Spring Well SMARTFLUSH SF103B User manual

Technical Support

If you have any further technical queries, please contact technical support on 01924-420029.

PLEASE DO NOT RETURN ANY ITEM WITHOUT AUTHORISATION

PLEASE LEAVE THESE INSTRUCTIONS WITH CUSTOMER

-------------------------------------------------------------------------------------------------------------------------------------

Guarantee

This product is guaranteed from date of purchase to e free from manufacturing defects for a period of 1

year (Extended warranty availa le) with the following conditions :

1) The product has een properly installed as per instructions.

2) Damage due to water ingress to controller, de ris from water supply, vandalism or misuse are not

included. Statutory rights are not affected.

Service : Woodroyd Electronic Services Ltd, 52 Ash ourne Drive, Cleckheaton BD19 2HZ

_______________________________________________________________________________

Environmental information

This product may contain sus stances that can e hazardous to the environment if not disposed of

properly. Electrical and electronic equipment should not e dumped with general household waste ut

must e separately collected for proper treatment and recovery. The crossed-out in sym ol is a

reminder of the need to dispose of the product properly at end of life; in this way you will assist in the

recovery, recycling and re-use of many of the materials in this product and help to reduce the amount of

electrical and electronic waste ending up in landfill and to improve quality of life y preventing the release

of potentially hazardous su stances into the environment. Please contact us for information on disposal

arrangements. Where possi le please recycle your packaging.

Producer registration num er WEE/DB0002ZR

_________________________________________________________________________________

Carefully designed and distri uted y:

SPRINGWELL MICROELECTRONICS LTD, 197 Raikes Lane, Birstall, Batley, West Yorkshire WF17 9QF

The manufacturer reserves the right due to continuous development to change specifications without notice

Tel: 01924 420029 Fax: 0870 7062353 e-mail: sal[email protected]

www.springwellmicro.co.uk

Producer registration num er WEE/DB0002ZR

sf2insv2.6.odt

SMARTFLUSH SF103B F TT NG NSTRUCT ONS

Smartflush ensures good hygiene while minimising water usage in Gents' urinals.

Pack contains: sensing/control unit with attery; valve, assem led ca le; clips, screws, wallplugs.

