4

EN

3.4 Safety Information

• Only water of drinking water quality may be used as intake water for the VIVREAU water lter

system. The VIVREAU water lter system is only suitable for cold water use within the water

intake temperature stated in Chapter 12. No microbiologically impaired water or water of

unknown quality may be used without appropriate disinfection.

• If there are ofcial instructions to boil tap water, VIVREAU ltered water must also be boiled.

When the requirement to boil water comes to an end, the lter cartridge must be replaced

and the connections cleaned.

• This lter media has been impregnated with silver to preserve the lter media and inhibit the

growth of bacteria that may affect the lter media. The antimicrobial properties of the treated lter

media do not protect users or others against bacteria, viruses, germs, or other disease organisms.

• It is generally recommended to boil tap water for certain groups of people (e.g. people with

weakened immune systems, babies). This also applies to ltered water.

• For hygiene reasons, the lter material of the cartridge is subjected to a special treatment with

silver. A small quantity of silver, which is harmless to health, may be released into the water.

This is in compliance with the World Health Organization (WHO) recommendations for drinking

water. At most, the values stated in the Alimentarius Austriacus code may be exceeded.

• Note for people with kidney disease or dialysis patients: during the lter process, the potassium

content may be increased slightly. If you suffer from kidney disease and/or have to stick

to a special potassium diet, we recommend prior agreement with your doctor.

• The water ltrate is classied in Category 2 according to DIN EN 1717.

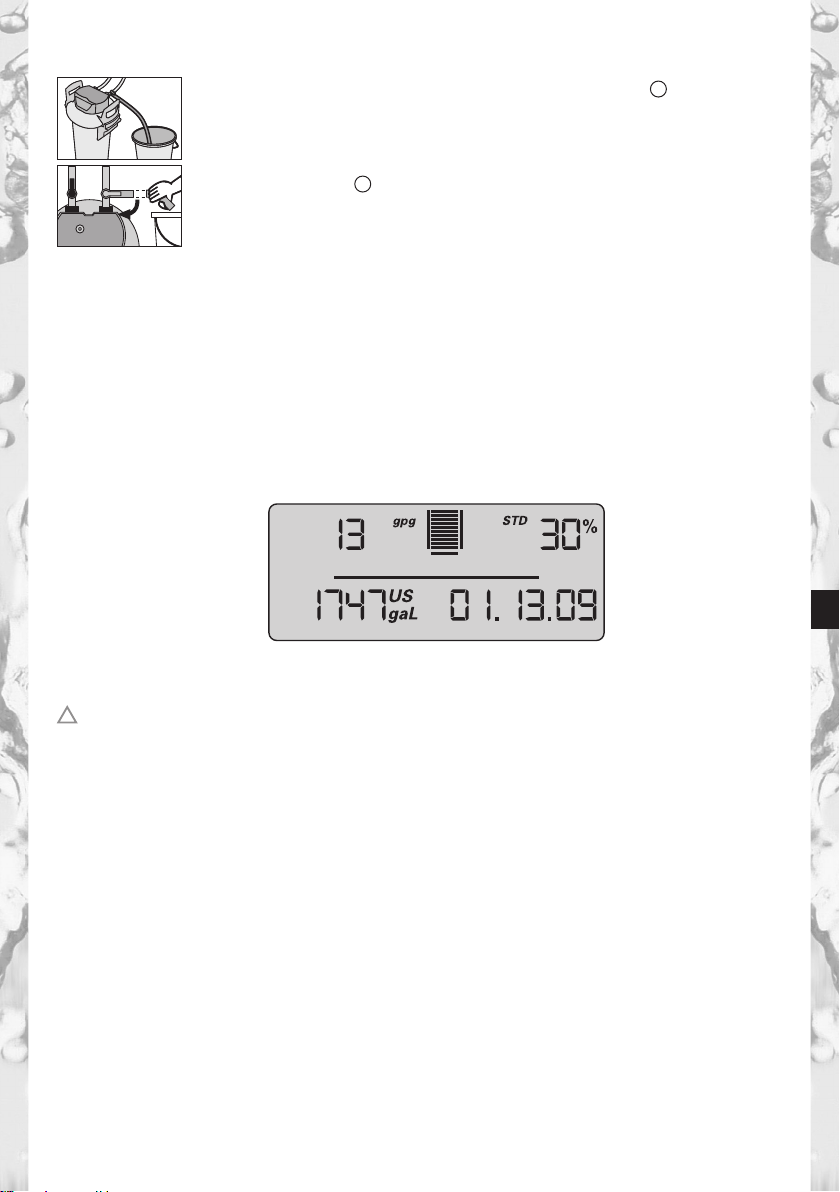

• If the VIVREAU lter system is not used for several days (2–3 days), we recommend that

the PURITY Quell lter system be ushed with at least x* liters according to the table below.

