Störk-Tronic ST552G-XQ1TUR.109 User manual

Order number: 900350.053 V2.73 Page 1

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

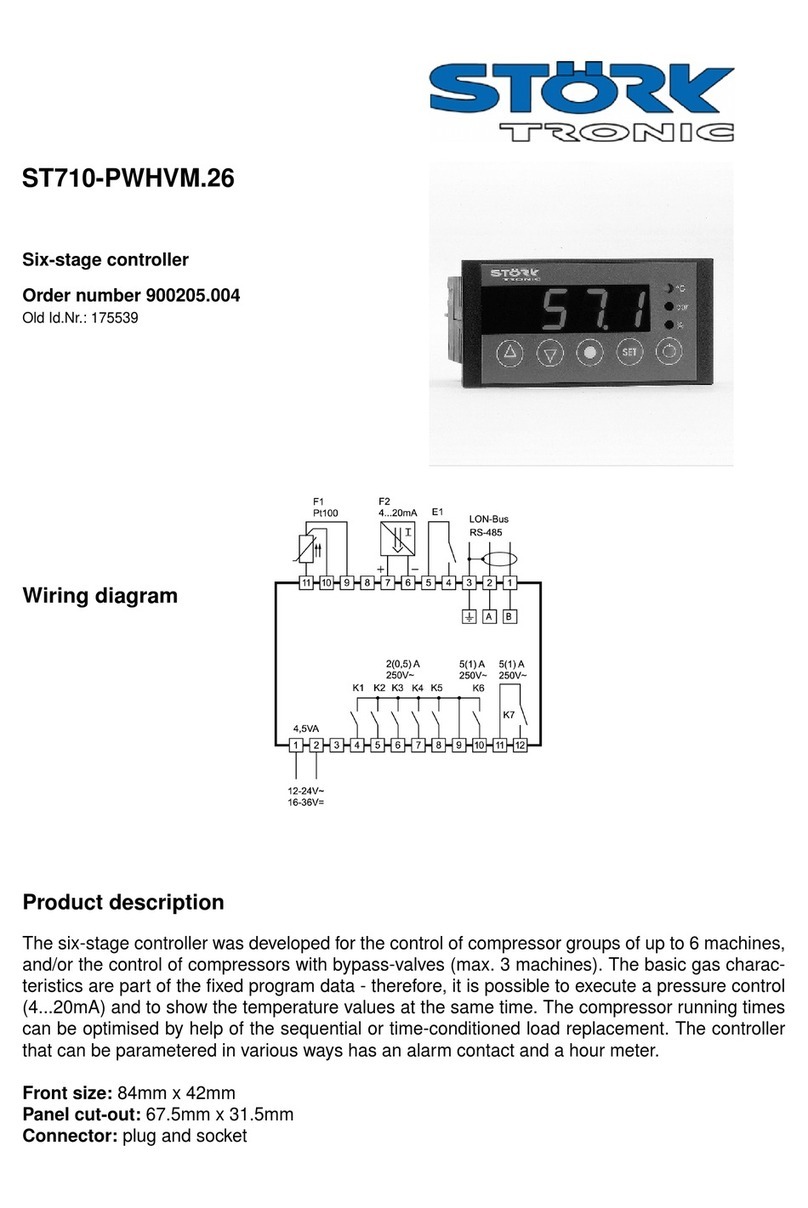

ST552G-XQ1TUR.109

100...240V~

LN

B

RS485

ST-Bus

A

K1...K4: 8(1,5)A 250V~

K1 K2

F1

Pt100

12

1234

1234123

1

21

23

PWM

GND

PWM

Out

S1: PWM

Power

123

K3 K4

E1

1

21

21

2

43

E2

F1

TC

T

_

S2: 4...20mA

8(1,5)A

250V ~

K7

Deep-frying controller

Order number: 900350.053

As of: 02.11.2021 V2.73

The ST552G fryer controller consists of a mineral glass-based touch panel that can be easily integrated into existing or

newly constructed installations. The controller can be supplied with a voltage of 100...240V AC and has two displays, five

switching outputs and two digital switching inputs. A temperature sensor type Pt100 or a thermocouple can be connected.