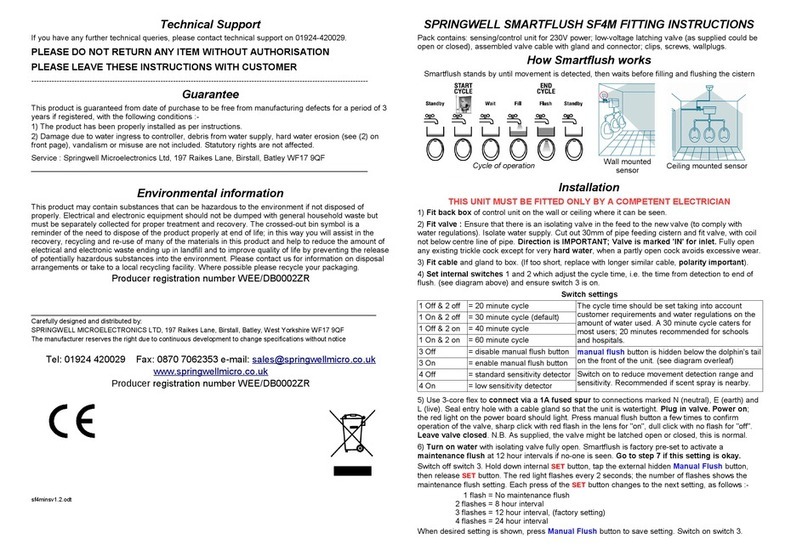

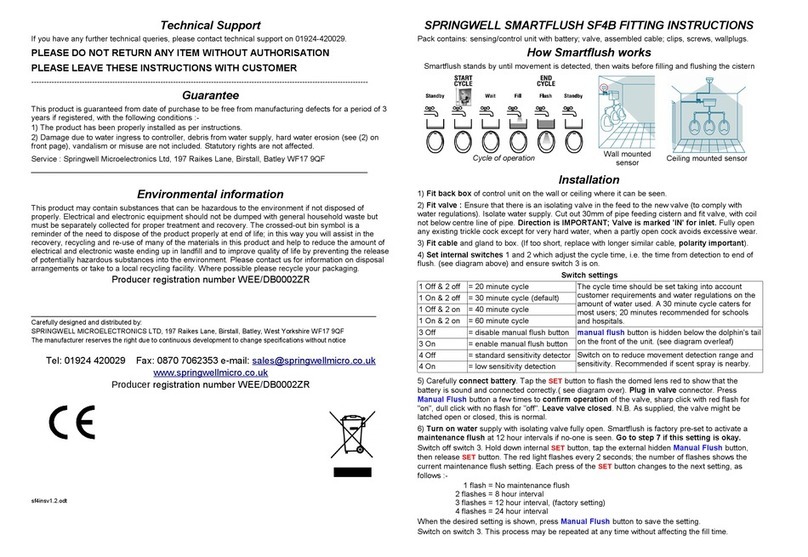

How Smartflush works

Smartflush stands y until movement is detected, then waits efore filling and flushing the cistern

nstallation

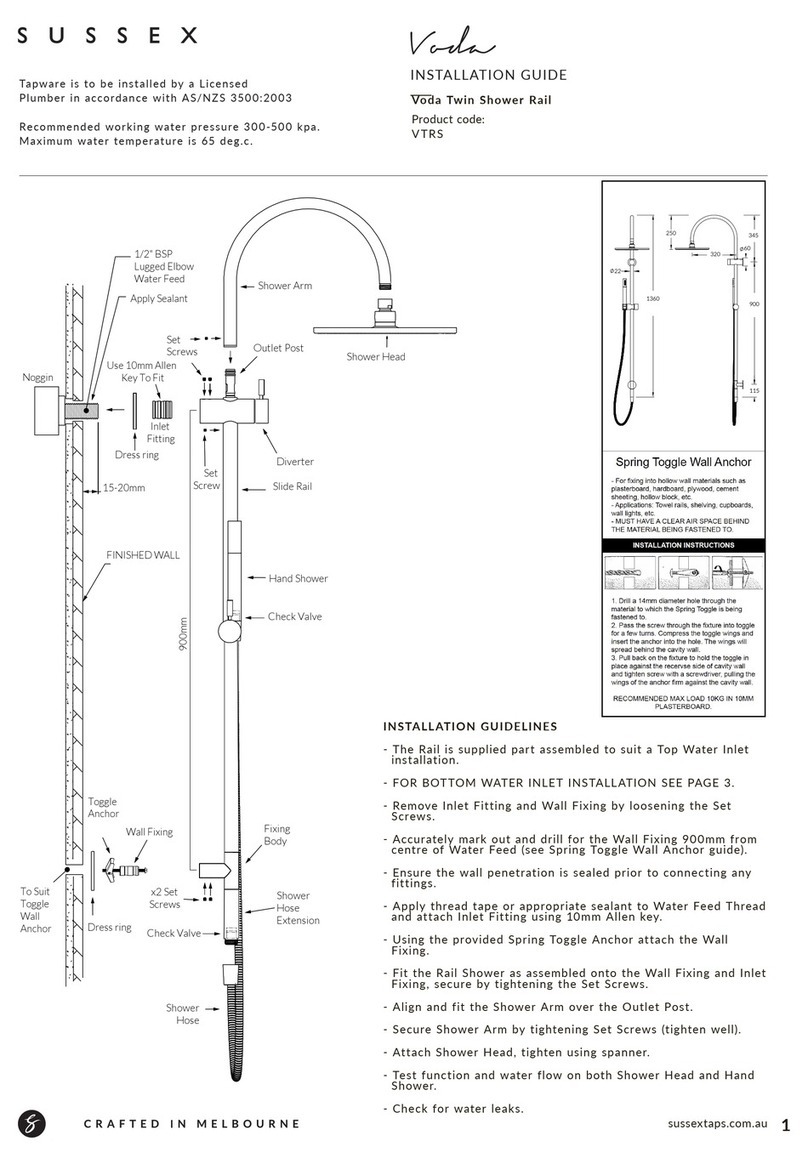

1) Fit back box of control unit on the wall or ceiling where it can e seen.

