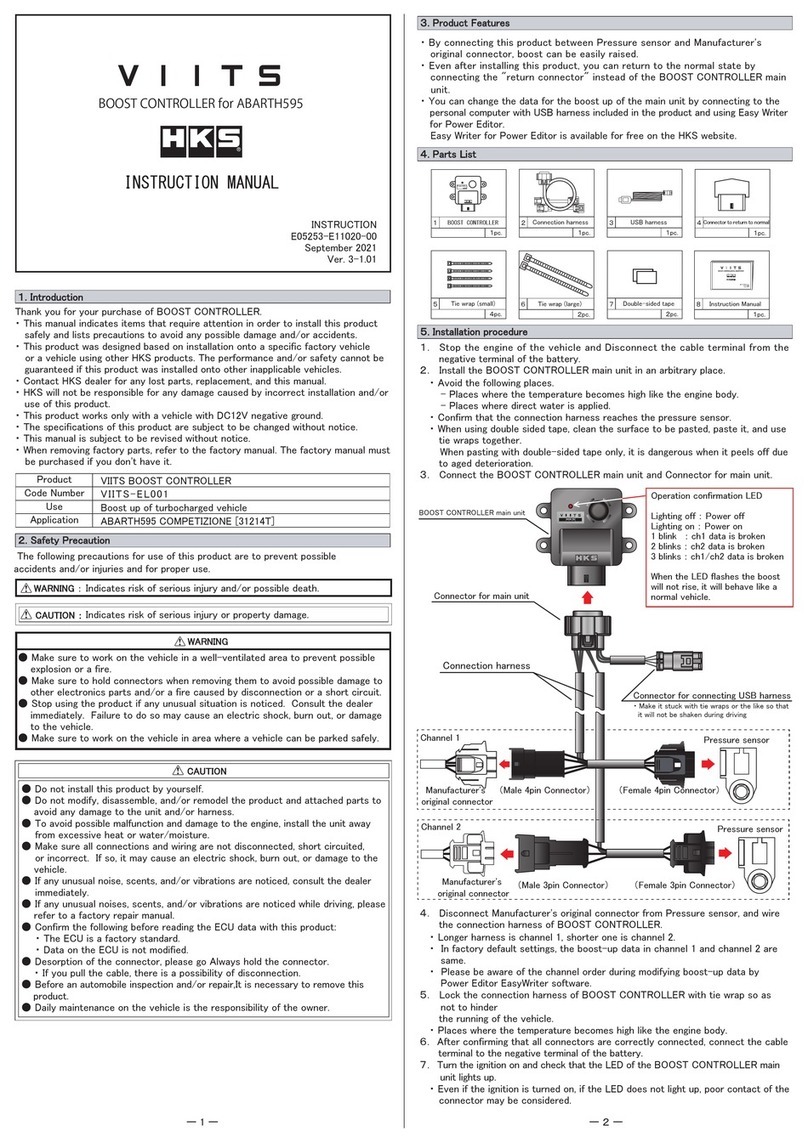

SRS Labs GMC12-LV-H6 User manual

( 1 / 12)

Instruction Manual

Models:

version 01.01 since 8 September 2017

ATTENTI N!

This instruction manual contains important information about the installation and the use of

the equipment. Please read and follow these instructions carefully.

Always ensure that the power to the equipment is disconnected before opening the

equipment or commencing any maintenance wor .

GMCXX-LV-H6_en_manual_M236

Hoist controller for LV

hoist

GMC12-LV-H6, GMC8-LV-H6

( 2 / 12)

1. Safety information

IMPORTANT INSTRUCTIONS!

All safety and operating instructions should be read before the equipment is installed or operated.

IMPORTANT SAFETY INFORMATIONS

The following general safety precautions have to be observed during all phases of operation, service,

and repair of this equipment. Failure to comply with these precautions or with specific warning in

this manual violates safety standards of design, manufacture, and intended use of this equipment.

