SST MEGAFLOW User manual

GAINESVILLE, FL. U.S.A. WWW.STUPIDSIMPLE.TOOLSSTUPID SIMPLE TOOLS

Product Manual003 January 2023

3-Stage Shop Air

System

WWW.STUPIDSIMPLE.TOOLSSTUPID SIMPLE TOOLS

Table of Contents SST003

Introduction

→

Quick Start Guide

Safety →

Component List →

Operations & Maintenance →

Warranty →

Liability →

01

02

03

04

05

06

07

I

Introduction SST00301

001 WWW.STUPIDSIMPLE.TOOLSSST003

The SST MEGAFLOW is a mega-tough 3-Stage

shop air filter & regulator with a aluminum

monoblock body designed to last a lifetime.

With an incredibly high Flow Rate of up to

6000L/min, it filters up to 0.01 micron. It

removes nearly all moisture, aerosols, dust

and foreign particles from your compressed

air to keep your tools running longer.

Stage 1 | Sintered Filter 5 Micron

Brass Filter which lasts longer than PE filters.

Removes 95% of the moisture, oil, and debris

particles up to 5micron.

Stage 2 | Coalescing Filter 0.1 Micron

High Quality Coalescing material. Removes

99.99% of the moisture, moisture vapor and

oil particles up to 0.01 micron

Stage 3 | Desiccant Filter 0.01 Micron

Diuse air to use desiccant beads eciently

dries out the rest of the humidity and

regulates the outlet air.

Introduction

Unit Weight 11.8 Lbs. (5.35Kg)

Unit Dimensions (IN) 14.1” W x 11.4” H 3.5” D

Unit Dimensions (MM) 360 x 290 x 90mm

Supply Input 3/4” NPT

Regulated Output 3/4” NPT

Set Pressure 7 - 125 PSI (0.5 - 8.5 Bar)

Max Input Pressure 220PSI (15Ba)

Max Air Flow 200 CFM

Flow rate See Chart (next page)

1st Stage 5.0 Micron Brass Sintered Filter

2nd Stage 0.01 Micron Coalescing Filter

3rd Stage Silica Desiccant Dryer

01 Technical Specifications

SST003 MEGAFLOW

003 WWW.STUPIDSIMPLE.TOOLSSST003

002

Quick Start Guide

Unpacking and Assembly

WWW.STUPIDSIMPLE.TOOLSSST003

1 Remove from Packaging

2 Install pressure gauge

3 Mount your MEGAFLOW

3A — Mounting Option 1: Back Mounting

3B — Mounting Option 2: Bracket Mounting

4 Plumb megaflow using 3/4” NPT fittings

(1/2” NPT adapters are included in packaging)

5 Purge air to clear fine silica dust

6 Test

02

Safefy

Health and Safety Warnings

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in mechanical failure, pneumatic explosion,

and/or serious injury.

1. Work Area Safety

a. Keep the work area clean and well-lit. Cluttered or dark areas

invite accidents.

b. Do not operate manufacturing machines, CNC or otherwise, in

explosive atmospheres, such as in the presence of flammable

liquids, gases, or dust. Machinery may create heat or sparks

which may ignite dust or fumes.

c. Keep children and bystanders away while operating machinery.

Distractions can cause you to lose control of the machine.

2. Personal Safety

a. Stay alert, watch what you are doing, and use common sense

when operating machinery. Do not use a machinery while you

are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating machinery may result

in serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust masks, gloves,

or protective clothing appropriate to the conditions will reduce

personal injuries.

c. Do not use damaged or worn pneumatic hoses or connectors.

Damaged components risk catastrophic failure at high

operating pressures.

