SSR Motorsports SR450S User manual

SR450S

IMPORTANT

YourSSRMotorsportsMotorcyclewillbringyoumuchpleasureifyou

followthepropermaintenanceandcareinstructions.

Bewarethoughalltheinformationinthisdocumentareprovided

withoutanyobligation.Subjecttochange,deletionorsubstitution

withoutadaptationtolocalrequirementsintechnicalinformation,

pricing,andproductionofafinaljudgmentofaparticularmodel

withoutpriornoticeorindicationofanyreasonbySSRMotorsports.

Maintenance

Compliancewithmaintenance,maintenanceandadjustmentoftheengineandchassis‐

partscontainedinthismanualisaprerequisitefortheproperfunctioningofthebikeand

helpstoavoidprematurewear.Impropermaintenanceofthecyclepartcouldresultin

damageorfailureofcomponents.Useofthemotorcycleunderextremeconditions,such

asonslopes,verymuddyorwetterrain,mayleadtoexcessivewearofcomponentssuch

aschainorbrakes.

Alsoobservetherunning‐inperiodandthecontrolandmaintenanceintervals,proper

maintenancecansignificantlyprolongthelifeofthemotorcycle.

Warranty

Thewarrantyperiodis90daysonEngine/Transmission(PartsOnly),30daysLimited

VehicleWarranty(PartsOnly),90daysLimitedBatteryWarranty.

Onlywhennotusedforcompetition.

Theworkplannedintheserviceschedulemustalwaysbeperformedbyanauthorized

dealerandallworkmustberecordedintheservicebookorabillwiththechassisserial

number.Ifapplicable,thewarrantyisvoid.Thewarrantymaybevoidandunsupported

fordamagesandconsequencesresultingfrommanipulationsand/orchangestothe

vehicle.

Transport

Riskofdamageifthevehicleisparkedonaslope,itmayrollawayorfallover.

Alwaysparkthevehicleonafirmlevelfloor.

Note

•Riskoffireduringoperationifthevehiclepartsbecomeveryhot.

•Donotparkthemotorcyclenearflammableorcombustiblematerials.Donotplace

objectsonthemotorcyclewhenitishot.

Alwayswaituntilthemotorcyclehascooled.

•Stoptheengine.

•TurnthefueltaptoOFF.

Environment

Thissportcanhavepotentialimpactsontheenvironmentandcauseconflictwithothers.

Responsibleuseofthebikeallowsriderstoavoidproblemsandconflicts.Inordernotto

jeopardizethefutureofmotorcyclesport,makesurethattheuseofthemotorcycle

complieswiththelawandrespectstheenvironmentandtherightsofothers.

