A120MAN IOM 1 of 7www.squibbtaylor.com 1.800.345.8105

While this informaon is presented in good faith and believed to be accurate, Individuals using this literature must exercise their independent judgment in evaluang product selecon and determining

product appropriateness for their parcular purpose, system requirements and cercaons. The manufacturer reserves the right to change product designs and specicaons without noce.

.comwww.

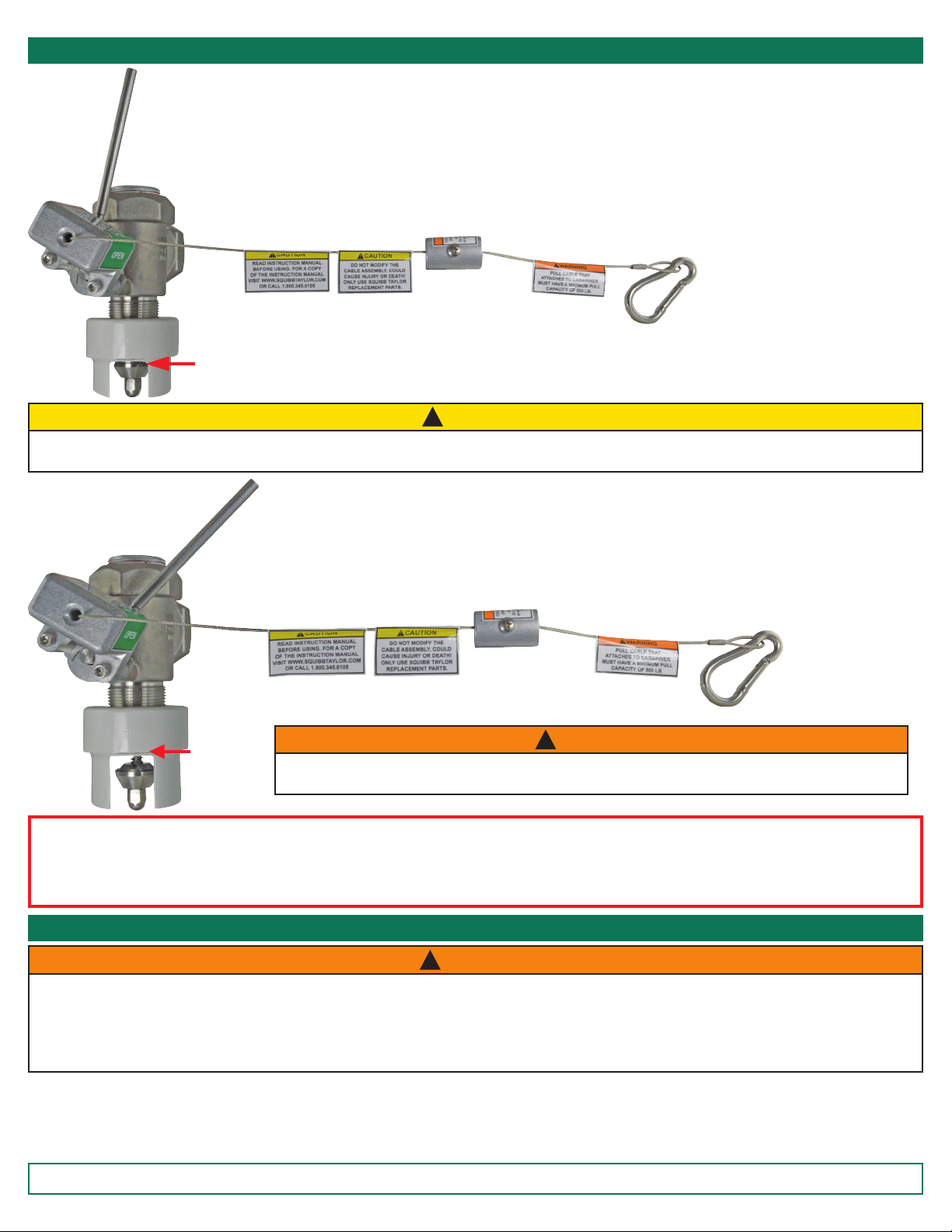

This instrucon manual covers installaon, operaon,

& maintenance for the A120MAN Manual Release for

1 1/4” (A120) & 1 1/2” (A125 & A15) internal valves

manufactured by Marshall Excelsior Co. for outdoor

Anhydrous Ammonia (NH3) applicaons.

