Squid Ink ALFAMAQ CoPilot 128 User manual

Rev Q 2003978

CoPilot

128/256

Industrial Inkjet

Printing System

User Guide

Rev Q 2003978

CoPilot 128 and 256

Industrial Inkjet

Printing System

User Guide

Revised 12/4/2018

P/N 2003978 Rev Q

Copyright and Trademarks

Copyright ©2018 Squid Ink Manufacturing.

All rights reserved. All trademarks and brand names

are the property of their respective owners.

1a. Cda. Jacarandas #14 Col. El Vergel, Iztapalapa. Ciudad

de México C.P. 09880

(55) 5426-4137 800 253-2627

Rev Q 2003978

Rev Q 2003978

Rev Q 2003978

Contents:

Safety.........................................................................................................9

Introduction .............................................................................................10

General System Description ....................................................................................... 10

System Components................................................................................................... 10

System Specifications ................................................................................................. 12

Software Specifications............................................................................................... 13

Options........................................................................................................................ 14

Installation and Setup.............................................................................15

General Recommendations ........................................................................................ 15

128 Printhead Overview.............................................................................................. 16

256 Printhead Overview.............................................................................................. 17

Controller Overview..................................................................................................... 18

Mounting ..................................................................................................................... 19

Printhead(s) ........................................................................................................................19

Controller ............................................................................................................................20

Printhead Height .................................................................................................................22

Photocell .............................................................................................................................25

Distance from Substrate......................................................................................................26

Rotating and Tilting the Printhead .......................................................................................27

Data Cable Connections ............................................................................................. 29

Connecting Photocell Trigger to Controller ..........................................................................29

Connecting an Optional Encoder to the Controller...............................................................29

Custom Triggering Device...................................................................................................30

Printhead Data Cable ..........................................................................................................31

Connecting a Second Printhead..........................................................................................33

Connecting a Second CoPilot Printing System ....................................................................34

Connecting an Optional Low Ink Warning Light ...................................................................35

Connecting to a desktop PC................................................................................................36

Connecting to a Local Area Network ...................................................................................36

USB Port ..................................................................................................................... 37

Optional Four Port USB Hub ...............................................................................................38

Power Supply.............................................................................................................. 39

Ink Supply ................................................................................................................... 40

Cartridge Ink System...........................................................................................................40

Bag Ink System ...................................................................................................................44

IMPORTANT! Handling of Ink Bags: ...................................................................................46

Operation .................................................................................................47

Priming........................................................................................................................ 47

Priming the Cartridge Ink System ........................................................................................47

Priming the Bag Ink System ................................................................................................48

Power up..................................................................................................................... 49

Home Screen .............................................................................................................. 50

Zoom Function ............................................................................................................ 52

Message Screen ......................................................................................................... 53

Rev Q 2003978

Message Screen Remote Server ................................................................................ 54

Settings Screen........................................................................................................... 55

Line Speed:.........................................................................................................................56

Distance to Trigger: .............................................................................................................58

Print Direction:.....................................................................................................................59

Encoder Divider:..................................................................................................................60

Repeat Print: .......................................................................................................................61

Counters: ............................................................................................................................62

Spit Function: ......................................................................................................................63

Peak Encoder Speed: .........................................................................................................65

USB Load:...........................................................................................................................66

Reset: .................................................................................................................................67

Ink Status ............................................................................................................................68

Print Engine Alignment:.......................................................................................................69

Calibrate Touchscreen ........................................................................................................70

Remote Database Server....................................................................................................72

Set Date: .............................................................................................................................75

Set Time:.............................................................................................................................75

Custom Keyboard: ..............................................................................................................76

Language: ...........................................................................................................................78

Static IP Address:................................................................................................................79

User Data:................................................................................................................... 80

Wireless Interface: ...................................................................................................... 81

WiFi:....................................................................................................................................82

Bluetooth:............................................................................................................................84

Description of CoPilot 128/256 Touchscreen Buttons ................................................. 85

Powering Off ............................................................................................89

Mounting Options ....................................................................................90

Floor Stand ................................................................................................................. 90

Conveyor Mounting Bracket........................................................................................ 91

Maintenance ............................................................................................92

Mounting Hardware and Connections......................................................................... 92

Nozzle Face Plate....................................................................................................... 92

Cleaning External........................................................................................................ 92

Flushing the Printhead ................................................................................................ 93

