Spruce AIRaider Manual

Doc. No. IN031

Rev. C

P ge 1 of 19

Installation &

Operation Manual

3 S ber W y

W rd Hill, MA 01835

All Residential and

Small System Models

(Except EZ95)

Doc. No. IN031

Rev. C

P ge 2 of 19

1. PRE-INSTALLATION

1.1. Safety Maers

1.2. Water Flow Requirements

1.3. Unpacking and Locating System Components

1.3.1. Unpack All System Components

1.3.2. Locate All Components

1.4. Use Qualified Tec nicians

1.5. Full Water Test

2. INSTALLATION INSTRUCTIONS

2.1. System Location

2.2. Readying t e AIRaiderTM for Installation

2.3. Plumbing Hook-up

2.4. Electrical Hook-up

2.5. Vent Line Installation

2.6 Air Filter

2.6.1 Remote Air Intake

2.7. System Start-up

2.8. System C eck

3. RETESTING

4. MAINTENANCE

4.1. Six-Mont Service (recommended)

4.2. Annual Service (required)

5. TROUBLE SHOOTING

LIMITED WARRANTY

Fi ure 1 – Typical System (433 & 321)

Fi ure 2 – Bypass/Solenoid Assembly

Fi ure 3 – Diagram of Installed System

Fi ure 4 – Water Connections

Fi ure 5 – Pressure Gauge and Pressure Tank

Fi ure 6 – 433 Wiring Diagram

Fi ure 7 – 321 Wiring Diagram

Fi ure 8 – Vent Line Connection

Fi ure 9 – Vent Line Installation (2 inc )

Fi ure 10 – Vent Line Intsallation (3 inc )

Fi ure 11 – Air Intake Connection

Fi ure 12 – Air Filter

Fi ure 13 – Installed AIRaiderTM

Table of Contents

Table of Fi ures

3

3

4

5

5

5

5

5

7

7

7

9

10

13

14

14

14

15

16

16

16

17

18

19

6

7

8

9

9

11

12

13

13

13

14

14

14

Doc. No. IN031

Rev. C

P ge 3 of 19

1. Pre-Installation

T e AIRaiderTM Systems are diffused bubble aeration systems for t e removal of radon and ot er VOCs from

residential and municipal water supplies. T is installation/operation manual is designed to guide professionals

t roug t e safe and proper installation of t e AIRaiderTM Systems.

Before beginning t e installation of t e AIRaiderTM System, t ere are 5 items to be considered.

T ey are:

1. Safety

2. Installation site requirements

3. Inspection of System components

4. Qualified Tec nicians are necessary

5. Knowledge of all contaminants in t e water

1.1. Safety Maers

Safety is t e most important step in t e installation process. Never perform any step of t e installation t at

you are not qualified to perform (i.e. electrical or plumbing ook up). It is important t at you read t roug

t e entire manual prior to beginning t e installation. W en performing t e installation, work slowly and

deliberately. Follow all instructions carefully and never take s ortcuts. Our team of tec nicians are available

to answer your questions at 800-355-0901.

WORK SAFELY!

Doc. No. IN031

Rev. C

P ge 4 of 19

1.2. Water Flow Requirements

T e standard residential AIRaiderTM Systems are designed for use wit water flows up to 20 gallons per

minute(GPM).* T e system s ould be installed wit an outflow ball valve. If ig er/lower system outflow is

needed, open/close t e ball valve by t e amount necessary to balance t e system. T e well pump output must

produce at least 1 GPM more t an t eoutput of t e AIRaiderTM (i.e. well output = 8 GPM ; AIRaiderTM outflow

seing = 7 GPM) for proper system performance. If t e well pump output is less t an t e system output t e

AIRaiderTM will run dry and possible damage may occur. To preveent t is from occuring t e water flow rate

must bedetermined before t e system is installed.

*S me AIRaiderTM Systems are n t rec mmended f r high fl w residential pr perties. Repressurizati n systems (except f r the

AIRaiderTMEZ95are s ld separately). Pr per repressurizati n system sizing is required t meet water fl w needs. C nsult manufacturer

if assistance is needed f r system selecti n.

In order to determine available water flow rate t e following are needed:

·Garden Hose

·Five Gallon Bucket

·A Stop Watc or Watc wit a Second Hand

Or

·A Water Flow Meter

Household water use must be discontinued durin the followin flow rate test.