Five LEDs each indicate the selected temperature setpoint and the selected time setpoint.

The controller is networked by means of an ST-Bus interface.

Sensor: Thermo couple, Pt100

Range: dependant on type of sensor

Front size: 154,8mm x 61,8mm

Installation size: 180 x 87mm

Tightness: Front IP65

Connectors: Screw terminal

Product description

Wiring diagram

Design

The unit is designed as a complete installa-

tion unit and is intended for rear mounting.

The innovative capacitance keypad allows a

smooth glass front and makes the unit par-

ticularly suitable for applications with a high

degree of contamination. All inputs and out-

puts are connected at the rear. The unit fulfils

the function of a temperature controller with

timer functions and is designed for use with

deep-fat fryers.

Function

The front of the unit has a three- and

four-digit display, eight control buttons and

twelve LEDs. Five LEDs indicate the select-

ed temperature setpoint (“TEMPERATURE 1,

2, 3, 4, 5”), five LEDs indicate the selected

timer (“TIME 1, 2, 3, 4, 5”) and one LED indi-

cates the current status of the control output

(“HEAT”). The LED on the Melt/Turbo key

indicates the operating status selected there.

If it is on, gentle heating is in progress. The

reverse display direction can be set via pa-

rameter P17.

A temperature sensor type Pt100 or a ther-

mocouple type J is connected for recording

the actual control value. Two switching in-

puts allow the external start and stop of the

timer and the connection of an alarm contact

for over-temperature. In case of over-temper-

ature, the display shows “UEb” or “Hot”

flashing and the control is switched off. The

function of the switching inputs can be deac-

tivated via the parameterisation.

Four NO contacts and one changeover con-

tact are provided as output relays. The func-

tion “heating thermostat 1” or “heating PID”

can be selected for output K1 via the pa-

rameterisation; deactivation is also possible.

Output K2 has the basic function “cooling

thermostat 2” and can be used for an re-

lease function. Output K3 operates the bas-

ket lowering after timer start and output K4

the basket raising after timer stop, both of

which also apply when a timer is stopped in

between. Output K7 is assigned to the limit

value alarm.

The controller has the option of “gentle heat-

ing” in case the fryer fat is still solidified. This

slowed-down heating process (Melt func-

tion) is active after mains on and ends when

a limit value is reached that can be set below

the setpoint. If the fat has visibly melted, the

Melt/Turbo key can be used to switch to ac-

celerated heating even before the limit value

is reached. When cooling down, the turbo

characteristic is initially maintained; only be-

low 50 °C, the reloading of unmelted fat is

assumed and the controller automatically

switches back to gentle heating.

You can also enter a variable frying time.

Taking a parameterisable weighing factor

into account, the time of the started timer is

increased or reduced dynamically, depend-

ing on the control deviation.

A pair of limit values that can be set in the

parameterisation allows a temperature alarm

related to the actual control value, whereby

relative and absolute limit values can be

selected. In these alarm cases, the control

continues to run. An internal buzzer allows

an acknowledgeable warning signal.

Parameterisation

Parameterisation mode can be activated

by pressing the Temperature Up and Tem-

perature Down buttons simultaneously for

3 seconds. Parameter P1 appears in the

display. Use the Up and Down buttons to

scroll through the parameters. To access

higher parameters quickly, scroll backwards

using the Down button. Press the Melt-Tur-

bo button to activate the value of the current

parameter, the digit which can be changed

will be flashing. Use the temperature selec-

tion button to select other digits. Once, you

return to P1,... the changed value is saved.

Now, you can return to normal mode by

pressing Up+Down. After 60 seconds, the

controller returns to normal mode automat-

ically without saving any changes.