Parts List .................................................................................................96

CoPilot 128/256 Replaceable Parts Main Components .............................................. 96

Mounting Hardware..................................................................................................... 97

Ink Systems .............................................................................................................. 102

Printheads................................................................................................................. 108

Component Dimensions ........................................................................110

128P/256 PN 2003902.............................................................................................. 111

Controller, Exploded View .................................................................................................111

CoPilot 128/256 System Updates .........................................................113

Applying Updates from USB ..................................................................................... 113

Rev Q 2003978

Piezo Printing System ...........................................................................115

Product Warranty ..................................................................................115

Customer Support .................................................................................118

8Safety

Rev Q 2003978

Rev Q 2003978

Safety

The Squid Ink CoPilot 128/256 printing system is easy to install, operate and maintain.

Follow these simple safety steps to insure a smooth and safe operation.

•The CoPilot 128/256 components are reasonably compact and lightweight. However,

while unpacking and setting up the printer, always take care and use proper lifting

techniques. Try to avoid over reaching and twisting while handling the printer and

accessories. If necessary, use two people to lift and move the printing system.

•While installing, maintaining and operating the printing system, always wear safety

glasses, gloves and protective clothing.

•Make sure the electrical power source is properly wired and grounded. The power

source should comply with all safety regulations and codes applicable to the

installation location.

•Turn off and unplug the printing system while servicing and performing maintenance.

Note: Some service and maintenance procedures require

the power be left on. During such procedures,

carefully follow the safety instructions.

•Use only Squid Ink Manufacturing ink or other Squid Ink manufacturing approved

fluids.

•The Squid Ink CoPilot 128/256 printer can use an ink cartridge or an ink bag system.

Do not open or puncture the ink supply cartridge or bag in any way other than normal

installation.

•Keep all fluids away from open flame and excessive heat.

•Avoid prolonged contact with skin. Fluids can be washed with soap and water.

•Never look directly into the printhead. If any fluid should make eye contact, flush

immediately with water and receive appropriate medical attention.

•Never pour fluids into sink, sewer or drain. Dispose of fluids in accordance with all

ordinances and regulations pertaining to fluid disposal.

10 Introduction

Rev Q 2003978

Introduction

General System Description

The CoPilot 128/256 printing system consists of a controller with an integrated user

interface, and up to two 128 or two 256 printheads with cartridge or bag ink systems. The

CoPilot printing system is designed to print superior quality high-resolution characters on

a variety of porous and non-porous surfaces.

Note: This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the

user will be required to correct the interference at his/her own

expense.

Attention! Messages for the CoPilot 128/256 Printing Systems are

created and edited using PC based Orion™ software.

Messages are then loaded onto the CoPilot controller via

Ethernet connection or from a USB device. Use the Orion

User Guide that came with your printer for information on how

to connect, create and print messages.

System Components

•Controller

•Printhead(s)

•Printhead Data Cable(s) 256 only

•Sensor (photocell)

•Encoder (Optional)

•Ink System (Bag or Cartridge)

•Mounting Hardware

Introduction 11

Rev Q 2003978

If you have purchased an optional level of Orion™ that allows a you to connect to multiple

printers, you will find upon opening the CoPilot 128/256 shipping carton a “DOWNLOAD

INSTRUCTIONS” card. Do not throw this card away! It contains a serial number that

will be needed for downloading the Orion™ message creation software and connecting

the CoPilot printing system. If your card becomes lost, you can still download the Orion™

message creation software and connect to a single printer. Please call our tech support

department at 1-800-877-5658 if you have any issues or questions.

12 Introduction

Rev Q 2003978

System Specifications

Print Technology Piezo impulse printhead technology.

Print Speed Up to 135 fpm (41 m/min) @ 205 dpi.

Vertical Print Resolution 185 dpi.

Horizontal Print Resolution 205 dpi.

Maximum Print Height 1.4 in (3.6 cm) per 256 printhead.

.7 in (1.8 cm) Per 128 printhead

Time & Date Internal Realtime clock with battery back-up.

Product Sensor External photocell and/or optional encoder.

Communication Interface One USB host and one Ethernet input.

Electrical Requirements 100 – 240 VAC, 50/60 Hz. 65W Max.

Operating Environment 34°F (1°C) to 122°F (50°C).

Storage Environment 0°F (-18°C) to 140°F (60°C).