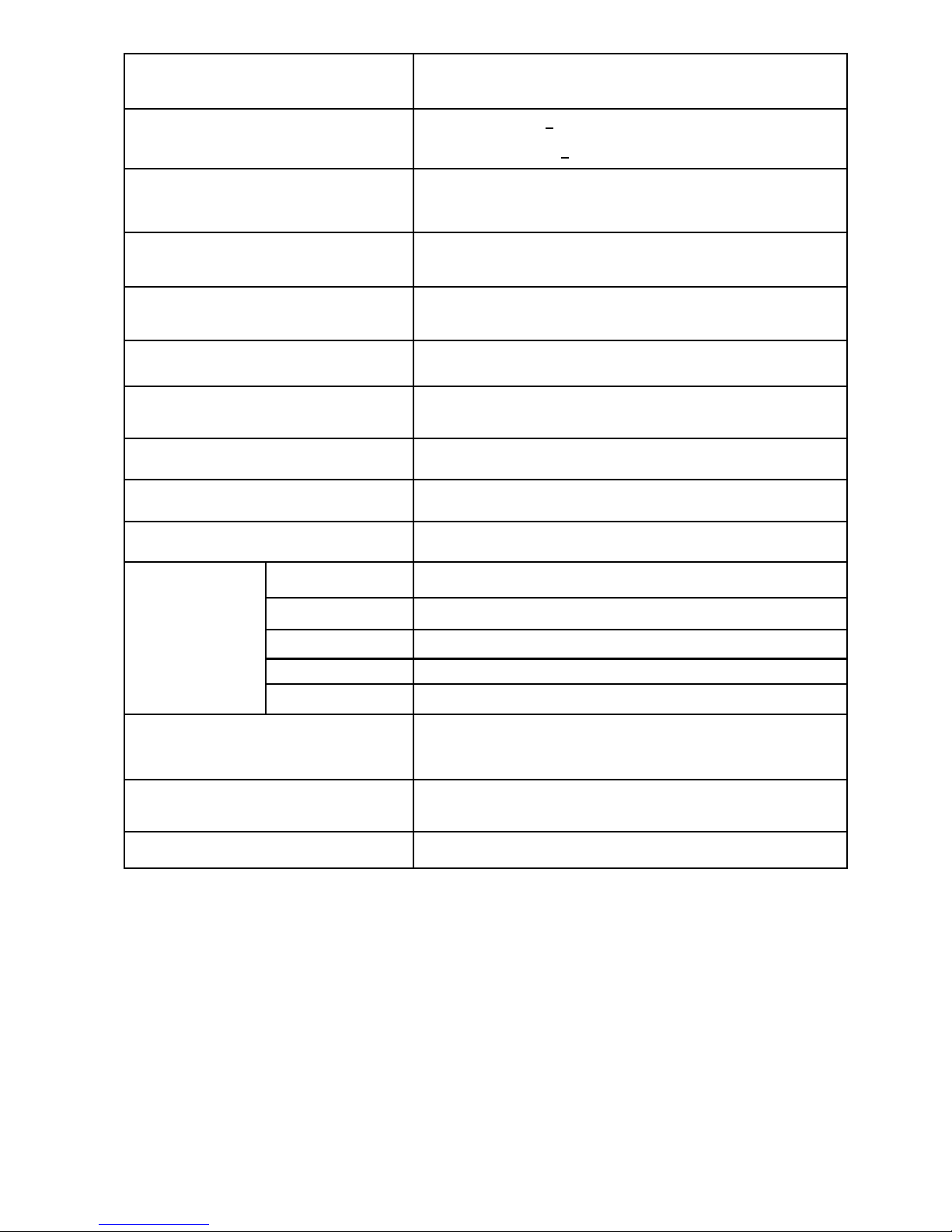

Technical Specification

I

TE

M

TE

C

H

NI C

A

L

D

A

T A

O

F

FR O

A

D

MO

TA

R

D

D

I

ME

N

S

I

ON

S

O

V

E

R

A

L

L

L

E

N

G

T H

2

1

7

5

m m

O

V

E

R

A

L

L

WI D

T H

8

1

0

m m

O

V

E

R

A

L

L

H

EI G

H

T

1

2

4

0

m m

F

/ R

W H

E

E

L

A

XI

S

D

I

S

TA

N

C

E

1

5

0

5

m m

S

E

A

T

H

E

I

G

H

T

9

6

0

m m

G

R

O

UN

D

C

L

E

A

R

AN

C

E

3

2

0

m m

N

. W

1

1

8

k

g

1

3

0

k

g

C

H

A

S

S

I S

F

R

A

M E T Y

P

E

A

L

U

MI N

IU

M

A

L

L

O Y

TWI N

-

S

P

A R

F

R

ON

T

TI R

E

S

IZ

E

8

0

/

1

0

0

-

2

1

1

1

0

/

7

0

-

1

7

R

E

A

R

TIR

E

SI Z

E

1

1

0

/

9

0

-

1

9

’

’

1

4

0

/

7

0

-

1

7

F

R

ON

T

S

U

S

P

E

N

SI O

N I

N

V

E

R

TE

D

C

AR

TR ID G

E

F

O

R

K

WI

TH

R

E

-

B

O

U

N

D

C

O

MP

R

E

S

SI O

N

-D

A

MP

I

N

G

A

DJ U

S

T

R

E

A

R

SU

S

P

E

N

SI O

N

MO

N

O

S

H

O

C

K

WI

TH

S

P

RI N

G-

P

R

E

L

O

A

D ,

R

E

- B

O

U

N

D

A

N D

C

O

MP

R

E

S

S

I

ON

-

D

A

MP

IN

G

AD

J

U

S

T

F

U

E

L

TA

N

K

C

A

P

AC

I TY

8

.

0

L

WI

TH

R

E

S

E

R

V

E

V

A

L

V

E

MOTEUR

TY

P E S I N G L E

CY

LINDER, 4-STROKE, LIQUID COOLED

MA

X P O W E R

3

2

K

W / 7

5

0

0

R

P

M :

4

3. 5

H

P/ 7

5

0

0

R

P

M

RATED POWER

3

0

.

5

K

W / 7

0

0

0R

P

M

COUPLE MAX

4

2

.

5

N

M/ 6

5

0

0

R

P

M

IDLE SPEED 1700±150 RPM

CONSOMMATION ≤340 g/kW.h

BORE X STROKE 96×62.1 mm

DISPLACEMENT 449 ml

COMPRESSION RATIO 11:1

VALVE TRAIN CHAIN DRIVE SOHC FOUR VALVE

LUBRICATION

TY

PE PRESSURE SPRAY

LUBRICATION OIL

TY

P E SAE 10W-40

IGNITION ADVANCE DEGREE 12°BTDC [3000RPM]

VALVE CLEARANCE (COLD) INTAKE VALVE: 0.16+0.03 mm

EXHAUST VALVE: 0.28+0.03 mm

DECOMPRESS

CLEARANCE EX VALVE CLEARANCE (0.28mm)+0.15mm=0.43mm

SPARK PLUG

TY

PE DENSO IK24/IK27

DIMENSION

350mm

×

297mm

×

423

mm

DRIVE

TY

P E C H A I N

DRIVE SPROCKET

1

3

T

CLUTCH

TY

P E MANU AL, MU LTI -WET

TRANSMISSION

TY

PE CONSTANT MESH, 5 SPEED,

LEFT

FOOT OPERATED

PRIMARY ADJUCTION RATIO 2.739(63/23)

GEAR RATIO

1ST 2.230(29/13);

2ND 1.625(26/16)

3RD 1.235(21/17)

4TH 1.000(19/19)

5TH 0.826(19/23)

