Spring Well SMARTFLUSH SF4B User manual

Technical Support

If you have any further technical queries, please contact technical support on 01924-420029.

PLEASE DO NOT RETURN ANY ITEM WITHOUT AUTHORISATION

PLEASE LEAVE THESE INSTRUCTIONS WITH CUSTOMER

-------------------------------------------------------------------------------------------------------------------------------------

Guarantee

This product is guaranteed from date of purchase to e free from manufacturing defects for a period of 3

years if registered, with the following conditions :-

1) The product has een properly installed as per instructions.

2) Damage due to water ingress to controller, de ris from water supply, hard water erosion (see (2) on

front page), vandalism or misuse are not included. Statutory rights are not affected.

Service : Springwell Microelectronics Ltd, 197 Raikes Lane, Birstall, Batley WF17 9QF

_______________________________________________________________________________

Environmental information

This product may contain su stances that can e hazardous to the environment if not disposed of

properly. Electrical and electronic equipment should not e dumped with general household waste ut

must e separately collected for proper treatment and recovery. The crossed-out in sym ol is a

reminder of the need to dispose of the product properly at end of life; in this way you will assist in the

recovery, recycling and re-use of many of the materials in this product and help to reduce the amount of

electrical and electronic waste ending up in landfill and to improve quality of life y preventing the release

of potentially hazardous su stances into the environment. Please contact us for information on disposal

arrangements or take to a local recycling facility. Where possi le please recycle your packaging.

Producer registration num er WEE/DB0002ZR

_________________________________________________________________________________

Carefully designed and distri uted y:

SPRINGWELL MICROELECTRONICS LTD, 197 Raikes Lane, Birstall, Batley, West Yorkshire WF17 9QF

The manufacturer reserves the right due to continuous development to change specifications without notice

Tel: 01924 420029 Fax: 0870 7062353 e-mail: sales@springwellmicro.co.uk

www.springwellmicro.co.uk

Producer registration num er WEE/DB0002ZR

sf4insv1.2.odt

SPRINGWELL SMARTFLUSH SF B FITTING INSTRUCTIONS

Pack contains: sensing/control unit with attery; valve, assem led ca le; clips, screws, wallplugs.

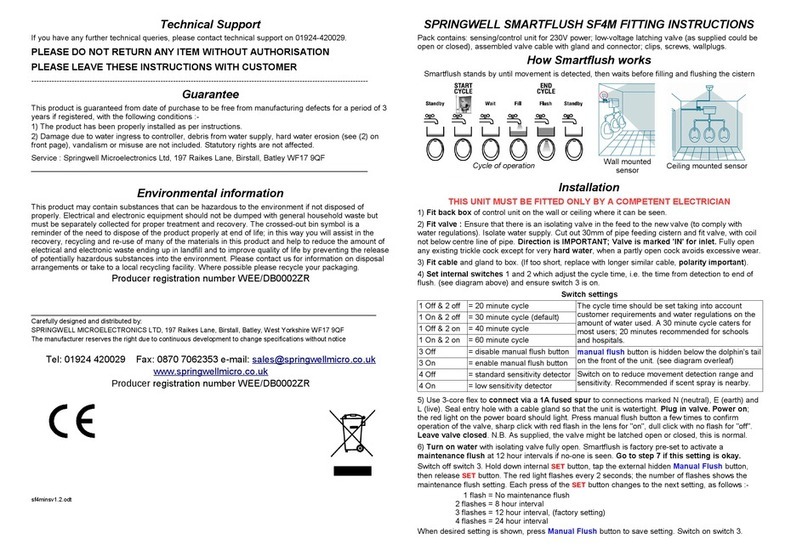

How Smartflush works

Smartflush stands y until movement is detected, then waits efore filling and flushing the cistern

Installation

1) Fit back box of control unit on the wall or ceiling where it can e seen.

2) Fit valve Ensure that there is an isolating valve in the feed to the new valve (to comply with

water regulations). Isolate water supply. Cut out 30mm of pipe feeding cistern and fit valve, with coil

not elow centre line of pipe. Direction is IMPORTANT; Valve is marked 'IN' for inlet. Fully open

any existing trickle cock except for very hard water, when a partly open cock avoids excessive wear.

3) Fit cable and gland to ox. (If too short, replace with longer similar ca le, polarity important).

4) Set internal switches 1 and 2 which adjust the cycle time, i.e. the time from detection to end of

flush. (see diagram a ove) and ensure switch 3 is on.

