SPX OTC 7380 User manual

Sheet No.

Issue Date: Rev. B December 23, 2010

© 2010 SPX

Form No. 558557

Operating Instructions

for: 7380

655 EisEnhowEr DrivE

owatonna, Mn 55060-0995 Usa

PhonE: (507) 455-7000

tEch. sErv.: (800) 533-6127

Fax: (800) 955-8329

orDEr Entry: (800) 533-6127

Fax: (800) 283-8665

intErnational salEs: (507) 455-7223

Fax: (507) 455-7063

Dial Torque Wrench

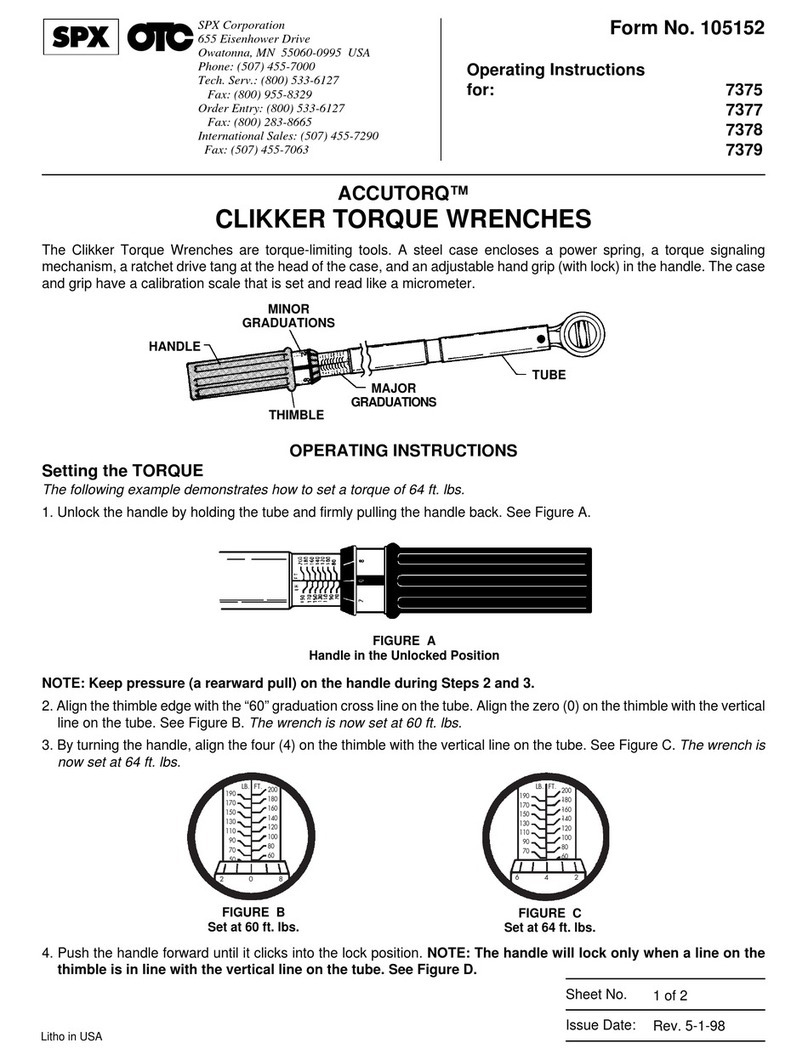

Basic Operating Instructions

1. Turn the bezel until the black pointer is resting on zero.

2. Attach a socket or attachment to the square drive.

3. Place the socket or attachment over the fastener to be torqued. The torque

wrench handle must be perpendicular (90 degrees) to the centerline of the

drive, socket and fastener.

4. Load the torque wrench at a slow and steady rate until the black pointer

indicates the desired torque.

5. Stop applying force. The pointer should return to zero.

CAUTION : To prevent personal injury, wear eye

protection that meets ANSI Z87.1 and OSHA standards.

Reset Knob

Square

Drive Bezel

Black Pointer

Orange

Memory

Pointer

CAUTION: To prevent equipment damage,

•

Never use the torque wrench beyond its rated capacity. Maximum torque capacity is reached when the black

pointer rotates 180 degrees from zero. Exceeding the maximum torque capacity damages the wrench and voids

warranty. If the pointer does not return to zero after a torque application, it is an indication that the wrench

was overloaded.

•

Load the torque wrench to near maximum torque capacity before starting, or when changing directions, to

remove residual energy that may be present from a previous torque application.

•

Threads on bolts, nuts, and other mating components must be clean, smooth, and lubricated to obtain accurate

and consistent torque readings.

•

Follow the manufacturer's recommended procedures for tightening fasteners.

Never torque a fastener that is

already tightened. First loosen the fastener; then torque it to the desired value.

•

Never use the torque wrench as a nut breaker.

1 of 2

Operating Instructions Form No. 558557, Sheet 1 of 2, Back

Multiply By To Obtain

FT-LBS 12 IN-LBS

CM-KG 0.8679 IN-LBS

IN-LBS 0.0833 FT-LBS

IN-LBS 1.1522 CM-KG

Conversion of Torque Units

Use the chart to convert units of torque. Note: Units may

be represented in various forms, such as Kgf.cm, which

is equivalent to CM-KG.

Certication

This torque wrench is certied to have been calibrated

prior to shipment for accuracy of ± 4% in both directions

on readings from 20% to 100% of capacity. On readings

below 20% of capactiy, the accuracy is ± one scale

increment.

