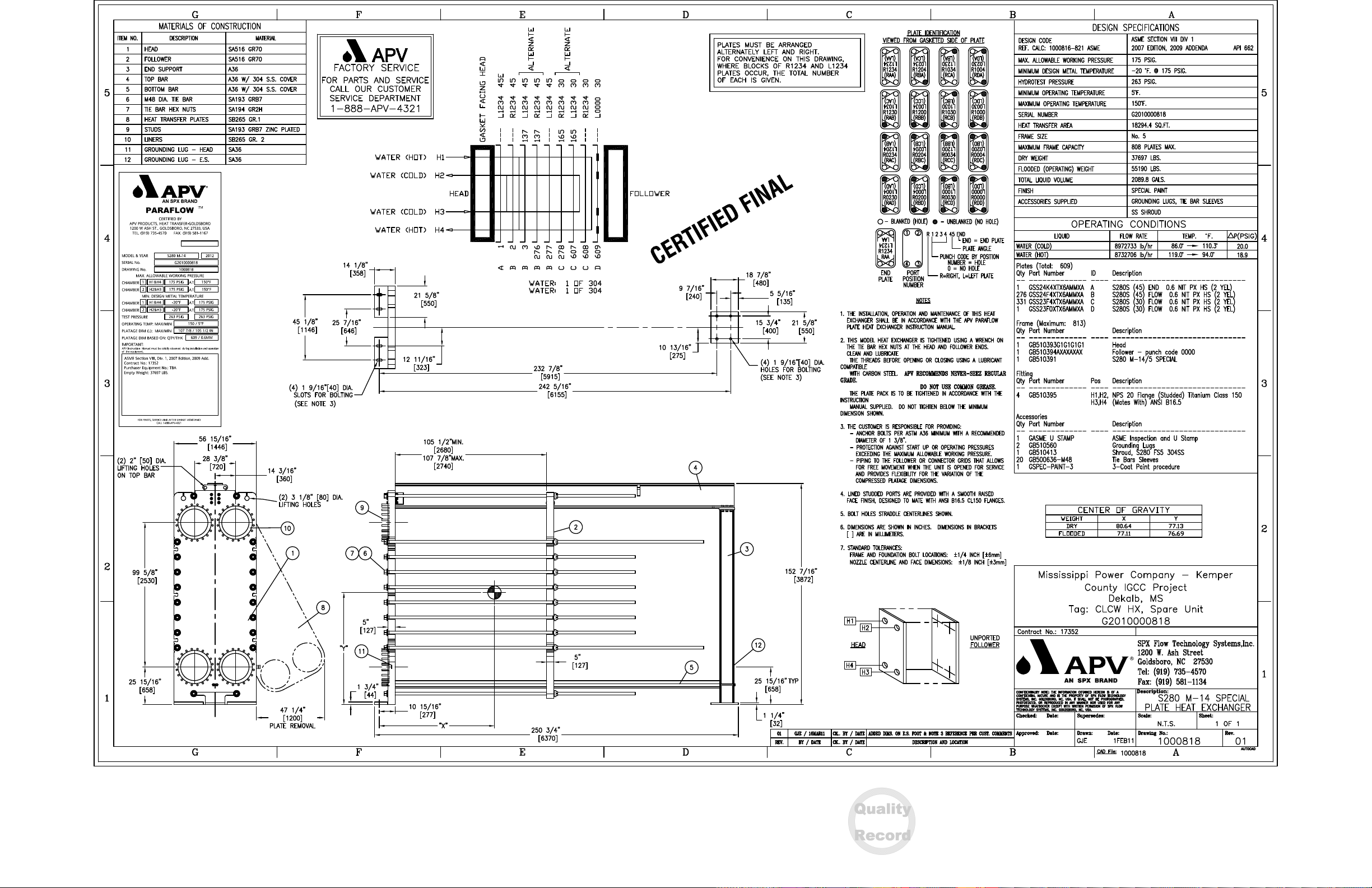

SPX FLOW S280 M-14 User manual

MISSISSIPPI POWER COMPANY

KEMPER COUNTY IGCC PROJECT

CONTRACT NO.: 17352

TAG NO.: CLCW HX, SPARE UNIT

SPX MATERIAL NO.: G2010000818

APV PLATE HEAT EXCHANGERS

SPX/APV MODEL: S280 M-14

SPX FLOW TECHNOLOGY SYSTEMS, INC.