.

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN

CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

• This document and other informaon from Squibb Taylor and authorized distributors provide product or system

opons for further invesgaon by users having technical experse.

• The user, through its own analysis and tesng, is solely responsible for making the nal selecon of the system and

components and assuring that all performance, endurance, maintenance, safety and warning requirements of the

applicaon are met. The user must analyze all aspects of the applicaon, follow applicable industry standards, and

follow the informaon concerning the product in the current product catalog and in any other materials provided

from Squibb Taylor or authorized distributors.

To the extent that Squibb Taylor or authorized distributors provide component or system opons based upon data or

specicaons provided by the user, the user is responsible for determining that such data and specicaons are suitable

and sucient for all applicaons and reasonably foreseeable uses of the components or systems.

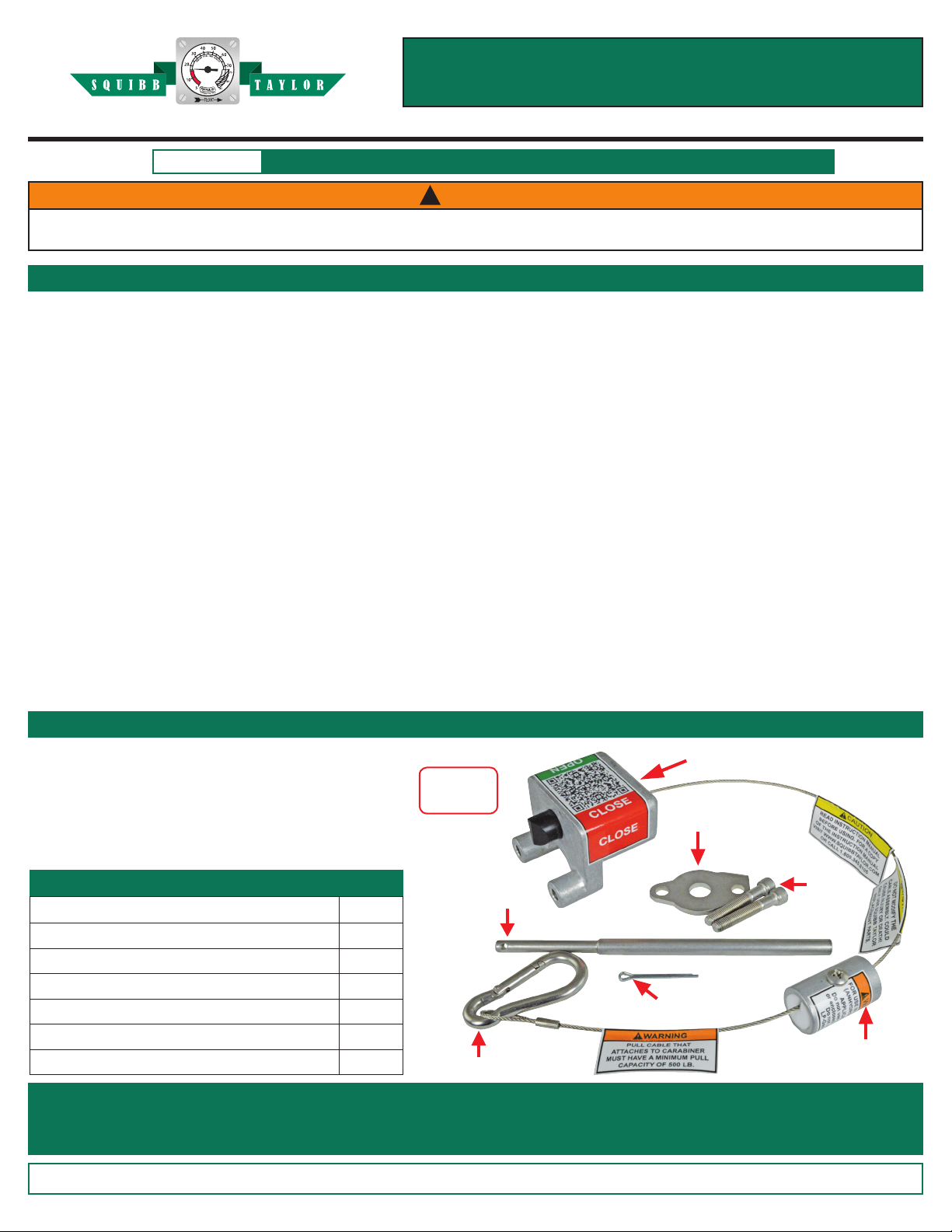

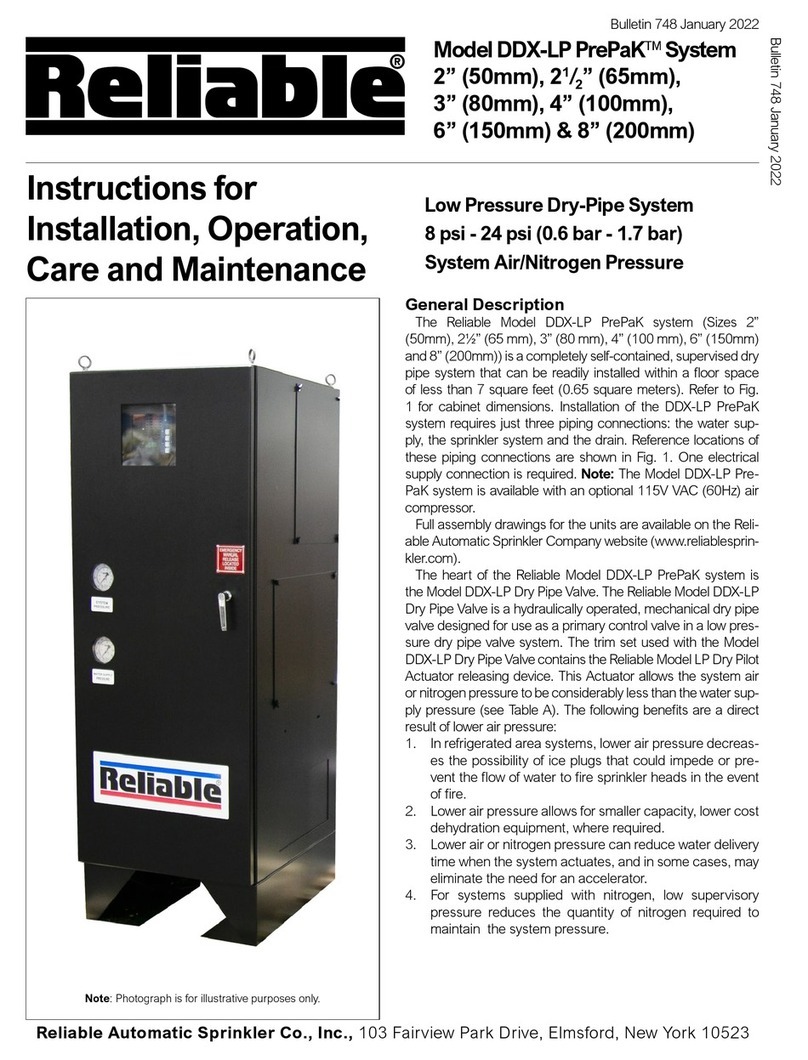

