40 Foot 3-Section Drill Cover

Great Plains | 195-614M | 11/05/2020 v

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intended Use Statement . . . . . . . . . . . . . . . . . . . 1

Prohibited Use . . . . . . . . . . . . . . . . . . . . . . . . 1

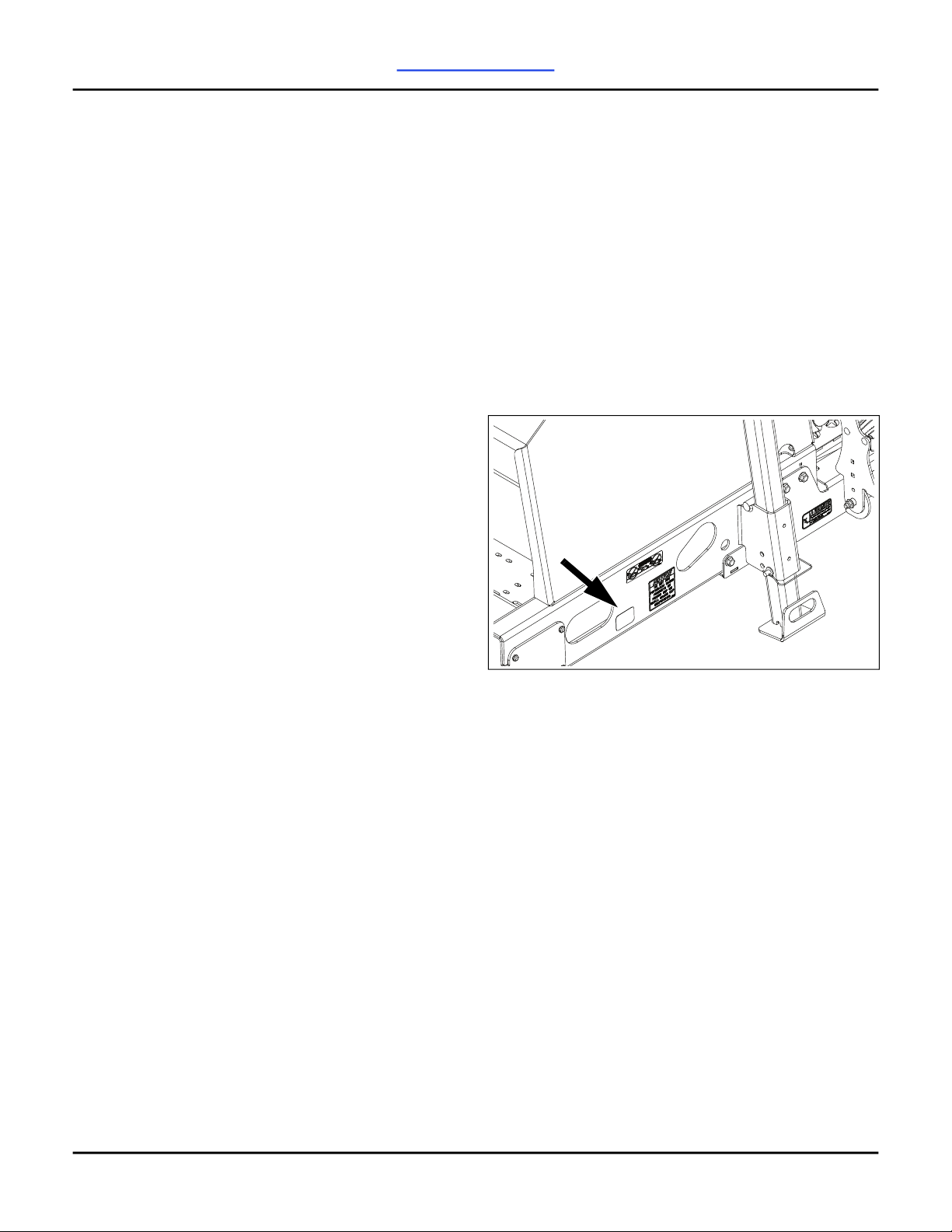

Machine Identification . . . . . . . . . . . . . . . . . . . . . 1

Directional Information . . . . . . . . . . . . . . . . . . . . . 1

Target Group for Operator Manual. . . . . . . . . . . . 2