1200 W. ASH STREET

GOLDSBORO, NC 27530

UNITED STATES

TEL 888 . 278 . 4321

www.spxft.com

IGCC - MULTIPAGE - DOCUMENTATION PACKAGE FOR G2010000818 - TAG NO

1000818 DATABOOK Rev: NA

APV NORTH AMERICA PO: MPC17352-0001

MM218132 0 Unit 1

Southern Company Generation Kemper County

Approved

TABLE OF CONTENTS

MANUFACTURING RECORD BOOK

SECTION

1 CERTIFIED FINAL DRAWING

2 CERTIFICATE OF CONFORMANCE

3 ASME CALCULATION

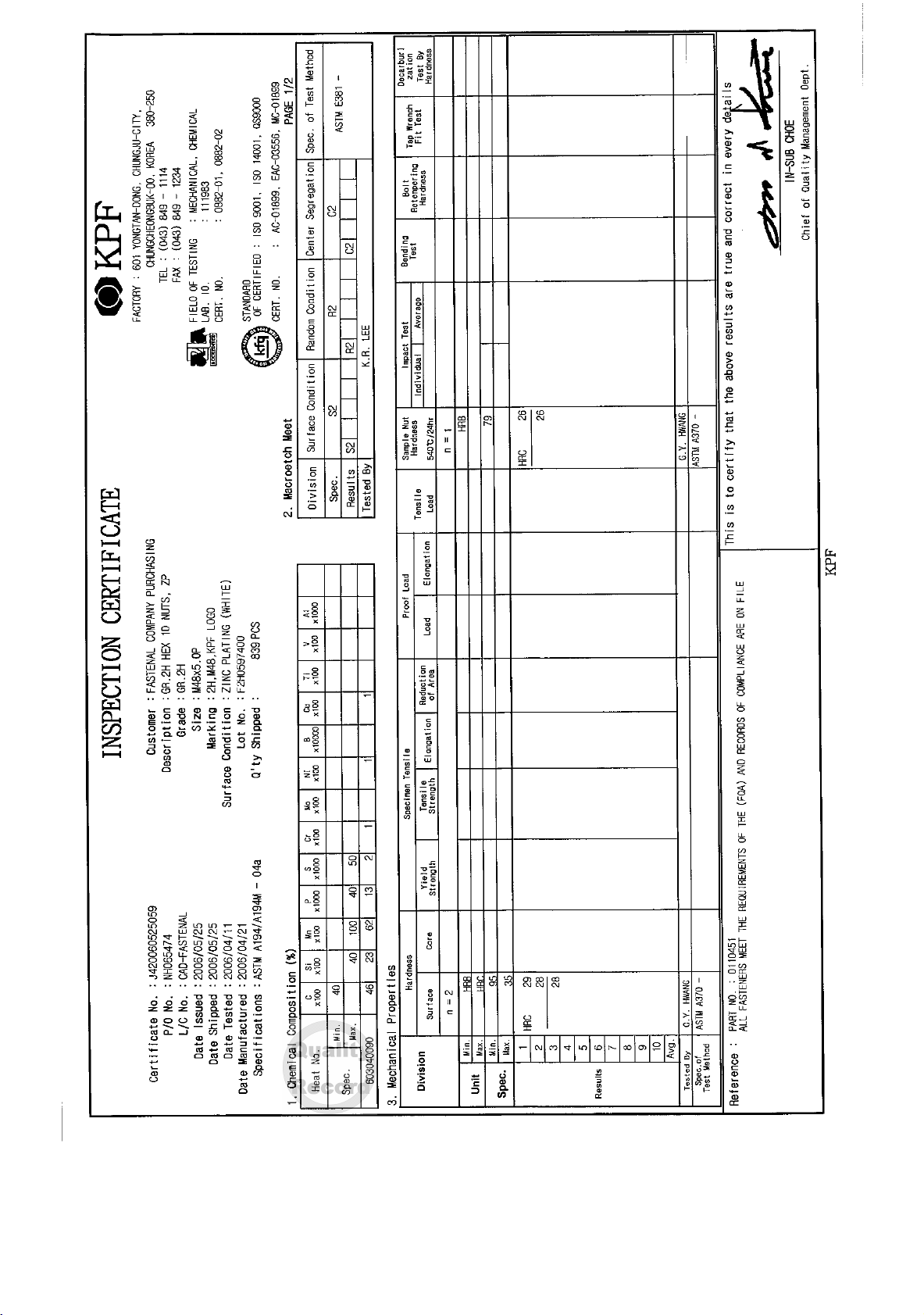

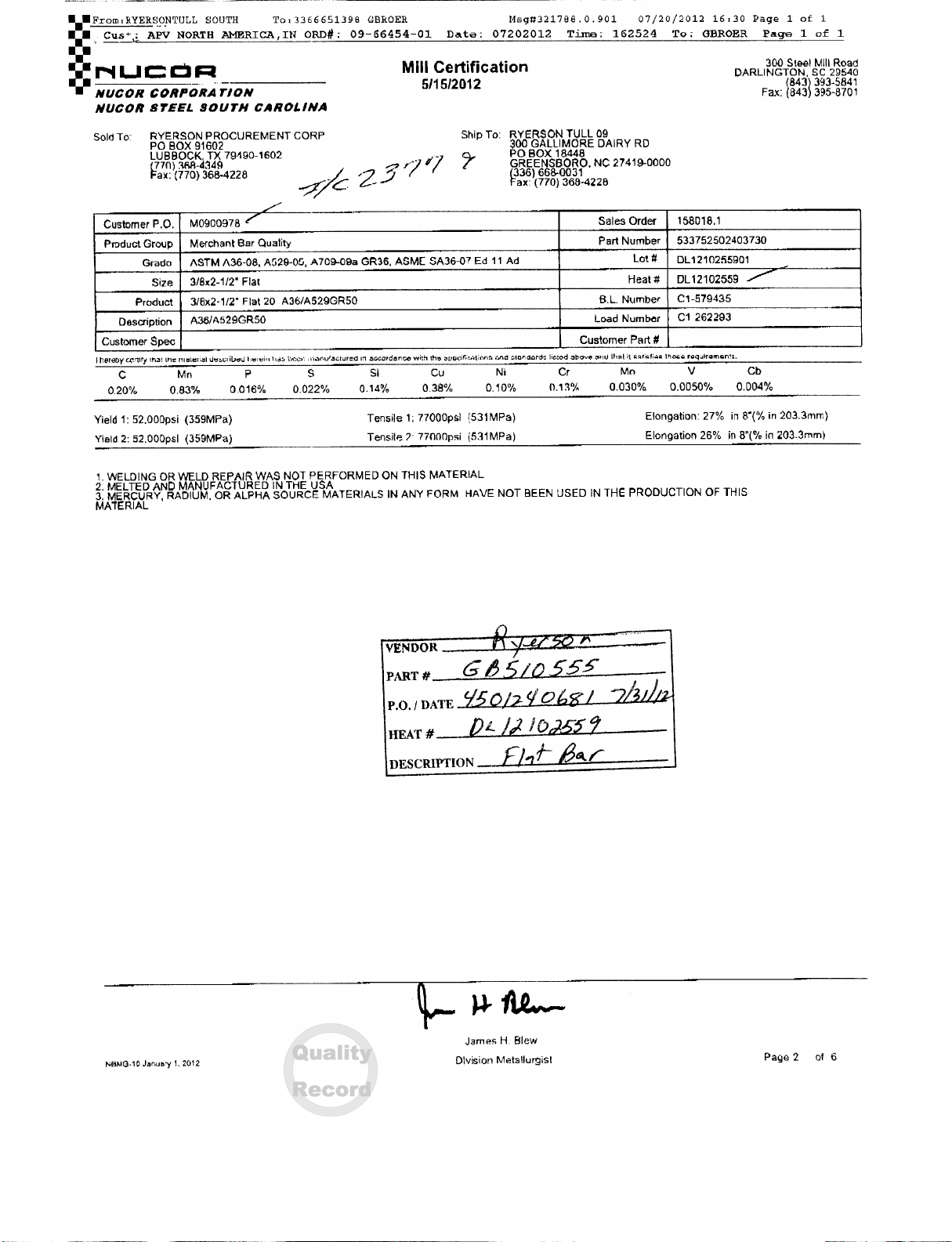

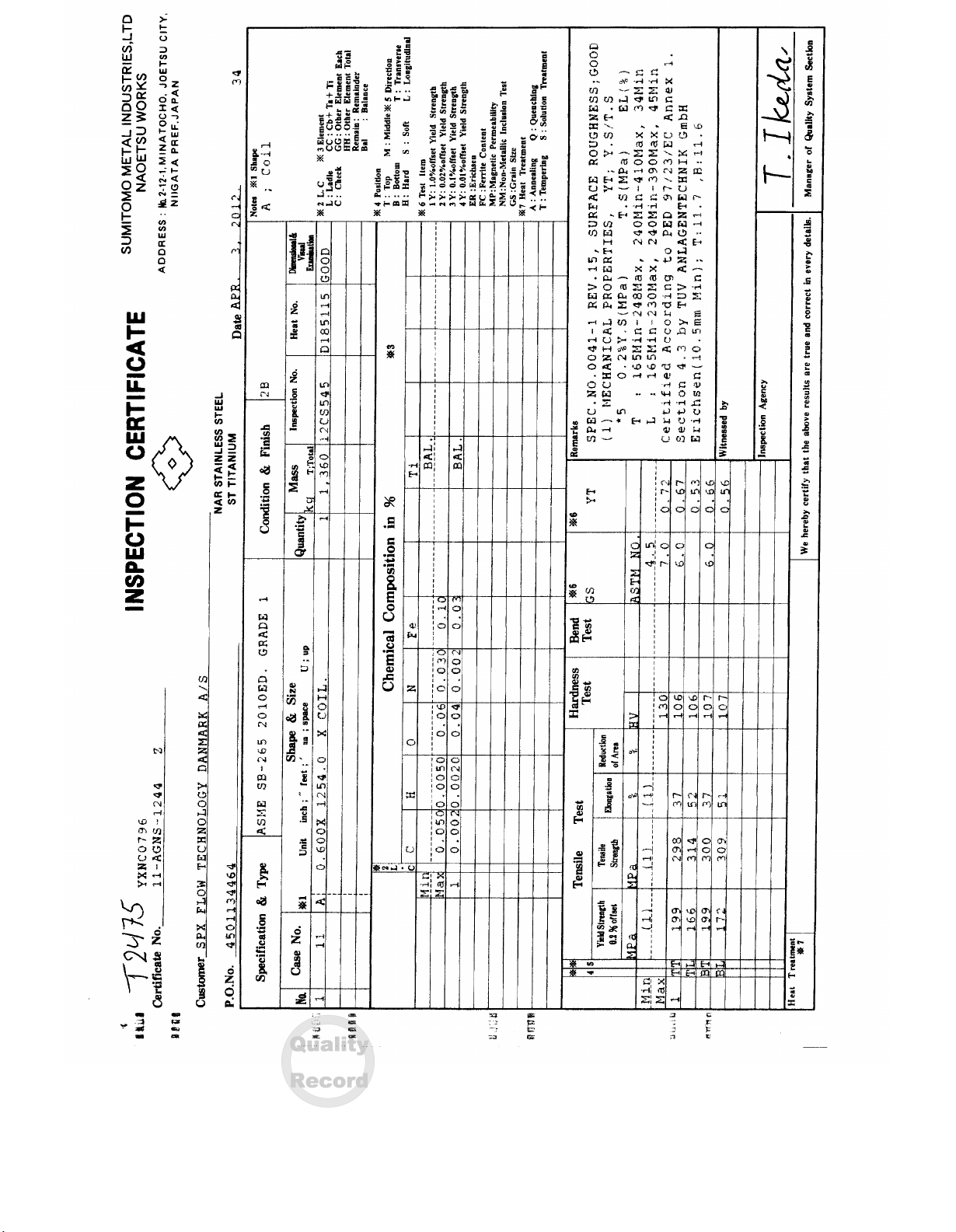

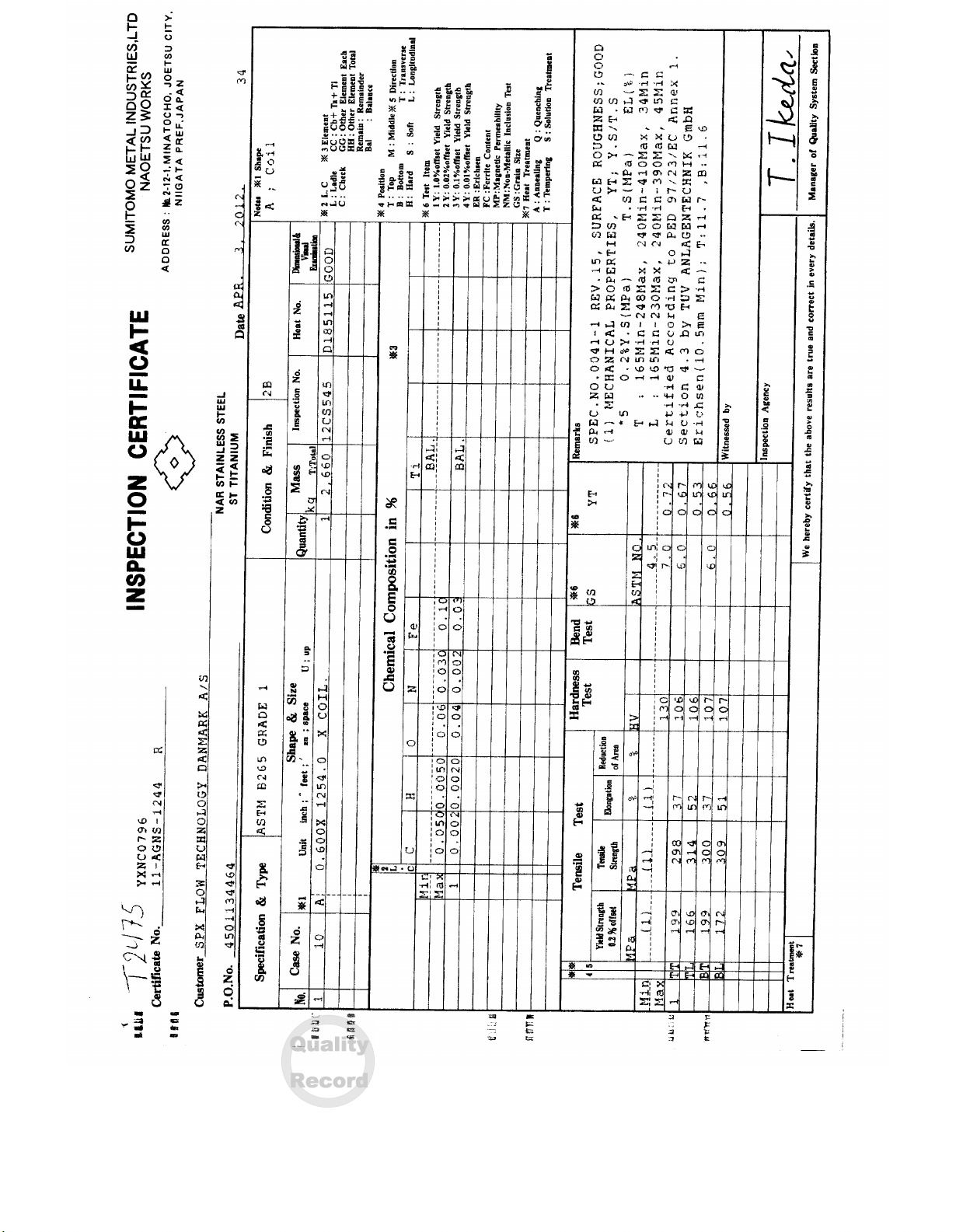

4 MATERIAL TEST REPORT