IGNITION

TY

PE DC/AC CDI

STARTER KICK / ELECTRIC

STARTING CAPACITY ≤15 s

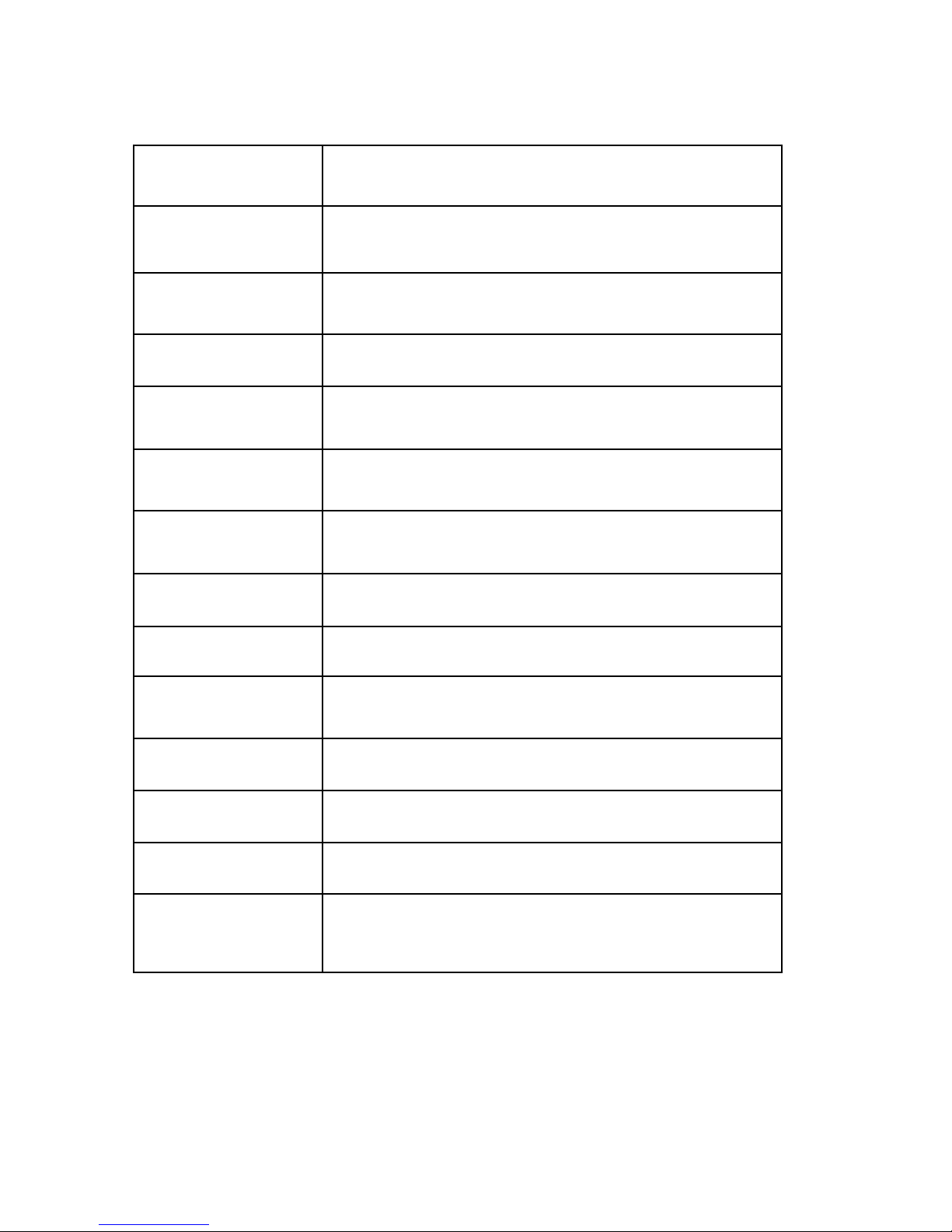

Lubrication system

I

TE

M

D

A

T A

E

N

G

I

N

E

O

I L

8

7

0

m

l

A

P

I

S

G

o

r

h

i

g

h

e

r

S

AE

1

0

W-4

0

A

T

D

R

A

IN IN

G

6

7

0

m

l

A

T

F

I

L

TE

R

C

H

AN

G

E

7

0

0

m

l

A

T

D

I

S

A

S

S

E

MB

L

Y

8

7

0

m

l

TR A

N

S

MI S

S

I

O

N

O

I L

9

5

0

m

l

API SG or higher

S

A

E 1

0

W

-4

0

A

T

D

R

A

IN IN

G

8

5

0

m

l

A

T

D

I

S

A

S

S

E

MB

L

Y

9

0

0

m

l

(Approximately O

n

e

Q

u

a

r

t )

ATTENTION: Low Oil level in Tr a n s m i s s i o n can cause transmission

failure. Warranty Void if transmission oil is not kept at mandatory level.

Failure to change transmission oil and oil filter on scheduled maintenance

and at recommended level of 950ml can cause the transmission to lock and

cause serious injury or death

I

TE

M

D

A

TA

C

O

O

L

A

N

T

C

A

P

AC

I TY

A

T

C

H

A

N G

E

1

.

1

1

li

t

e

r

D

I

S

A

S

S

E

MB

L

Y

1

.

2

0

l

i

t

e

r

A

N

TI FR E

E

Z

E

H

I

G

H

Q

U

A

LI

TY

E

T H Y

L

E

N

E

G

L Y

C

O

L

A

N

TIF R

E

EZ

E C

O

N

TA

I

NI N

G

S

I

LI C

A

TE

-

FR E

E

C

O

RR O

S

I O N I

N

-

H

I

B

I

TO

R

S

S

TA

N

D

A

R

D

S

C

O

O

L

AN

T

C

ON

C

EN

TR A

-

TI O

N

1

: 1

MI XTU R

E

WI

TH

D

I

STI LL

ED

W A

TE

R

Tire Specifications

I

TE

M

S

TA

N

D

A

R

D

S

R

E

P

A

I R

L

I

MI

T

C

O

L

D

TIR

E

PR

E

S

S

UR

E

3

3

/

2

. 3

(

ps

i

/

b

a

r

)

MA X

L

O

A

D

F

R

ON

T

4

3

0 /

1

9

5

(

l

b

s/ k

gs

)

R

E

A

R

5

4

8 /

2

6

5

(

l

b

s/ k

gs

)

Battery specifications

I

TE

M

D

A

T A

B

A

TTE

R

Y

C

A

P

A

C

I TY

1

2

V

-

6

A

h

C

UR R

E

N

T

C

ON S U MPTIO

NM

A

X

0

.

1

m

A

V

O

L

TA

G

E

(

2

0

0

/

6

8

0

F

)

F

U

L

L

1

3

.

0

-

1

3

.

2

V

Spark plug specifications

I

TE

M

D

A

T A

S

P

A

R

K

P

L

U

G

S

TA

N

D

A

R

D

S

D

E

N

S

O I

K

2

4

O

P

TI O

N

A

L

N

G

K I

FR 8

H

-

1

1

INSPECTION BEFORE USE

Inspection Item

Inspection Objective

Engine oil Inspect for

proper

f i l l

lev

el

Gearbox oil Inspect for proper level (900ml)

Coolant Inspect for

proper

f i l l

lev

el

Fuel Be sure there is

enough

fuel to ride planned distance

Cooling system Inspect for leaks, cracks,

and

fluid

f l o w

Throttle

Check for

free travel of throttle grip and that the throttle grip has a smooth

operation and in both t

he

forward and back to the closed position

Clutch Adjust the clutch cable to fully disengaged

Steering Be sure the bars

mov

e

freely from lock to lock and steering head is tight

Brake Inspect for free

trav

el of pedal and

lev

er and that there

is

full braking power

Tire Check tire pressure and inspect tires for cracks

Spokes Inspect and tighten loose spokes if necessary

Other Bolts and Parts Inspect attachment points and other bolts to ensure they are tight

Exhaust muffler

Inspect for loose bolts and the exhaust is secure

BREAK-IN

The motorcycle is shipped with break in Oil

ONLY

!

Once the engine is run for an initi

a

l 30 minutes, drain and replace the

o

il with:

Synthetic API SG or higher SAE 10W-40

Failure to do so may decrease the engine transmission life or cause premature failure.

During initial break-in newly machined surfaces will be in contact with each other and these surfaces will wear in quickly.

Break-in maintenance at 150km is designed to compensate for this initial minor wear. Timely performance of the break-in

maintenance will ensure optimumservice life and performance from the engine.

The general rules as follows:

Start the engine and let it run at idle until the engine is thoroughly warmed up.