Displays

Display 1

T1 T2 T3 T4 T5 T6 T7 T8

Display 2

Display 1 (left): Temperature

LEDs 1...5 (left): Temperature selection

Display 2 (right): Timer

LEDs 1...5 (right): Timer selection

Top centre LED: Status heating output

Button LED: Gentle heating (Melt)

Function of the control buttons

General notes

With the present capacity keyboard, unde-

sired reactions of the controller are possible,

for technical reasons, when steam vapours

occur without the operator having pressed

a key. For these applications, a special de-

laying selection and setting mimic can be

selected (P47=1), in which an additional

key press is forced at the beginning of each

setting procedure. If this is not needed in

practice, it is possible to switch to the faster

selection and setting (P47=0, no delay).

Key 1: UP - Temperature

Use this button to increase a tem-

perature value activated via the

temperature selection. A delayed one-finger

setup is implemented. After tapping the but-

ton the display gets dark for a short period

(parameter P49) for unlocking. Once the

display comes back, the value is increased

without any further delay by tipping or keep-

ing the button pressed to increase the in-

crement and reach distant end values faster.

The maximal increment can be parameter-

ised.

For non-delayed key operation the timer side

has the same behaviour, if the actual value

is selected as the permanent display (P32

= 0). only the short darkening of the display

doesn’t take place.

Single-finger setup is implemented on the

parameter level, too. Here, the UP button is

used for switching to the following parameter

and for adjustment, after the value was acti-

vated with the Melt/Turbo button and the dig-

it to be adjusted was selected via the selec-

tion button. You can scroll through the digits.

Key 2: DOWN - Temperature

Use this button to reduce a temper-

ature value activated via the temper-

ature selection. The procedure corresponds

to increasing the value via the UP button.

The same applies to the parameter level.

Order number: 900350.053 V2.73 Page 2

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

General notes

The down button is also used for acknowl-

edgement of the buzzer. Since the timer re-

mains active when parameterisation mode is

activated, the buzzer can also be acknowl-

edged there.

Key 3: Temperature selection

Use this button to select the setpoint

to be used by the controller. Scroll

to select, each push of the button switches

the display further one step. The selected

temperature setpoint remains active even

after disconnection of mains supply. Special

presets are also possible.

In “delayed key operation” the selection

lamp goes off when initially pressed briefly,

then the button must be released and from

then on you can change instantaneously. In

non-delayed key operation the change takes

place immediately

.

Key 4: MELT/TURBO

Use this button to toggle between

gentle heating and fast heating

when the controller is switched on. This is

only possible below an adjustable threshold

below the limit value (P73). “MELT” mode is

always activated when the device is turned

on. A key delay can be set with parameter

P48.

The status LED is on during “gentle heat-

ing” mode (MELT function). It is possible to

select the reverse behaviour with parameter

P17, i.e. the LED is on during fast heating

(TURBO function).

With the “Superturbo” function, which can

be triggered with this key above the limit

value from P73, thermostatic control takes

place until a switch-off value (P15) set at

the setpoint is reached. In this zone, the key

toggles between thermostatic and PID char-

acteristics. The “Superturbo” option must be

enabled with P16. The status lamp always

indicates the active “Superturbo” by flash-

ing.

Key 5: UP - Timer

Use this button to increase a time

value activated via the time selec-

tion. One-finger setup is implemented. Keep

the button pressed, after a short unlocking

delay, the value is increased without delay.

Now, you can also release the button and

press it repeatedly briefly. In this case, the in-

crement increases so that you can set high-

er end values more quickly. Changing the

time is possible while the timer is running

down. The new value will be saved and used

immediately for the active timer operation.

The procedure in relation to the selected

key operation mode (parameter P47) corre-

sponds to the temperature side. In non-de-

layed key operation mode however, there is

no additional keypress on this side.

Key 6: DOWN - Timer

Use this button to decrease a time

value activated via the temperature

selection. The procedure corresponds to in-

creasing the value via the UP button.

Key 7: Timer selection

Use this button to select the time

to be used by the timer. Scroll to

select, each push of the button switches the

display further one step. The selected time

value remains active even after disconnec-

tion of mains supply.

Special presets are also possible.