2) Turn off water supply. Fully open (or remove) any existing trickle cock. Ensure that there is an

isolating valve in the feed to the new valve (to comply with water yelaws). Flush pipe of any de ris.

Cut out 30mm of pipe feeding cistern and fit valv .

NB! It is very important to fit valve the right way round, the Asco valve is marked 'IN' for inlet.

3) Fit cabl and gland to ox. (If too short, replace with longer 1mm2 ca le, polarity important).

4) S t int rnal switch s 1 and 2 which adjust the cycle time, i.e. the time from detection to end of

flush. (see diagram a ove) and ensure switch 3 is on.

Switch s ttings

1 Off & 2 off = 20 minute cycle

1 On & 2 off = 30 minute cycle

1 Off & 2 on = 40 minute cycle

1 On & 2 on = 60 minute cycle

The cycle time should e set taking into account

customer requirements and water yelaws on the

amount of water used. A 30 minute cycle caters for

most users.

3 Off = disa le manual flush utton

3 On = ena le manual flush utton

4 (if fitted) = not used

manual flush button is hidden in the middle of the

dolphin's ody on the front of the unit. (see diagram

overleaf)

5) Carefully conn ct batt ry. A short press of the "SET" utton will flash red in the domed lens to

show that the attery is sound and connected correctly.( see diagram over) Plug in valve connector.

Press manual flush utton a few times to confirm operation of the valve, sharp click with red flash for

"on", dull click with no flash for "off". L av valv switch d off. N.B. As supplied, the valve might e

latched open or closed, this is normal.

6) Turn on wat r supply, isolating valve/stopcock fully open. Smartflush is factory pre-set to activate

a maint nanc flush at 12 hour intervals if no-one is seen. Go to st p 7 if this s tting is okay.

Hold down internal "SET" utton, press and release the external hidden "MANUAL FLUSH" utton,

then release "SET" utton. The red light flashes every 2 seconds; the num er of flashes shows the

current maintenance flush setting. Each press of "SET" utton changes to the next setting, as

follows :-

1 flash = No maintenance flush

2 flashes = 8 hour interval

3 flashes = 12 hour interval, (factory setting)

4 flashes = 24 hour interval

When desired setting is shown, press "MANUAL FLUSH" utton to save setting and close the valve.

Cycle of operation Ceiling mounted sensor

Wall mounted

sensor

7) Start a cist rn fill - hold down internal "SET" utton, press and release the external hidden "MANUAL

FLUSH" utton, then release "SET" utton. Ignore flashing light. Check for a reasona le flow of water

and adjust with trickle cock on pipe end if required. If flow noise is a pro lem, e.g. next to sleeping

quarters or classrooms, reduce the flow y means of a trickle cock.

As soon as th flush starts, pr ss and r l as the "MANUAL FLUSH" utton to switch off the valve.

8) When the cistern has emptied, again hold the "SET" utton, press/ release "MANUAL FLUSH" to

start fill, release the set utton. The light in the domed lens flashes every 2 seconds to show setting in

progress. Wait until cistern is part way through flushing th n pr ss and r l as the "MANUAL

FLUSH" utton to switch off the valve. The cistern fill time is now memorised and will e used every time

a flush is started whether automatically or via manual flush. Maximum fill time is 31 minutes.

9) S t switch 3 as required (see 4 overleaf). Inspect to ensure ox is water-tight and final check all

screws, gland and connections for security. Screw controller unit lid onto ox.

10) Fill in your part of warranty sheet and leave it with this leaflet with the owner/manager.

Explain section 4 (switch settings) to the person in charge of uilding maintenance.

SWITCHES/CONNECTIONS/INDICATOR

Multipl cist rns

2 or 3 cisterns with a common feed may e controlled from a single controller and valve. In this case,

adjust outlet cocks feeding each cistern so that they have roughly equal fill times (during step 6), then set

up the fill time using whichever cistern takes longest to fill (step 7). Contact technical support if further

advice required.

