its UV output

is no longer sucient for

proper disinfecon.

Replace the lamp with the

part as indicated on the

silver label on the reactor or

on the Maintenance parts

screen.

Low UV Intensity.

Remove and clean the

quartz sleeve and sensor.

Check water quality meets

requirements on page 5 and

add ltraon as required.

Replace lamp.

Wrong lamp or sensor

installed.

Replace component with

proper model as indicated.

The UV sensor is no

longer communicang

with the system.

Ensure all modules are

connected properly to the

system and to each other.

Modules can be tested

individually by plugging in

one at a me and cycling

power to the system.

Replace any module that is

not detected when plugged

directly into the controller.

A bad connecon has

been detected in the IEP

port.

Missing or incorrect

lamp key.

Ensure the lamp key

(packed with the lamp, on

the connector) is installed.

Unplug and reinstall the

key. Ensure the key part

number matches Lamp on

Maintenance Parts screen.

18|Page

So Alarms: The following remaining errors give a 15 second audible chirp only

System Display Problem Resoluon

The module indicated is

no longer communicat-

ing to with the system.

Ensure all modules are

connected properly to the

system and to each other.

Modules can be tested

individually by plugging in

one at a me and cycling

power to the system.

Replace any module that is

not detected when plugged

directly into the controller.

Refer to ow meter manual for detailed

troubleshoong

Warning: Aer any hard alarm, the home or facility should be disinfected. Follow the steps

under the “System Disinfecon” heading.

Temperature Management Devices

Your UV system is designed to run connuously to ensure opmal disinfecon. However, during

periods when no water is drawn through the system, the energy from the disinfecon process

can cause the temperature of the water inside the chamber to rise. In extreme situaons

elevated water temperature or the uctuaon in temperature can lower the output of the UV

lamp. In these cases, or if the elevated water temperature is a nuisance, SpringWell recommends

one of the following forms of temperature management devices.

Cooling Fan - Designed for use on High Output systems, the fan runs connuously to

cool the water by forced convecon. The long-life fan is powered independently

using a compact modular power adapter that operates from 90-265V (47-63Hz).

Order PN SPRW-130014.

Temperature Relief Valve (TRV) - On reaching a higher temperature, the TRV is

designed to drain a small amount of water to allow fresh, cooler water to enter the

system. The TRV works without power and comes complete with 10’ of drain line.

Order PN SPRW-UV-TRV05 for 1/2” ports, PN SPRW-UV-TRV07 for 3/4” ports, PN

SPRW-UV-TRV10 for 1” ports and PN SPRW-UV-TRV15 for 1 1/2” ports.

Boil Water Advisory: If any failure occurs on a UV system, the water must not be used for

human consumpon unl the system is returned to a safe operaonal mode. If the water

is used for human consumpon during this period, the water must be boiled (minimum 20

minutes at a full boil) prior to consumpon.