The procedure in relation to the selected

key operation mode (parameter P47) corre-

sponds to the temperature side.

Key 8: START/STOP

As soon as this button is pressed

and released again, the selected

timer is started. The remaining time appears

in the display. The timer can be stopped at

any time. When the timer has elapsed, the

acoustic signal will be active for 3 seconds.

It can be acknowledged by pressing the

DOWN button. The timers have no influence

on the control operation. If you press the but-

ton for at least 2 seconds, the timer will be

stopped again.

In addition, you can turn the controller to

standby by pressing the button for at least

5 seconds. In the right display, OFF will

appear. Press the button again, to turn the

controller on again. Via the parameterisation,

you can also set up a button delay for the

restart (P43). In addition, you can change

the message displayed to OFF (parameter

P36). Via the parameterisation, you can also

deactivate the standby function completely

(parameter P41). In this case, the controller

will always be on after Mains ON

.

Key 4+8: Reset of fat

time registration

Pressing these buttons

simultaneously for at least 3 seconds will

reset the time registration. The warning mes-

sage OIL is withdrawn and, if necessary,

the control blocking is also cancelled. The

accumulated operating time is deleted. The

display briefly shows rES. Note that the re-

set is only possible if a warning status has

occurred or if blocking has occurred, and

also only below an adjustable temperature

limit. This is to prevent the user from continu-

ing to operate the fryer without changing the

fat. However, the reset can also be enabled

unconditionally.

Setpoint level

Para-

meter

Description of function Setting range Default

value

Temperature setpoints

S1 Temperature setpoint 1: P4 ... P5 110 °C

S2 Temperature setpoint 2: P4 ... P5 120 °C

S3 Temperature setpoint 3: P4 ... P5 130 °C

S4 Temperature setpoint 4: P4 ... P5 140 °C

S5 Temperature setpoint 5: P4 ... P5 150 °C

Timer setpoints

T1 Time 1: 0:00 ... 59:59 Min. 1:11 Min.

T2 Time 2: 0:00 ... 59:59 Min. 2:12 Min.

T3 Time 3: 0:00 ... 59:59 Min. 3:13 Min.

T4 Time 4: 0:00 ... 59:59 Min. 4:14 Min.

T5 Time 5: 0:00 ... 59:59 Min. 5:15 Min.

Order number: 900350.053 V2.73 Page 3

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

General notes

Para-

meter

Description of function Setting range Default

value

Cust.

value

General control parameters

P1 Delta W control circuit 2 -99...+99.0 K 10.0 K

P2 Hysteresis control circuit 1 0.1...99.0 K 1.0 K

P3 Hysteresis control circuit 2 0.1...99.0 K 1.0 K

P4 Bottom setpoint limitation 0...999 °C 0 °C

P5 Top setpoint limitation 0...999 °C 999 °C

P6 Correction actual value 1 -20.0...+20.0 K 0.0 K

P7 Display actual value 1 - -

P8 Initial temperature selection after Mains On 0: Selection as before

1...5: Selection of setpoint 1...5

0

P9 Initial time selection after Mains On 0: Selection as before

1...5: Selection of time value 1...5

0

PID parameter

P11 Control circuit 1: Proportional range in PID control 0.1…999 K 20.0 K

P12 Control circuit 1: Integral time in PID control (I portion) 0...999 sec.

(0 sec. = inactive)

500 sec.

P13 Circuit. 1: Derivative action time in PID control (D portion) 0...999 sec.

(0 sec. = inactive)

50 sec.

P14 Control circuit 1: Cycle time in PID control 2...100 sec. 10 sec.

P15 „Superturbo end“ around the setpoint -50...+50.0 K 15.0 K

P16 Switching mode of the Melt/Turbo key 0: Normal operation

1: Switch to „Superturbo“

1

P17 Behaviour of the MELT/TURBO LED 0: on during MELT

1: on during TURBO

0

Relay delay

P18 Switch-off delay for heating relay 0.0...99.0 sec. 0.0 sec.