Avoid full-throttle starts and rapid acceleration.

Maximum

continuous engine speed during the first 150km must not exceed 5,000 rpm (or 10 hours Max)

After 150km ride maintenance the machine per the maintenance schedule.

After the break-in procedure has been properly carried out, the motorcycle is

ready

for regular operation. However, since

premature high r/min (rpm) will lead to engine trouble, take care to use the necessary skill and technique in

operating

the

motorcycle.

Never run

the

engine with full throttle at low speed operation. This rule is applicable not only during break-in but at all

times.

This procedure should be followed each time:

Piston is replaced

Piston rings are replaced

Cylinder is replaced

Crankshaft or crank

bearing

are replaced

Maintenance

The Maintenance Schedule specifies how often you should have your motorcycle served, and what things need attention. It

is essential that your motorcycle be served as scheduled to retain its high level of safety,

dependability,

and emission

control performance.

Remember,

proper maintenance is your responsibility.

PR

ECAUTION

Make sure the engine is off before you begin any maintenance or repairs.

Exhaust contains poisonous carbon monoxyde. Be sure there is adequate ventilation whenever you operate the

engine. Let the engine and exhaust system cool before touching

Be ca reful when

working

around gasoline. Keep cigarettes, spark, and flames away from all fuel related parts

Regular Maintenance

Place the motorcycle on the firm level ground using optional work stand or equivalent support

Use genuine or recommend part and lubricants or other

equivalents.

Parts that do not meet design specifications may cause

damage to the motorcycle

Use only metric tools when

servicing

the

motorcycle,

metric nuts, bolts, screws are not interchangeable with British

fasteners. Always replace with new gaskets, O-rings, cotter pins, piston pin clips, snap rings, etc after disassembling the

engine.

When

tightening

bolts and nuts, begin with larger diameter or inner bolt first. Then tighten to specified torque diagonally in

incremental steps unless a particular sequence is specified.

Clean parts in

cleaning

solvent upon disassembly, lubricate and sliding surface before

assembly. Always inspect all parts for proper installation

and

operation after reassemble

Route all electrical wires, cables and harness

routing

as designed.

MAINTENANCE SCHEDULE

Required maintenance schedule is based upon average riding condition. Sustained high speed operation, or operation in

unusually wet or dusty

conditions,

will require more frequent service than specified in the REQUIRED MAINTENANCE

SCHEDULE.

See

SPECIA

L MAINTANCE SCHEDULE for competition maintenance need.

Perform the Pre-ride inspection at each scheduled maintenance period

Symbol in maintenance schedule means:

IInspect, Clean, Lubricate and/or Replace as Necessary

CClean

RReplace

AAjust

LLubricate

* Unless the rider is mechanically qualified and has proper tools, see authorized dealer for service

* * Special maintenance strongly recommend to look for authorized dealer service.

NOTE1. Clean after every ride for dusty conditions

NOTE2. Replace every 2 years. Replacement requires mechanical skill

NOTE3. Replace after the first break-in ride

NOTE4. Inspect after the first break-in ride

NOTE5. Replace the transmission oil when the clutch plates are replaced.