Switch settings

1 Off & 2 off = 20 minute cycle

1 On & 2 off = 30 minute cycle (default)

1 Off & 2 on = 40 minute cycle

1 On & 2 on = 60 minute cycle

The cycle time should e set taking into account

customer requirements and water regulations on the

amount of water used. A 30 minute cycle caters for

most users; 20 minutes recommended for schools

and hospitals.

3 Off = disa le manual flush utton

3 On = ena le manual flush utton

4 Off = standard sensitivity detector

4 On = low sensitivity detection

manual flush utton is hidden elow the dolphin's tail

on the front of the unit. (see diagram overleaf)

Switch on to reduce movement detection range and

sensitivity. Recommended if scent spray is near y.

5) Carefully connect battery. Tap the SET utton to flash the domed lens red to show that the

attery is sound and connected correctly.( see diagram over). Plug in valve connector. Press

Manual Flush utton a few times to confirm operation of the valve, sharp click with red flash for

"on", dull click with no flash for "off". Leave valve closed. N.B. As supplied, the valve might e

latched open or closed, this is normal.

6) Turn on water supply with isolating valve fully open. Smartflush is factory pre-set to activate a

maintenance flush at 12 hour intervals if no-one is seen. Go to step 7 if this setting is okay.

Switch off switch 3. Hold down internal SET utton, tap the external hidden Manual Flush utton,

then release SET utton. The red light flashes every 2 seconds; the num er of flashes shows the

current maintenance flush setting. Each press of the SET utton changes to the next setting, as

follows :-

1 flash = No maintenance flush

2 flashes = 8 hour interval

3 flashes = 12 hour interval, (factory setting)

4 flashes = 24 hour interval

When the desired setting is shown, press Manual Flush utton to save the setting.

Switch on switch 3. This process may e repeated at any time without affecting the fill time.

Cycle of operation Ceiling mounted sensor

Wall mounted

sensor

7) Empty the cistern ready to set the fill time Hold the SET utton, tap Manual Flush to start filling,

release the SET utton. When flushing starts, tap Manual Flush to close the valve. While filling, check

for a good flow of water and adjust with trickle cock on pipe end if required. If flow noise is a pro lem,

e.g. next to sleeping quarters or classrooms, reduce the flow y means of a trickle cock.

8) Set the fill time Each time the valve opens, it should stay open long enough to fill and flush, hence it

should start and end empty, so this is where we tell it how long to stay open. Hold the SET utton, tap

Manual Flush to start filling, release the SET utton. The light in the domed lens flashes every 2

seconds to show setting in progress. Wait until the cistern is part way through flushing then tap the

Manual Flush utton to close the valve. The cistern fill time is now memorised and will e used every

time a flush is started whether automatically or manually. Maximum fill time is 31 minutes.

9) Set switch 3 as required (see 4 overleaf). Check all screws, gland and connections for security.

Screw controller unit lid onto ox.

10) Fill in your part of the registration sheet and leave it with these instructions with the owner/manager.

Please explain section 4 (switch settings) to the person in charge of uilding maintenance.

SWITCHES / CONNECTIONS / INDICATOR

Multiple cisterns

2 or 3 cisterns with a common feed may e controlled y a single controller and valve. In this case,

adjust outlet cocks feeding each cistern so that they have roughly equal fill times (during step 7), then set

up the fill time using the slowest cistern (step 8). Contact technical support if further advice is required.

Regular Maintenance

Every 3 years in hard water areas, dismantle and if necessary clean the valve and internal strainer, then

reassem le and operate Manual Flush to confirm correct operation. It is wise to change the attery at

this time rather than waiting for failure to operate (typically 4-6 years). Ensure that the view from the

controller is not o structed. Test PIR detector as elow.

Smartflush Installation Troubleshooting Guide

All units are fully tested prior to despatch. If there is an apparent fault please check the following :-

PROBLEM - UNIT WORKS ON MANUAL FLUSH BUT DOES NOT APPEAR TO SEE ANYONE

Test the infra-red detector (PIR) as follows :-

1) Ensure valve is closed. (If necessary, use Manual Flush utton with switch 3 on).

2) Press and hold SET button, watching the domed lens. It should flash once to confirm that the attery

is good, then again a second later to show that test mode has een entered. Release utton.

3) Watch the light, which flashes when slow movement is detected. (Can take up to 1 second ).