5 PAINT REPORT

6 DYE PEN REPORT

7 HYDROSTATIC PRESSURE TEST SHEET

8 ASME U-1 DATA REPORT

9 NAMEPLATE FACSIMILE

10 SIGNED INSPECTION AND TEST PLAN

11 INSTRUCTION MANUAL

SPX FLOW TECHNOLOGY SYSTEMS, INC.

1200 W. ASH STREET

GOLDSBORO, NC 27530

UNITED STATES

TEL 888 . 278 . 4321

www.spxft.com

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Document Title:

APV Order Number:

Customer:

Customer Contract No.:

Certificate of Conformance

G2010000816-821

Mississippi Power Company

17352

ISSUE:

DATE:

BY:

Page

00

25Oct12

GJE

1 of1

SPX Flow Technology Systems, Inc.

PH: (919) 735-4570 FX: (919) 581-1134

Certificate Of Conformance

Customer: Mississippi Power Company

Customer Contract No:

Location:

Project:

17352

Dekalb, MS

Kemper County IGCC Project

This is to certify that the following Plate Heat Exchangers comply with

the purchase order and were built to ASME Section VIII, Division 1 2007

Edition, 2009 Addenda using approved designs and materials.

Signed & Approved: Gregory Eckard Project Manager / Mechanical Engineer

Material # Model # Tag #

G2010000816 S280 M-14 CLCW HX, Operating Unit 1

G2010000817 S280 M-14 CLCW HX, Operating Unit 2

G2010000818 S280 M-14 CLCW HX, Spare Unit