Do not operate in an explosive atmosphere

Do not operate this equipment in the presence of flammable gases or fumes. Operation of any

electrical instrument in such an environment constitutes a definite safety hazard.

ater, moisture, heat and humidity

Do not operate this equipment near water or in areas with wet floors, also not in high humidity

atmosphere where condensation forms on the equipment. It should never be placed near or over

heat register or other source of heated air and it should not be installed or operated without proper

ventilation.

( 3 / 12)

2. Functions and Control

Motor Controller has been designed to control from 1 to 12 electrically compatible motors, either

separately or simultaneously – controlled via switches located on front panel or a cable

remote/pendant. Optionally you can lin GO/STOP button by lin connector.

Each device is equipped with unique APA module / Automatic Phase Align / which guarantees that on

any align of input phases the motors are still moving in the same direction. If any line wire will be

disconnected the hoist controller stops and ensure safe operation. Unit is also equipped wit AVM

module / Automatic voltage metering /. This module chec s main voltage for AC400V +-20%, star

configuration and if there is any problem with main voltage you’re notified and unit will not run any

hoist

Unit will not wor when:

• One phase is missing

• Under voltage on lines

• Overvoltage on lines

All electrical components carry their own individual cSA/UL, CE and comply with European Directives.

The components are housed in robust steel 19" rac casing with powder coating. Complete unit

complies with the CE according the Certification of conformity attached to this manual.

3. Operation

The Motor/hoists connected with the GMCseries controller, can be activated individually or

simultaneously using the GO switch located on the front panel or wireless remote. Units can be

optionally lin ed together to create bigger systems.

3.1 How to start

• Connect the CEE32/5p plug to the AC400V +-20% power supply – turn the ey to ON

position. When the main is OK there will be power LED lit in green, otherwise the unit is off.

Chec phase voltages, frequency and contact manufacturer in case of help.

• Connect the plugs for the electric hoists to the Harting 6 soc ets.

• Chec that the emergency STOP mushroom is not engaged on device or any other lin ed

device in system.

Move lever on front panel or WMC remote corresponding to each motor, to the position required:

o UP - Lever in upper position

o STAY – Lever in middle position

o DOWN - Lever in lower position

• Pushing the GO button will activate the motors to move simultaneously

• Releasing the GO button will stop the movement of the motors simultaneously.

• When is device not used is highly recommended to turn it OFF by ey located on front panel.

( 4 / 12)

3.2 To Move a Single Several hoist:

• Set the UP/DOWN toggle switch for that motor to the desired direction. The associated LED

should light Green for UP, or Red for DOWN direction

• Hold the GO button until the motor are moved the desired height, then release.

3.3 Link of Base units:

Two or up to 30 units can be lin ed via lin connector located on front panel.

For lin you’ll need 5pin DMX data cable.

Due safety requirements link works only in LOCAL LINK MODE of controller

( 5 / 12)

4. GMC8-LV series base unit

4.1 GMCseries front panel

4.2 Hoist protection:

• GMC12: Each three hoist are protected by single C10/3p MCB

• GMC8: Each two hoist are protected by single C10/3p MCB

*C16 or C20 are equipped on request

4.3 Power key switch positions:

• OFF: Power off / Only battery charger is active in this state/

• PICKLE: Power to the hoist is enabled

• AUTO: Power to the hoist is enabled when GO command is received

4.4 GROUP STOP key switch positions:

• OFF: Trip of any brea er or mains GFI brea er will not cause E-STOP

• ON: Trip of any brea er or mains GFI will cause E-STOP of unit

4.5 RESET:

Reset button for SIL3 e-stop relay reset. Needs be pressed every time when unit has been turned

on, E-STOP mushroom has been pressed or when the GROUP stop has been activated.

4.6 EMERGENCY STOP:

E-Stop is red color mushroom. Once the E-STOP button has been pressed, it loc s into the active

position and must be rotated cloc wise and released before disengaging. After engaging the E-stop

button the RESET need to be pressed to reset system.

( 6 / 12)

4.7 GO:

This green pushbutton turns the selected channels of Hoist Control system ON when is active. Once

the GO button has been depressed, the energizing of the hoists is turned off.

4.8 DIRECTION SWITCHES:

They allow changing the direction of movement fore each motor/hoist separately or in groups. LED

close to the switch indicates the movement direction.

