Deekax TALTERI DIVK-290 DEMA User manual

TALTERI

DEEKAX Air Oy

Patruunapolku 4 Puh. 0207 912550

79100 LEPPÄVIRTA www.deekaxair.fi

R

DIVK-290 DEMA

AIR EXCHANGE EQUIPMENT

INSTALLATION AND USER

MANUAL

THE QUALITY GOALS OF AIR CONDITIONING COME TRUE

WITH THE RECOVERY SYSTEM

TALTERI removes used air from interior and brings in fresh air.

Humidity and impurities are exhausted through thermal recovery

unit that heats the filtered ambient air cost-effectively. The fresh

warm air is channelled draught-free and noise-free into the

premises in necessary quantities.

ENSURE THE QUALITY OF AIR EXCHANGE!

QUALITY TESTED

MACHINE PARTS AND TECHNICAL INFORMATION

1 Exhaust air.................... 125mm

2 Outdoor air.................... 125mm

3 Extract air.................(2x) 125mm

4 Supply air ................(2x) 125 mm

5 Main switch

6 Supply fan EC 118 W

7 Extract fan EC 118 W

8 Heat exhanger

9 Postheater 1000 W

10 Extract/supply air filter (G4) ISO Coarse>75%

11 Supply air filter (F7) ISO ePM1

12 Summer bypass

13

Touchscreen control panel

14 Manual overheat protection

Measurements of the machine:

height .....................435 mm

width.......................585 mm

depth......................460 mm

weight.......................38 kg

RIGHT HANDED MODEL(R)

5

6

8

9

11 12

10

10

14

7

LEFT HANDED MODEL (L)

5

9

14

10 10

8

11

12

6

7

13

2

LpA

Fan speed

%

Fan input power

W

Sound pressure level

of the installation space

dB(A)

Extract air (E)

and supply air (S)

Soundpower

level in the air

ducts by octave

bands L

w

Total sound power level

Hz

63

125

250

500

1000

2000

4000

8000

20

14

18

P

36

32

26

22

0

0

0

0

22

T

29

25

28

32

12

0

0

0

27

30

16

23

P

39

37

34

30

15

0

0

0

28

T

34

33

31

32

23

20

0

0

30

40

23

30

P

43

42

42

37

22

23

0

0

36

T

42

40

36

38

32

30

19

0

37

50

32

32

P

49

49

47

41

27

28

17

0

40

T

46

41

43

38

36

26

14

43

60

47

36

P

54

53

52

47

31

33

22

0

44

T

50

50

46

47

43

42

32

21

48

70

67

38

P

58

58

56

50

34

37

26

15

46

T

54

53

50

52

47

48

38

27

53

80

96

43

P

60

60

60

55

37

41

29

18

52

T

56

55

56

50

51

42

33

56

L

WA

90

135

45

P

64

64

63

57

39

44

32

21

56

T

60

59

58

60

53

54

46

37

60

100

186

48

P

65

65

65

60

41

46

35

24

58

T

62

60

61

63

56

57

49

41

63

45 56

4

4

3

3

2

1

585

81 141 141 141 81

130

215

297

430

460

4

4

3

3

2

1

585

81 141 141 141 81

RIGHT HANDED (R) LEFT HANDED (L)

4

4

3

3

2

1

585

81 141 141 141 81

130

215

297

430

460

4

4

3

3

2

1

585

81 141 141 141 81

RIGHT HANDED (R) LEFT HANDED(L)

Instal-

lation kit 1

50

100

150

200

250

300

350

20 40 60 80 100 120

100%

Airflow

l/s

External pressure of the ductwork

Pa

80%

60%

40%

DIVK-290 DEMA airflows

Extract

Supply

Instal-

lation kit 2

o

o

o

o

3

INSTALLING THE CHANNELLING

The channels for exhaust air and incoming air should be installed, if possible, in a warm space below the vapour

barrier to suspended ceilings or casing. The vapour barrier remains intact and the channels do not need heat

insulation. This also ensures that the airflow in the channels will not freeze due to poor heat insulation as well as there

will be no condensing.

Cleansing of channels also becomes easier. The outside air and exhaust air channels are isolated under warm

conditions, see the instructions.

The channels are compiled of type-approved, rubber gasket parts and winded joint channel. Disconnections will be

removed for sealing and noise reasons. Connections will be secured with closing drawstrings and channels attached

securely to the framework with mounting strings so it will persist also cleaning.

Measuring- and regulation equipment of airflow are installed to exhaust channels after noise deductors and inflow

channels before the deductors. For cleansing, a cleansing hatch should be installed.

Remember, that a good functioning channel is: measured correctly, hermetic, carefully attached, properly isolated and

with hermetic inlets!

T

HE S

YSTEM IS AS GOOD AS ITS W

EAKEST PART!

CHANNEL INSULATION

Since the channels are mounted to the upper base, it must be

carefully isolated so that:

humidity will not condensate on pipe surfaces, the air will not freeze

before heat has been stored, the heated incoming air will not freeze

before it is blown into interior.

The two main rules of channel isolation are:

The warm air channels are always isolated in outer conditions with at

least 10 cm of mineral wool and windscreen plating. The cold air

channels are always isolated in inside premises with 10 cm of mineral

wool and steam barrier plating, for instance AE

-chase or AIM-mat.

I

nsu

lation

ex

amples are sho

w in

figure 4.

CHANNELS OF OUTSIDE AND EXHAUST AIR

The outside air will be obtained through grate without an insect net.

The air inlet will be situated to as clean space as possible, far from the

refuse discharge, smokestack, ventilation outlet and exhaust air tube.