03

WARNING

005 WWW.STUPIDSIMPLE.TOOLSSST003

Safefy

Health and Safety Warnings

3. Use & Care

a. Do not force MEGAFLOW to perform beyond its rated power

output or temperature capabilities. Use the correct 3D printer

for your application. The correct 3D printer will do the job

better and safer at the parameters for which it was designed.

b. Service should never be performed without first disconnecting

the air input from MEGAFLOW. If the air input cannot be

physically disconnected, the air supply should be locked-out

and tagged-out by the technician.

c. Install the MEGAFLOW out of the reach of children or animals,

and do not allow persons unfamiliar with MEGAFLOW or these

instructions to operate the system. High pressure pneumatics

are dangerous in the hands of untrained users.

d. Maintain your MEGAFLOW. Check for misalignment or binding of

filter components, breakage of parts, and any other condition

that may aect the 3D printer’s operation. If damaged, have

replace the aected components before use. Accidents can

result from poorly maintained air regulator systems.

e. Use MEGAFLOW, pneumatic tools, and accessories, etc. in

accordance with these instructions, taking into account the

working conditions and the work to be performed. Use of a

high pressure air regulator for operations dierent from those

intended could result in a hazardous situation.

4. Service

a. Have your MEGAFLOW serviced by a qualified repair person

using only identical replacement parts. Doing so will ensure that

the safety of the power tool is maintained.

006 WWW.STUPIDSIMPLE.TOOLSSST003

03

SST003

C

A

MEGAFLOW Component List

AMEGAFLOW Manifold Body 1

BPressure Gauge 1

COutput Pressure Adjustment Knob 1

DDrain Pin and Spring 2

EFilter Health Indicator 2

FFilter Canister Housing 3

GFilter Canister Housing O-Ring 3

HSintered Filter 1

ISintered Filter Cover Bell 1

JThreaded Post 2

KSintered Filter Flow Nut 1

LCoalescing Filter 1

MDessicant Tube 1

NFlow Blade 2

ODessicant Upper Mesh Filter 1

PDessicant Lower Mesh Filter 1

QSintered Filter O-Ring 1

RCoalescing Filter O-Ring X

SDessicant Stage O-Ring 1 X

TDessicant Stage O-Ring 2 X

№ Part Name Amt. # № Part Name Amt. #

B

E

H

J

L

M

04

Operations & Maintenance

Filter Info and Maintenance

SST004

008

During all maintenance procedures, air input should

be physically disconnected

IMPORTANT

Stage 1 — Sintered Filter

Removes 95% of the moisture, oil, and debris particles up to 5 micron.

The brass sintered filter element was designed with a much higher

surface area than traditional systems in order to provide a prolonged

filter life.

REPLACE WHEN: With air input applied, the MEGAFLOW Filter

indicator shows RED.

• The element should be replaced every 6 months to 1 year,

depending on the use levels.

• Replacement Filter Elements are available on the

WWW.STUPIDSIMPLE.TOOLS website!

HOW TO REPLACE

1. Ensure air input has been disconnected from the unit

2. Remove the 1st stage Filter Canister Housing by unscrewing it from the MEGAFLOW

Manifold Body (A)

3. Unscrew the Sintered Filter Flow Nut to allow the used Brass Sintered Filter Element to fall

4. Place the new Brass Sintered Filter Element on top of the Sintered Filter Flow Nut,

with the O-ring in between, and screw onto the threaded post.

a. DO NOT OVERTIGHTEN

5. Visually confirm that the filter is experiencing no misalignment

6. Install the replacement coalescing filter

a. DO NOT OVERTIGHTEN

7. Re-install the Filter Canister Housing

a. Ensure O-Ring is properly seated in the top lip groove

b. Hand Tighten Only

WWW.STUPIDSIMPLE.TOOLSSST003

Purchase Filters →

USE COUPON CODE

I-READ-INSTRUCTION-

MANUALS

FOR 10% OFF

:)

05

009 WWW.STUPIDSIMPLE.TOOLSSST003

Stage 2 — Coalescing Filter

High Quality Coalescing material. Removes 99.99% of the moisture,

moisture vapor and oil particles up to 0.01 micron

REPLACE WHEN: With air input applied, the MEGAFLOW Filter

indicator shows RED.

• Replacement Filter Elements are available on the

WWW.STUPIDSIMPLE.TOOLS website!