G2010000819 S280 M-14 CLCW HX, Operating Unit 3

G2010000820 S280 M-14 CLCW HX, Operating Unit 5

G2010000821 S280 M-14 CLCW HX, Operating Unit 4

Kemper County MM218132

Approved

ENGINEER: Greg Eckard

DATE:

CALC NO.: 1000816-821 ASME REV NO.: 00

HEAT EXCHANGER MODEL: S280 MGS-14

REFERENCE DRAWING NUMBER: 1000816-821

DESIGN PRESSURE: 175.00 psi

TEST PRESSURE: 263.00 psi

MAXIMUM DESIGN TEMPERATURE: 150.00 F

MINIMUM DESIGN METAL TEMPERATURE: -20.00 F

P.O. NO: 17352

TAG NO.:

CUSTOMER: Mississippi Power Company

LOCATION: Dekalb, MS

03-Feb-11

PRESSURE VESSEL CALCULATIONS

FOR AN

APV PLATE HEAT EXCHANGER

IN ACCORDANCE WITH THE

ASME BOILER AND PRESSURE VESSEL CODE

SECTION VIII, DIVISION 1

2010 EDITION

1 of 5

Kemper County MM218132

Approved

ENGINEER: Greg Eckard

DATE:

CALC NO.: 1000816-821 ASME REV NO.: 00

THE FOLLOWING PARAMETERS APPLY TO THIS HEAT EXCHANGER DESIGN:

P = 175.000 psi DESIGN PRESSURE (UG-21, Appendix 3)

A = 5104.755 sq in PRESSURE AREA

d = 47.677 inches SHORT SPAN (fig. UG-34 sketch j)

D = 107.070 inches LONG SPAN (UG-34b)

G = 473.543 inches GASKET PERIMETER (Appendix 2-3)

Hg = 2.264 inches GASKET MOMENT ARM (Appendix 2-3, table 2.5.2)

L = 339.536 inches TIE BAR PERIMETER (UG-34b, Appendix 2-10)