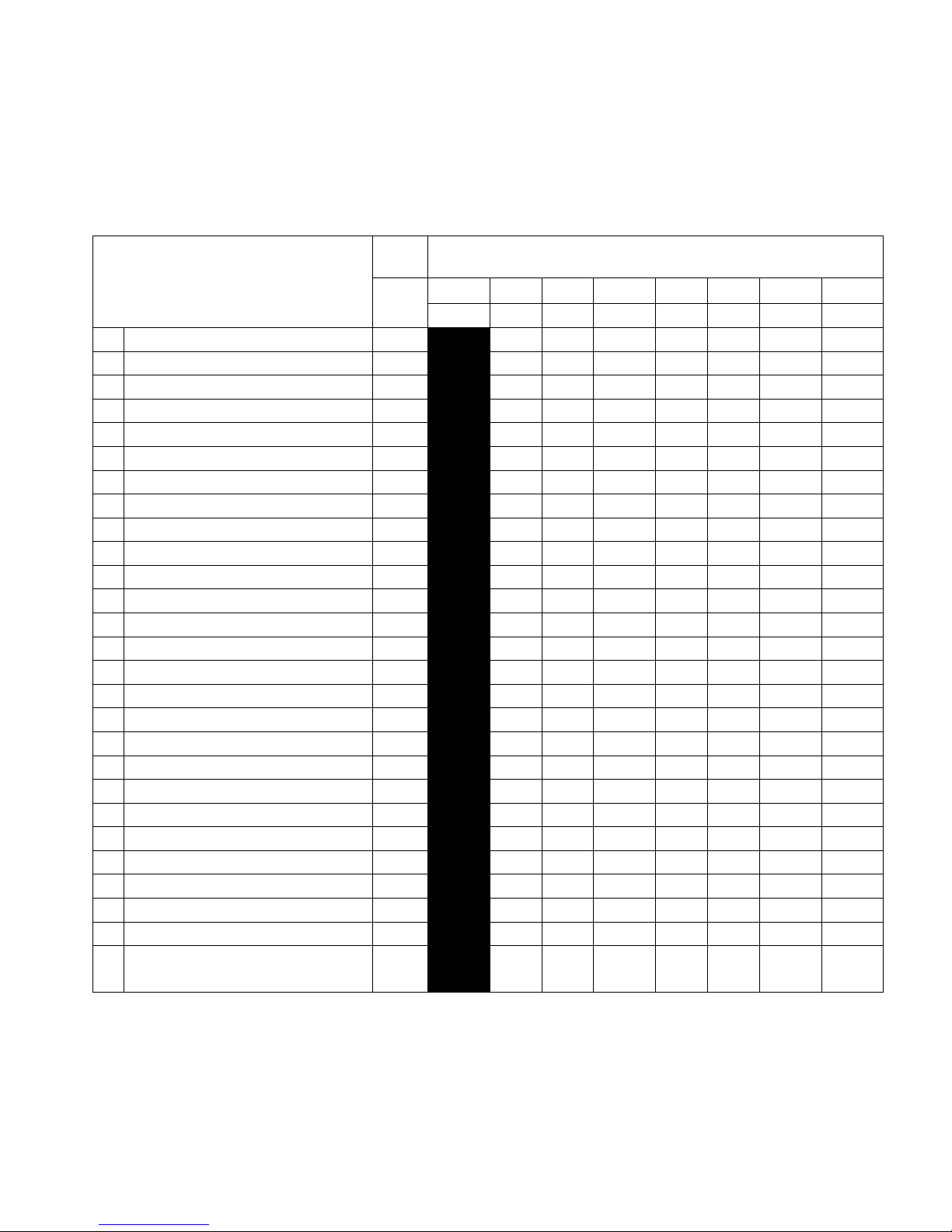

Required Maintenance Schedule

MAINTENANCE ITEMS

SCHEDULE BY HOURS OR KILOMETERS

NOTE

Hours

10 30 50 70 90 110 130

km 150

1500

3500

6000 9000 12000

15000

* ENGINE OIL R R R R R R R

* AIR FILTER R R R

GEARBOX OIL R R R R R R R

ENGINE OIL FILTER R R

RADIATOR COOLANT R R

* ENGINE VALVE CLEARANCE I I

SPARK PLUG R R

** FUEL FILTER C C

* FUEL LINE I I I I I I I

* THROTTLE ASSEMBLY I I I I I I I

COOLING SYSTEM I I I I I I I

SECONDARY AIR SUPPLY I I I I I I I

DECOMPRESSOR SYSTEM I I I I I I I

ENGINE IDLE SPEED I,L I,L I,L I,L I,L I,L I,L

DRIVE CHAIN I I I I I I I

DRIVE CHAIN SLIDER I I I I I I I

ENGINE IDLE SPEED I I I I I I I

BRAKE PAD WEAR I I I I I I I

BRAKE SYSTEM I I I I I I I

HEADLIGHT FOCUS I I I I I I I

* CLUTCH I I I I I I I

SIDE STAND I I I I I I I

* SUSPENSION I I I I I I I

MUFFLER I I I I I I I

NUTS, BOLTS, FASTENERS I I I I I I I

WHEELS/TIRES I I I I I I I

* SUSPENSION

BUSHINGS/BEARINGS I I I I I I I

MOTOR

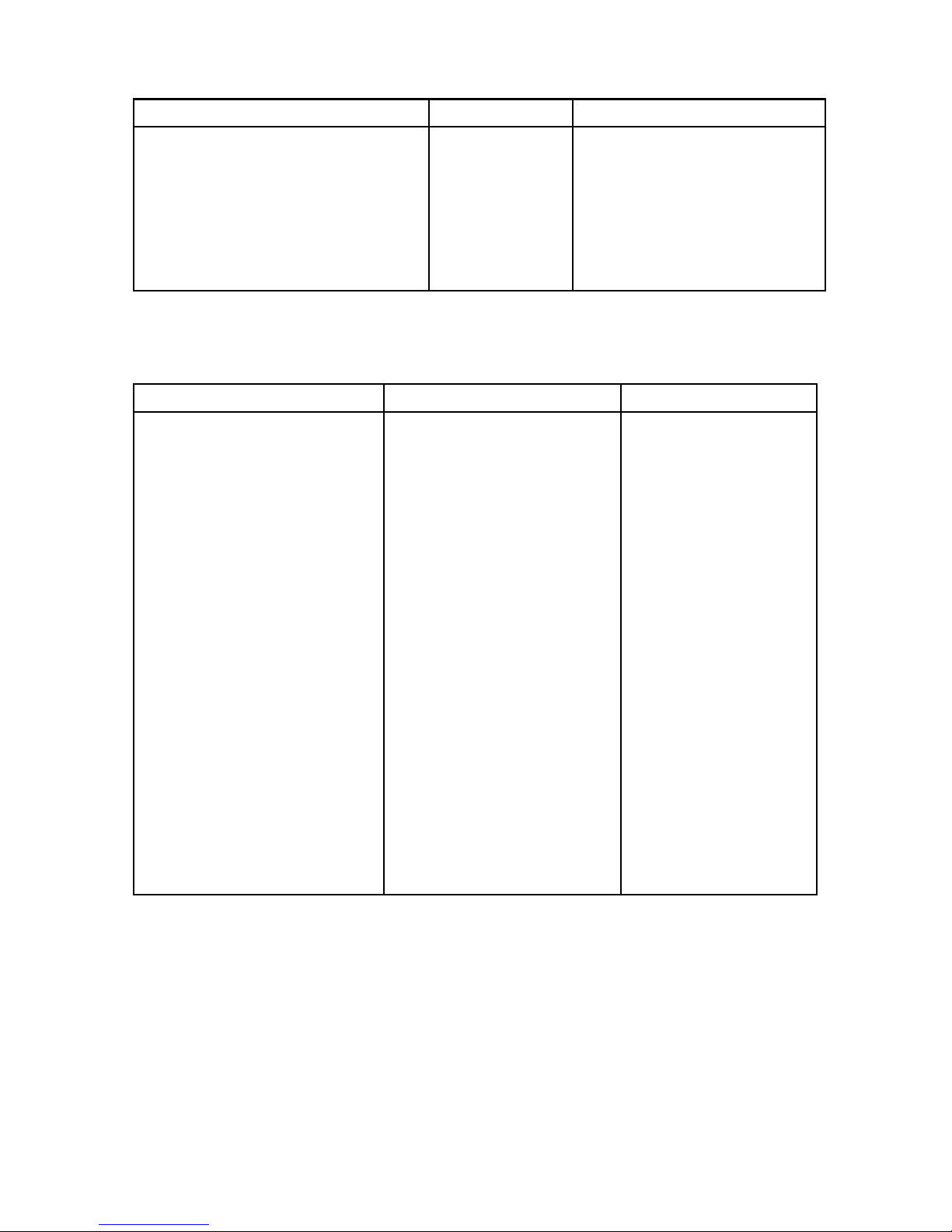

ITEM CAUSE REMARK

Cy

linder head gasket

Clutch disc

Cy

linder gasket

Right crankcasecover gasket

Compression leak

Wear or discoloration

Leakage

Damage

Replace

whenev

er disassembled

Replace

whenev

er disassembled

Replace

whenev

er disassembled

CHASSIS

ITEM CAUSE REMARKS

Front / rear tire

Front / rear brake pad

Sub-f

rame mountingbolts

Chain guide plate

Side

cov

er

Front number plate

Front /

rear

f ender

Clutch

lev

er / holder

Brake

lev

er

Air throttle lever

Handlebar

Throt t le hous ing

Grip rubber

Gearshif

t pedal

Brake pedal

wear

wear

Fatigue or damage

Wear or damage

Damage

Damage

Damage

Free play or damage

Free play or damage

Free play or damage

Free play or damage

Bends or cracks

Damage

Damage

Damage

Damage

Damage

Minimum knob height: 8mm

Minimum thickness:1mm

NOTE:

These parts and their possible replacement schedule are based upon average riding

conditions. Machines subjected to severe use require more frequent servicing.