HOW TO REPLACE

1. Ensure air input has been disconnected from the unit

2. Remove the 2nd stage Filter Canister Housing by unscrewing it from the MEGAFLOW

Manifold Body

3. Remove the used coalescing filter by unscrewing it

4. Install the replacement coalescing filter

a. DO NOT OVERTIGHTEN

5. Re-install the Filter Canister Housing

a. Ensure O-Ring is properly seated in the top lip groove

b. Hand Tighten Only

Operations & Maintenance

Filter Info and Maintenance

SST004

Purchase Filters →

USE COUPON CODE

I-READ-INSTRUCTION-

MANUALS

FOR 10% OFF

:)

05

010 WWW.STUPIDSIMPLE.TOOLSSST003

Stage 3 — Desiccant Dryer

The desiccant dryer stage uses color indicating silica beads to remove

any residual humidity from the compressed air.

REPLACE WHEN: The silica beads shift from blue pink to BLUE.

• Replacement Filter Elements are available on the

WWW.STUPIDSIMPLE.TOOLS website!

Operations & Maintenance

Filter Info and Maintenance

SST004

HOW TO REPLACE

1. Ensure air input has been disconnected from the unit

2. Remove the 1st stage Filter Canister Housing by unscrewing it from the MEGAFLOW

Manifold Body (A)

3. Unscrew the Sintered Filter Flow Nut to allow the used Brass Sintered Filter Element

to fall

4. Place the new Brass Sintered Filter Element on top of the Sintered Filter Flow Nut,

with the O-ring in between, and screw onto the threaded post.

a. DO NOT OVERTIGHTEN

5. Visually confirm that the filter is experiencing no misalignment

6. Install the replacement coalescing filter

a. DO NOT OVERTIGHTEN

7. Re-install the Filter Canister Housing

a. Ensure O-Ring is properly seated in the top lip groove

b. Hand Tighten Only

Ensure you purge air after Desiccant lter replacement

IMPORTANT

Purchase Filters →

USE COUPON CODE

I-READ-INSTRUCTION-

MANUALS

FOR 10% OFF

:)

05

012 WWW.STUPIDSIMPLE.TOOLSSST003

Limited Warranty, Limitations of Warranty and Disclaimer of Liability

SST Lifetime Warranty

Terms & Limitations

SST00406

LIMITED PRODUCT WARRANTY

STUPID SIMPLE TOOLS™warrants that the MEGAFLOW™ (the “Product”) will, at the

time of purchase by the first retail purchaser (“End User”), comply with the product

specifications (the “Specifications”) published by Stupid Simple Designs, LLC (“SST” or

the “Company”). This warranty is made only to the End User and is not assignable.

PRODUCT WARRANTY DISCLAIMER. LIMITATION OF DAMAGES.

TO THE EXTENT PERMITTED BY LAW AND EXCEPT FOR THE EXPRESS LIMITED

PRODUCT WARRANTY SET FORTH IN THIS AGREEMENT, SLICE (SST?)MAKES NO

(AND EXPRESSLY DISCLAIMS ALL) WARRANTIES, EXPRESS, IMPLIED OR STATUTORY,

WITH RESPECT TO THE PRODUCTS SUPPLIED UNDER THIS AGREEMENT, INCLUDING

WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS

FOR A PARTICULAR PURPOSE, NONINFRINGEMENT, OR ARISING FROM COURSE OF

PERFORMANCE, DEALING, USAGE OR TRADE. WITHOUT LIMITING THE GENERALITY OF

THE FOREGOING, SLICE MAKES NO CLAIM, REPRESENTATION, OR WARRANTY OF ANY

KIND AS TO THE UTILITY OF THE PRODUCTS FOR THE END USER’S INTENDED USES.

REMEDY FOR BREACH OF WARRANTY AND LIMITATION OF DAMAGES.

If notified in writing of a valid warranty claim within three months of the date of

purchase by the End User, SST will, at its option, (i) correct the non-conforming Product

so that it materially complies with the Specifications; (ii) provide a replacement Product;

or (iii) terminate the Agreement and refund the purchase price paid for the Product.

SST shall not be obligated to correct, cure, or otherwise remedy any nonconformity

or defect in the Product if the End User has made any changes whatsoever to the

Product, if the Product has been misused or damaged in any respect, or if the End User

has not reported to Slice the existence and nature of such nonconformity or defect

promptly upon discovery thereof. IN NO EVENT SHALLSST BE LIABLE FOR ANY PUNITIVE,

RELIANCE, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING

LOST REVENUE, LOST PROFITS, OR LOST SAVINGS) IN EXCESS OF THE PURCHASE PRICE

OF THE PRODUCT, HOWEVER CAUSED AND UNDER ANY THEORY, EVEN IF IT HAS NOTICE

OF THE POSSIBILITY OF SUCH DAMAGES. This section states SST’s entire liability and the

End User’s sole and exclusive remedy for breach of warranty.