19|Page

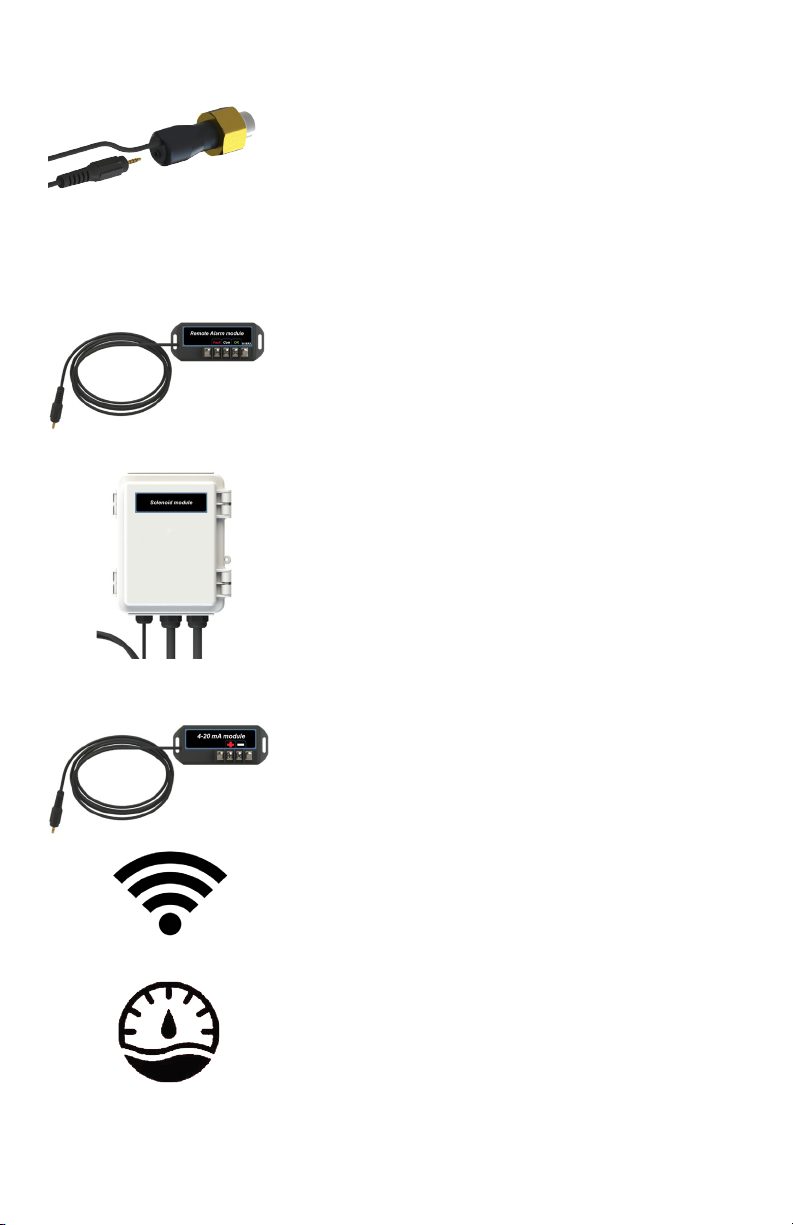

Expansion Modules

Controllers incorporate an “Innite Expandability Port” (IEP)

which allows for expansion to the UV sensor and all other

modules. Each module (including the sensor) comes with

both a male and female connecon. Connect any device to

the controller and all subsequent devices are then connected

into the female end of last device added in a “daisy chain”

conguraon.

The following oponal expansion modules are available for use on UV5 & UV6 UV controllers.

Contact your authorized distributor for purchasing informaon.

REMOTE ALARM CONNECTION MODULE: Allows for a

connecon to a remote device such as a buzzer, light, alarm

system, PLC, etc., via a pair of contacts. In normal operaon

the OK and COM contacts will be connected, and in a fault

condion (Low UV, Lamp fail, Power Fail), the Fault and COM

contacts will be connected. Maximum contact rang is 30V / 1A

(use 16-22 AWG). Order PN SPRW-MOD-RAM.

SOLENOID CONNECTION MODULE: Connects a NORMALLY

CLOSED line voltage solenoid valve to the controller. Maximum

contact rang is 240VAC (50-60Hz) / 30VDC / 2A. On a non-

monitored system, the solenoid will only close on a lamp failure

error. On a monitored system, the solenoid is closed when

the UV level drops below 50%. Also note that in cases where

emergency use of untreated water is required, the controller

can be placed into a manual override mode allowing for the

ow of water in an alarm condion. Order PN SPRW-MOD-

SOL1.

4-20 mA MODULE: Outputs a 4-20mA signal of the UV output

to a remote device such as a data logger or computer. Order PN

SPRW-MOD-420.

The WiFi module and accompanying IoT applicaon allows you

to connect your UV system to a smart phone, tablet, computer

or other connected plaorm. View system status, receive SMS

or email messages of alarm condions and monitor the health

of your UV from anywhere via this connected plaorm. Connect

the device via the APP found on Google Play or the APP Store

and connect your UV device to your router, then download the

soware for your connected device. Order PN MOD-APP.

The Ultrasonic Flow Meter enables your UV system to dim

power in mes of low to no ow, saving you money on energy,

reducing water temperature, and decreasing the risk of fouling.