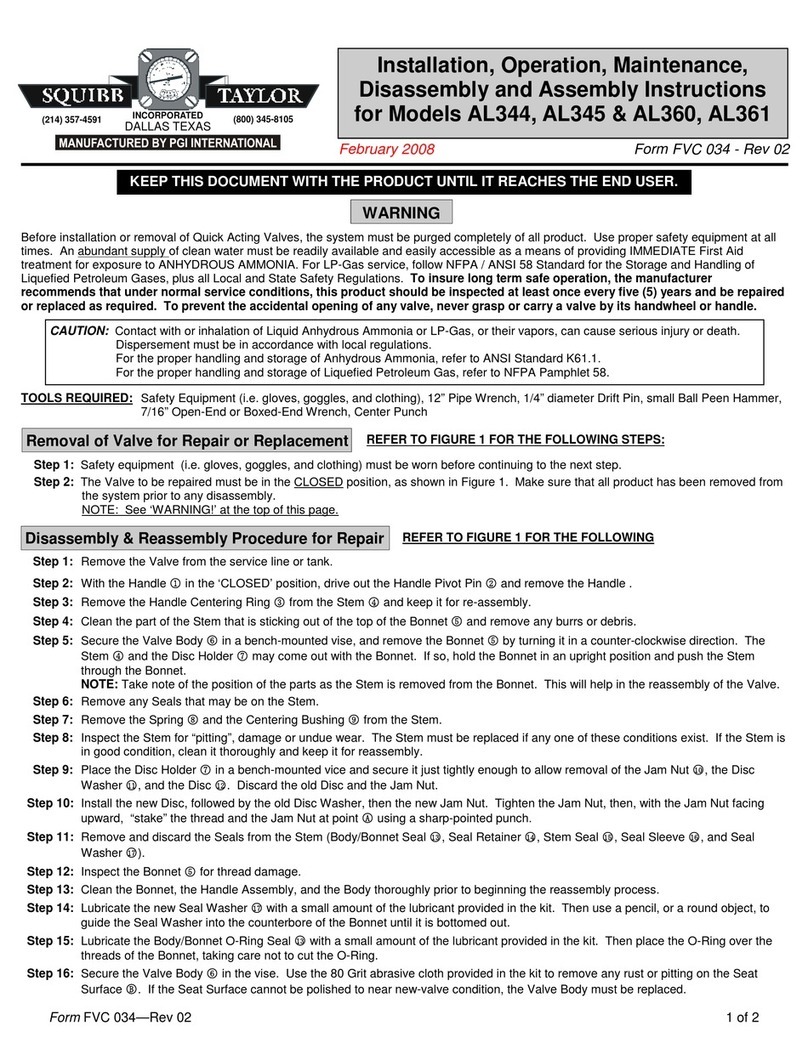

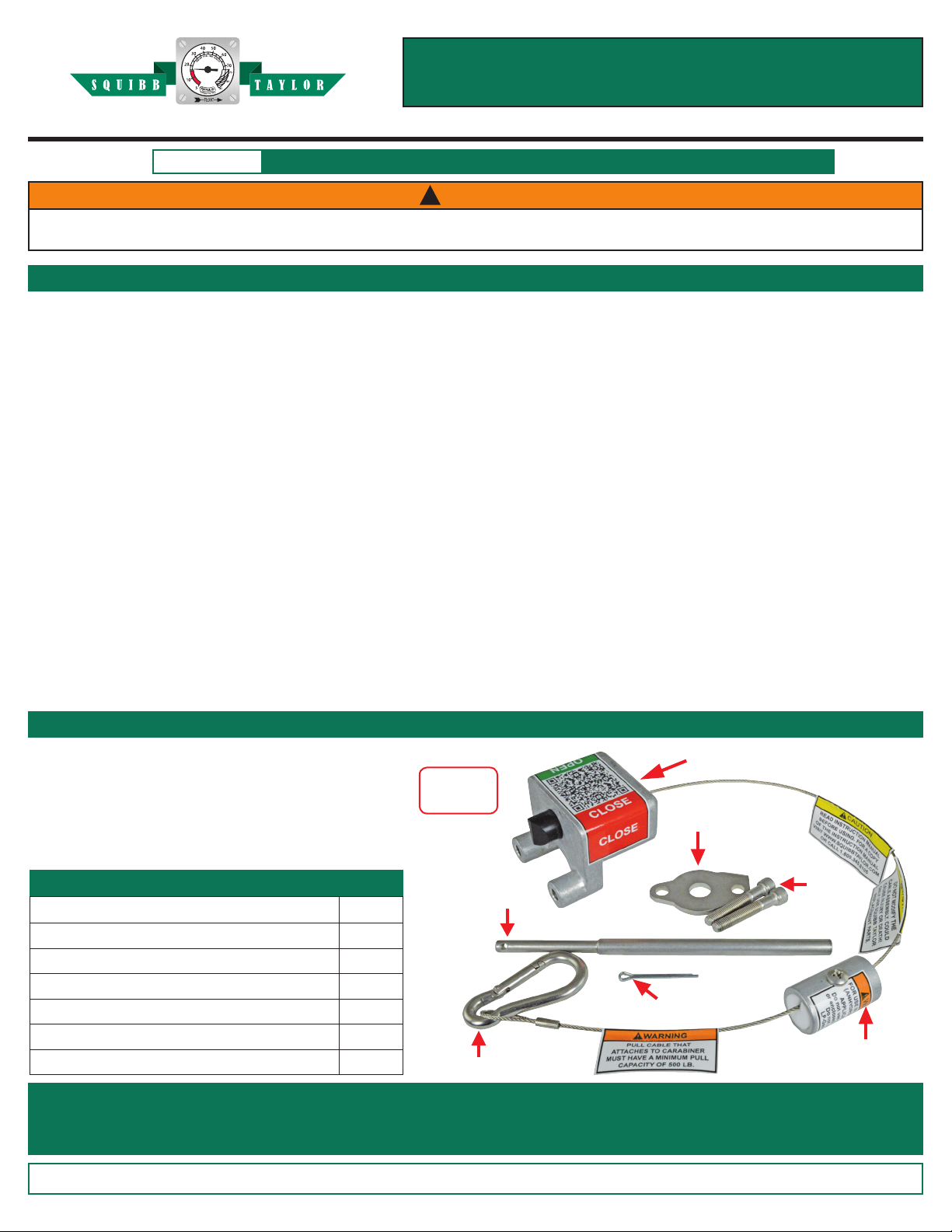

Manual Release with Break-Away Coupling 1 Pc.

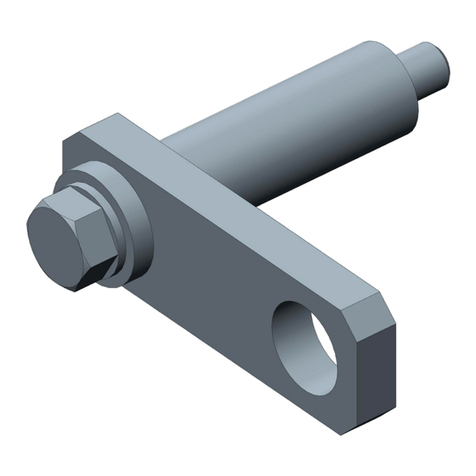

Lever 1 Pc.

Plate 1 Pc.

Coer Pin 1 Pc.

Hex Mounng Cap Screws 2 Pc.

Carabinier 1 Pc.

Carabinier

Cap

Screws

Manual Release

Plate

Lever

Coer Pin

Break-Away

Coupling

Patent

Pending

!WARNING

ANHYDROUS AMMONIA APPLICATIONS ONLY.