Liability

Health and Safety Warnings

07 SST004

Assumption of Liability

Air Powered Machinery and Pneumatic Equipment are useful

tools when installed with STUPID SIMPLE TOOLS®products

in accordance with proper safety protocols by eld

professionals. When congured with a high pressure air

compressor, the MEGAFLOW is a powerful industrial product

designed for installation and conguration by manufacturers

and professionals and is inherently dangerous. By installing

and/or operating a MEGAFLOW Air lter and Regulator,

you agree to take responsibility for any and all risks

associated with the installation and operation of the

MEGAFLOW Air Filter and Regulator and any associated up or

down-line equipment.

Pressurized air generation requires compressing multiple

cubic feet of air, and the ambient humidity in it, resulting

in substantial water condensation in high humidity areas.

MEGAFLOW is NOT DESIGNED TO TAKE THE PLACE OF

AIR DRYER SYSTEMS.

US and International Patents Pending

013 WWW.STUPIDSIMPLE.TOOLSSST003

WARNING: This product can expose you

to chemicals including Crystalline

Silica, which is known to the State

of California to cause cancer and

birth defects or other reproductive

harm. For more information, go to

www.P65Warnings.ca.gov

CALIFORNIA PROPOSITION 65

Thank you for

your purchase!

Our goal is to build the greatest tools out there.

We sweat the small stu and we hand assemble

& test every tool leaving our workshop in Florida.

If you have a question, issue, or just want to

talk shop — we’re here for you (during normal

business hours, of course).

SUPPORT @ STUPID SIMPLE .TOOLS

WWW . STUPID SIMPLE .TOOLS

CONTACT

CHECK OUT OUR OTHER TOOLS!