R gular Maint nanc

Every 2 or 3 years depending on water quality, dismantle and if necessary clean the valve and internal

strainer, then reassem le and operate manual flush to confirm correct operation. It is wise to change the

attery at this time rather than waiting for failure to operate (typically 3-5 years). Ensure that the view

from the controller is not o structed and that the domed lens has not een damaged or painted. Test PIR

detector as elow.

Smartflush nstallation Troubleshooting Guide

All units are fully tested prior to despatch. If there is an apparent fault please check the following :-

PROBLEM - UNIT WORKS ON MANUAL FLUSH BUT DOES NOT APPEAR TO SEE ANYONE

T st th infra-r d d t ctor (PIR) as follows :-

1) Ensure valve is turned off. (If necessary, use manual flush utton with switch 3 on).

2) Pr ss and hold SET button, watching the red light uilt into the domed lens. The light should flash

once to confirm that the attery is good, then flash 1 second later to show that test mode has een

entered. Release utton.

3) Watch the light, which flashes when slow movement is detected. (Can take up to 1 second ).

4) Exit test mode y a short press of the SET utton or the manual flush utton if ena led. (If left in test

mode, unit automatically reverts to normal operation after 16 minutes to avoid call- acks).

5) At end of test return switch 3 to desired position.

N.B. If the a ove test works and manual flush also works and fills for the correct time, then the unit will

work correctly in normal use. The controller normally giv s no indication that it has seen anyone,

except that the red light flashes just once at the start of each timing cycle. The unit can e made ready

for a new cycle y opening and closing the valve using manual flush, then waiting for 10 seconds.

PROBLEM - VALVE WILL NOT TURN OFF

N.B. Valve has a magnetic latch so may e left open or shut while disconnected.

a) T st batt ry and connections y a short press of the SET utton. Red light should flash once. If

no response, check wires or connector are correctly connected and have not een damaged.

Disconnect attery then reconnect, ensuring oth pins are connected and that red wire goes to "+".

) Pr ss th manual flush utton (see facing page). It opens or closes the valve on each press.

Ensure that switch 3 is switched ON (Away from edge of ox) otherwise manual flush is disa led.

The red light flashes each time the unit tries to open the valve using manual flush, to test for

reversed wires.

c) Is th valv fitt d th corr ct way round ? On the Asco valve, the inlet end is stamped with the

word 'IN'. A reversed valve will usually allow water to flow all the time mains pressure is applied.

d) Remove coil retaining clip. Slid off coil ass mbly. If valve stays open, the pro lem is inside the

valve ody. Dismantle and inspect as per (e) elow.

e) If the valve was previously working or it appears to e trying to close, d bris insid th valv is

the most likely cause. Dismantle the value, taking careful note of order of assem ly and direction of

spring. Clean moving parts and strainer. The plunger should move freely against the spring

pressure. Inspect orifice and seal for dirt/damage.

f) Wiring fault ? Check valve connector and controller connector for loose or shorting wires. Check

connector polarity :- Brown +2 goes to pin 2 on the Asco valve. Check attery connector on oth

pins.

g) Controll r or valv faulty ? Most pro lems are related to installation; controller and valve faults

are rare. The valve can e tested with a 4.5 volt attery (as used in some pedal cycle lights) or a

PP3. Touch the valve wires BRIEFLY onto the attery; rown positive for on, lue positive to turn off.

The valve state is held magnetically so no power is consumed while the valve is in either state.

PROBLEM - VALVE WILL NOT TURN ON

a) Slack n compr ssion nuts on each side of the valve to ensure that there is water pressure on

the Inlet side and that there is no lockage after the valve (e.g. a stuck washer on a cistern cock.)

) See a, ,e,f and g of previous pro lem.

PROBLEM - CISTERN ALWAYS SEEMS TO BE EMPTY / UNIT NOT WORKING

The cistern should e empty etween flushes. When a fill cycle occurs, the cistern should fill and

flush and the valve should turn off during the flush, hence the cistern will usually remain empty. With

a typical fill time of 3 minutes and a cycle time of 30 minutes the unit will appear to e 'not working'

for 27 out of every 30 minutes even at usy times, so the chance of seeing any activity on a spot

check is remote. If in dou t see first pro lem (facing page).