Mid-Ran e Flow Rate Test:

1. Aac garden ose to t e drain connection on t e base of t e well pressure tank.

2. Open t e drain valve and run water for 15 minutes.

3. Aer 15 minutes, c eck t e pressure gauge on t e well system. Adjust t e drain valve (open or close) as

needed to maintain t e required running system pressure (constant pressure on gauge) wit t e well pump

running continuously.

4. Run for 5 minutes w ile ensuring t at t e pressure is not fluctuating.

5. Run water from t e ose into a five gallon bucket. Using a stop watc , time ow many seconds it takes to fill

t e bucket (X sec.).

6. Determine t e GPM by dividing 60 seconds by t e number of seconds it took to fill t e bucket (X sec.).

Multiply t e answer by 5 gallons. T is gives you t e GPM. GPM = ( 60 / X ) x 5

7. Repeat steps 5 and 6 and average t e 2 numbers. T e answer is t e well pump output in gallons per minute.

It is recommended t at t is number be indelibly recorded in an obvious location, toget er wit t e date of test,

as it will be required w en seing t e AIRaiderTM System and may be required for future troubles ooting of

t e well pump system or t e AIRaiderTM System.

Doc. No. IN031

Rev. C

P ge 5 of 19

1.3. Unpackin and Locatin System Components

1.3.1. Unpack All System Components

Remove all packing material and discard appropriately away from t e work area.

1.3.2. Locate All Components

C eck to ensure all components are intact and included in s ipment (See Figures 5 and 8).

Included Component List (may vary wit order)

·Tank Assembly

·Control Panel* and Float Switc es

·Jet Pump and Bladder Tank assembly**

·Brass – Bypass/Solenoid assembly, pump brass, and tank brass***

·Installation Kit – oses, ose clamps, pressure gauge, manual, etc.

* M dels 211 and 321 d n t c me equipped with a c ntr l panel

** Pump and Tank packages are s ld separately and will vary with the rder.

*** Standard systems are equipped f r a ¾” plumbing c nnecti n. Please specify plumbing c nnecti n requirements when rdering.

1.4. Use Qualified Technicians

A Licensed Plumber, Electrician, Contractor and/or Certified Water Treatment Specialist may be required to

install t e AIRaiderTM System in accordance wit t e installation instructions. All wiring must be performed in

accordance wit t e National Fire Protection Association’s (NFPA)”National Electrical Code, Standard #70”-

current edition-for all commercial and industrial work. All wiring must be performed by a qualified and

licensed electrician. C eck your Local and State Code and Licensing requirements. Failure to follow t e

instructions may lead to poor system performance and/or possible system damage.

The Installation must comply with all applicable Local and State Codes

and NFPA National Electrical Code, Standard #70.

1.5. Full Water Test

A full Water Sample Analysis must be performed to determine t e quality of t e water t at requires treatment.

In many water supplies, contaminants ot er t an Radon are present and may need to be pre-treated in order

for t e AIRaiderTM to work properly. T e AIRaiderTM System is only effective for t e removal of Radon and

some ot er VOCs. T e Aeration Process employed by t e AIRaiderTM System and ot er Radon removal

systems can worsen problems due to iron or manganese contaminants in t e water supply. For optimal

removal of Radon or ot er VOCs, ot er contaminants suc as iron, or manganese must be removed before t e

water supply enters t e AIRaiderTM System.

Failure to remove other contaminants can reduce the effectiveness of the system

and may result in system dama e.

Doc. No. IN031

Rev. C

P ge 6 of 19

2. Installation Instructions

OVERVIEW

Now you are ready to begin t e installation process. T e eig t steps to properly install t e AIRaiderTM System

are listed below. Read all components of eac step prior to beginning t e actual installation.

1. System Location

2. Readying t e System for Installation

3. Plumbing Hook Up

4. Electrical Hook Up

5. Vent Line Installation

6. Remote Air Intake Installation

7. System Start Up

8. System C eck

SAFETY TIP: Do Not undertake any step for

which you are Not Qualified

AIRaider 433 AIRaider 321

Fi ure 1

Typical System

(Repressurization systems not s own. Sold separately.)