C = 0.300 UG-34 d sketch j

b = 0.188 inches Appendix 2-3, Table 2-5.2, figure (1a) or (1b)

m = 1.000 ELASTOMER 75A SHORE (Table 2-5.1, Appendix 2-3)

y = 200.000 psi ELASTOMER 75A SHORE (Table 2-5.1, Appendix 2-3)

BOLT (TIE BAR) DESIGN

REFERENCE: APPENDIX 2 - MANDATORY

MATERIAL: SA-193 GR B7

Sa = 25000 psi @ ATMOSPHERIC TEMPERATURE

Sb = 25000 psi @ DESIGN TEMPERATURE

BOLT LOAD:

DESIGN CONDITIONS: Wm1 = A*P+2b*G*m*P Appendix 2-5, formula 1

GASKET SEATING: Wm2 = b*G*y Appendix 2-3 & 2-5 (formula 2)

NOTE: THE FORMULAS HAVE BEEN MODIFIED FOR NONCIRCULAR GASKETS

Wm1 = 924408.38 lbf

Wm2 = 17757.86 lbf

TOTAL BOLT AREA REQUIRED IS THE GREATER OF THE FOLLOWING (Appendix 2-3 & 2-5d):

DESIGN CONDITIONS: Am1 = Wm1/Sb = 36.976 sq in

GASKET SEATING: Am2 = Wm2/Sa = 0.710 sq in

TOTAL BOLT AREA SUPPLIED:

SIZE 1 M48 x 5 QTY (n1) 20

SIZE 2 QTY (n2) 0

BOLT TENSILE AREA (As) = 0.7854 * (D - 0.9382 * P) ^ 2

Note: D is the bolt diameter, P is the bolt pitch

TOTAL AREA (Ab) = As1 * n1 + As2 * n2 45.668 sq in

TOTAL BOLT AREA SUPPLIED (45.668 sq in) IS GREATER THAN REQUIRED (36.976 sq in)

03-Feb-11

2 of 5

Kemper County MM218132

Approved

ENGINEER: Greg Eckard

DATE:

CALC NO.: 1000816-821 ASME REV NO.: 00

UNPORTED SLAB THICKNESS

The head and follower covers are designed as noncircular flat plates attached with bolts causing an

edge moment. The thickness of the covers without openings is determined in accordance with UG-34 -

UNSTAYED FLAT HEADS AND COVERS.

SLAB MATERIAL: SA-516 GR 70

Sop = 20000 psi @ 150 F

CA = 0.000 inches Corrosion Allowance

E = 1 Joint Efficiency (no welded joints)

THICKNESS "T1" REQUIRED AT OPERATING CONDITIONS

T1 = d*SQR[((Z*C*P/(Sop*E))+((6*W*Hg)/(Sop*E*L*d*d))] UG-34 Formula 5

Z = MINIMUM OF: 3.4-(2.4*d/D) OR 2.5 UG-34 Formula 4

W = Wm1 = A*P+2*b*G*m*P Appendix 2-5 Formula 3

Z = 2.331

W = 924408.384 lbf

MINIMUM REQUIRED UNPORTED THICKNESS, INCLUDING CA T1 = 3.970 inches

THICKNESS "T2" REQUIRED DUE TO GASKET SEATING

T2 = d*SQR[((Z*C*P/(Sgs*E))+((6*Wgs*Hg)/(Sgs*E*L*d*d))]

P = 0 psig at gasket seating conditions

Wgs = ((Am+Ab)*Sa)/2 Appendix 2 - 5 Formula 4

Am = GREATER OF: Am1 = Wm1/Sb OR Am2 = Wm2/Sa (From page 2)

Am = 36.976 sq in

Sgs = 20000 psi

Wgs = 1033051.250 lbf

MINIMUM REQUIRED UNPORTED THICKNESS, INCLUDING CA T2 = 1.438 inches

MINIMUM REQUIRED UNPORTED THICKNESS, INCLUDING CA, @ OPERATING OR GASKET

SEATING CONDITIONS

T = GREATER OF: T1 OR T2

T = 3.970 inches

03-Feb-11

3 of 5

Kemper County MM218132

Approved

ENGINEER: Greg Eckard

DATE:

CALC NO.: 1000816-821 ASME REV NO.: 00

REINFORCEMENT REQUIRED FOR PORTED SLABS

A finite element analysis calculation (using ALGOR's Linear Stress Analysis package, version 9.20)

in accordance with U-2(g) has been performed to calculate the required port reinforcement thickness.