VIVREAU LLC recommends that the lter system not be decommissioned for a long period.

After stagnation periods of over 4 weeks, the lter should be ushed with at least x** liters (US

gallons) according to the table below, or else replaced. Please also note that the maximum

usage period of the lter cartridge is 12 months (Chapter 6).

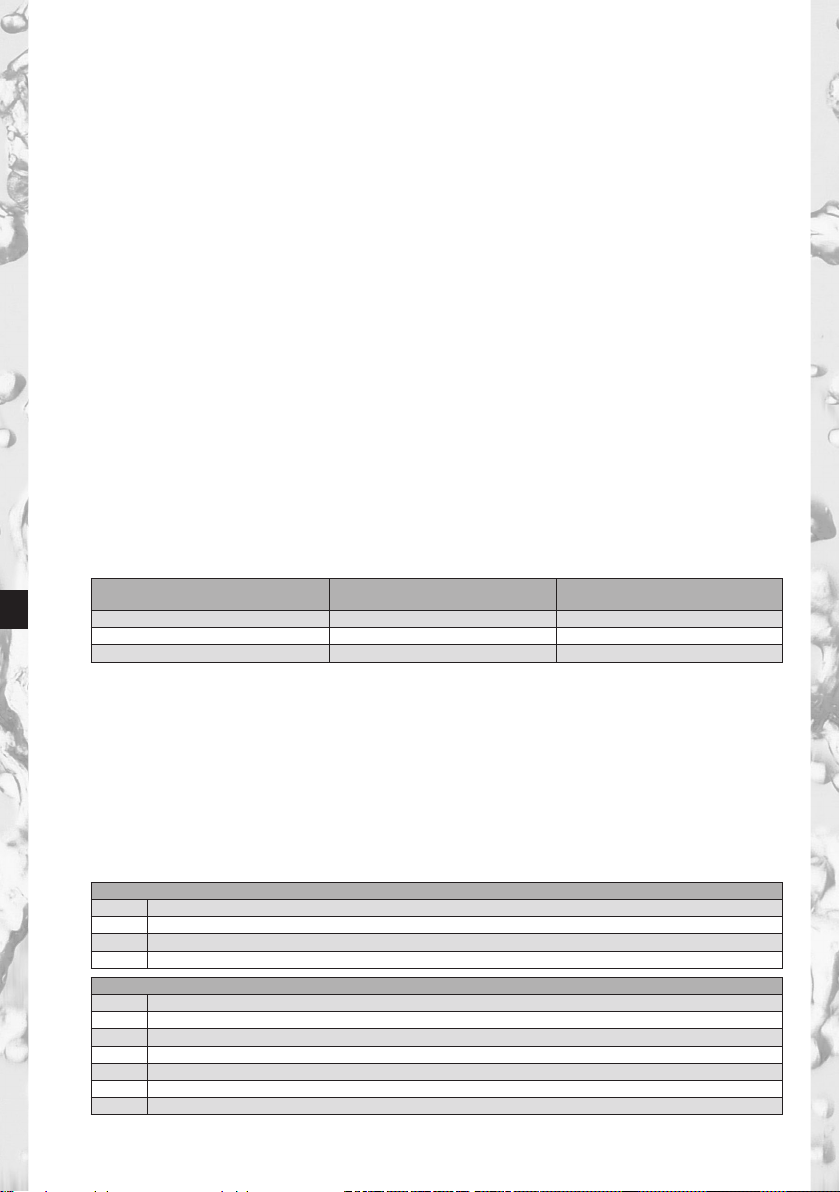

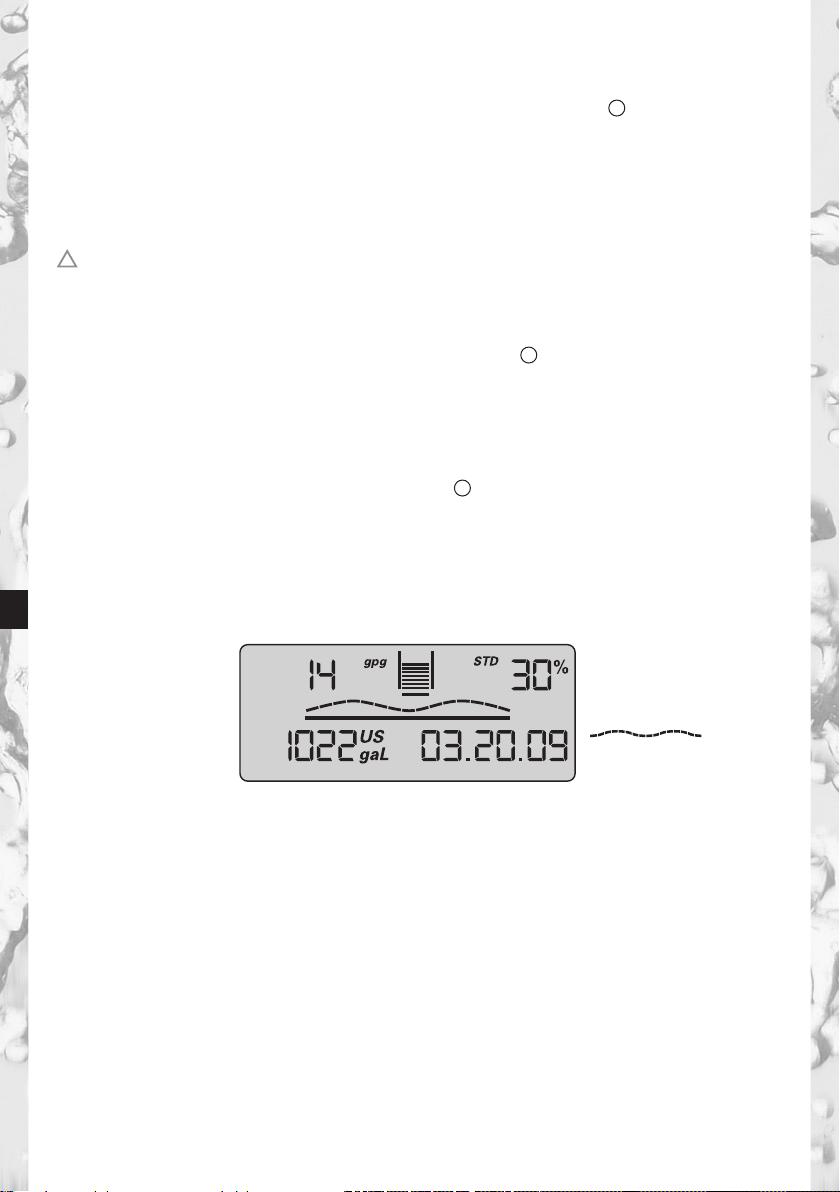

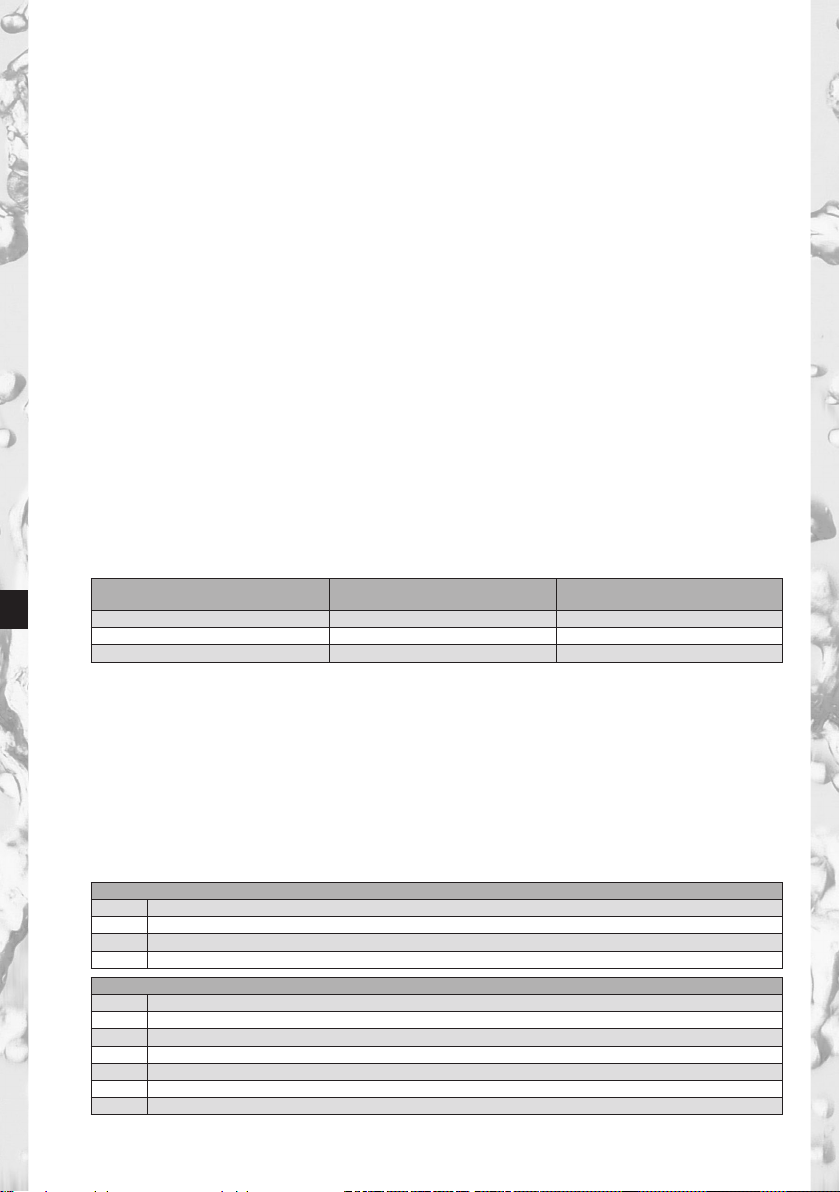

Filter System x* Flushing amount

after 2-3 days stagnation

x** Flushing amount

after 4 weeks stagnation

PURITY 450 6 litres (1.6 US gallons) 30 litres (8.0 US gallons)

PURITY 600 12 litres (3.2 US gallons) 60 litres (15.9 US gallons)

PURITY 1200 24 litres (6.4 US gallons) 120 litres (31.7 US gallons)

• The lter system is not resistant to heavily concentrated cleaning agents (e.g. bleach,

chlorinated solvents, strong oxidising agents) and must not come into contact with them.

• The lter system must not be opened or dismantled during operation.

The lter cartridge must not be opened.

• The pressure vessel and the pressure vessel lid of the lter systems have a service life of up to

ten years (from the date of installation), provided that they are installed and used correctly and the

operating conditions outlined in the Technical Data chapter are adhered to. They must always be

replaced after a maximum of ten years. The hoses must be replaced in rotation after a maximum of

ve years.