Doc. No. IN031

Rev. C

P ge 7 of 19

2.1. System Location

W en selecting t e location for t e AIRaiderTM System, five factors s ould be among t ose considered:

1. System Plumbing Hook-up. Find a location t at will minimize t e amount of plumbing necessary, t is is

typically in proximity to t e well tank.

2. Electrical Hook-up. Keep in mind t e need for accessibility to a 20 Amp dedicated 120VAC power supply.

3. Ex aust Line Venting. T e location of t e system must allow for outside venting of t e system ex aust above

t e eave of t e structure. T e Manufacturer requires t at t e ex aust pipe pitc back toward t e system

(see Section 2.6).

4. Remote Air Intake. If t e system must be installed in an area wit questionable air quality (i.e. furnace room,

garage, crawl space) t en ducting from t e air intake to a remote location aving good air quality may be required.

5. System must be level. T e system s ould not be located on a significant slope as t is may impede

system performance.

Place t e system in t e location acceptable to customer t at maximizes t e ease of installation. All Local and

State codes as well as any applicable AARST, EPA and/or State Radon standards must be ad ered to w en

locating t e AIRaiderTM (i.e. away from electrical panel, furnace, exits, etc.).

2.2. Readyin the AIRaiderTM for Installation (see Figure 3 for diagram of installed system)

1. Aac bypass assembly to jet pump (See Figure 2).*

2. Aac pump brass assembly to pump intake.

3. Aac all oses and ose clamps as per plumbing

diagram (see Figure 4).* All ose clamps must be

tig tened to prevent leakage. Never substitute ose

provided wit out consulting manufacturer. Usage of

t e wrong ose will result in water leakage and

possible system damage.

* Pr cedures may vary with different

repressurizati n systems.

Fi ure 2

Bypass/Solenoid Assembly

(Grundfos MQ3-45 s own)

Byp ss ssembly

Pump br ss

Doc. No. IN031

Rev. C

P ge 8 of 19

Fi ure 3

Diagram of Installed System

(sold separately)

PATENTED AERATION PROCESS

UNTREATED WATER

FROM WELL

(

EXISTING TANK

)

GRUNDFOS

MQ3-45*

TREATED WATER

SUPPLY

MOUNTING

BRACKET

AIR ider 433

Doc. No. IN031

Rev. C

P ge 9 of 19

2.3. Plumbin Hook-up

All Plumbin should be performed in accordance with Local and State Codes by a Qualified

and Licensed Plumber.

1. S ut off water main valve located aer t e pressure tank.

2. Drain water line.

3. Plumb system into water line aer t e pressure tank and all ot er water treatment equipment.

4. Plumb water line from t e existing pressure tank into t e bypass opening labelled “Water In”

(See Figure 4). Bypass pictured may vary fr m bypass supplied.

5. Plumb water line to ouse into t e bypass opening labelled “Water Out” (See Figure 4).

6. Install pressure gauge on jet pump assembly (See Figure 5).

7. Install 2.1 gallon pressure tank (See Figure 5).

8. Making sure t e Bypass is in t e correct bypass configuration, slowly open t e water main valve and

c eck for leaks.

9. Slowly c ange bypass to t e “service”configuration (in a position w ere water flows t roug t e aeration

system and t en into t e ouse). Prime jet pump as per pump manufacturer’s instructions.

Fi ure 4

Water Connections

Fi ure 5

Pressure Gauge and Pressure Tank

Out to house (w ter out)

In from well

(w ter in)

Out to solenoids

In from AIR ider

Pressure G uge Pressure T nk

Doc. No. IN031

Rev. C

P ge 10 of 19

2.4. Electrical Hook-up

All Electrical Work should be performed in accordance with Local and State Codes, and NFPA National

Electrical Code, Standard #70 by a Qualified and Licensed Electrician.

WARNING: Never perform electrical work while standin in water.

Do not aempt wirin on a live circuit.

WARNING: Power Supply Volta e must match that marked on the System

Name Plate. Improper wirin may result in system dama e.

1. Turn main power switc , located on t e AIRaiderTM, to t e “Off” position.

2. Connect t e Jet Pump power cord to t e Jet Pump. Note t e Jet Pump power cord from t e AIRaiderTM is

provided wit an electrical receptacle. T e Jet Pump may be connected eit er by connecting a suitable

power lead wit plug and plugging into t e receptacle or by removing t e receptacle from t e Jet Pump

power cord and connecting t e power cord directly to t e pump. Follow wiring instructions provided by t e

pump manufacturer.