4.9 Charger status LED:

Status LED of charger located on WMC front panel is

• Green : Battery is fully charged

• Green blin ing : Battery is charged for 90% or greater capacity

• Orange blin ing : Not in rapid mode – waiting to be charged

• Red : Battery is in rapid charge mode

• Red blin ing : Battery is ultra rapid charge mode

• No LED : Battery is not inserted

( 7 / 12)

4.10 GMCseries back panel

4.11 MAINS:

CEE32A/5p mains input plug on 1.5m cable + also fuse for mains transformer T2.5A.

4.12 AUX output:

AUX output for additional AC230 powered devices. Protected by C16/1p brea er on front panel.

4.13 Limit STOP:

LIMIT STOP connector for external e-stop from NLP device.

( 8 / 12)

5. Output connectors wiring

5.1 Harting6 LV hoist connector

5.2 Remote connector *optional

Neutri NC5-MAH/FAH

Connectors are used for lin operation of units. Up to 30 units can be lin ed and in local operation

mode their control is via one GO and E-STOP button

Pin Function note

1 Data CMN Data Common

2 Data - Data Minus

3 Data+ Data Plus

5.3 Loadcell E-STOP connector *optional

Neutri NC4-FAH

Pin Function note

1 DC24-36V Connected to 3

2 Active 1 Active line 1

3 DC24-36V Connected to 1

4 Active2 Active line 2

Both safety lines are separate and NO /normally open/. For loadcell E-STOP activation contacts need

to go to NO /normally closed/ state for E-STOP activation.

For reset a loadcell e-stop function please cycle the E-STOP mushroom on device.

Pin Function Note signal

1 Live L1 brown

2 Live L2 blac

3

Live L3

gray

4 Control COMMON

5 Control UP

6 Control DOWN

Ears/body Earth Yellow/Green

( 9 / 12)

6. Technical data

• Mains input AC400V +-20% 50/60Hz

• Mains Plug: CEE32A/5p

6.1 Protections and Safety:

• Short circuit protection of group of hoist by automatic circuit brea ers C20A

• APA – Automatic Phase Align

• AVM – Automatic voltage metering

• Double mechanical bloc ing contactors

• Double - Recessed Emergency stop with SIL3 certification

6.2 Metal Housing:

• 1.5mm Steel housing with gray powder coating

• 3mm Steel front panel

6.3 Dimensions W x D x H :

MC12-LV-H6: 6U box

MC8-LV-H6: 6U box

7. Guarantee

GMC series hoist controller is sold with 2 year Manufacturer’s guarantee. To have extended warranty

conditions please contact manufacturer at sales@srs-group.com.

Guarantee covers the original factory installed components of the controller and their correct

functioning.

Warranty void if: - any part or replacement components is installed or modified without authorization

from the manufacturer and/or the internal circuit is tampered or modified and/or the controller is

operated outside normal use conditions – electrical power supply is not conform or there is

connection error or mechanical damage of controller, including overload, improper use.

We as manufacturer always help you to repair your unit.

( 10 / 12)

8. Declaration of conformity

DECLARATION OF CONFORMITY

According to guide lines 89 336 EEC and 92 31 EEC, 90 337 CEE Annex II A:

Name of producer:

SRS Group, s. r. o.

Address of producer:

Rybničná 36/D, SK- 83106 Bratislava, Slova Republic

www.srs-group.com/ sales@srs-group.com, +421244681417

Declares that the product

Name of product: GMCseries

hoist controller: MC4-LV, MC8-LV, MC12-LV + variants

Types

:

MC4-LV-H6, MC8-LV-H6, MC12-LV-H6 + variants : Low voltage hoist/motor controller

Corresponds with following harmonized standards:

Safety:

EN 60065

EN 60950

EN 60204-1

EN 13850

EN 12100-2

AS/NZS 3820

EMC: EN55103-1, resp. EN55103-2

And

Is in compliance with following requirements:

Machinery directive

: 2006/42/EC

Low Voltage directive:

2006/95/EC

Bratislava, 4 May 2016

Robert Sloboda

( 11 / 12)

( 12 / 12)

Copyright 2017 SRS Group, s.r.o. | Specifications subject to change without notice.