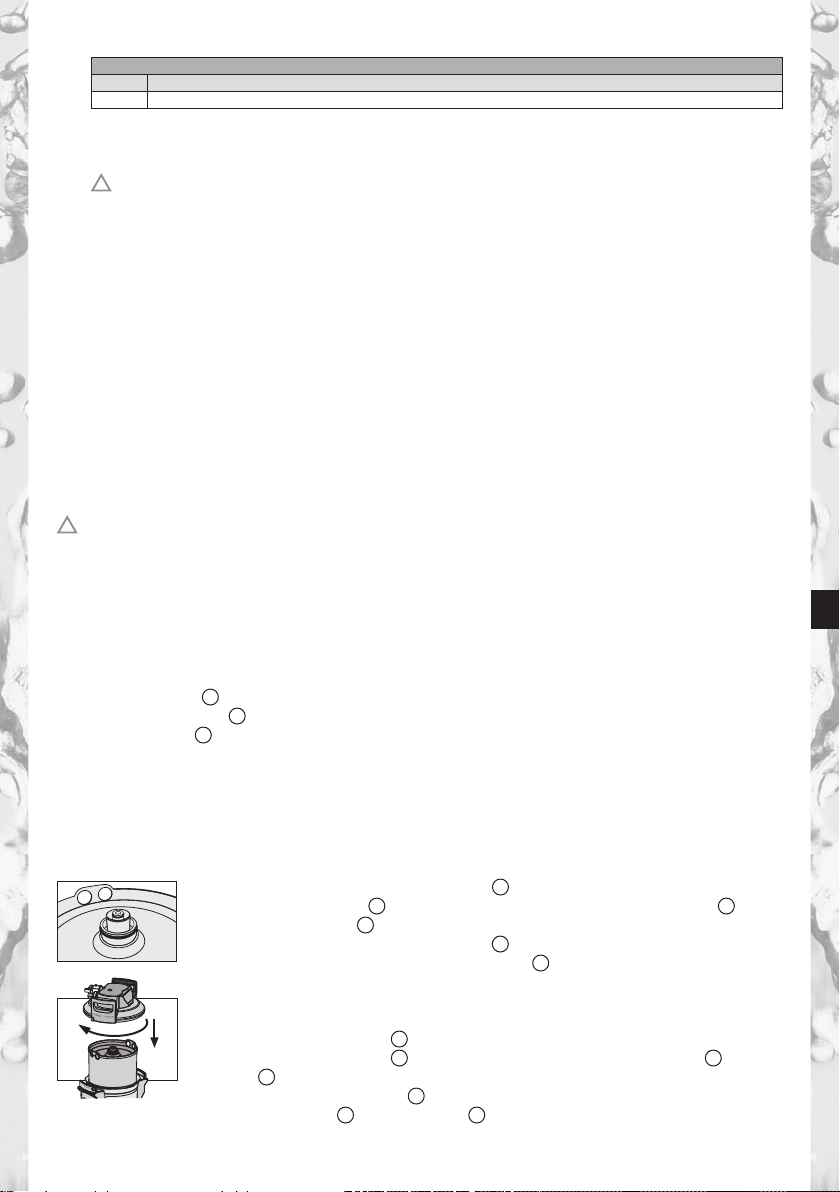

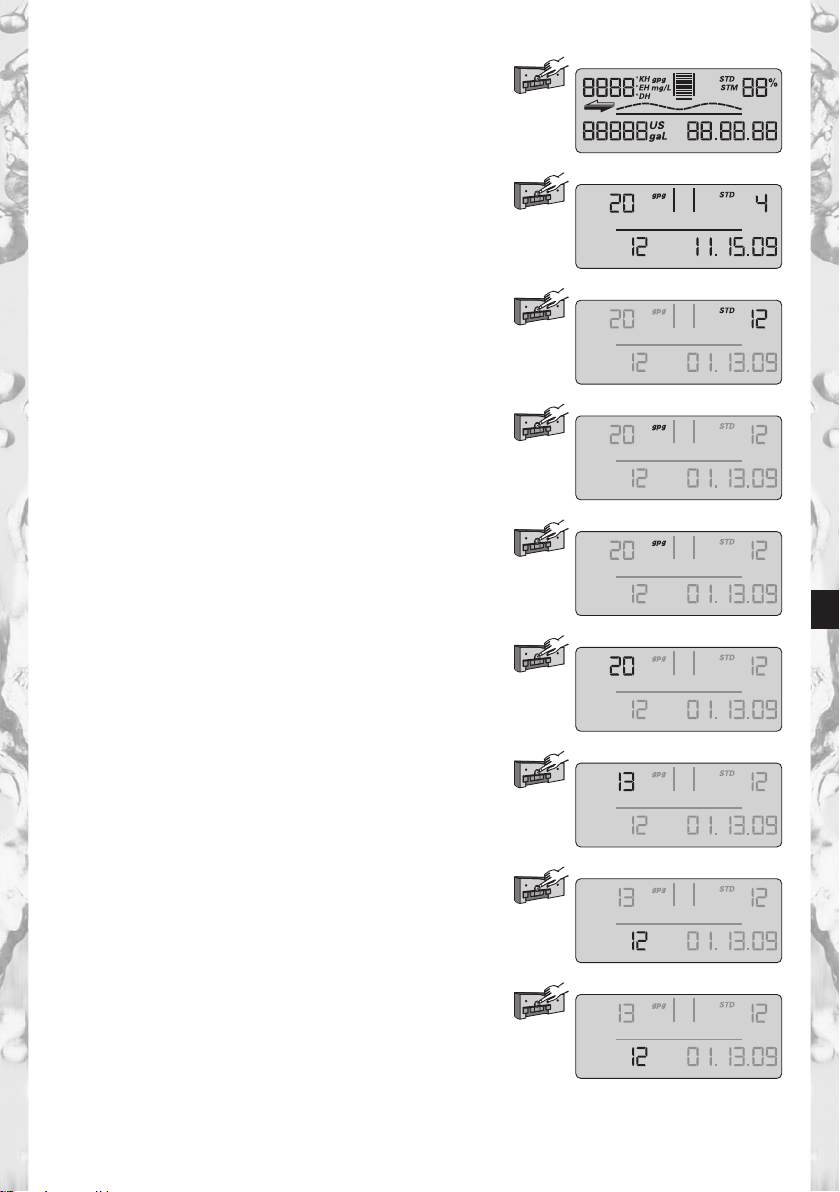

Production date:

Production code sticker lter cartridge and packaging. Example B715002010

7 Production year, here: 2017

15 Production week, here: calendar week 15

002 Batch No. lter medium, here in terms of quantity the second batch used

010 Serial number of the lter cartridge, here the tenth cartridge from the second batch

Production code sticker connector head - Example: 1001801 E 119317008764

1001801 VIVREAU identication number

ESupplier ID

7 Production year, here: 2017

19 Production week, here: calendar week 19

3Production day from Monday (1) to Friday (5), here: Wednesday

17 Production year, here: 2017

008764 Serial identication number