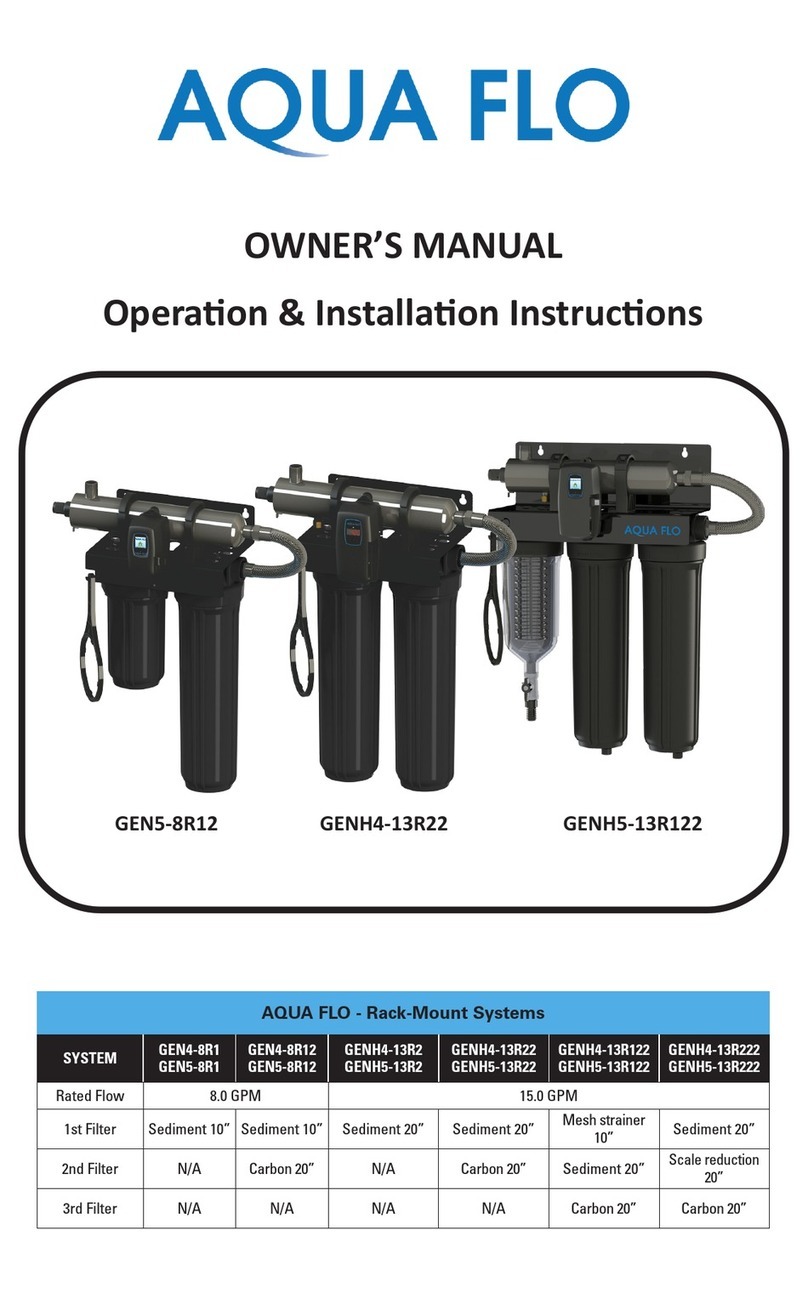

Other manuals for MEGAFLOW

1

Popular Water Filtration System manuals by other brands

Atlas Filtri

Atlas Filtri OASIS DP RO Instructions for installation

WaterLogic

WaterLogic F-FWEG1-M-A-NT Series user manual

Baker Hughes

Baker Hughes FD-1500 instruction manual

NTF

NTF AL Series instruction manual

Premier

Premier WP-2 LCV Installation, operation and maintenance manual

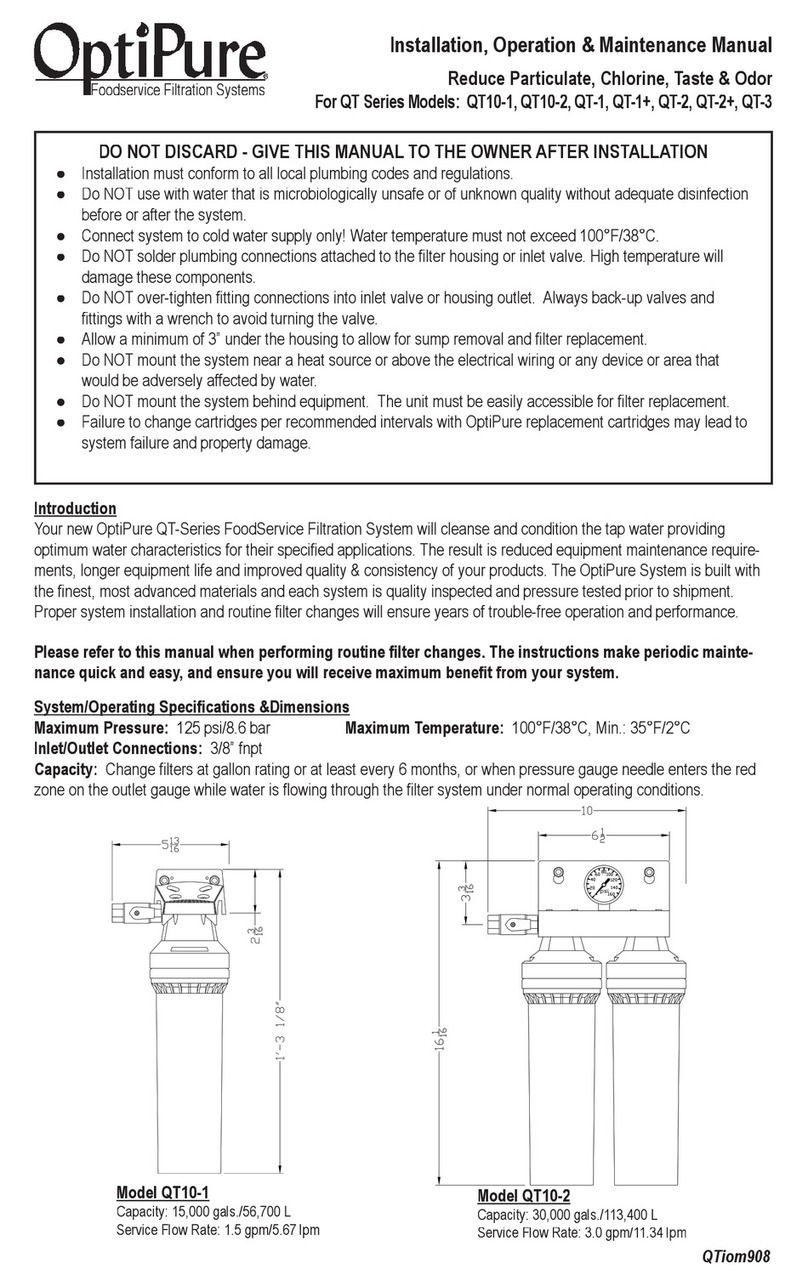

OptiPure