The air inlet will be located to a height of at least 2 meters from ground

on the northern side of the building, opposite side to the traffic. Due to

warm summer weather, the outlet channel has to be thermally isolated

in a loft space. Outgoing exhaust air will be channelled above the

rooftop through well-isolated channel and by 700-900mm high isolated

roof duct. (Figure 5).

Fireplaces like hearths, ovens and sauna heating systems must

have a separate isolated combustion air channels with slide cop

ing.

Figure 4

Minimum insulation thickness of

the ventilation duct ( mm)

Rafter

Blown wool

Steam barrier

Mineral wool

Figure 5

Outdoor air inlet and

exhaust

air outlet.

size of the

duct / dm3/s

100

125

160

Temperature difference between the inside

and outside of the duct

5

o

C

30

30

30

20

40

80

10

o

C

30

40

40

20

o

C

50

50

50

30

o

C

60

60

60

40

o

C

80

80

80

50

o

C

100

100

100

Mineral wool

Supply air and

transfer air vents

Figure 6

INSTALLATION OF VENTS

Income and outlet vents are installed according to the plan.

Special attention is needed while installing income vents since a

wrong

vent in a wrong place and wrong mounting will affect the air

draught and reduce satisfaction. Steam barriers are well tightened.

In saunas, the income air is channelled above the sauna stove and

outlet will be taken from underneath the sauna platform. The sauna

fans are manually adjustable.

In kitchens, the outlet appliance should be the stove hood with

adjustment plate of three positions and an airflow gauge. The exhaust

vent is operated by the means of the adjuster. The kitchen exhaust

will be attached to the air exchange unit.

In case sound isolation is needed between the separate rooms,

cushioned air transfer vents are used, figure 6. Air transfer routes in

doorways and under the doors will greatly reduce the privacy.

TALTERI DIVK-290 INSTALLATION

The air exchange unit is meant f or warm inner f acilities. Suitable installation spots are,

among others, of fice, dressing or household facilities and technical or warm storages. In case

the temperature of the installation location is lower than room temp

erature, the factory settings

of the appliance must be changed to obtain f aultless f unctioning. The unit can not be installed

into cold outer premises or garages. Exhaust of condensing water proceeds through a water-sealed

joint hose into a washing basin or “dry” floor well. Check the horizontal position of the unit and free flow of

the condensing water.

UPPER BASE DUCT

The channelling is usually mounted to the upper base thermal insulation.

The steam barrier must be hermetically taped.

43 200 200 43

20

90

130

485

WALL BRACKET

6kpl D=6,5mm

MOUNTING OF TALTERI

The machine can be raised on top of a boiler or a cabinet. A flexible mat

installed under the machine acts as sound insulation. The condensate hose and

the electrical connections must be installed at the same time.

Another way is to mount the machine to the ceiling

: with four M8 threaded

rods the machine can be mounted through its ceiling mounting plate using

rubber dampers. When using a steam barrier assembled on the roof

trusses, the machine can be suspended from it with four M8 threaded rods

using rubber dampers.

The third way is to mount the machine on the wall with a wall mounting

bracket. After installing the wall mounting bracket, the machine is lifted

onto the bracket, the horizontal plane of the machine is checked and

adjusted. If necessary, the lower part of the machine can be secured. After

removing the locking screw, the bottom metal sheet of the machine is

released by first bending the sheet off one and then the other guide.

4

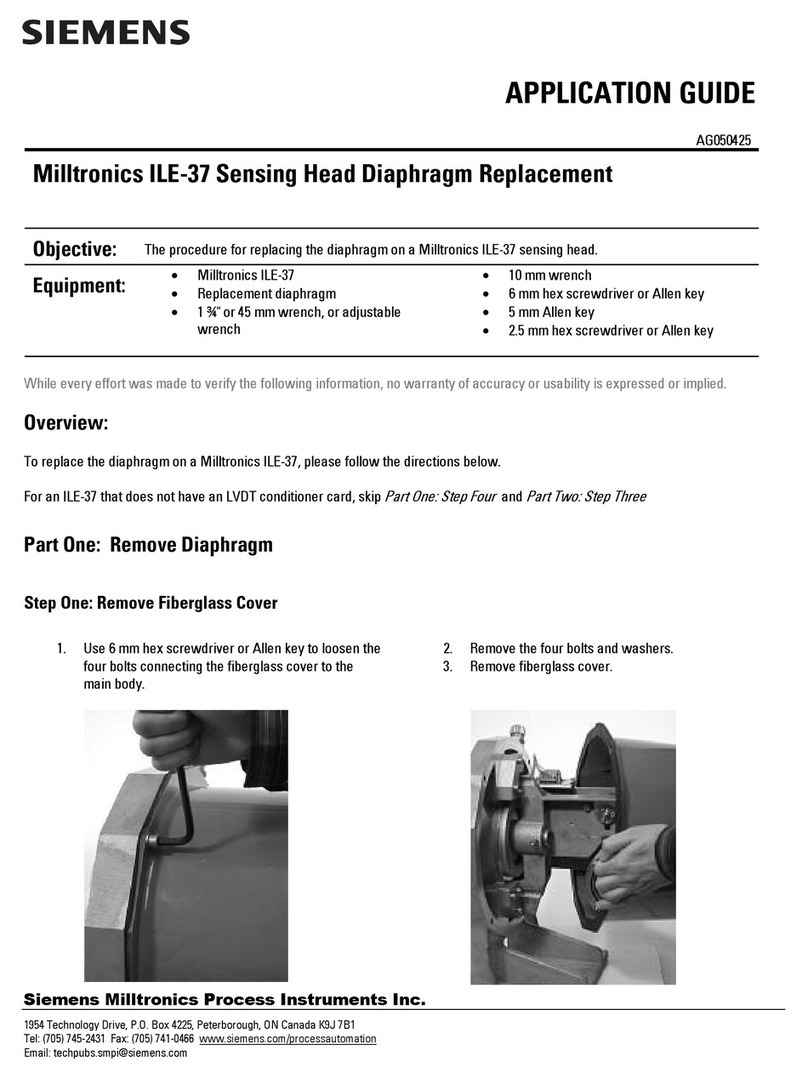

Fig 1 Fig 2 Fig 3

Fig 4 Fig 5 Fig 6 Fig 7

INSTALLATION OF THE COVER PLATE OF THE COVER

The cover plate is installed above the exhaust fan before installing the

machine.