PROBLEM - FILLING TIME TOO SHORT / LONG

S t filling tim again, carefully following the fitting instructions. Remem er to start the self-timed fill

with the cistern empty, i.e. having just flushed. The fill time is always accurate to 1 second or so due

to the quartz crystal used. Any fill time up to 30 minutes may e set. If a 20 minute cycle is selected

and fill time is longer than 20 minutes, the unit will automatically compensate, so no pro lems will

arise. If a fill time of longer than 30 minutes is needed, then either there is a restriction to the flow or

the water pressure is too low. As supplied Smartflush can work with a 4 gallon cistern fed with as

little as a 1 metre head. A low pressure valve is availa le for more extreme conditions, or it may e

possi le to switch to a mains pressure rather than tank feed. (Before doing so check local

regulations) .

Fluctuations in mains pressure may cause the fill time to e too short or too long, ut this will only

result in a missed or dou le flush occasionally. Minor fluctuations are compensated for y the fact

that the unit will remain "in step" as long as the valve turns off sometime during the emptying of the

cistern, ecause the cistern always empties to the same level.

Manual flush T st/s t indicator

Other Spring Well Plumbing Product manuals

Popular Plumbing Product manuals by other brands

Hans Grohe

Hans Grohe Focus 04506 1 Series Installation/User Instructions/Warranty

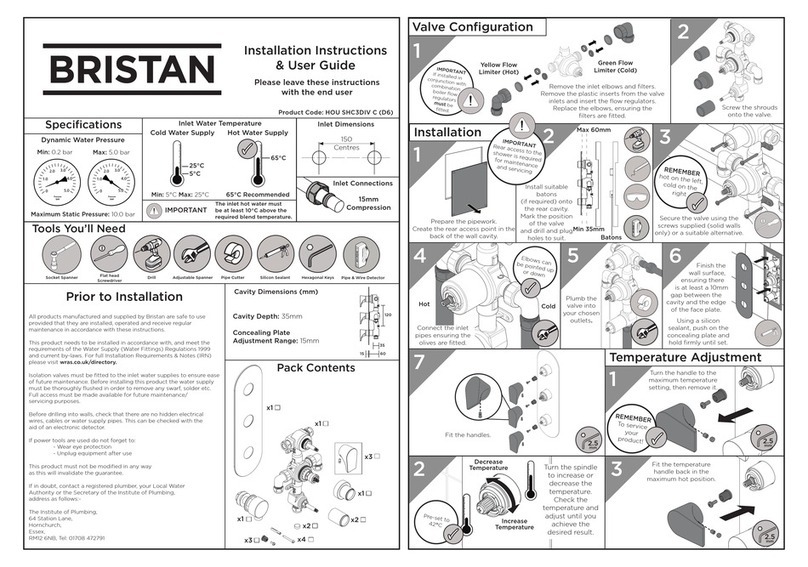

Bristan

Bristan HOU SHC3DIV C Installation instructions & user guide

Taymor

Taymor LUNA 06-8728S installation instructions

Kohler

Kohler K-5024-T quick start guide

Grohe

Grohe 36 264 manual

DURAVIT

DURAVIT WT4210 0100 Instructions for mounting and use

Roca

Roca AQUAKIT COMFORT-S installation instructions

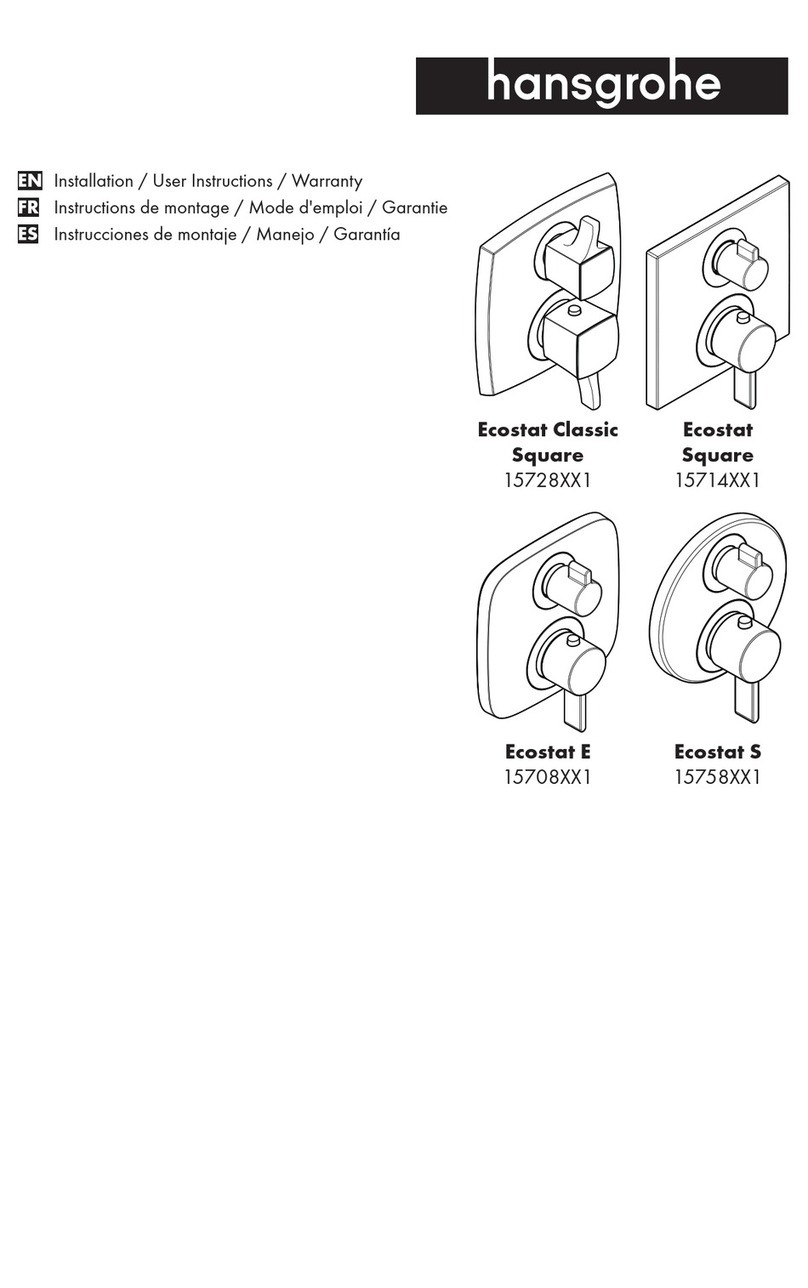

Hans Grohe

Hans Grohe Ecostat Classic Square 15728 1 Series Installation/User Instructions/Warranty