Document: GMCXX-LV-H6_en_manual_M236 | Version 01.01 | Actual as of: 8 September

2017

SRS Group s.r.o.

Rybnicna 36/D | 831 07 Bratislava | Slova ia

Phone: +421 2 44 681 417 | Fax: +421 2 4468 1419

Email: sales@srs-group.com | www.srs-group.com

This manual suits for next models

1

Table of contents

Other SRS Labs Controllers manuals

Popular Controllers manuals by other brands

Specified Air Solutions

Specified Air Solutions VIRTUAL WALL installation manual

Morningstar

Morningstar GenStar GS-MPPT-60 quick start guide

Nevco

Nevco 761 Soccer Operator instructions

Omnitronic

Omnitronic SMARD-24RCA user manual

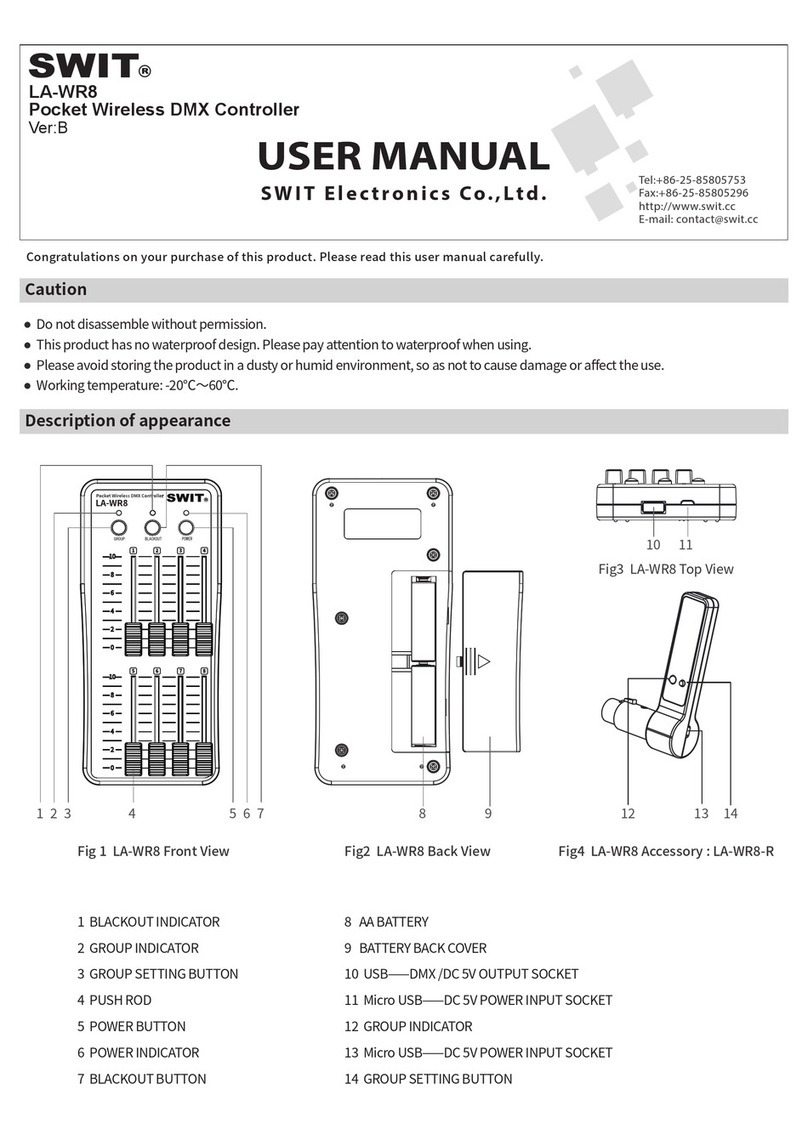

SWIT Electronics

SWIT Electronics LA-WR8 user manual

Mitsubishi Electric

Mitsubishi Electric FX3U-ENET-ADP user manual