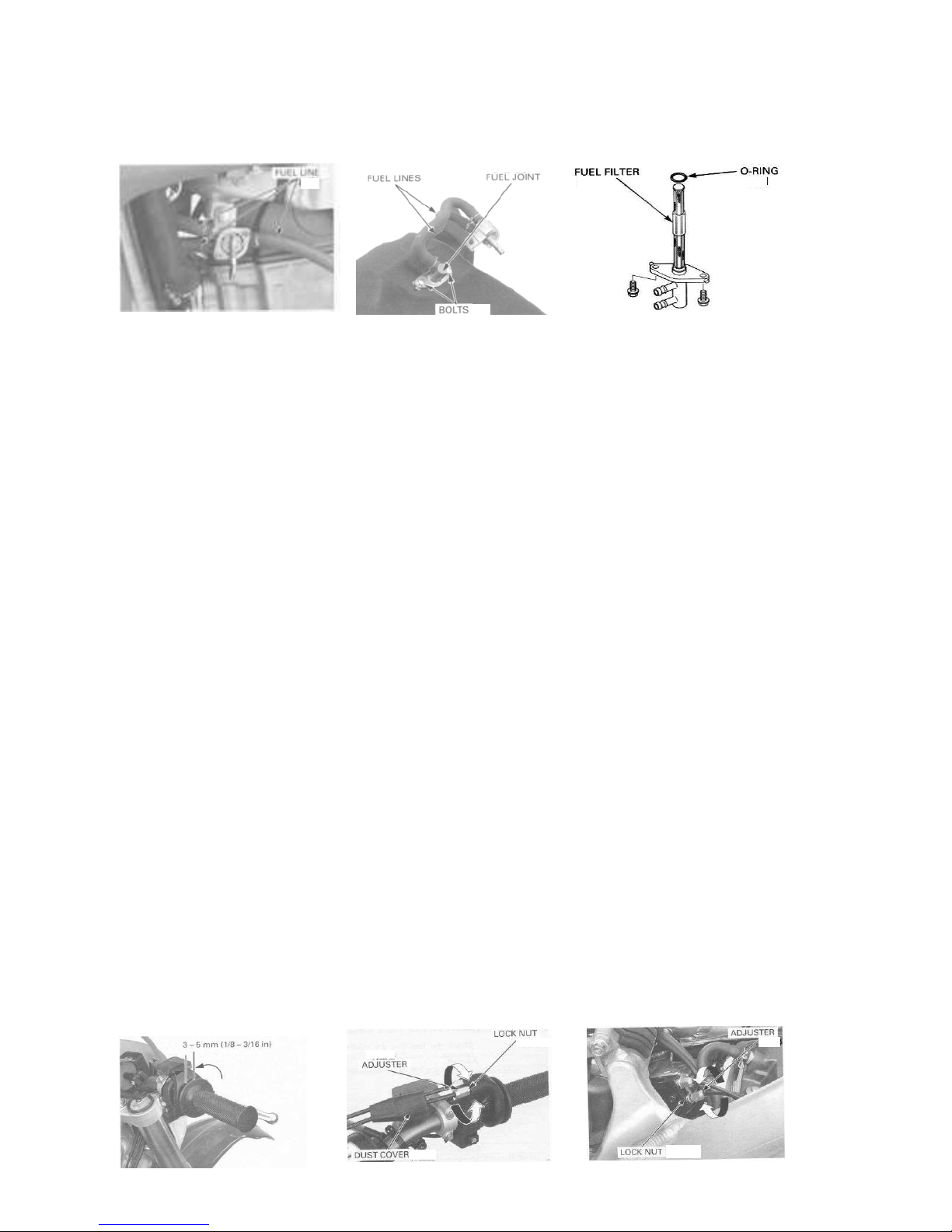

CARBURATION SYSTEM

Inspect the fuel line for damage or leak, if necessary replace fuel line.

FUEL FILTER

Remove

the

fuel tank. Drain the gasoline into a container and remove the fuel line, nuts and the clamps. Wash the fuel filter

and reinstall the O-ringand reinstall components onto the fuel tank.

Reinstall

the

fuel tank on the motorcycle. Make sure the tank does not leak.

THROTTLE

OPE

RATION

Check for smooth throttle grip at full

opening

and automatic full closing in all

steering

positions. Check the throttle cable and replace

them if they are

de t e r io ra t e d ,

kinked or damaged. Lubricate the throttle cable if

throttle

operation is not smooth.