This analysis is summarized in APV Publication 3392. The following equation has been derived from

the results of this analysis.

TBPA = 6398.097 sq in AREA ENCLOSED BY ALL TIE BARS

ATMIN = 3812.589 sq in MAXIMUM AREA ENCLOSED BY SIDE TIE BARS

LOCATED INSIDE VERTICAL PORT CENTERS

VTC = 10.433 inches MAXIMUM VERTICAL SPAN OF SIDE TIE BARS

LOCATED INSIDE VERTICAL PORT CENTERS

TBMD = 31.646 inches MAXIMUM VERTICAL SPAN FROM TOP / BOTTOM END

TIE BARS TO TOP / BOTTOM SIDE TIE BAR LOCATED

INSIDE VERTICAL PORT CENTERS

A = 0.9348 CONSTANT VALUE FOR US UNITS

THICKNESS "T3" REQUIRED FOR PORT REINFORCEMENT

T3 = A*(P/Sop)^0.5*d^1.0066*[(TBPA/ATMIN)*(VTC/TBMD)]^0.0201

MINIMUM REQUIRED REINFORCED THICKNESS, INCLUDING CA T3 = 4.226 inches

MINIMUM THICKNESS "Tport" REQUIRED FOR PORTED SLABS

Tport = GREATER OF: T OR T3

Tport = 4.226 inches

LOADINGS

The slab thickness for this heat exchanger is based on the loadings is section UG-22(a), taking

into consideration both the internal and external (full vacuum) pressures. UG-21 states that the

pressure vessel shall be designed for at least the most severe condition of coincident pressure

and temperature expected in normal operation. The internal pressure is used in this calculation

since it creates the maximum differential pressure between the inside and outside of the vessel.

Loadings in sections UG-22 (b) through (i) have been considered with no additional thickness

required.

03-Feb-11

4 of 5

Kemper County MM218132

Approved

ENGINEER: Greg Eckard

DATE:

CALC NO.: 1000816-821 ASME REV NO.: 00

HYDROSTATIC TEST PRESSURE

REFERENCE: UG-99 STANDARD HYDROSTATIC TEST

LOWEST STRESS RATIO (LSR): 1 UG-99(b)

MINIMUM TEST PRESSURE = 1.5*MAWP*LSR = 263.00 psi

(PER NOTE 33, MAWP MAY BE ASSUMED TO BE THE SAME AS THE DESIGN PRESSURE)

IMPACT TESTING

The slab material, at 5.0 inches nominal thickness, is supplied in the normalized condition.

The slab material is thus classified by curve D in section UCS-66. The governing thickness for

determining whether impact testing is required is 5.0 / 4 = 1.25 inches [UCS-66(a)(3)].

Using 1.25 inches as the minimum thickness, table UCS-66 indicates that impact testing is

required for minimum temperatures less than -21.0 F. The tie bar material impact test exemption

temperature is -55.0 F. Therefore, no impact testing is required for this frame since the

minimum temperature is -20.0 F. (reference: UG-20, UG-84 & UCS-66)

DESIGN SUMMARY

DESIGN TEMPERATURE: 150.00 F

MINIMUM METAL DESIGN TEMPERATURE: -20.00 F

MAXIMUM DESIGN PRESSURE: 175.00 psi

MINIMUM TEST PRESSURE: 263.00 psi

HEAD AND PORTED FOLLOWER:

MINIMUM REQUIRED THICKNESS: 4.226 inches

UNPORTED FOLLOWER:

MINIMUM REQUIRED THICKNESS: 3.970 inches

TIE BARS:

REQUIRED TOTAL ROOT AREA: 36.976 sq in

SUPPLIED TOTAL ROOT AREA: 45.668 sq in

03-Feb-11

5 of 5

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Kemper County MM218132

Approved

Table of contents