1.Remove the cover insulation.

2.Turn the cover plate into the hole with the screw heads down, the

screw heads below the edges of the hole (Fig.1)

3. Move the cover plate according to the different cover options -

mounting kit 1 right-handed (Fig. 2) - mounting kit 1 left-

handed (Fig. 3)

- mounting kit 2 right-handed (Fig. 4) - mounting kit 2 left-handed (Fig.

5)

4. Install the cover insulation.

5. Glue the additional insulation to the cover plate

DIVK

-

290

INSTALLATION TO A SUSPENDED CEILING

The ceiling-mounting plate is attached

to the

ceiling

with M8

thread bars (not included in the delivery).

BACKUP NUT

RUBBER SILENCER

WASHER

NUT

The head of the threaded bar can not

reach below the bottom of the plate.

The unit will be pushed to the mounting plate and

tightened with four M8 bolts so that the machine seals

ag

ai

nst the plate

M8 THREADED BAR

SPACING BETWEEN MOUNTING

PLATE AND REAR WALL 10-15mm. IF

THE ELECTRICAL CABLE IS

IMPORTED FROM ABOVE

435

THE UNIT IS PULLED

INTO THE MOUNTING

PLATE “RAILS”

BOLT M8X40

WASHER

THE UNIT IS ATTACHEDTO

THE MOUNTING PLATE

FROM THE INSIDE BY FOUR

M8 BOLTS

5

105 105

130 130

575

398

215

130

297

81 81

141 141 141

585

460

THE TOP SURFACE OF THE

MOUNTING PLATE EDGING IS

INSTALLED AT THE LEVEL OF THE

CEILING SURFACE.

DIVK heat exchanger

units have a water trap

built from a condensate hose located under

the base plate (Fig 1). If a condensate trap

outside the machine is used, the machine's

own water trap must be removed and care

must be taken to ensure that the condensate

hose is downsloping.

If the water hose is connected to a 32 mm

sewer pipe located inside the wall, the

connection must be sealed to prevent any

water vapor

entering to the electrical

connection space located under the

machine.

In this case, the supply of intake air

must be ensured by a separate branch made

in the pipe (Fig 2).

If the water hose is connected to the sink

drainage ring, a water trap must be made

next to the sink water trap (Fig 3).

It is not recommended to lead the

condensate hose to a water trap or floor

drain where hot wash or shower water is led.

After installation, check the drainage of water

from the condensate tank.

TALTERI

Electrical enclosure

TALTERI

50-100 mm

Fig 3

Fig 2

Branch vent

Fig 1

TALTERI

Door of the unit

Door of the unit

Electrical enclosure

TALTERI has a

built-in

condensate

water trap

. The

drain hose

directs the water

directly

downwards from

the rear wall of

the machine to

the floor drain. If

a separate water

trap is installed,

the water trap

inside the

machine must be

removed.

ALARM

NC

YHT

NO

M

L

N

230 V

max.

8A

250V

NO

- machine running

NC

- machine off

- alarm temperatures

- alarm sensors

- over-temperature alarm

- machine in standby mode

NC

YHT

NO

max.

8A

250V

VAK

NO NC

GENERAL ALARM

ALARM

Spring return damper motor connection

The damper motor closes

- the machine stopped

- the machine in standby mode

- the machine alarm

ELECTRICAL CONNECTIONS

The fan speed of Talteri ventilation unit can be controlled with

Ultra PC EC, PG EC, DS-600 EC and DSA-900 EC cooker hood

or 0-10 V voltage signal from Control panel.

The voltage signal connected to

CO2/%RH1

terminal.

Sensor 1(EXT) can be operated through maintenance menu

of the operating panel.

The boosting of Talteri ventilation unit can controlled with

Ultra KTS cooker hood.

There is a control panel and when the closing damper of the cooker hood

is open the fan speed is enhanced.

Maintenance menu is used to set boost 0, there can be operated the

guantity of boost too.

Input

230V,

50 Hz

10 A

-power

cord

(plug)

Operator panel

+24 0 0-10

CO2/%RH1

+24 00-10

CO2/%RH2

0-10

+24 0 0-10 +24 0

FILTER

+24 0

Heat recovery

bypass

Winter

YHT

summer

ALARM

NC

YHT

NO

G+ G0 OUT1

CO2

sensor

VAK

0

0-10V

COOKER HOOD

0-10v voltage signal

0

0-10V

PC EC

PG EC

Syöttö

230V,

50 Hz

10 A

VS+ GND RH

switch

Pressure

switches

COOKER HOOD

with boosting information

KTS

switch

NO

COM

NC

open

closed

cooling

coil

actuator

DC 24 V

0-10v

max.