4) Exit test mode y a short press of the SET utton or the Manual Flush utton if ena led. (If left in test

mode, the unit automatically reverts to normal operation after 16 minutes to avoid call- acks).

5) After testing, return switch 3 to the desired position to leave Manual Flush utton ena led or not.

6) To avoid false triggering, e.g. y scent sprays, switch on switch 4 for lower sensitivity.

N.B. If the a ove test works and Manual Flush also works and fills for the correct time, then the unit will

work correctly in normal use. The controller normally gives no indication that it has seen anyone,

except that the red light flashes just once at the start of each timing cycle. The unit can e reset ready for

a new cycle y opening and closing the valve using Manual Flush, then waiting for 10 seconds.

PROBLEM - VALVE WILL NOT CLOSE

N.B. The valve has a magnetic latch so it may e left open or shut when disconnected.

a) Test battery and connections:- Press and hold the Manual Flush utton; after the first flash, it will

then flash a few times depending on the attery state, up to 4 flashes or a eep to show attery

change is needed. With switch 3 on, Manual Flush should alternately open and close the valve. If

no response, check that wires and connector are correctly connected and have not een damaged.

Disconnect attery then reconnect, ensuring oth pins are connected and that red wire goes to "+".

) Press the Manual Flush utton (see facing page). It opens or closes the valve on each press.

Ensure that switch 3 is switched ON (Away from edge of ox) otherwise Manual Flush is disa led.

The red light flashes each time the unit tries to open the valve using Manual Flush, to test for

reversed wires. If the red light flashes as the valve closes, the lue and rown wires are reversed.

c) Is the valve fitted the correct way round ? On the Asco valve, the inlet end is stamped with the

word 'IN'. A reversed valve will usually allow water to flow all the time mains pressure is applied.

d) Remove the coil retaining clip. Slide off the coil assembly. If the valve stays open, the pro lem

is inside the valve ody. Dismantle and inspect as per (e) elow.

e) If the valve was previously working or it appears to e trying to close, debris or scale inside the

valve is a likely cause. Dismantle the valve, taking careful note of order of assem ly and direction of

the spring. Clean moving parts and strainer (soaking in lemon juice removes scale well). The plunger

should move freely against the spring pressure. Inspect the orifice and seal for dirt or damage. The

orifice should e a smooth circle; in areas with very hard, a rasive water, the orifice may ecome

pitted, causing leakage through the valve, needing valve replacement. See (2) on front page.

f) Wiring fault ? Check valve and controller connectors for loose or shorting wires. Check connector

polarity :- Brown +2 goes to pin 2 on the Asco valve. Check attery connector on oth pins.

PROBLEM - VALVE WILL NOT OPEN

a) Slacken compression nuts on each side of the valve to test that there is water pressure on the

Inlet side and that there is no lockage after the valve (e.g. a stuck washer on a cistern cock.)

) See a, ,e and f of previous pro lem.

PROBLEM - CISTERN ALWAYS SEEMS TO BE EMPTY / UNIT NOT WORKING

The cistern should e empty etween flushes. When a fill cycle occurs, the cistern should fill and

flush and the valve should turn off during the flush, hence the cistern will usually remain empty. With

a typical fill time of 3 minutes and a cycle time of 30 minutes the unit will appear to e 'not working'

for 27 out of every 30 minutes even at usy times, so the chance of seeing any activity on a spot

check is small. If in dou t see first pro lem (facing page).

PROBLEM - FILLING TIME TOO SHORT OR LONG

Set the filling time again, carefully following the fitting instructions. Remem er to start the self-

timed fill with the cistern empty, i.e. having just flushed. The fill time is accurate to 1 second or so

due to the quartz crystal used for timing. Any fill time up to 30 minutes may e set. If a 20 minute

cycle is selected and fill time is longer than 20 minutes, the valve will open immediately on detection

and stay open for the set fill time. If a fill time longer than 30 minutes is needed, then either there is

a restriction to the flow or the water pressure is too low. As supplied Springwell Smartflush can work

with a 20 litre cistern fed with as little as a 1 metre head. A low pressure valve is availa le for more

extreme conditions.

Fluctuations in mains water pressure may cause the fill time to e a little too short or too long, ut

this will only result in a missed or dou le flush occasionally. Minor fluctuations are compensated for

ecause the unit will remain "in step" as long as the valve turns off during the emptying of the

cistern, ecause the cistern always empties to the same level.

