4

FOREWORD

This manual has been prepared for those persons who will operate and maintain the

Piranha Ironworker. It is important that all persons responsible for the care and

operation of this equipment read and understand the information presented in this

publication.

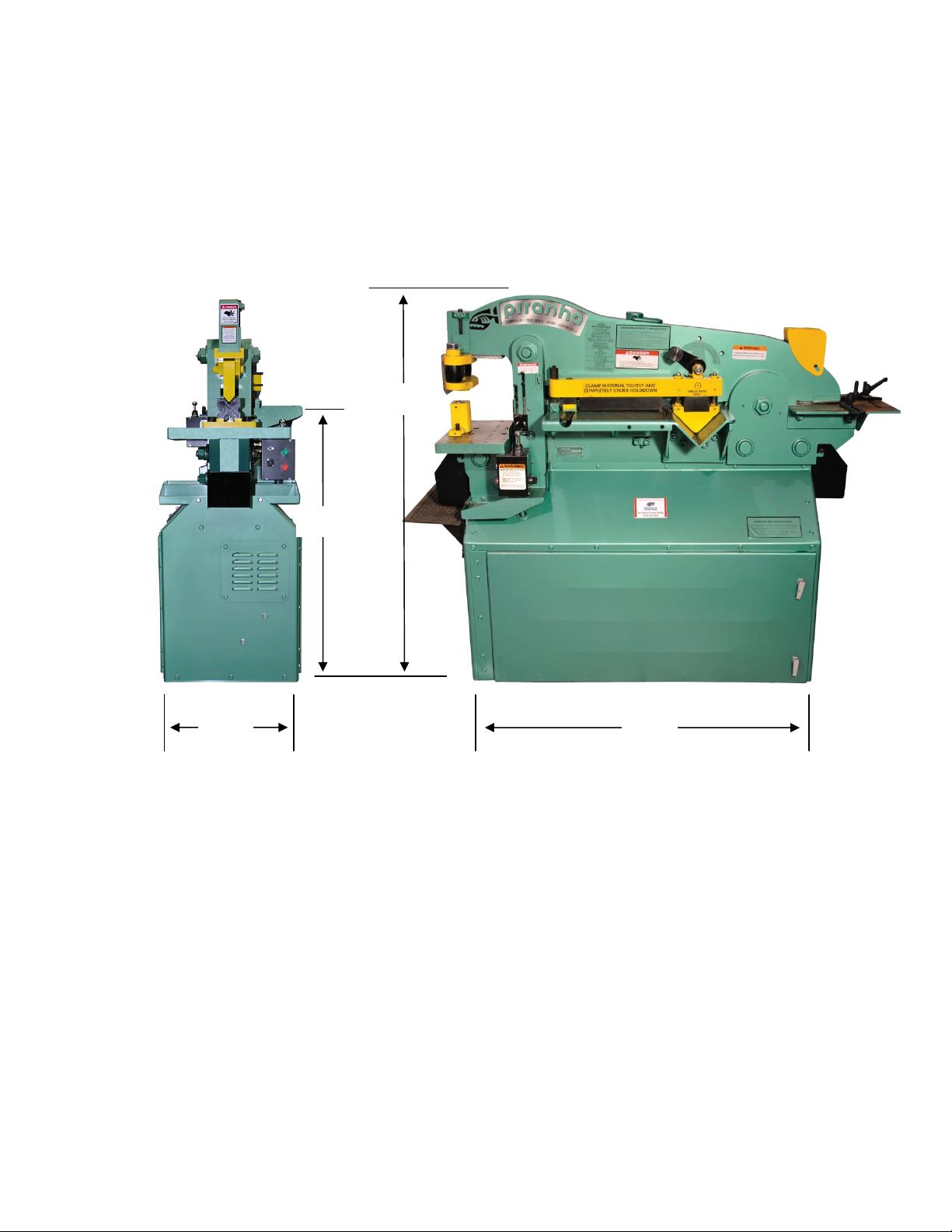

The illustrations and instructions on the following pages were the most recent

available at the time of publication and selection of this material was made based on

a standard machine arrangement. Differences between the machine you received

and the views contained in this manual are the result of design improvement and / or

the addition of optional accessories specified on your order.

WARRANTY

Mega Manufacturing will replace (F.O.B. our factory), or refund the purchase price

for any goods which are defective in materials and workmanship within 12 months of

date of purchase. The buyer must return the warranty registration card within thirty-

(30) days of the purchase date, and at the seller's option, return the defective

materials freight and delivery prepaid to the seller, which shall be the buyer's sole

remedy for defective materials. Seller shall not be liable to purchaser or any other

person for consequential or incidental damages. Hydraulic and electrical

components are subject to their respective manufacturer's warranties. This warranty

does not apply to machines and / or components, which have been altered in any

way, or subjected to abusive or abnormal use, inadequate maintenance, and

lubrication, or to use beyond seller’s recommended capacities and specifications.

Seller shall not be liable under any circumstances for labor costs expended on such

goods or consequential damages. Seller shall not be liable to purchaser or any

other person for loss or damage directly or indirectly arising from the use of the

goods, or from any other cause. No employee, agent, officer, or seller is authorized

to make oral representations or warranty of fitness or to waive any of the foregoing

terms of sale and none shall be binding on the seller.