Training and Instruction . . . . . . . . . . . . . . . . . 2

Range of Application . . . . . . . . . . . . . . . . . . . . . . 2

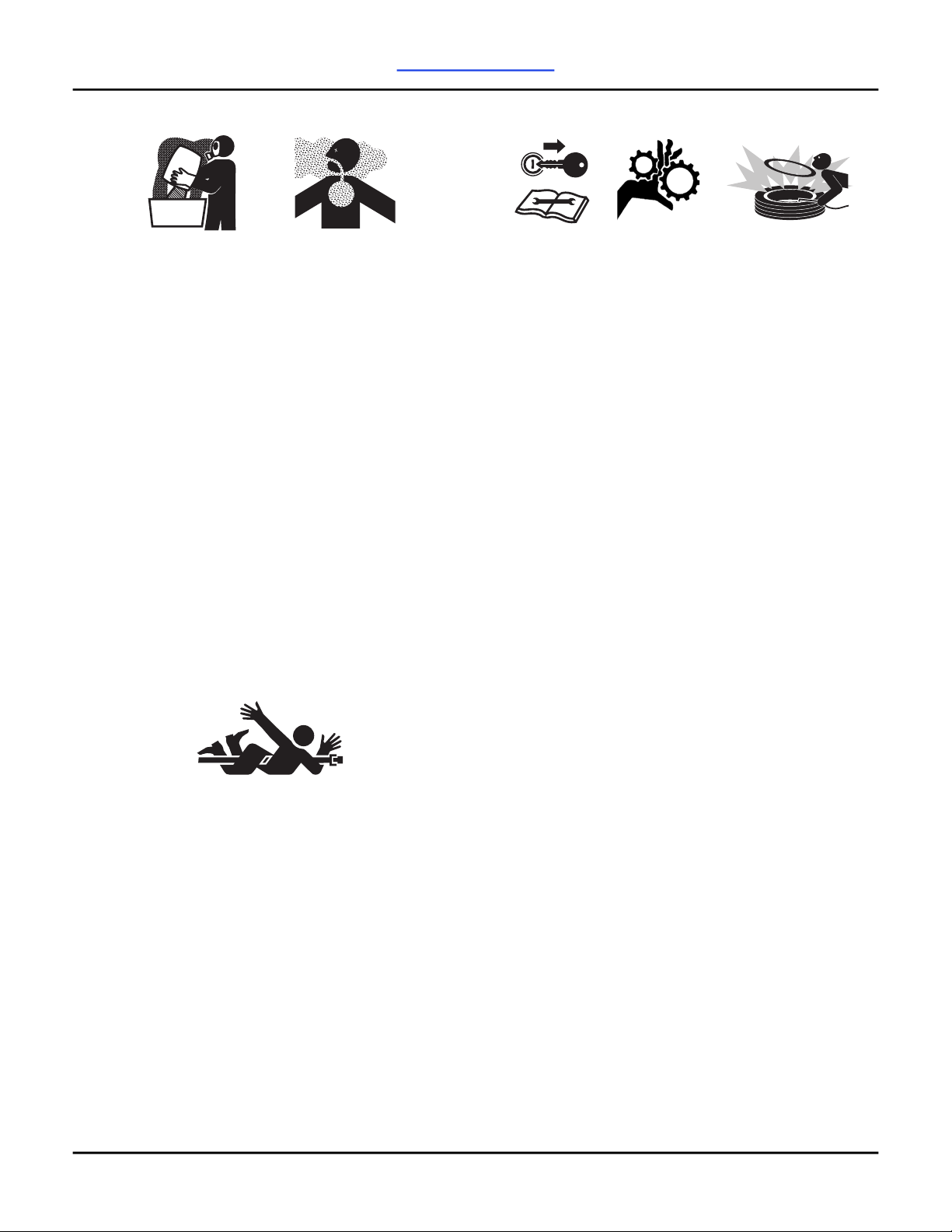

Safety Information . . . . . . . . . . . . . . . . . . . . . . . 3

Before Getting Started . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Handling and Disposing of Chemicals . . . . . . 4

Operation Noise Hazard. . . . . . . . . . . . . . . . . 4

PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tire Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