8A

250V

switch

MODBUS

A/D+

B/D-

0

MODBUS

O O O

O O O

O O O

ON OFF BIAS B

ON OFF Term

ON OFF BIAS A

boosting

setpoint 0

tip of the data in

pressure comp

setpoint 0

tip of the data in

HUMIDITY

TRANSMITTER

Pulse

switch

Pulse

switch

sensor 1 sensor 2

Overpressure/

extended time

boosting

out-of-

house/

remote

cooling

water radiator

ALARM INDICATION

AND OPERATING

POTENTIAL FREE CONTACT

INFORMATION MACHINE

OR

SPRING RETURN DAMPER

MOTOR CONTROL

Electrical connections must be done following the insta

llation manual

and wiring diagram.

ELECTRICAL CONNECTIONS CAN BE DONE ONLY BY

AN ENTREPRENEUR WITH RESPECTIVE INSTALLATION

RIGHTS.

The following can be connected as

accessories:

- Carbon dioxide transmitter;

- Humidity transmitter;

- Separate Overpressure or Extended

time switch

(pulse switch);

- Separate Boost switch (pulse

switch);

or setting off as pre-data (for

instance, sauna oven,

stove hood);

- Remote control or out-of-home

switches (pre-data);

- Differential pressure switches for

filters;

- External speed control 0-10V.

- Modbus.

The functions can be operated

through maintenance –

and setup menus of the operating

panel

.

The electrical connection box opens from the bottom of the machine

(from below) by removing the screws.

The electrical connection box is displayed by pulling it up to its limit.

Supply voltage can be connected by contact plug.

The control panel is connected to the control card with a modular

connector.

6

CONSENSATE WATER

7

Electrical

enclosure of

the unit

Triac

Input

230V,

50 Hz

10 A

-power

cord

(plug)

( IU )

VS+ GND RH

G+ G0 OUT1

CO2-sensor

Humidity

sensor

Pulse

switch

Switch

Differential

pressure

switch

Accessories

+24 0 0-10

CO2/%RH1

+24 00-10

CO2/%RH2

OVERPRESSURE/

EXTENDED TIME

TEHOSTUS

0-10

OUT-OF HOUSE/

REMOTE

+24 0 0-10

COOLING

+24 0

WATER RADIATOR

FILTER

+24 0

HEAT RECO-

VERY BYPASS

WIN-

TER

YHT

SUM-

MER

T1 T2 T3 T4 T5 T6

OUT-

DOOR

SUP-

PLY

EX-

TRACT

EX-

HAUST

WA-

TER

PRE-

HEATER

POST-

HEATER

CONTROL

PANEL

230VAC

L N PE

FUSE

TEMPERATURE SENSORS

Control board

ECU

ALARM

NC

YHT

NO

R

POST-

HEATER

50c 90c

2A

1A 5B

4B

SWITCH

ON-OFF

N

LN

L

43

5

KS KS

EXTRACT SUPPLY

0-10 0-100 0

SUPPLY / EXTRACT

N NU U

SUPPLY

FAN

EXTRACT

FAN

N3 2 1

K

S

N3 2 1

KS

N3 2 1

K

S

N3 2 1

K

S

L

DIVK-290 DEMA

MODBUS

A/D+

B/D-

0

O O O

O O O

O O O

ON OFF BIAS B

ON OFF Term

ON OFF BIAS A

Pulse

switch

THE INTRODUCTION OF A VENTILATION UNIT

BEFORE OPERATING YOUR AIR EXCHANGE SYSTEM,

MAKE SURE THAT:

- There are no loose objects within the unit or the air impeller;

- The coverings of construction-time are removed from

the outlet- and exhaust air holes;

- All isolations and steam barriers are in order;

- The heat transfer and fans are in their places;

- The condensing water outlet is installed and the water

is drained out;

- The air impellers and their adjusters are in working order;

- Afterheating is regulated and working.

USAGE DURING INSTALLING

The air exchange unit should be started as soon as

installation permits.

Efficient air exchange promotes drying of the constructions

and prevents damage.

In case channelling has not been completed, fans and adjustments

are missing,filter paper must be used in place of fans to keep

the channels clean andprovide sufficient counterpressure for

preventing overload. The unit must be used with full power and

check the drainage of the condensing water.

The appliance, filters and heat exchangers must be cleaned

and the systemadjusted after the construction works are

completed.

BASIC ADJUSTMENT OF AIRFLOW

The unit alone can not produce good interior ear in case

the channels and fans are installed carelessly and main

adjustments are not made.

Regulate the inlet and outlet fans to the planned positions

and start the unit

at design power speed. Measure the airflow in outside- and

exhaust air channels.

The outlet must be 5-10 % higher than inlet. Check the

pressure level of thechannels by checking from the fans and

adjust it accordingly to obtain the pressure level of 20-30 Pa

for fans; adjust and lock the pattern.Draw measuring- and

adjustment records!

USAGE AND CORRECT LEVEL OF AIR EXCHANGE

The air exchange level is regulated by changing the

working speed of the air impeller from the operating panel.

Airflow of different adjustable positions can be seen

from table 2.

Adjustable position 1 is for basic air exchange for an empty house.

Adjustable position 2 and 3 are normal working positions.

Adjustable position 4 and 5 are efficiency positions (i.e. for saunas).

The selection of the speed is performed from the control panel maintenance

menu. The fans can be adjusted for five different speed settings between

20-100%

The correct usage positions will be found by experience;

observing the purity of the air or sultriness when coming in

from outside, observing moisture on the windows or drying

of the sauna.

AFTERHEATING AND SUMMER BYPASS OF INLET AIR

The unit is equipped with 1000 W electrical battery operated

by the means of triac-adjuster operated by the operating device

for afterheating the heat recovered inlet air.

The temperature of inlet air is usually regulated to +16C.

The temperature may be adjusted to higher during winter so there

would be no draught like feeling. In case of severe frost and

efficiency mode the heating power might turn out insufficient –

in such circumstances, the air exchange should be reduced.