Warnin : Never remove the Receptacle from the Jet Pump Power Cord without connectin the wires thus

exposed to the jet pump, inside the jet pump electricalenclosure. Always secure the Jet Pump Enclosure

Cover aer makin electrical connections.

3. Make sure all connections in t e control panel are tig t.

4. Bring in power to t e control panel using t e ole provided, eit er an appropriate strain relief bus ing, or

electrical conduit fiing(s), wit correctly rated electrical wire or cable must be used in accordance wit all

applicable Electrical Codes.

5. Connect t e power line to t e control panel as s own in t e appropriate wiring diagram (See Figures 6 & 7).

6. Connect power line to power source.* T e required Voltage is eit er 120V or 240V and is indicated by an

“X” marked in t e c eck box next to eit er t e 120V or 240V marking on t e nameplate. Follow all code

requirements regarding wire and circuit breaker size.

* Manufacturer recommends that the AIRaiderTM System be directly wired to the panel

on a dedicated circuit.

Doc. No. IN031

Rev. C

P ge 11 of 19

Fi ure 6

AIRaiderTM 433 Wiring Diagram

Doc. No. IN031

Rev. C

P ge 12 of 19

Fi ure 7

AIRaiderTM 321 Wiring Diagram

Doc. No. IN031

Rev. C

P ge 13 of 19

2.5. Vent Line Installation

Use only 2”, 3” or 4” Schedule 40 PVC or equivalent pipe

for vent line. Follow all applicable AARST, EPA, and/or

State Standards for Radon or VOC ventin .

1. Place t e lid of t e AIRaiderTM on to t e tank lining up t e

clips wit t e clasps on t e tank. Adjust clasps so t at w en

anc ored to t e clips t e lid sits snugly on t e tank gasket.

2. Connect vent line to AIRaiderTM lid using t e enclosed

rubber coupling (See Figure 8).

3. T e vent line must be routed in a fas ion t at allows t e

system to ex aust above t e level of t e roof (See Figure 9).

NOTE: When “Freeze Up” is p ssible, a minimum pipe diameter

f 3” is rec mmended (See Figure 10).

4. T e vent line must be pitc ed back toward t e system to

prevent condensation build up.

5. Cement all fiings to ensure no leakage will occur. Be certain

to use cement t at is suitable for potable water applications.

6. Install weat er cap on top of t e vent line. T is cap s ould

not restrict air flow and must prevent rain, snow and ot er

contaminants from entering t e vent line.

Failure to install a proper vent line

may cause contamination of the

water, out assin of contaminants

into the buildin , and/or limit

system performance.

* The Manufacturer has f und that vent lines less than 250 equivalent

linear feet d n t cause a decrease in c ntaminant rem val percentages.

90° Bend = 15 Equiv. Linear Ft ; 45° Bend = 7 Equiv. Linear Ft.

Fi ure 10

Vent Line Installation (3 inc )

Fi ure 8

Vent Line Connection

Fi ure 9

Vent Line Installation (2 inc )

Doc. No. IN031

Rev. C

P ge 14 of 19

2.6 Install Air Filter (Figure 11)

1. Install air filter provided using t e PVC pipe and fiings provided.

2.6.1 Remote Air Intake (Figure 12)

If a Remote Air Intake is required because of air quality or

quantity issues then use only 1-1/4” or lar er Schedule 40 PVC

or equivalent pipe for the air intake line.

1. Connect air intake line to t e blower using t e proper

reducer coupling.

2. Run t e intake line from t e pipe connection on t e blower to t e

location selected for air intake.

N te: Manufacturer rec mmends a rubber c upling r similar means t

disc nnect the intake line fr m the bl wer.

3. Connect t e Air Filter to t e intake vent line using t e proper

reducer coupling.

Note: Any outside Air Intake must be mounted ig enoug off

t e ground to prevent t e drawing in of snow, water and ot er

contaminants. Do not locate t e Air Intake in t e vicinity of vents

from furnaces, barbecue grills, etc.

NOTE: In-Line Air Filters are available fr m the Manufacturer.

Fi ure 11

Air Intake Connection

2.7. System Start-Up

1. Remove cover and lid and pour ¼ cup of c lorine into t e first

c amber. (T is will disinfect t e system.) Replace t e lid making sure

all clasps are engaged properly.

