1009510 Rev A 2

TABLE OF CONTENTS

INTRODUCTION ......................................... 2

SAFETY PRECAUTIONS ............................ 2-3

SPECIFICATIONS ........................................ 3

SAFETY DECALS AND LABELS.................. 3-4

CONTROLS ............................................ 4-5

ASSEMBLY AND SET-UP .......................... 6-7

OPERATING INSTRUCTIONS.................... 7-10

MAINTENANCE AND STORAGE ............. 10-11

SERVICE AND ADJUSTMENTS .............. 11-20

WARRANTY....................................... 21-24

INTRODUCTION

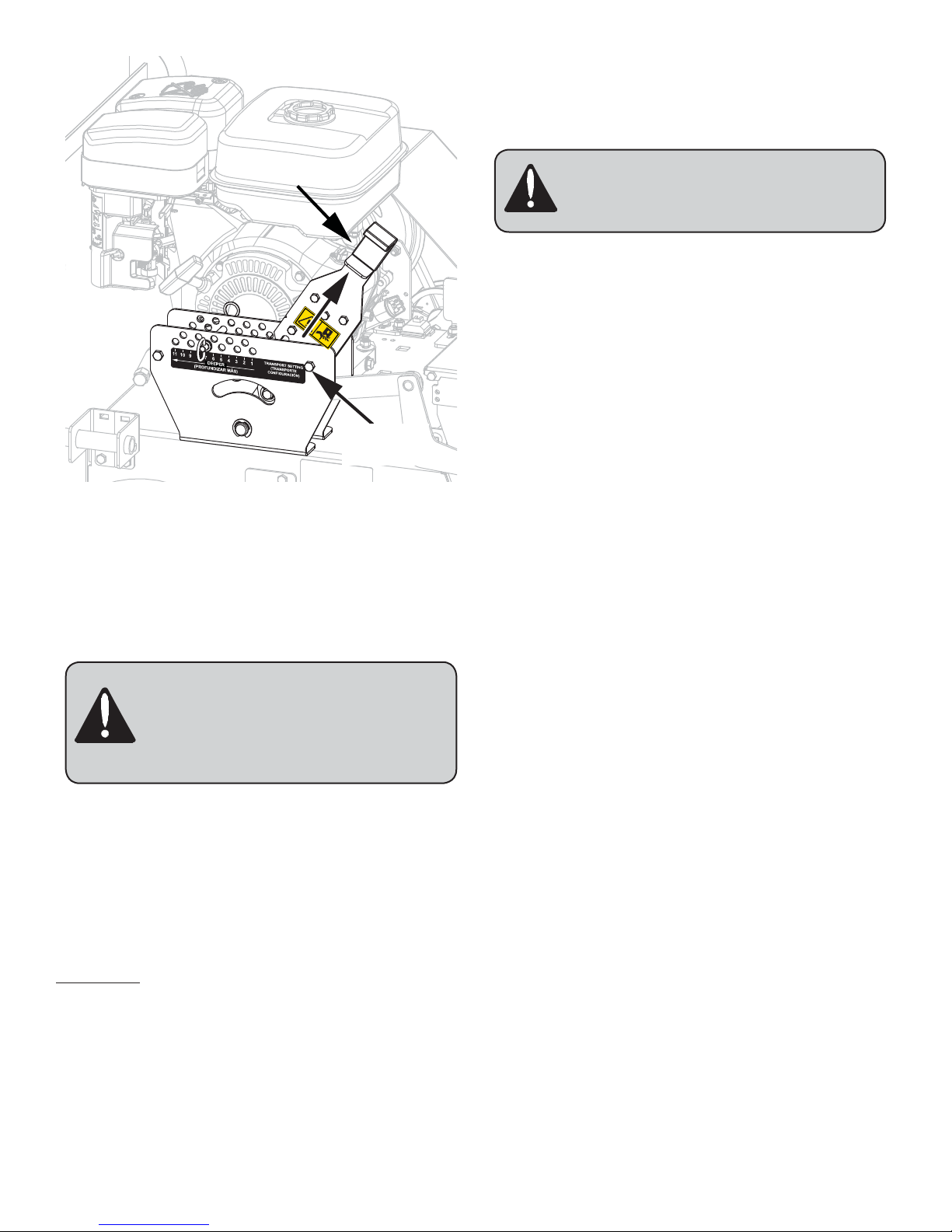

UNDERSTANDING THE MACHINE SAFETY LABELS:

The machine safety labels shown in this section are placed in

important areas on your machine to draw attention to potential

safety hazards.