The overheating protection launched during malfunctioning

must be annulled manually.

For the summer time, heat exchanger cell is closed by the bypass

plate, so that the extract air does not heat the outside air.

CONDENSING WATER AND FREEZING PREVENTION

THE SUMMER BYPASS OF THE HEAT RECOVERY UNIT MUST BE IN THE WINTER POSITION WHEN THE

AIRFLOWS ARE BEING ADJUSTED.

In freezing weather, water would freeze in the heat exchanger

unless the frost protection reduced the speed of the supply fan

during the defrost cycle. In severe frosts, defrost cycles are

frequent.

Under abnormal conditions (humidity / cold), the heat exchanger may

freeze and the defrost cycles will not have time to defrost it. In this

case, the machine must be stopped, the door opened, if necessary, the

cold air flow must be prevented and let the heat exchanger to defrost.

In the service menu under WASTE AIR COLD menu, the frost

protection setpoint can be changed 0-10oc. The default setting is 5 oc,

if freezing occurs, the setpoint is increased. In dry conditions, the

setpoint can be decreased.

Check the condensate drain from the machine.

Exhaust air heat exchanger cools the moisture exchanger

condenses into water, Which flows the condensation water in the

pool and from there through a hose through a water trap open sewer.

8

9

THE CHANGES OF THE SERVICE MENU SETTINGS ALWAYS HAVE TO BE SAVED

.

Factory setting

10 min

3

Factory setting

17

o

C

MODBUS MENU

Check the separate Modbus manual

SEPARATE FIREPLACE SWITCH OR PRESSURE COMPENSATION

Factory setting

10 min

1

SERVICE MENU

SETTINGS

Note: swipe right at

the top of the screen

INTRODUCTION OF THE AHU CONTROL PANEL

Settings are applied via the service menu

0-10V external control (0-10V hood,remote monitoring) select the deployment

SENSOR 1 "EXT" or SENSOR 2 "EXT"

External control controls the basic speed , replaces the fan speed set in the menu.

Out-of-home, overpressure and boost are in use normally.

The main screen shows the fan speed at REMOTE CONTROL and

below of it is the speed of the inlet fan.

External control fan speeds

0-2V fan 0

2-5V fan 2

5-7V fan 3

7-9V fan 4

9-10V fan 5

DEFAULT SETTINGS

1. 30 %

2. 40 %

3. 60 %

4. 80 %

5. 100 %

FAN SPEED PRIORITY

Fan speed preselection is performed from the control panel service menu.

Inlet and outlet fans can be individually adjusted for five different speeds with fan speeds of 20-100%

BOOSTING FROM THE COOKER HOOD WITH CONTACT TIP INFORMATION.

Intensification time settings 0 and 5...120 min. In 0 position with different switch

pre-data.

Intensification limit settings 1...4 (the air impellers higher than basic speed)

Overpressure duration specification 0 and 5...20 min. In 0 position with different

switch pre-data.

Overpressure limit regulation 1...4 (inlet air impeller higher than outlet air impeller)

REGULATION of the INLET AIR TEMPERATURE

Inlet air temperature range 5...30 oC,

can be adjusted via SETTINGS menu

CO2 AND/or RH SENSORS ACTIVATION

CO2 AND HUMIDY PERCENTAGE SETTING

Note: set the sensor on in the settings menu

10

10

LED OPERATION REASON

BLINGIN RED

RED

YELLOW

GREEN

SENSOR FAULT

RETURN WATER GOLD

INCOMING AIR GOLD

INCOMING AIR HOT

FILTER PRESSURE-

CAP SWITCH

MAINTENANCE INTERVAL

REMINDER

OUT-OF-HOUSE SWITCH

OVERPRESSURE ACTIVATED

INTENSIFICATION ACTIVATE

co2/RH INTENSIFICATION ACTIVATE

PRE-HEATING ACTIVATE

AFTERHEATING OR

AFTERCOOLING ACTIVATED

-

HUMIDITY AND CARBON

DIOXIDE VALUE

IF SENSORS ARE INSTALLED

(accessory equipment)

BLINGIN YELLOW

BLINGIN GREEN

ACTIVATING/DEACTIVATING OVERPRESSURE or (EXT.TIME), INTENSIFICATION AND

AFTERHEATING

OPERATING PANEL USER INSTRUCTION

MAIN DISPLAY AND ADJUSTMENT OF BLOWING SPEED

EDIT

FUNCTIONS

RETURN

EDIT

SET

SET SET

Touch screen buttons:

Boosting

Fireplace switch

(pressure compensation)

Out-of-house mode

Fan speed adjustment 1....5

SET

EDIT

EDIT

EDIT

The button can be used to browse

the menu upwards and change settings.

The button can be used to browse

the menu downwards and change setting value.

Return to the previous or main menu.

CLOCK

THE DISPLAY ALSO

SHOWS POSSIBLE

INCREASED EFFICIENCY AND

MALFUNCTIONS

TEMPERATURE DISPLAY FOR

TEMPERATURE OFOUTSIDE AIR,

INCOME AIR, OUTLET AIR AND

EXHAUST AIR

ACCURACY OF TEMPERATURE

SENSORS +2 oC

Selecting language suomi, svenska, english or eesti

SETUP MENU

Maintenance interval and reset

Display sensor and overheating faults,

temperature deviations, filter exchange and starts

Fault list reset

Air exchange can be reduced/increased during selected time periods.

5 different periods can be programmed. Each time period can be set for one or several weekdays.

In office-mode, the unit stops for the period out of selection and display reads standby.