20|Page

Standard Output Systems

EQUIPMENT SPECIFICATIONS

Mul-Use / Residenal systems

MODEL

SPRW-UV4-2

SPRW-UV5-2

SPRW-UV6-2

SPRW-UV4-3

SPRW-UV5-3

SPRW-UV6-3

SPRW-UV4-6

SPRW-UV5-6

SPRW-UV6-6

SPRW-UV4-11

SPRW-UV5-11

SPRW-UV6-11

SPRW-UV4-15

SPRW-UV5-15

SPRW-UV6-15

SPRW-UV4-21

SPRW-UV5-21

SPRW-UV6-21

Flow Rate

30mJ/cm

2

@ 95% UVT

2 gpm 3 gpm 6 gpm 11 gpm 15 gpm 21 gpm

7.6 lpm 11.4 lpm 22.7 lpm 41 lpm 56.8 lpm 79 lpm

0.45 m

3

/hr 0.70 m

3

/hr 1.4 m

3

/hr 2.5 m

3

/hr 3.4 m

3

/hr 4.8 m

3

/hr

Flow Rate

16mJ/cm

2

@ 95% UVT

4 gpm 6 gpm 11 gpm 20 gpm 30 gpm 39 gpm

15.1 lpm 23 lpm 41 lpm 77 lpm 113.6 lpm 150 lpm

0.87 m

3

/hr 1.4 m

3

/hr 2.5 m

3

/hr 4.6 m

3

/hr 6.8 m

3

/hr 8.9 m

3

/hr

Flow Rate

40mJ/cm

2

@ 95% UVT

1.6 gpm 2.4 gpm 4.4 gpm 8.3 gpm 12 gpm 16 gpm

6.1 lpm 9.1 lpm 17 lpm 31 lpm 45.4 lpm 59 lpm

0.36 m

3

/hr 0.50 m

3

/hr 1.0 m

3

/hr 1.9 m

3

/hr 2.7 m

3

/hr 3.6 m

3

/hr

Port Size ½”FNPT ½”MNPT ¾”MNPT ¾”MNPT 1”MNPT 1”MNPT

Electrical 90-265V/50-60Hz. 1A Max.

Plug Type American: NEMA 5-15P

Lamp Power (Was) 8 15 22 39 50 42

Power (Was) 14 20 30 49 62 51

Replacement Lamp SPRW-UV-210 SPRW-UV-290 SPRW-UV-470 SPRW-UV-820 SPRW-UV-999 SPRW-UV-850

Replacement Sleeve SPRW-UV-

Q210

SPRW-UV-

Q290

SPRW-UV-

Q470

SPRW-UV-

Q820

SPRW-UV-

Q999

SPRW-UV-

Q850

Reactor

Dimensions

6.4 x 26.2 cm

(2.5 x 10.3”)

6.4 x 36.4 cm

(2.5 x 14.3”)

6.4 x 54.2 cm

(2.5 x 21.3”)

6.4 x 89.5 cm

(2.5 x 35.2”)

6.4 x 101.6 cm

(2.5 x 40.0”)

8.9 x 91.7 cm

(3.5 x 36.1”)

Chamber Material 304 Stainless Steel, A249 Pressure Rated Tubing

Controller Dimensions 171.5 x 92.1 x 101.6 mm (6.8 x 3.6 x 4”)

Operang Pressure 0.7-10.3 bar (10-150 psi)

Operang Water Temperature 2-40° C (36-104° F)

UV Monitor YES on all “UV6” models. Upgrade available for “UV5” models (NOT available on UV4 models)

Solenoid Output YES (oponal solenoid module (SPRW-MOD-SOL1) sold separately)

Dry Contacts YES (remote alarm module (SPRW-MOD-RAM) sold separately)

4-20mA Output YES (4-20mA module (SPRW-MOD-420) sold separately)

Temperature Mgmt. Valve NA SPRW-UV-

TRV05 SPRW-UV-TRV07 SPRW-UV-TRV10

Cooling Fan NO

OPTIONAL

(SPRW-

130014)

Lamp Change Reminder YES

Lamp Out Indicator YES

Shipping Weight 2.9 kg

(6.3 lbs)

3.6 kg

(7.9 lbs)

4.4 kg

(9.6 lbs)

6.0 kg

(13.2 lbs)

6.5 kg

(14.4 lbs)

8.2 kg

(18.0 lbs)

This manual suits for next models

32

Table of contents

Popular Accessories manuals by other brands

Rittal

Rittal SK 3185830 Assembly and operating instructions

Milanity

Milanity SLEV05 user manual

PCB Piezotronics

PCB Piezotronics 354C10/NC Installation and operating manual

Thermo Scientific

Thermo Scientific 3554-35A Operator's manual and parts list

Siemens

Siemens SITRANS LG240 operating instructions

Triumph

Triumph 45-6090W instruction manual