On your machine safety labels, the words DANGER, WARNING,

and CAUTION are used with this safety-alert symbol. DANGER

identifies the most serious hazards.

The operator's manual also explains any potential safety hazards

whenever necessary in special safety messages that are

identified with the word CAUTION and the safety-alert symbol.

Safety Alert Symbol

CAUTION: THE Spyker S120-4510

Power Seeder should only be operated

and maintained by thoroughly trained

individuals. The machines could cause

serious injury to anyone who misuses them

or does not understand their operation. All

operators and maintenance personnel are

urged to read this entire manual for their

personal safety.

NOTE: The engine manufacturer is responsible for all engine-

related issues with regards to performance, power-rating,

specifications, warranty and service. Please refer to the engine

manufacturer's owners/operator's manual, packed separately

with your unit, for more information.

SAFETY PRECAUTIONS

1.0 Training

1. Read the Operator’s Manual and other training

material. If the operator(s) or mechanic(s) cannot read

English, it is the owner’s responsibility to explain this

material to them.

2. Become familiar with the safe operation of the

equipment, operator controls, and safety signs.

3. All operators and mechanics should be trained. The

owner is responsible for training the users.

4. Never let children or untrained people operate or

service the equipment. Local regulations may restrict

the age of the operator.

5. The owner/user can prevent and is responsible for

accidents or injuries occurring to themselves, other

people or property.

2.0 Preparation

1. Evaluate the terrain to determine what accessories

and attachments are needed to properly and

safely perform the job. Only use accessories and

attachments approved by the manufacturer.

2. Wear appropriate clothing including safety glasses,

hearing protection, long pants, and safety shoes.

Long hair, loose clothing or jewelry may get tangled in

moving parts.

3. Inspect the area where the equipment is to be used

and remove all objects such as rocks, toys and wire

which can be thrown by the machine.

4. Use extra care when handling gasoline and other fuels.

They are flammable and vapors are explosive.

• Use only an approved container

• Never remove gas cap or add fuel when engine is

running. Do not smoke.

• Never refuel or drain the machine indoors.

• Always shut off the engine and permit it to cool

before removing the cap of the fuel tank.

• If the fuel container spout will not fit inside the fuel

tank opening, use a funnel.

• When filling the fuel tank, stop when the gasoline

reaches one inch from the top. This space must

be left for expansion. Do not overfill.

• Clean up oil or fuel spillage.

5. Check that safety switches and shields are attached

and functioning properly. Do not operate unless they

are functioning properly.

6. Do not remove any shield, guards, decals or safety

devices. If a shield, guard, decal or safety device is

damaged or does not function, repair or replace it

before operating the unit.

3.0 Operation

1. Never run an engine in an enclosed area.

2. Only operate in good light, keeping away from holes

and hidden hazards.

3. Be sure free wheel lever is in neutral, machine on level

surface, and parking brake is engaged before starting

engine. Always keep feet and hands clear of the engine

frame and slicer blades when starting engine.

4. Be sure of your footing while using pedestrian

controlled equipment, especially when backing up.

Walk, don’t run. Never operate on wet grass. Reduced

footing could cause slipping.

5. Slow down and use extra care on hillsides. Be sure

to travel in the recommended direction on hillsides.

Turf conditions can affect the machine’s stability. Use

caution while operating near drop-offs.

6. Slow down and use caution when making turns and

when changing directions on slopes.

7. Never raise or lower the slicer blade depth adjustment

with the slicer blades running.

8. Never operate with guards not securely in place. Be

sure all guards are attached, adjusted properly, and

functioning property.

9. Do not change the engine governor setting or over-

speed the engine.

10. Stop on level ground, disengage drive, shift free wheel

control to neutral, engage parking brake, shut off