Weekday and clock selection

The summer bypass plate control. The user of the unit can set the bypass plate manually to

SUMMER/WINTER or AUTOMATIC mode

In summer mode the bypass plate is activated

During the automatic mode, the plate works according to outside temperature. Set value 15...20 oC

The automatic mode has adjustmen

t amplitude of approx 2 hours

CO2 transmitter ON/OFF switching.

Setting of CO2 upper limit.

Set value

250

...1500ppm, 50ppm steps

Regulation of inl

et air afterheating set value

5...30

o

C

SETTINGS

Fan speed adjustment 1....5

%RH transmitter ON/OFF switching.

Setting of RH upper limit.

Set value 30...80%, 5% steps

Regulating amplitude 5...20min

Touch screen buttons:

Boosting

Fireplace switch

(pressure compensation)

Out-of-house mode

Fan speed adjustment 1....5

The button can be used to browse

menu upwards and change settings.

The button can be used to browse

menu downwards and change setting value.

Return previous or main menu.

11

Set value of intensification duration

0 and 5…120 min.

In

0

position

different switch

pre

-

data.

Set value of overpressure duration t

ime

(hearth switch) 0 and 5…30 min.

In 0 position different switch pre-data.

.

12

MAINTENANCE MENU

Changes of the

SERVICE

MENU

settings always have to be saved

Startup with remote control or separate switch;

“remote control ON” the unit operates only

if pre-data is switched on

OR

Out-of-house mode

“Remote control off” the unit operates on

minimum speed with pre

-

data switched on

Usable if the differential-pressure switch is present

Maintenance interval reminder settings 0

-

12 months

SWIPE RIGHT AT THE TOP OF THE SCREEN

SETTINGS

HOME overpressure activated

OFFICE continuation time activated

Modbus

Touch screen buttons:

Boosting

Out-of-house mode

Fan speed adjustment 1....5

The button can be used to browse

menu upwards and change settings.

The button can be used to browse

menu downwards and change setting value.

Return previous or main menu.

Inlet air cooling temperature

-

10...15

o

C

Inlet air heating temperature 30...40

o

C

CO2 and/or RH sensors activation

The external control 0-10 V activation

Office-mode continuation time setting

30…120 min. Usable with a separate

pulse-switch if the weekly clock is used

in office-mode.

CO2 and humidity percentage setting

Return to default settings.

Note VLK’s units post-heating fuction must be switched

on

from th

e service

menu

Extended time(office mode)

13

F

reeze

-

alert

settings

-

10…

10

o

C

Anti

-

freeze appliance’s control

Pre

heating activation

Regulation of VKL-appliance’s

water battery backup-sensor

Set values 0 and

5...10

o

C

,

0

–

deactivated

Afterheating selection

ELECTRICITY or WATER

Regulation of Inlet Air and Pre-heating value

The value of pre-heating should be regulated

to be approx 5c higher than the

limit of cold exhaust air

Overpressure duration specification 0 and 5...20min.

In 0 position with different switch pre-data.

Overpressure limit regulation 1...4

(inlet air impelle

r higher than outlet air impeller)

Intensification time settings 0 and 5...120min. In 0

position with different switch pre-data.

Intensification limit settings 1...4 (the air impellers

higher than basic speed)

The changes of the service m

enu settings always have

to be saved

BACKLIGHT BRIGHTNESS AND STANDBY SCREEN

Adjustment of backlight

Press and hold the FUNCTIONS for about 5 seconds

Options : not in use, time and temperatures

EC speeds preselection is performed from the control

panel maintenance menu.

Inlet and outlet fans can be individually adjusted for

five different speeds with fan speeds of 20

-

100%

14

1. Operating panel

The operation is directed according to settings inserted by the user or installer/manufacturer th

rough the operating panel

as well as according to temperature sensors and set periods.

The operating panel returns from processing state to basic state 2 minutes

after the last button pressing. The return time

from normal position is 2 minutes.

Maintenance menu – for setting suitable parameters for the installation. Maintenance menu is hidden from the end-

user.

“Restoring factory settings” option is also present in the maintenance menu that can be used for turning all settings to

default settings.

The user can use four different selections on the operating panel: weekday and time with the shortcut icons, blowing

speeds, temperatures and air quality values in case there are sensors for these functions.

2. Operating card

The controller card controls the operation of the device user's choices and measurement data from the sensors Received

by. The controller card is

in addition to two transmitter inputs Which can be connected% RH or CO2

transmitter. The card has an additional 4 pcs

switch data inputs and two

EC - a five-speed fan outputs. The control panel is connected to the controller card, a modular six-pole.

3. Controlling of the air impellers

3.1. Speed controlling in default state

The supply and exhaust air controlled 5 speed. Maintenance menu can be selected fans (20-100%) are suitable for

speeds of the subject. The fan speeds are individually user selectable. At speeds in the service menu is the default

setting which the machine starts.

3.2. Overpressurization

Overpressurization state selectable from the outer switch or operation panel. Outlet impeller runs at basic speed, inlet

impeller is set to value of the maintenance menu. The intensifications have no impact at this point. The duration of

overpressurization in minutes is selectable by the user. New push from the switch launches overpressurization from the

beginning. Overpressurization can be shut down also from operating panel. Anti-freeze is deactivated when

overpressurization is switched on.

3.3. Intensification

Intensification of air exchange can be activated from the operating panel or stove hood. Activation from the panel sets

the durability of intensification in minutes (5...120min). Maintenance menu is used to set the quantity and default time.

In this case, CO2/%RH intensification has no impact. Intensification is activated also according to external data.

3.4. CO2- and %RH- intensification

CO2 – transmitter or data given by the transmitter is the basis for air exchange intensification in regulating intervals.