Substrate Capabilities Porous or non-porous applications.

Ink Capabilities Solvent or oil-based inks.

Ink System Ink system utilizes Squid Ink Manufacturing 500ml

cartridge or pigmented bag ink systems.

Low Ink Indicator message alert on touchscreen.

Agency Certifications TUV and CE certified (Pending).

Introduction 13

Rev Q 2003978

Software Specifications

Time & Date Multiple formats including: 1,2,4, digit year, 1,2-digit

month, 3 Letter months, custom month string, 1 letter

day of month (Korean), 2-digit day of month, 1-digit day

of week, 1,3 letter days of week, 2-digit week of year,

3-digit Julian year, 1 letter hour, (a-x), 2-digit hour 12

or 24, 2-digit minute, 2-digit second, 1,2 letter meridian

(A/P, AM/PM), custom week string.

Counters Supports 16 Counters, one of which can be designated

as a daily counter.

Shift Codes Four programmable shift codes with automated

rollover.

Bar Codes Code 39, Interleaved 2 of 5, UPC-A, EAN-8, EAN-13,

Code 128, UCC-128, SCC-14 ITF, SCC-14 28, SSCC-

18, MSI, DataMatrix, QR, MicroQR and PDF417 bar

codes standard.

Fonts Arial, Courier, Tahoma and Lucida resident fonts for

use in variable data elements. Static elements in any

Windows®font.

Printing Features Reverse, Rotate, Repeat, Invert.

Message Storage Capacity 1024 Messages, but there is capacity to store much

more than 1024 messages based on the message

complexity.

Message Length Limited by substrate length up to 120”.

Logos and Graphics The Orion Graphical Interface Software will support

virtually any type of image file.

Languages English.

14 Introduction

Rev Q 2003978

Options

Encoder For operation with variable speed conveyors.

Bar Code Laser Scanner Allows scan and print message retrieval.

Starter Kit Includes ink, cleaner and flush, printhead wipes, hand

cleaner, and latex gloves.

Installation and Setup 15

Rev Q 2003978

Installation and Setup

General Recommendations

Material Handling

The most critical item in consistently achieving good quality printing is material handling.

This is an area controlled by the customer and the installer. It is imperative that adequate

product guides be provided and that they are installed and maintained properly. Incorrect

or inconsistent product handling will cause print quality problems, maintenance problems

and could lead to printhead damage. The customer is responsible for maintaining proper

material handling equipment.

AC Power

Our experience has shown that the AC power in many locations where the printing system

is installed can be subject to line noise, brownouts, and blackouts due to motors and

material handling equipment failure. If you experience line noise, brownouts or blackouts

on a regular basis, a good-quality line conditioner or Uninterruptible Power Supply (UPS)

should be installed to ensure data integrity. In many cases, these devices may not be

necessary and it is acceptable to start an installation without them. However, if system

lock-ups or occasional distorted print occurs, the first corrective measure should be to

isolate and clean up the AC power.

Work Area

The CoPilot 128 and CoPilot 256 may require priming from time-to-time due to

environmental contaminants collecting on the nozzle plate. The priming process requires

the use of clean, lint-free wipes that become soiled with ink during use. Because of this,

we recommend that a small storage cabinet or box be located near the printer in which to

keep the wipes and to keep them clean. Also, a small waste can is recommended for

soiled wipe disposal.

Vibration

The CoPilot 128 and 256 print engines do not de-prime easily. They are remarkably

tolerant to bumps by passing products and to normal conveyor vibrations. However,

sustained, long-term vibration may lead to erratic performance. In cases where the

conveyor is especially vibration-prone, the entire printing system can be mounted on a

stand. Optional stands are available from Squid Ink for these applications.

Maintenance Access

When planning the installation, allow for easy access to the printheads so that priming

and cleanup can be done conveniently.