Sterling Plumbing

Sterling Plumbing WINDHAM 402015 Specifications

Galvin Specialised

Galvin Specialised GalvinCare 50197 Product installation guideline

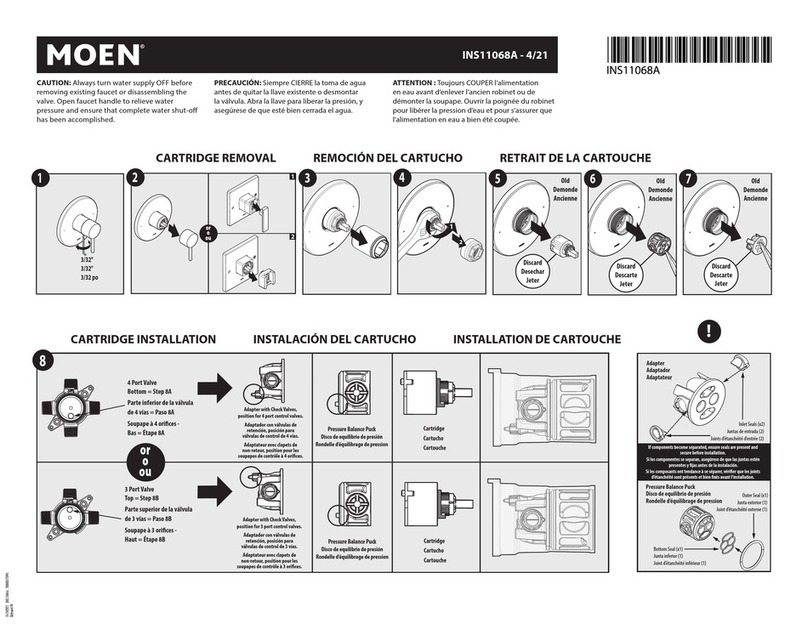

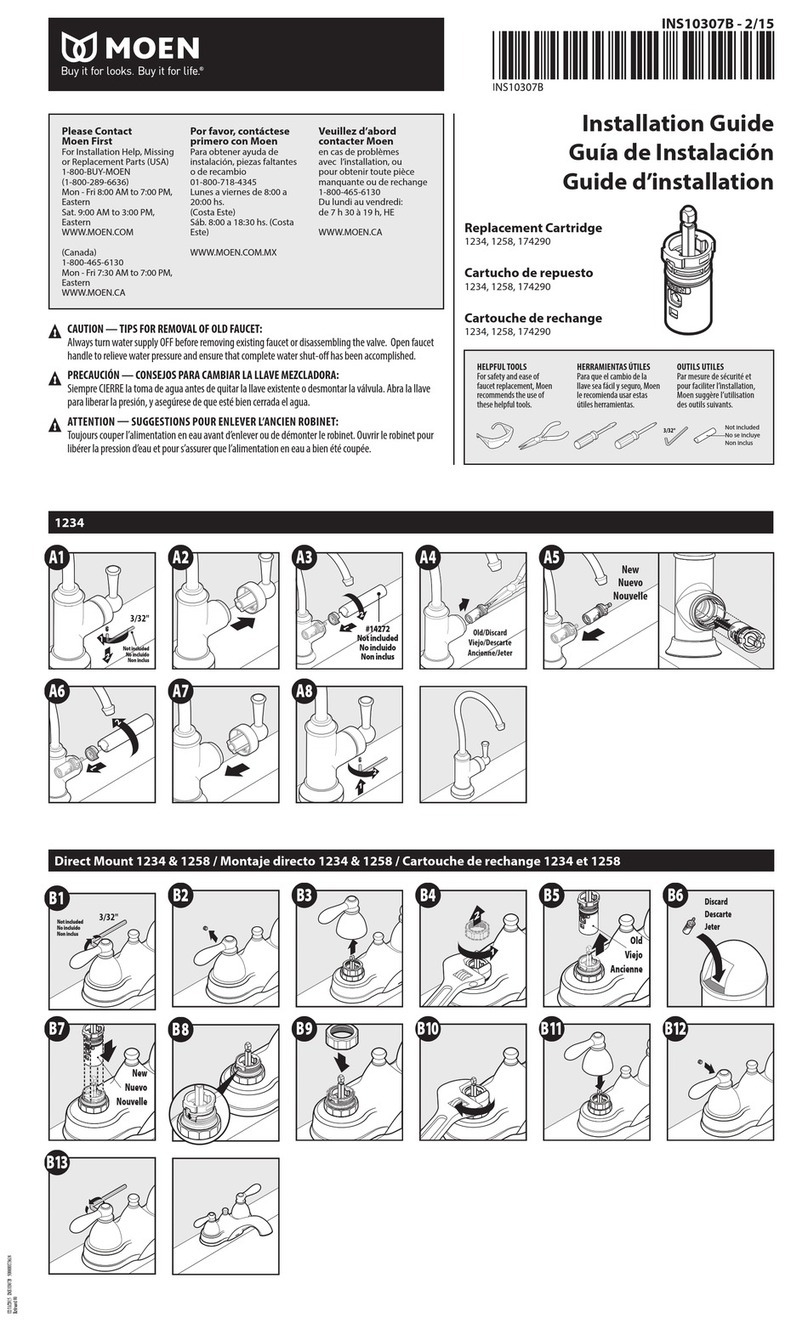

Moen

Moen 87435 Series manual

Olympia

Olympia L-7240 Installation and Maintenance