The CO2 maximum limits are set from the panel by the user (250…1500ppm, 50ppm steps). CO2

measuring values can

be seen on the operating panel. The air exchange is periodically intensificated by data of %RH – transmitter or

transmitters. The maximum limits of relative humidity are set from the panel by the user (30…80%, 1% steps). %RH

measuring values can be seen on the operating panel. The card has two transmitter inputs that can be chosen separately

for CO2 or %RH activation and deactivation. Regulation interval is a parameter set through the maintenance menu that

determines how often the impeller speed can change in intensification mode. Set value 5…20 minutes by 1

minute. The

regulation interval is same for both CO2- and % RH intensification.

3.5. Out-of-house function

The “out-of-house” function can be selected from the external switch or from the operating panel. The impellers are set

on minimum speed. However, pr

eviously set intensification or overpressurization will be completed before the impeller

speed is reduced or stopped altogether.

3.6. Weekly clock

The program selectable by the user enables to reduce/increase air exchange during selected periods of time. 5 different

time periods can be programmed at the same time. Each time period can be set with one or several weekdays.

OPERATIONAL DESCRIPTION

15

3.7. Office mode

The installer can select the office mode from the maintenance menu – this is useful in case the air exchange system is installed

into an office where activities take place mostly during daytime. The speeds are controlled by the weekly clock.

The mode is equipped with continuation switch that enables persons who remain in the office for longer to prolong the

functioning of the appliance by set interval. Intensification and out-of-house mode functions are not usable in the office mode.

Remote control mode can also be selected from the maintenance menu that enables to switch the unit on and off by the mean of

pre-programmed data and weekly clock functions are deactivated.

4. Setting the temperature

Temperature is measured from four different sources: temperature outside, inlet temperature, outlet temperature and exhaust air

temperature. The temperatures are displayed on the operating panel. The precision of measurement is +/- 1 degree.

4.1. Afterheating

The thermostat leads the afterheater located in the inlet channel. The heater can be electrical or water heater and is selected by

the installer from the maintenance menu. The heater keeps inlet air at the exact temperature selected by the user. The desired

temperature can be set from the operating panel. Set values are between 5 – 30 degrees.

4.2. Preheating

Preheater is an electric heater located in the outlet channel. The preheater´s thermostat is driven based on the temperature of

exhaust air. Preheating is meant for prevent freezing of the recovered heat. The temperature setting of the thermostat can be

selected by the installer from the maintenance menu with limitations of 0 – 10 degrees.

4.3. Summer cassette function

The unit is equipped with summer cassette for heat exchange during summertime. The user can select the function manually or

let the functioning be determined automatically according to the temperature outside. During the Summer-

mode, the bypass plate

of the cassette is activated.

The automatic functioning can be set with external temperature between 15 – 20 degrees.

5. Alarms and reminders

5.1. Activation of overheat protection

Information on activation of overheats protection connected to electrical afterheater and preheater is received from the heater. In

case the protection launches, the impellers are automatically set on minimum speed, red indicator light blinks on the operating

panel and the display informs about malfunctioning.

5.2. Inlet air too cold

Inlet air minimum temperature must be set from the maintenance menu. When the air temperature is lower than set, the

information will be displayed on operating panel and red indication light is turned on. The inlet impeller is stopped and the

speed

of outlet impeller is reduced to minimum. These actions prevent the water-circulation battery from freezing.

5.3. Income air too hot

Maximum limit of income air temperature must be set from the maintenance menu. When the air temperature exceeds the set

limits, respective information will be displayed on operating panel and red indication light is turned on. The inlet impeller is

stopped and the speed of outlet impeller decreased to minimum.

5.4. Exhaust air too cold

The exhaust air temperature minimum limits must be set from the maintenance menu (-10 … 10 degrees). When the air

temperature is lower, warning is displayed on the operating panel and red indication light is turned on. The temperature is

attempted to keep above the set value by reducing the speed of inlet air impeller (see also preheating) by regulating it one-step at

a time. In case the air temperature does not rise over the alarm limit even when the impeller is completely stopped, the red

indication light starts to blink and freezing alert is displayed. In case the temperature is restored to normal, normal functioning

will be also restored by increasing the impeller speed one-step at a time.

5.5. Danger of water battery freezing

In VKL machines can be set the temperature of the water radiator from the service menu “radiator return min temp”

and when the value falls down, a notification is displayed and the red ind

icator lights up in the control panel. The inlet

fan is stopped.

5.6. Alarms for remote monitoring

General alerts may be taken into the remote control from potentially free relay. Alarms are obtained inlet air hot or

cold, danger of water battery freezing, overheat protectors and if the machine is stopped.

5.7. Maintenance interval reminder

When the maintenance interval is complete, the respective information is displayed on the operating panel and the indication

light blinks green. The user can reset the reminder after the filters have been changed. The maintenance interval counter is reset

and the new alert will be transmitted after the period has been completed again. The maintenance interval can be set between 3 –

12 months.

5.8. Filter-dirty notice

Differential pressure switch can be installed to the equipment that measures dirtiness of the inlet air filter by monitoring its

differential pressure. When the switch runs, the display transmits the necessity of filter-change and the indication light blinks

yellow. Differential pressure switch is taken into use through the maintenance menu and it deactivates maintenance interval

reminder

MAINTENANCE OF TALTERI

For producing good indoor climate continuously, the air exchange systems require regular maintenance.

The metallic grease filter of stove hood must always be kept clean for fire safety reasons. Cleansing with hot

water dishwasher once a month is

necessary. Substances suitable for machine washing may darken the

aluminium parts of the filter.

The inlet and outlet filters of Talteri must be cleansed at least twice a year.