16 Installation and Setup

Rev Q 2003978

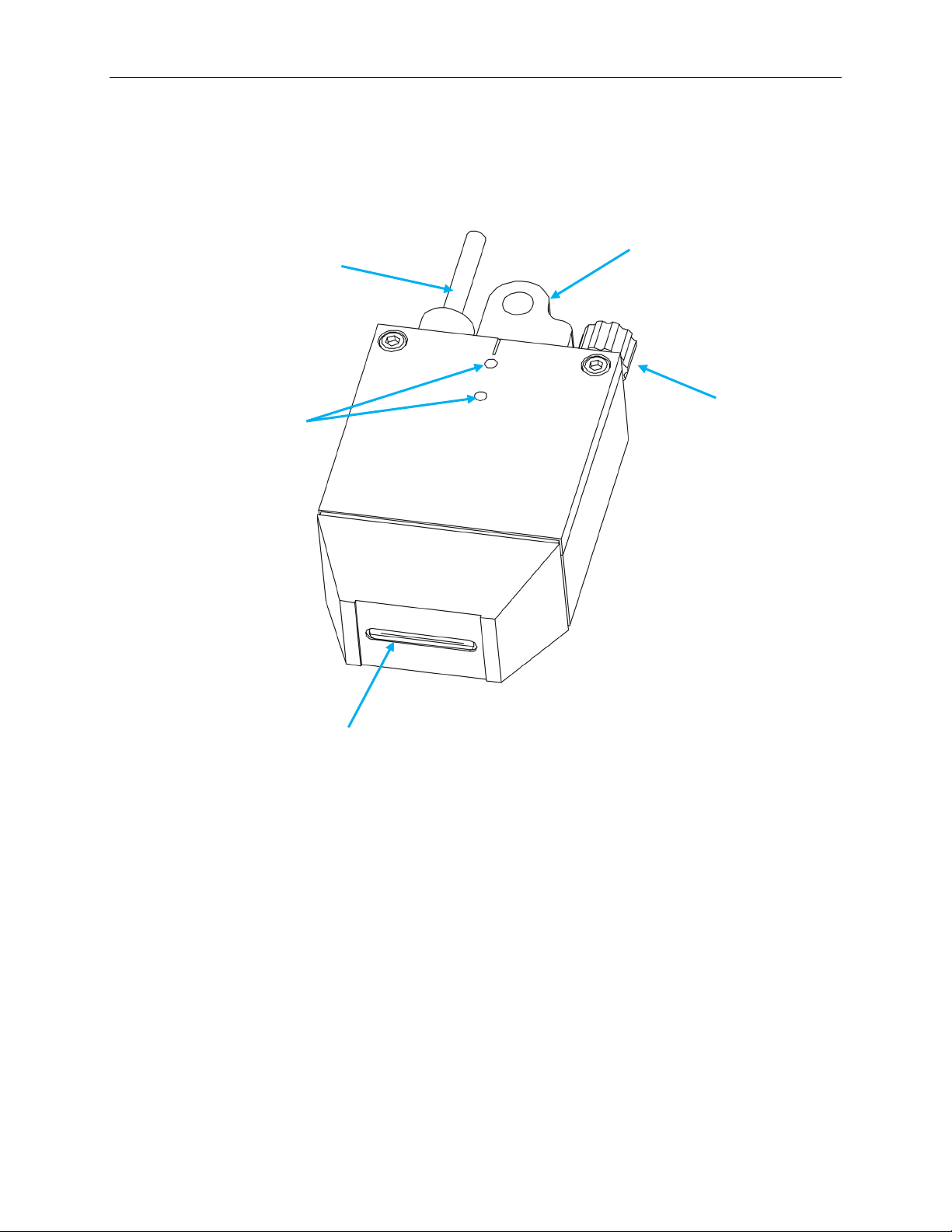

128 Printhead Overview

Note: The data cable for the 128 printhead is permanently attached

to the back of the printhead. It does not unplug.