High Pressure Fluids . . . . . . . . . . . . . . . . . . . 5

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Chain. . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Lights and Devices . . . . . . . . . . . . . . . 5

Shutdown and Storage. . . . . . . . . . . . . . . . . . . . . 5

Proper Waste Disposal . . . . . . . . . . . . . . . . . . . . 5

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Preparation and Setup. . . . . . . . . . . . . . . . . . . 13

Pre-Setup Checklist . . . . . . . . . . . . . . . . . . . . . . 13

Hydraulic Hose Connections . . . . . . . . . . . . . . . 13

Electrical Connections . . . . . . . . . . . . . . . . . . . . 13

Hitch Drill to Tractor . . . . . . . . . . . . . . . . . . . . . . 13

Drill Hitches . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . 15

Drill Leveling. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Center Box Frame Leveling . . . . . . . . . . . . . 15

Opener Frame Clearance. . . . . . . . . . . . . . . 15

Wing Box Alignment. . . . . . . . . . . . . . . . . . . 17

Align Transfer Drive Shaft - Ground Drive . . 17

Truss Tube Tension . . . . . . . . . . . . . . . . . . . 18

Hydraulic Manifold Blocks . . . . . . . . . . . . . . . . . 18

Setting Closed-Center Block . . . . . . . . . . . . 18

Ground Drive Setup . . . . . . . . . . . . . . . . . . . . . . 19

Preparation Checklist . . . . . . . . . . . . . . . . . . 19

Set Range . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Set Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . 20

Hydraulic Drive Setup . . . . . . . . . . . . . . . . . . . . 20

Preparation Checklist . . . . . . . . . . . . . . . . . . 20

Set Drive Configuration . . . . . . . . . . . . . . . . 20

Adjust for Dry Fertilizer Density . . . . . . . . . . . . . 21

Material Loading. . . . . . . . . . . . . . . . . . . . . . . . . 21

Rear Compartment Loading . . . . . . . . . . . . . 22

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ground Drive Calibration . . . . . . . . . . . . . . . 22

Hydraulic Drive Calibration . . . . . . . . . . . . . . 24

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pre-Start Checklist . . . . . . . . . . . . . . . . . . . . . . . 28

Field Operation. . . . . . . . . . . . . . . . . . . . . . . . . . 28

Before Operating Checklist. . . . . . . . . . . . . . 28

Begin Operating . . . . . . . . . . . . . . . . . . . . . . 28

End Operating . . . . . . . . . . . . . . . . . . . . . . . 29

Material Rate Manual . . . . . . . . . . . . . . . . . . . . . 29

Hydraulic Jack . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tool Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Wing Parking Stands . . . . . . . . . . . . . . . . . . . . . 29

Walkboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Walkboard Ladders . . . . . . . . . . . . . . . . . . . . . . 30

Raise and Lower Openers . . . . . . . . . . . . . . . . . 31

Opener Lock-Up . . . . . . . . . . . . . . . . . . . . . . 31

Folding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Transport Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Raise Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Lower Drill. . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Unfolding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Drill Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Basic Box Components . . . . . . . . . . . . . . . . 33

Two Compartment Box Components . . . . . . 34

Divider Flap . . . . . . . . . . . . . . . . . . . . . . . . . 34

Box Dividers . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rain Flap . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Feed Cups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Feed Cup Components . . . . . . . . . . . . . . . . 37

Feed Cup Funnel . . . . . . . . . . . . . . . . . . . . . 37

Feed Cup Flap . . . . . . . . . . . . . . . . . . . . . . . 37

Slide Gate. . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Openers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Opener Down Pressure . . . . . . . . . . . . . . . . 38

Opener Overview . . . . . . . . . . . . . . . . . . . . . 41

Acremeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Markers (Option) . . . . . . . . . . . . . . . . . . . . . . . . 42

Single Marker Operation. . . . . . . . . . . . . . . . 42

Dual Markers Operation . . . . . . . . . . . . . . . . 42

Section Control (Option) . . . . . . . . . . . . . . . . . . . 42

Shaft Monitor (Option) . . . . . . . . . . . . . . . . . . . . 42

Scale Kit (Option) . . . . . . . . . . . . . . . . . . . . . . . . 42

Touch800® Terminal (Option) . . . . . . . . . . . . . . 42

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43