2. C eck t at all plumbing and electrical connections ave been

properly completed.

3. Slowly c ange bypass to t e “service” configuration (in a position

w ere water flows t roug t e aeration system and t en into t e

ouse). C eck for leaks.

4. Turn power switc for AIRaiderTM to “On”. Solenoid Valves will

now open allowing water into t e system. T e aeration process will

also start. C eck for leaks.

5. Allow t e AIRaiderTM to fill wit water.

6. Once filled, prime jet pump (see pump manufacturer’s instructions).

T e normal operating range is between 40 PSI – 60 PSI.*

* Priming pr cess f r the Jet Pump and Pressure Seings may vary with

Repressurizati n System.

Figure 13

Installed AIRaiderTM

Fi ure 12

Air Filter

Doc. No. IN031

Rev. C

P ge 15 of 19

2.8 System Check

1. Run t e system t roug a couple of cycles to ensure all components are working properly.

2. T e blower timer is preset for 5 minutes delay for models 433 and 321 (211 does not ave a timer). Aer t e

solenoid valves s ut, c eck t at t e blower continues running for t e preset number of minutes delay.

3. Open t e tank and c eck t e system.

a. Remove t e tank lid.

b. Lower t e water level in t e tank by opening a bat tub tap, or similar, wit in t e residence. T e

boom float will fall wit t e water level. W en minimum water level is reac ed, t ere will be an

audible click and t e solenoids will open, allowing t e tank to start filling; t e blower s ould also

start running. T e water level must rise regardless of ow many taps are open wit in t e residence.

c. W ile t e tank is filling, li t e lower float. Water in flow s ould stop and t e blower will remain

running (until t e end of t e preset delay).

d. Release t e lower float. W ile t e tank is still filling, li t e upper float. Water in flow s ould stop

and t e blower will remain running.

e. Release t e upper float.

f. Remember to s ut off any open taps wit in t e residence.

4. Replace t e lid and secure all clasps. Wit t e System running c eck t e lid for air leaks between lid gasket

and tank. If leaks occur t e clasps s ould be adjusted until leaks are eliminated.

5. Make sure you ave properly labeled t e system wit t e necessary installer information (i.e. company

name, p one number, date installed, etc). Leave all system information wit t e ome owner.

6. T e AIRaiderTM System is now operational.

Doc. No. IN031

Rev. C

P ge 16 of 19

3. Retestin

Aer t e AIRaiderTM Installation, t e installer s ould perform anot er water analysis to ensure proper system

performance. T is sample s ould be performed one week aer t e date of installation.

Samplin Procedure:

1. Remove aerator from faucet or spigot, if applicable.

2. Run water so t at t e AIRaiderTM operates for two cycles.

3. Turn off water for 5 minutes.

4. Turn water on and proceed wit sampling as per t e laboratory instructions.

4. Maintenance

Proper maintenance of t e AIRaiderTM can prevent possible system failure and provide years of

trouble-free service.

4.1. Six-Month Service (recommended)

T e following procedures s ould be followed to maintain t e AIRaiderTM :

·C eck and/or clean t e blower air intake filter.

·C eck and/or clean any filters or strainer installed on t e inlet line to t e AIRaiderTM. In installations wit

particularly ig levels of sediment cleaning of filters may be required more frequently.

·C eck and clean inlet screen on pump.

·Using a wet/dry vac, clean sediment from boom of aeration tank if necessary.

·Clean (if necessary) tank and diffusers of all mineral build up.

·C lorinate tank and lines by pouring ¼ cup of c lorine into t e first aeration c amber.

·C eck all control panel connections and electrical components (blower, pump, timer, fuses, etc.)

for proper operation.

·C eck float switc es for proper operation.

·Inspect vent line for possible obstructions.

·Run system t roug two cycles to ensure good working order.

Doc. No. IN031

Rev. C

P ge 17 of 19

4.2. Annual Service (required)

T e following procedures s ould be followed annually to maintain t e AIRaiderTM :

·Clean solenoids and switc coil locations.

·C eck all ose connections.

·C eck and/or clean t e blower air intake filter.

·C eck and/or clean any filters or strainer installed on t e inlet line to t e AIRaiderTM.

·C eck and clean inlet screen on pump.

·Using a wet/dry vac, clean sediment from boom of aeration tank if necessary.