Nozzle

Face

Photocell Mounting

Bracket Holes

Data Cable

from Controller

Printhead Mounting

Bracket

Ink Line

Fitting

Installation and Setup 17

Rev Q 2003978

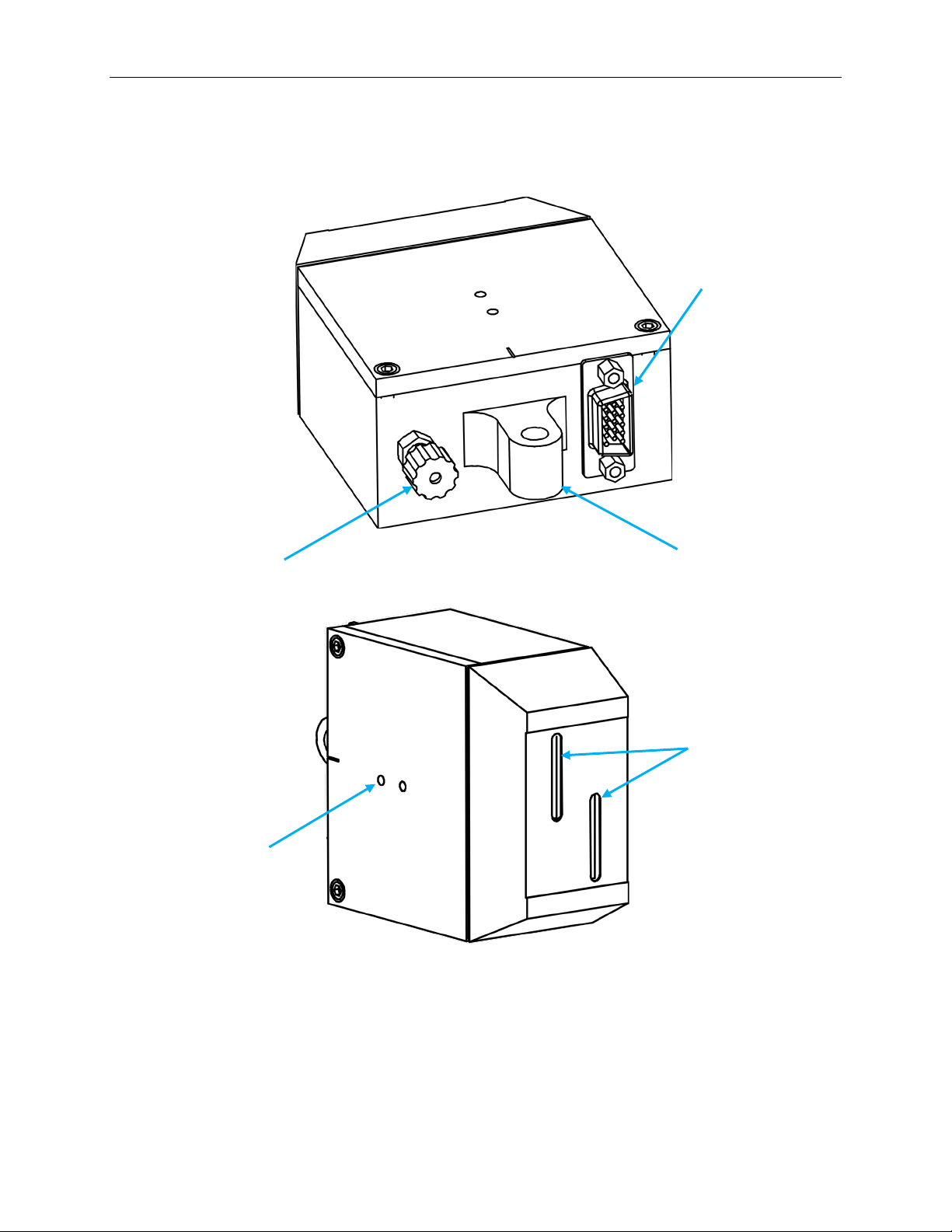

256 Printhead Overview

Nozzle

Faces

Data Cable

Connection

Mounting

Bracket

Ink Line

Fitting

Photocell

Mounting

Bracket Holes

18 Installation and Setup

Rev Q 2003978

Controller Overview

Data Cable

Connection for

Printhead 1

Data Cable

Connection for

Printhead 2

Power Cord

Receptacle

Power

Switch

USB

Port

Network

Connection

Photocell/Encoder Out to

Second CoPilot System

Photocell/Encoder In

Fuse

Low Ink 1

Connect

Low Ink 2

Connect

Installation and Setup 19

Rev Q 2003978

Mounting

Each installation is unique and Squid Ink Manufacturing cannot anticipate customer

requirements for attaching mounting brackets to the production line. Several mounting

systems are available for the Copilot 128/256 printing system. Follow the instructions for

the specific mounting system ordered with your printer.

Attention! Use only the supplied mounting hardware to attach the

printhead(s) and controller to the mounting brackets.

Using mounting hardware other than that supplied by

Squid Ink Manufacturing can result in damage to the

printhead and/or the controller assembly.