In summertime the summer cassette plate will be set to summer mode

when the external air should come in fresh and clean.

The heat recovery cell will be pulled out of the unit and washed thoroughly in autumn just before the heating

season begins –the heat recovery will then be at its best. Check the condition of sealing and push the heat

recovery cell back to its place.

The inner painted walls of the unit are easy to clean. Check the condition of sealing, clean the outlet hose of

condensing water and make sure the water flows freely and without any obstructions.

The impellers, air exchange adjusters and thermostats are components that do not require regular

maintenance.

Electrical works can be carried out only by a qualified electrician.

Exhaust air heat exchanger cools the moisture exchanger condenses

into water, which flows the condensation water in the pool and from

there through a hose through a water trap open sewer.

Under abnormal conditions (humidity / cold), the heat exchanger may freeze and the defrost cycles will not

have time to defrost it. In this

case, the machine must be stopped, the door opened, if necessary, the cold air

flow must be prevented and let the heat exchanger to defrost.

In the service menu under WASTE AIR COLD menu, the frost protection setpoint can be changed 0-10

o

c.

The default setting is 5

o

C, if freezing occurs, the setpoint is increased. In dry conditions, the setpoint can be

decreased.

Check the drainage of condensing water!

In case the water-lock dries out and makes pulping noise, you can pour into it a drop or two of cooking oil.

In really cold weather, the head recovery unit heats the preheated inlet air with afterheating. The functionality

can be proved by comparing the temperature of inlet air to the set value of the inlet air afterheating.

The overheat protection has been activated in case the temperature has risen +90

o

C (for instance, in case

of power failure). Reset the overheat temperature by pressing the switch under the threaded contact

protection.

The channels must be checked if the impeller works but the air exchange is inadequate or the temperature

changes in the channels between the interior and the machine. Temperature changes and humidity

concentration in channels must be prevented by improving the i

nsulation

.

DEEKAX Air Oy

R

Patruunapolku 4 Puh. 0207 912550

79100 LEPPÄVIRTA www.deekaxair.fi

The heat recovery cell in the

winter position

The heat recovery cell in the

summer position, the bypass plate is turned

in the front of the cell, the outdoor air passes

behind the heat recovery cell.

Table of contents

Other Deekax Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Allen-Bradley

Allen-Bradley 140G-N-TLH3 Installation

Dixon

Dixon BAYCO BC Series Maintenance instructions

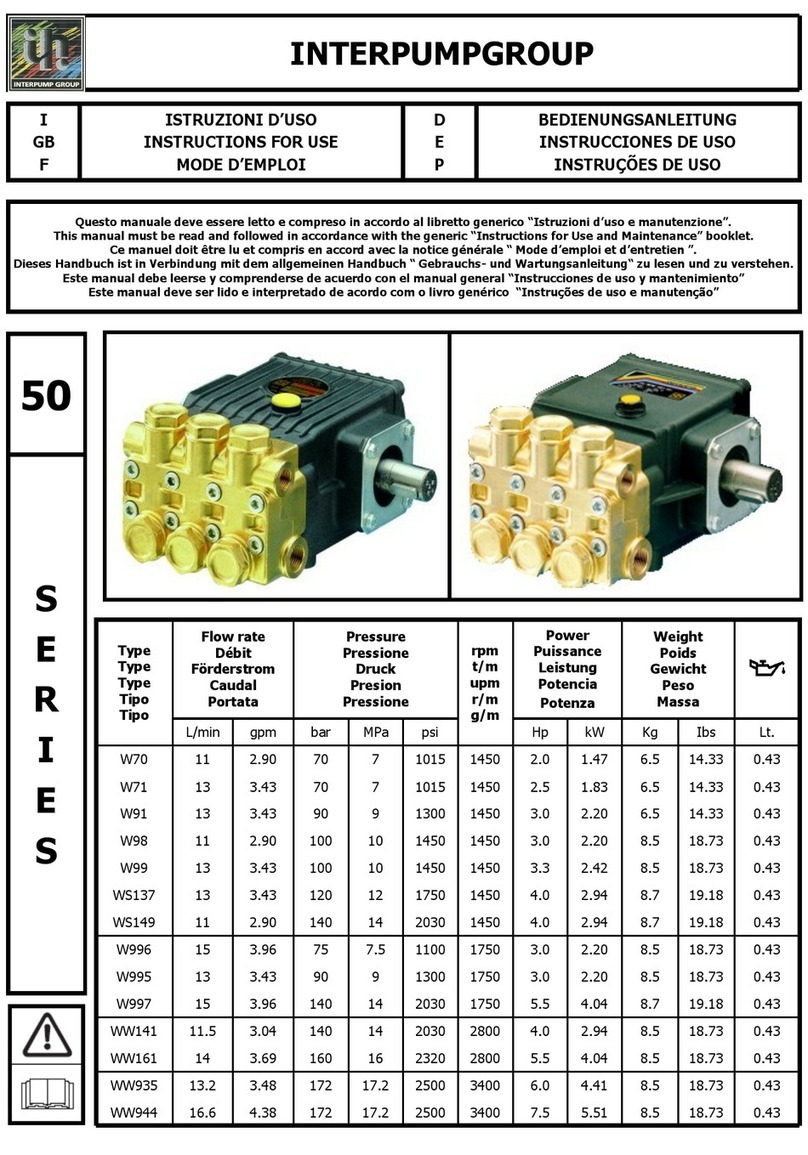

Interpump Group

Interpump Group 50 Series Instructions for use

nbs

nbs Citadel 2.0 Series Installation, operation and maintenance manual

JohnDow Industries

JohnDow Industries JDI-27DC user manual

MBM

MBM FC 10 PLUS Service manual