PROBLEM - CONTROL UNIT IS CHIRPING

If the unit starts to sometimes make a chirping noise, then the attery is overdue for replacement. At

first, on detection of movement, if the attery is low the unit will sound a dou le chirp ut will still try

to open the valve as normal. Pressing the Manual Flush utton will sound the dou le chirp then

flash the red light and if switch 3 is on, will open the valve.

Once the attery is too weak to open the valve, the unit will sound a dou le chirp when movement is

detected, limited to once per minute. The unit does not chirp unless movement is detected or the

Manual Flush utton is pressed.

Other Spring Well Plumbing Product manuals

Popular Plumbing Product manuals by other brands

Grohe

Grohe Taron manual

PEERLESS

PEERLESS P18437 instruction manual

Glacier bay

Glacier bay HD67596W-7001 Installation and care guide

Symmons

Symmons Allura Series Installation and service instructions

Grundfos

Grundfos Sololift2 CWC-3 Installation and operating instructions

Hansa

Hansa MATRIX 4404 0000 Mounting and operating instructions

Armitage Shanks

Armitage Shanks Sensorflow 21 installation instructions

TLV

TLV PowerDyne P46SRN instruction manual

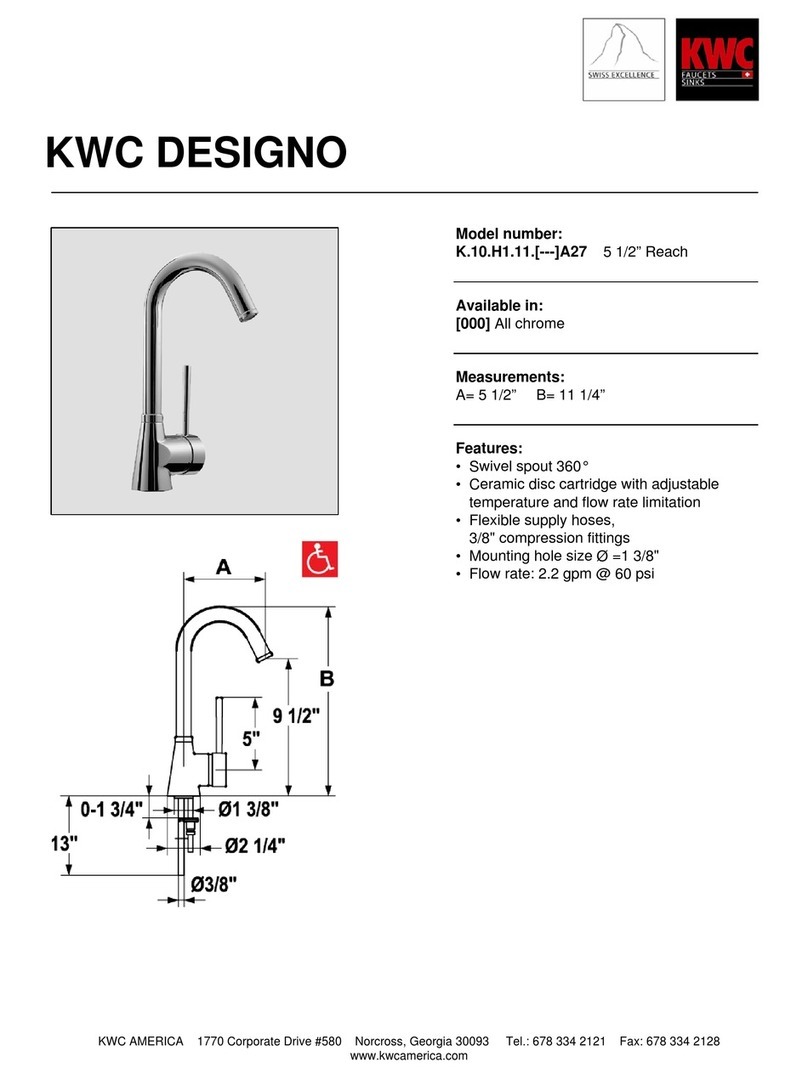

KWC

KWC DESIGNO K.10.H1.11 Specification sheet

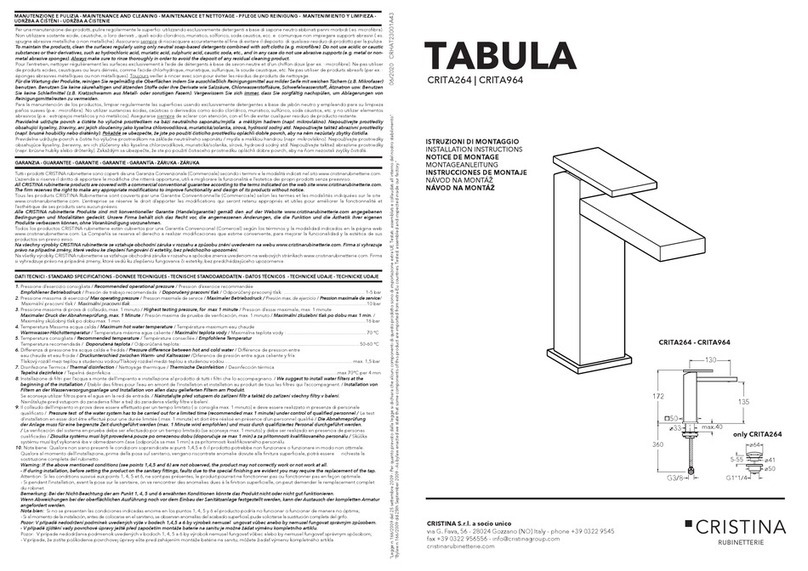

CRISTINA

CRISTINA TABULA CRITA264 installation instructions

ProFlo

ProFlo PFTS39CP installation instructions

Felton

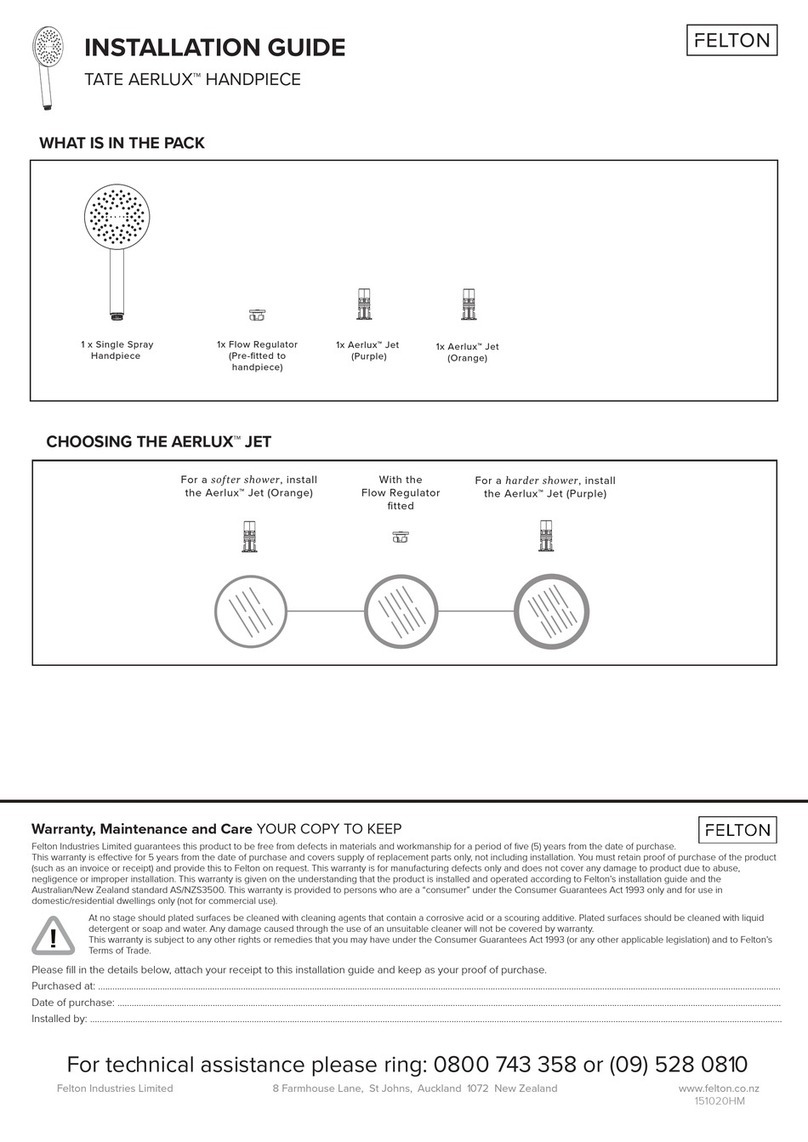

Felton TATE AERLUX installation guide