·Clean (if necessary) tank and diffusers of all mineral build up.

·C lorinate tank and lines by pouring ¼ cup of c lorine into t e first aeration c amber.

·C eck all control panel connections and electrical components (blower, pump, timer, fuses,etc.) for

proper operation.

·C eck float switc es for proper operation.

·Inspect vent line for possible obstructions.

·Run system t roug two cycles to ensure good working order.

·Perform Water Test.

* Every 3 years during the annual service replace all h ses.

** Every 5 years during the annual service replace the s len id valves.

Doc. No. IN031

Rev. C

P ge 18 of 19

Symptom

No water in ouse

System running dry

Water not entering system

Jet Pump not Functioning

Pressure in tank is less t an 40 PSI

Low water flow at faucets

Loud banging w en solenoids s ut

Solenoids c aer w en closing

Blower not running

Blower does not stop running

Pump is s ort cycling

Solution

· C eck power: switc in on position; circuit breaker at panel in on

position; fuses in control panel intact.

· C eck pressure in tank. If below t e proper seings, reset t e

pump as described in system start-up.

· Bypass System. If t ere is still no water, main well pump may not

be functioning.

· C eck on/off float for proper operation. Replace if necessary.

· C eck sediment strainer and/or filter (if applicable) and clean if necessary.

· Install a flow restrictor or meter down t e ball valve until t e

AIRaiderTM outflow is 1 GPM or more less t an t e water flow

entering t e system.

· C eck solenoids for proper operation. Replace if necessary.

· C eck float switc es float for proper operation. Replace if necessary.

· C eck sediment strainer and/or filter (if applicable) and clean if necessary.

· C eck fuse in control panel.

· C eck breaker at electrical panel.

· Replace jet pump if necessary.

· Reset Jet Pump as described in system start-up.

· C eck bladder tank.

· Replace jet pump and/or bladder tank as necessary.

· Clear sediment strainers on faucets.

· Clear pump inlet screen/water injector.

· Replace pump if necessary.

·Install water ammer suppressor or loop of flexible ose in pump

inlet line.

· S orten t e lengt of pipe between t e well pressure tank and

t e system.

· C eck On/Off float for proper operation. Replace if necessary.

· C eck fuses in control panel.

· Replace Timer if necessary.

· Replace Blower if necessary.

· C eck On/Off float for proper operation.

· C eck Timer Seings.

· Replace Timer Relay if necessary.

· Bladder Tank may be ruptured. Replace if necessary.

· C eck pressure switc on pump for proper operation.

5. Troubleshootin

Doc. No. IN031

Rev. C

P ge 19 of 19

Limited Warranty

Subject to applicable consumer protection legislation, Spruce Environmental Tec nologies, Inc.

(Spruce) warrants t at t e AIRaiderTM will be free from defective materials and workmans ip for t e

period of two (2) years from t e date of purc ase.

Warranty is contingent on installation in accordance wit t e instructions provided. T is warranty

does not apply w ere repairs or alterations ave been made or aempted by ot ers; or t e unit as

been abused or misused. Warranty does not include damage in s ipment unless t e damage is due

to t e negligence of Spruce. To make a claim under t ese limited warranties, you must return t e

defective item to Spruce. All ot er warranties, expressed or written are not valid. Spruce is not

responsible for installation or removal cost associated wit t is warranty. In no case is Spruce liable

beyond repair or replacement of t e defective product FOB Spruce.

SPRUCE SPECIFICALLY DISCLAIMS ANY WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF. THERE IS NO WARRANTY OF MERCHANTABILITY.

ALL OTHER WARRANTIES, EXPRESSED OR WRITTEN, ARE NOT VALID.

In order to obtain service under t is warranty, t e consumer must contact t e installer or dealer w ere t e

unit was purc ased. T e installer or dealer must t en contact Spruce directly for a Return Merc andise

Aut orization (RMA) number and s ipping information. No returns can be accepted without an

RMA. Spruce may require t e defective part(s) to be returned to place of manufacture (freig t pre-paid)

to process t e warranty claim. Defective part(s) covered under t is warranty will be replaced or

repaired at t e place of manufacture and returned to t e installer or dealer (freig t pre-paid).

In replacing or repairing parts or products, Spruce reserves t e rig t to make suc c anges in t e

details of design construction, arrangement or make materials as s all in its judgment constitute

an improvement over former practice.