OptiPure QT10-2 Installation, operation & maintenance manual

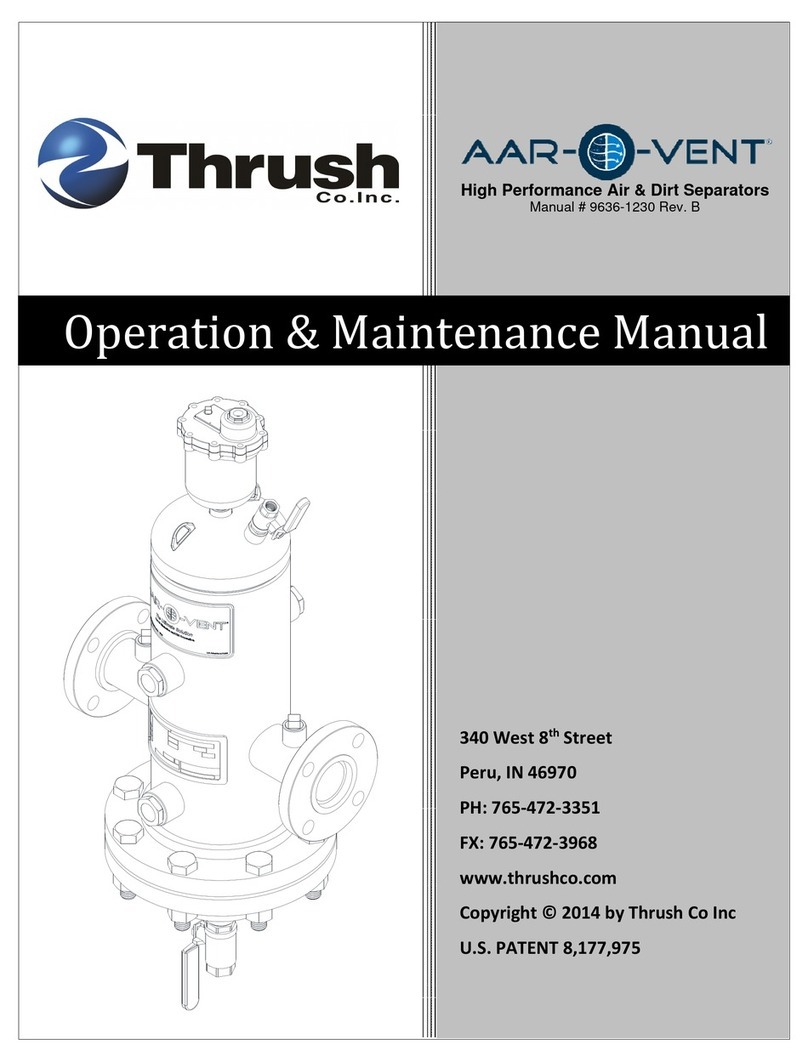

THRUSH

THRUSH AAR-O-VENT TASF Operation & maintenance manual

Danfoss

Danfoss VLT AHF005 Design guide

Commodity Axis

Commodity Axis Poly-Reactor ViaAqua PR 20/20 Booklet

Pond Boss

Pond Boss PonDuett 3000 operating manual

Spectra Watermakers

Spectra Watermakers AQUIFER 360 EXPEDITION owner's manual

IMI

IMI norgren F64C Installation & maintenance instructions