Printhead(s)

Example of Typical Printhead Mounting (128 shown)

Mounting Post

Mounting

Collar

Data Cable

Printhead

Adjustment

Handle

Printhead Angle

Settings

20 Installation and Setup

Rev Q 2003978

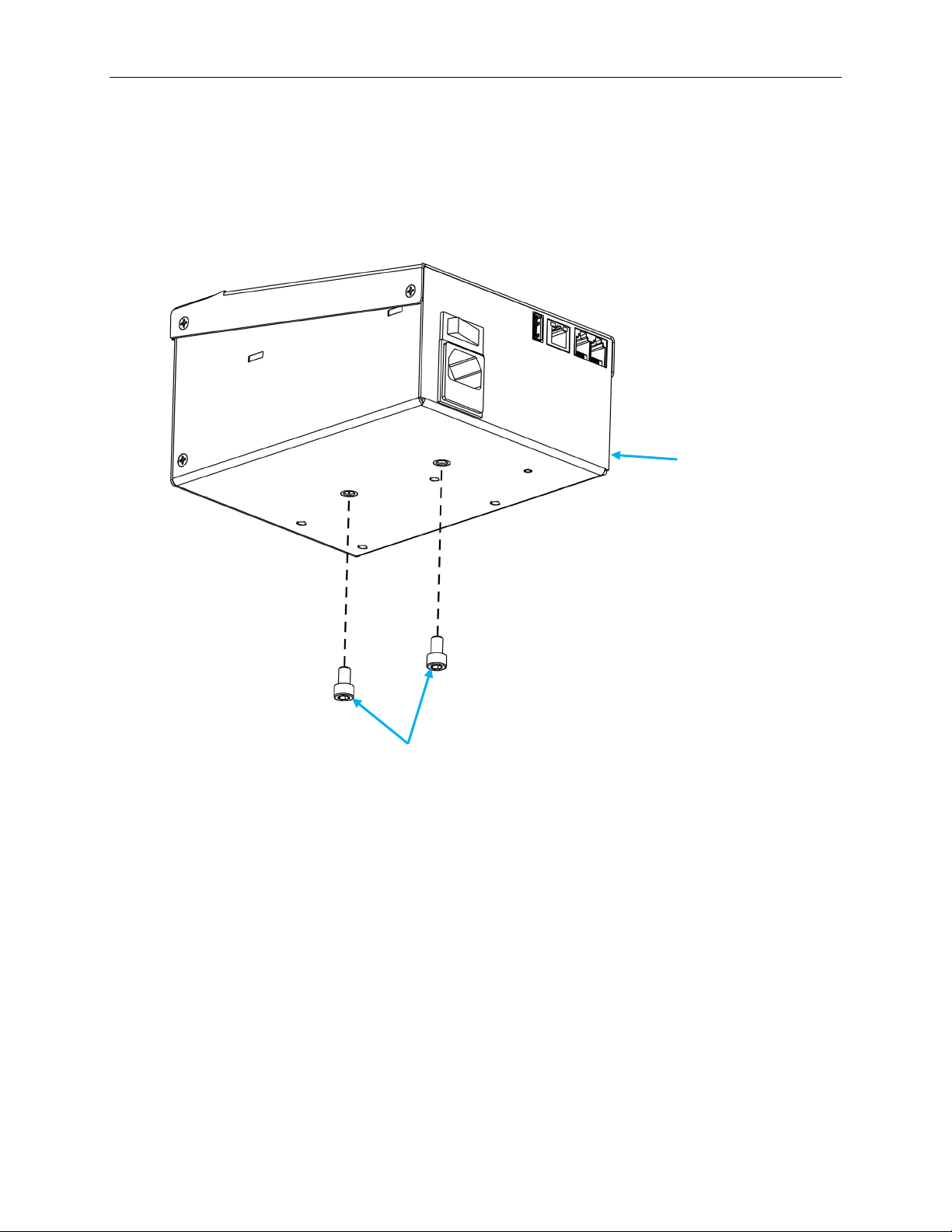

Controller

There are two (2) mounting holes for supplied mounting screws located on the bottom of

the CoPilot controller. Use these holes and the supplied mounting screws to attach the

controller to the mounting bracket.

Attention! Use only the supplied mounting screws to attach the

touchscreen controller to the mounting brackets. Using

mounting screws other than that supplied by Squid Ink

Manufacturing can result in damage to the controller

assembly.

Touchscreen

Controller

Supplied Touchscreen

Controller Mounting Screws

This manual suits for next models

1

Table of contents

Other Squid Ink Printer manuals