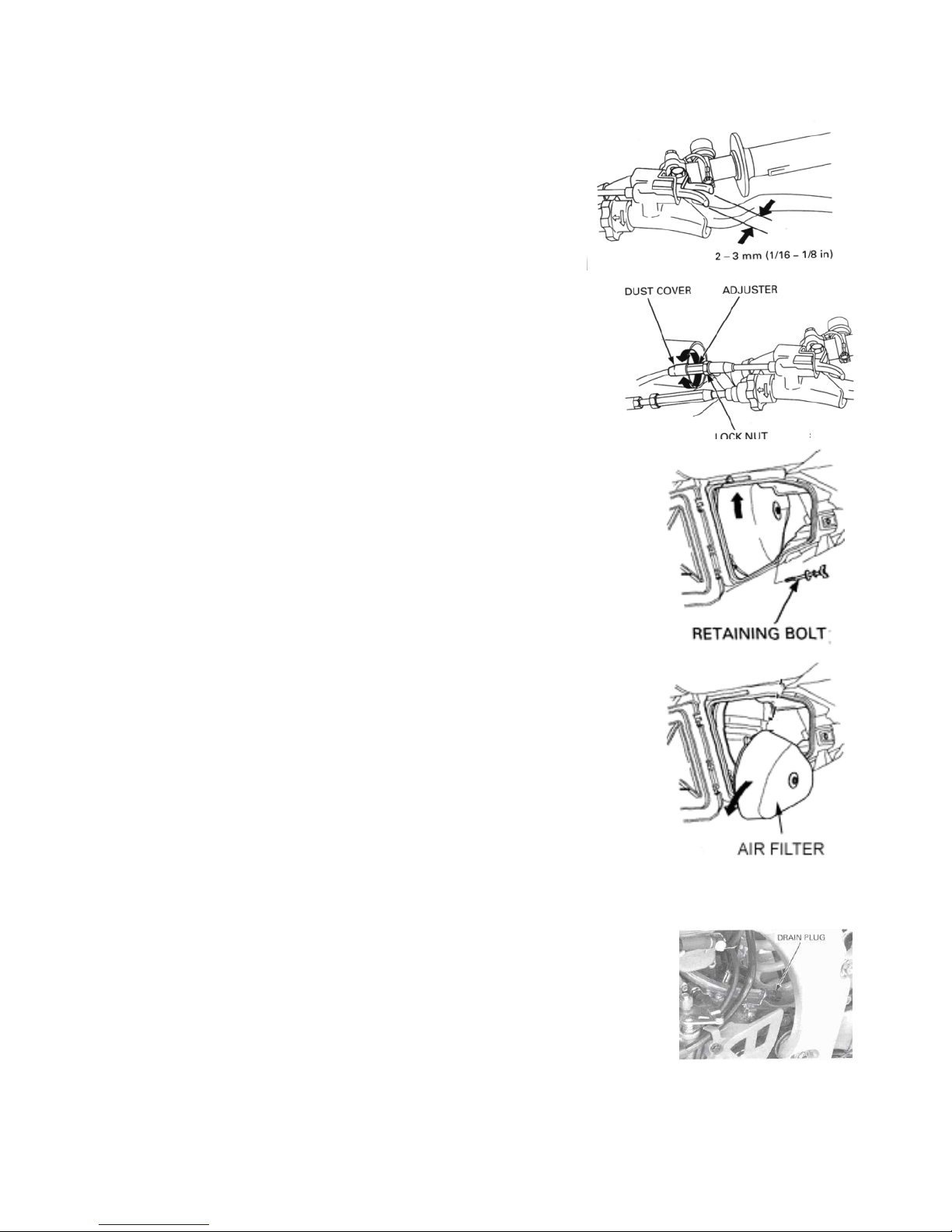

Measure the free play at the throttle grip flange.

FREE PLAY

3

-5mm(1/

8-3/

16in)

Throttle grip free play can be adjusted at either end of the throttle cable.

Minor adjustments are made with the upper adjuster. Remove the dust cover from the adjuster. Adjust the free play by

Loosening

the lock nut and

turning

the adjuster.

Tighten the lock nut af ter

making

the

adjustment.

Reinstall the dust cover and recheck the throttle operation. Major

adjustments are made with the carburetor end of cable.

CHOKE LEVER

FREE PLAY:

2-3

mm(1/8

-3/1

6in)

Check for smooth choke lever operation and lubricate the cable if re-

quired.

Inspect the cable for cracks which could allow moisture to enter. Replace the

cable if necessary.

Measure the choke lever free play at the lever end. Choke lever free play can

be adjusted at the choke cable. Remove the dust cover from the adjuster.

Adjust the free play by

loosening

the lock nut and

turning

the adjuster.

Tighten the lock nut. Reinstall the dust cover. Recheck the free play at the lever.

AIR FILTER

Loosen the air cleaner

re t a in i n g

bolt. Remove the air filter. Remove

the

air

filter from the holder.

Thoroughly wash the air filter in clean non-flammable or high flash-point

cleaning

solvent. Then

wash the element again in a solution of hot water and

dishwashing

liquid soap. Clean the

inside of the air cleaner housing.

After cleaning, be sure there is no dirt or sand trapped between the inner and outer layer of the

cleaner. Wash again if necessary.

Allow the air cleaner to dry thoroughly.After drying, soak the air filter in clean Foam

Fi

l

ter

Oil or

an equivalent.

Apply air filter oil to the entire surface of the air filter and rub it with both hands to saturate the

element with oil.

Gently squeeze

out

excess oil. It is important not to over oil or under oil the element. Apply a

thin coat of grease or an equivalent to the sealing surface.

Assemble the air filter and the holder .Slip the air cleaner

retaining

bolt through the assembly.

Tighten the

retaining

bolt securely.

NOTICE

: If the air filter assembly is not installed correctly, dirt and dust may enter

the

engine

resulting

in wear of the piston ring and cylinder.

CRAN

KCA

SE BREATHER

Remove the breather hose drain plug, then drain any fluids or dirt from

the hose into a proper container. Reinstall the drain plug.

SPARK PLUG REMOVAL

Remove the fuel tank and disconnect the spark plug cap. Remove The

spark plug and inspect it for damage

Clean around the spark plug base with compressed air before removing

and be sure that no debris is allowed to enter the combustion chamber.

INSPECTION

Check the following and replace if necessary:

1) insulator for damage

2) electrodes for wear

3) burnt or discoloration

If the electrode is contaminated with accumulated debris or dirt replace

the spark plug.

(this motorcycle’s spark plug is equipped with an iridium center

electrode. Re- place the spark plug if the electrode is contaminated.)

Replace the plug if the center electrode is rounded as shown in the pic-

ture.

(Always use the specified spark plugs on this motorcycle)

RECOMMENDED SPARK PLUG (OR EQUIVALENT) Standard: DENSO:

IK24

Optional: DENSO: IK27

Check the gap between the center and side electrodes with a wire

Type feeler gauge

(To prevent damaging the iridium center electrode, use a wire type

Feeler gauge to check the spark plug gap. Do not adjust the spark Plug

gap if the gap is out of specification, replace with a new one.) Spark

plug gap: 0.4 mm

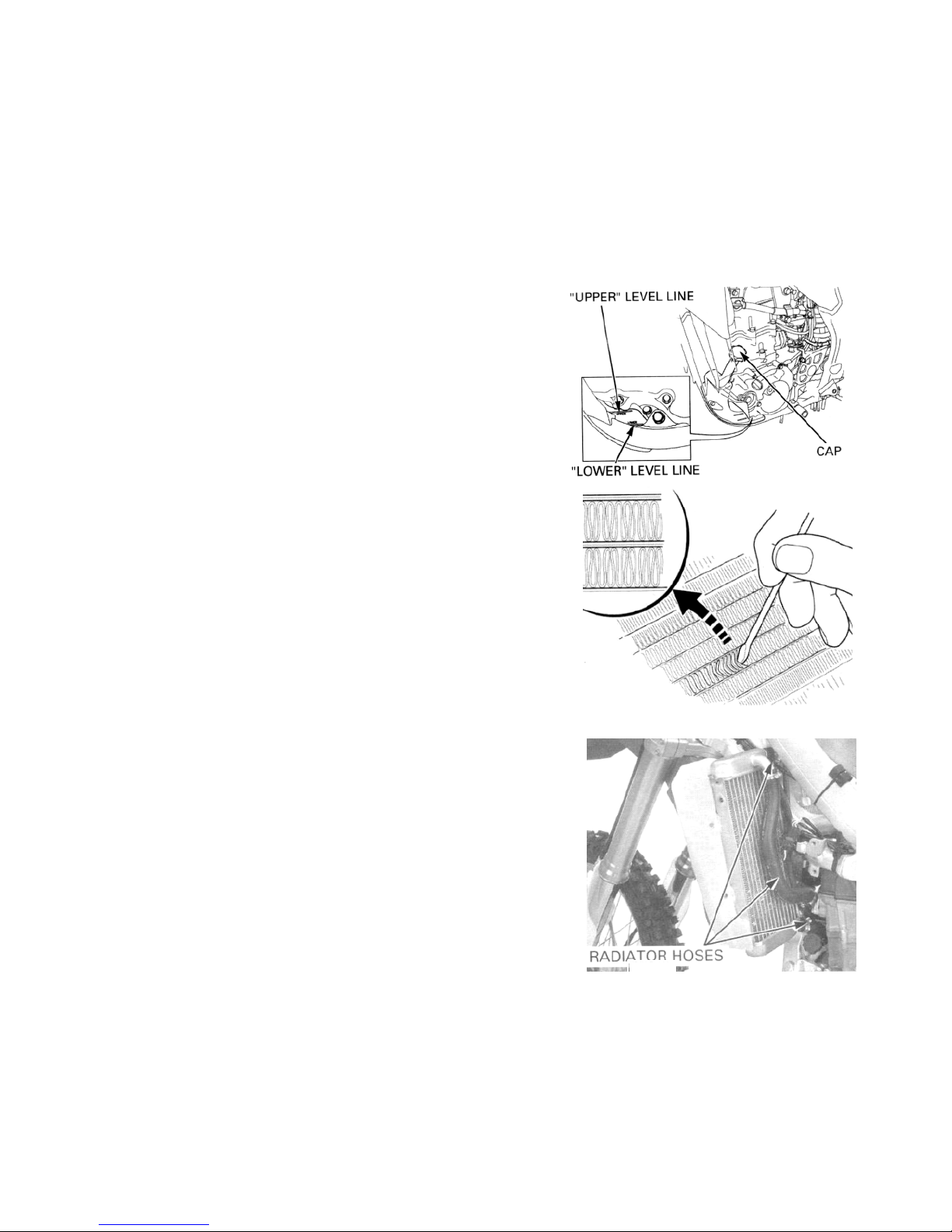

RADIATOR COOLANT

Inspect the level of the radiator coolant should be between “upper” and

“lower” when the motorcycle

running

under the normal

temperature. If need, put recommended coolant fluid in:

Remove the radiator cap. Put standard coolant concentration 1:1 to

the upper line and then reinstall the cap.

Recommended antifreeze

Professional coolant or an equivalent high quality ethylene glycol

antifreeze

containing

silicate free corrosion inhibitors.

COOLING SYSTEM

Remove the radiator grills. Check the radiator air passage for clogs

or damage.

Inspect the hoses for cracks and deteriorations.

Use low pressure water and a soft brush to wash off any dirt that may

be stuck in the radiator core.

Replace if

necessary.

Check the tightness of the hose clamps and

radiator

mounting

bolts.

VALVE CLEANCE / DECOMPRESSOR SYSTEM

VALVE CLEARANCE INSPECTION

Inspect and adjust the valve clearance while the engine is cold

(below 35Ԩ/950 f)

Remove the cylinder head cover.

Remove the crankshaft hole cap and O-ring.

Turn the crankshaft clockwise to align the punch mark with the index

mark on the right crankcase cover. Make sure the piston is at TDC

(Top Dead Center) on the compression stroke.

Check that the index line on the cam sprocket aligns with the ”ᇞ”

mark on the cam holder.

INLET VALVE :

Insert the feeler gauge between the valve lifter and the cam lube. Check

the valve clearance for the intake valves using a feeler gauge.

Valve clearance IN: 0 .16+ 0.0 3mm

EXHAUST VALVE:

Insert the feeler gauge between the rocker arm and shim.

Check the valve clearance for the exhaust valves using a feeler gauge.

Valve clearance Ex: 0.28+0 .03mm

VALVE CLEARANCE ADJUSTMENT:

Remove the camshaft holder assembly

The shims my stick to the inside of the valve lifter. Do not allow the shims

to fall into the crankcase.

The shims can be easily removed with tweezers or a magnet.

Clean the valve shim contact area in the valve lifter with compressed air.

Measure the shim thickness and record it.

Table of contents

Other SSR Motorsports Motorcycle manuals

SSR Motorsports

SSR Motorsports SNAKE EYES XF250-GS User manual

SSR Motorsports

SSR Motorsports Lazer6 User manual

SSR Motorsports

SSR Motorsports SSR150 User manual

SSR Motorsports

SSR Motorsports Lazer5 User manual

SSR Motorsports

SSR Motorsports SR250S User manual

SSR Motorsports

SSR Motorsports SR300S User manual

Popular Motorcycle manuals by other brands

MV Agusta

MV Agusta Brutale 675 Workshop manual

APRILIA

APRILIA RSV MILLE - PART 1 1999 User manual content

Royal Enfield

Royal Enfield Himalayan 2018 owner's manual

MOTO GUZZI

MOTO GUZZI 2005 Griso 1100 Use and maintenance book

KTM

KTM 85 SX 19/16 owner's manual

Beta Motorcycles

Beta Motorcycles XTRAINER 250 2T EUROPA 2022 manual