Using Attachments

Attachments used with the torque wrench alter the effective

lever length (L) of the wrench, which in turn changes the

amount of torque applied. Use the following formulas to

calculate torque adjustments.

Maintenance

•

Clean the torque wrench by wiping it with a soft cloth. Do not immerse the torque wrench in liquid.

•

Store the torque wrench in its protective case.

•

Periodic accuracy checks and calibrations are required. An out-of-calibration torque wrench can cause part or tool

breakage. A calibration should be performed at least once a year, or every 5,000 torque application cycles, whichever

comes rst. Recalibration is also recommended after any abnormal handling.

•

Should the torque wrench require repair service, contact your nearest OTC-authorized torque wrench repair center,

and provide them with date of purchase information. If the wrench is determined to be in warranty, it will be repaired

or replaced at no charge and returned freight prepaid. If the unit is determined to be out of warranty, it will be repaired

for a nominal service charge plus return freight.

The Memory Feature

1. Turn the bezel until the orange memory pointer comes to a stop against the black pointer. Note: Reverse bezel direction

for counterclockwise torques.

•

Clockwise torque with 3/8 inch and smaller drive wrenches: Turn the bezel counterclockwise.

•

Clockwise torque with 1/2 inch and larger drive wrenches: Turn the bezel clockwise.

2. Continue turning the bezel until the orange memory pointer is at zero.

3. Place the socket or attachment over the fastener to be torqued. Ensure the alignment is perpendicular (90 degrees)

to the handle and centerline of the drive, socket and fastener.

4. Load the torque wrench at a slow and steady rate until the black pointer indicates the desired torque. The black pointer

should push the orange memory pointer toward the desired torque. If the black pointer moves away from the orange

memory pointer, the bezel was rotated in the wrong direction.

5. Stop applying force. The black pointer should return to zero.

6. Reset the memory pointer by turning the reset knob, located in the center of the bezel, until the memory pointer stops

against the black pointer.

TW = Torque reading on wrench

TE = Torque applied to fastener by extension

Note:

• Donotuseuniversaljointsanduniversalsocketsdue

to the complexity of determining the error.

• Socketextensionbarsthatarein-linewiththesquare

drivedonotcauseerrorandneednoadjustments.

Sheet No.

Issue Date: Rev. B December 23, 2010

© 2010 SPX

Operating Instructions Form No. 558557

2 of 2

One Year Limited Warranty

Effective 2-17-97

This product, and all parts making up this product, with the exceptions noted below or

otherwise stated under a separate warranty, are warranted against defects in materials

and workmanship for a period of one year from date of purchase.

This warranty is expressly limited to the original retail purchaser of the product or

part for use in the ordinary course of the buyer’s business.

This warranty does not cover any product or part that has been abused, worn out, contaminated,

rusted, heated, ground, or otherwise altered, damaged due to side loading, used for a purpose

other than for which it was intended, or used in a manner inconsistent with any instructions

regarding its use.

Chains, batteries, electric motors, knives, and cutter blades, which are sold with OTC

products, are not covered under this warranty. Electric motors are separately warranted by

manufacturers under conditions stated in their warranties.

THIS WARRANTY IS EXCLUSIVE OF THIS PRODUCT, AND OTC MAKES NO OTHER

WARRANTY OFANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, WITH RESPECTTO

THEPRODUCTSMANUFACTURED OR SOLD BYIT, WHETHERASTOMERCHANTABILITY,

FITNESS FORAPARTICULAR PURPOSE, ORANY OTHER MATTER. No agent, employee,

or representative of OTC has any authority to bind OTC to any afrmation, representation,

or warranty concerning OTC products or parts, except as stated herein.

To qualify for warranty consideration, return the OTC product, freight prepaid, to an OTC

authorized hydraulic service center. If any product or part, manufactured or distributed by

OTC, is found to be defective by OTC, in its sole judgment, OTC will, at its option, either

repair or replace such defective product or part, and return it via best ground transportation,

freight prepaid.

THIS SHALL BE THE EXCLUSIVE REMEDY AVAILABLE FOR ANY DEFECTS IN THE

PRODUCTS OR PARTS MANUFACTURED OR SOLD BY OTC, OR FOR DAMAGES

RESULTING FROM ANY OTHER CAUSE WHATSOEVER, INCLUDING, WITHOUT

LIMITATION, OTC’S NEGLIGENCE. OTC SHALL NOT, IN ANY EVENT, BE LIABLE TOANY

BUYER FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES OF ANY KIND, WHETHER

FOR DEFECTIVE OR NON-CONFORMING GOODS, NEGLIGENCE, ON THE BASIS OF

STRICT LIABILITY, OR FOR ANY OTHER REASON.

The purpose of this exclusive remedy shall be to provide the buyer with repair or replacement

of products or parts, manufactured or distributed by OTC, found to be defective in materials

or workmanship, or negligently manufactured. This exclusive remedy shall not be deemed

to have failed its essential purpose so long as OTC is willing and able to repair or replace

said defective products or parts in the prescribed manner.

Repair Service

Should your torque wrench require repair service, contact your nearest OTC

authorized torque wrench repair center, and provide them with the date of

purchase information. If the unit is determined to be in warranty, it will be

repaired or replaced at no charge and returned freight prepaid.

If the unit is determined to be out of warranty, it will be repaired for a nominal

service charge plus return freight.

Table of contents

Other SPX Power Tools manuals