Record t e following for your records:

Serial No. Date Purc ased:

3 Saber Way

P.O. Box 8244

Ward Hill, MA 01835

P one: (800) 355-0901

Fax: (978) 521-3964

E-mail: [email protected]

3 Saber Way

P.O. Box 8244

War Hill, MA 01835

Phone: (800) 355-0901

Fax: (978) 521-3964

E-mail: [email protected]

Table of contents

Popular Water Filtration System manuals by other brands

Pentair

Pentair PRF-RO Installation and maintenance manual

KENT

KENT Ace Star Mineral RO Instruction handbook

Scanomat

Scanomat TopBrewer Cleaning manual

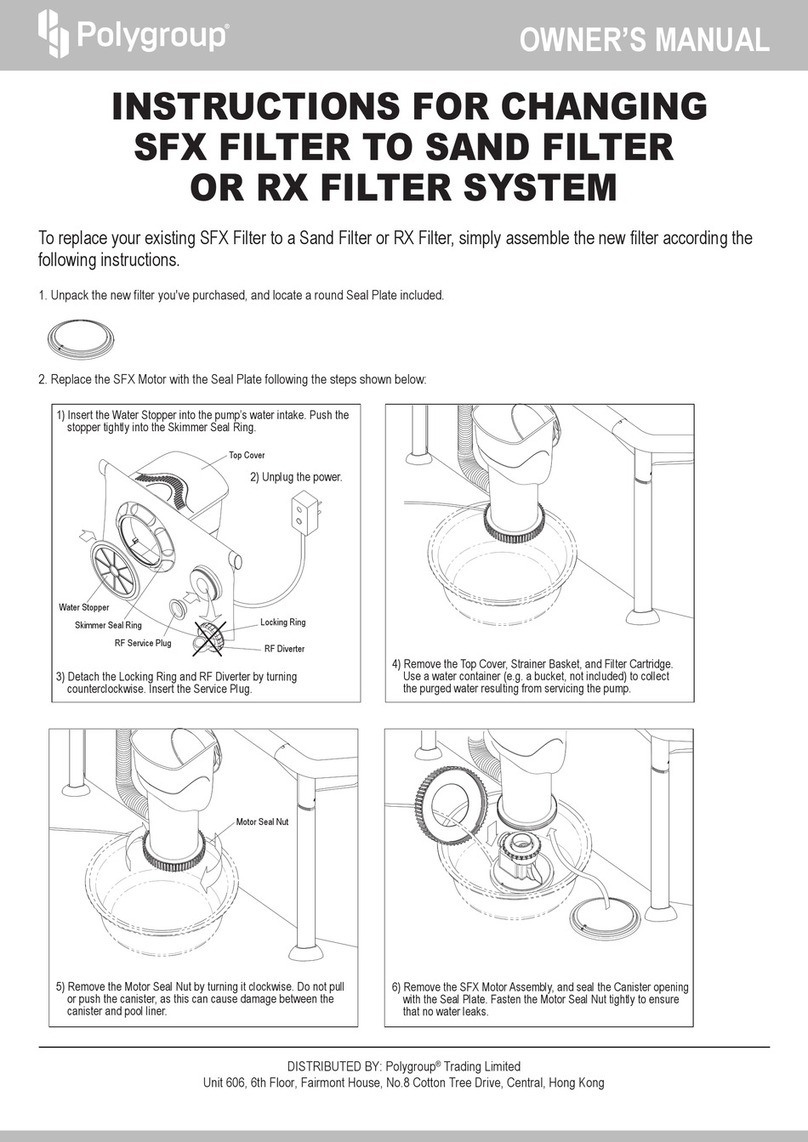

Polygroup

Polygroup SFX Series instructions

emaux

emaux SSCnano Installation and operation manual

Master Water Conditioning

Master Water Conditioning MBA Series Installation and operation manual

Kinetico

Kinetico SuperSoft Installation instructions and user manual

Brilix

Brilix FSP350 Installation and user guide

Watts Premier

Watts Premier WP-4V Installation, operation and maintenance manual

Trion

Trion AIR BOSS owner's manual

IDEAL H2O

IDEAL H2O 100 GPD Setup and maintenance guide

T.I.P.

T.I.P. HNB 1600 E operating instructions