Key lock

P19 Key lock (Setpoint adjustment disabled) 0: Not locked

1: Locked

0

Alarm parameters

P21 Lower alarm limit -99...999 °C/K -99 K

P22 Upper alarm limit -99...999 °C/K 200 K

P23 Hysteresis alarm, one side 0.1...99.9 K 1.0 K

P24 Alarm function 0: Alarm limit relative

1: Alarm limit absolute

1

P25 Special function in case of alarm 0: Not active

1: Display flashing, buzzer active

0

P26 Alarm suppression after Mains On 0...60 min. 0

P27 Buzzer duration when timer elapsed 0...60 sec.

(0 sec. = inactive)

5 sec.

P28 Buzzer type 0: continuous

1: pulsating

0

P29 Blinking after timer expiry 0...180 sec.

(0 sec. = inactive)

0 sec.

Display parameters

P31 Display mode basic level 0: Integral numbers

1: Resolution 0.5 K

2: Resolution 0.1 K

2

P32 Type of temperature display 0: Actual value display

1: Setpoint display

0

P33 Type of time display 0: Remaining time display

1: Operating time display

0

Order number: 900350.053 V2.73 Page 4

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

Parameter list

Para-

meter

Description of function Setting range Default

value

Cust.

value

P34 Temperature scale 0: Fahrenheit

1: Celsius

1

P35 Message in case of overtemperature 0: UEb

1: Hot

0

P36 Display in case of standby off 0: AUS

1: OFF

0

P37 Blinking mode during timer

(when the timer has elapsed, P29 is effective)

0: during buzzer

1: during buzzer and after timer has elapsed

2: different blinking intervals during/after the

timer and during activated buzzer

0

Key parameters

P41 Standby function 0: Not active

1: Standby with button click

2: Standby via ST-Bus

3: Standby with button and ST-Bus

1

P42 Internal buzzer mode 0 ... 15 (0 = buzzer inactive)

Bit mask (add values):

+1: Button klick

+2: Baking end

+4: Error, high temperature/sensor error

+8: Errors like an alarm relay

15

P43 Delay of Start/Stop key at Standby-On 0.1…5.0 sec. 1.0 sec.

P44 Delay before start of Turbo setup 0.0...2.0 sec. 0.5 sec.

P45 Maximum increment/decrement in turbo setup,

temperature setting

1...20 K 5 K

P46 Maximum increment/decrement in turbo setup,

time setting

1...20 sec. 5 sec.

P47 Key operating mode 0: standard mode (no delay)

1: delayed key operation

1

P48 Key delay for MELT/TURBO key 0.1 ... 5.0 sec. 0.5 sec.

P49 Key delay for setup (if P47=1) 0.5 ... 3.0 sec. 1.0 sec.

Input and output parameters

P51 Function of external input E1 0: No function

1: External start/stop

2: Access to parameter level

0

P52 Function of external input E2 0: No function

1: Message overtemperature

2: Feedback in case of "Gas" and "Gas+fan"

heating mode

0

P53 Switching mode input E2 0: Active when open

1: Active when closed

1

P54 Assignment output K1 0: Not active

1: Thermostat control circuit 1

(not with P56=2 and P56=3)

2: PID control circuit 1

2

P55 Assignment output K2 0: Not active

1: Thermostat 2

2: on together with controller on

1

P56 Type of heating 0: Gas heating with feedback

1: Electrical (or gas heating without feedback)

2: Gas+fan, gentle heating realised via fan

3: Gas+fan, gentle heating realised via burner

2

P57 Type of PWM / analogue signal (fan selection) 0: Active when high (230V~)

1: Active when low (24V=)

0

P58 Tolerance time for burner start and restart chance 1...20 sec. 10 sec.

P59 Min. on/off time during burner clocking 1.0...5.0 sec. 5.0 sec.

Order number: 900350.053 V2.73 Page 5

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

Parameter list

Para-

meter

Description of function Setting range Default

value

Cust.

value

Fan Parameters

P61 Minimum speed at fan 0...100 % (PWM/analogue signal) 30 %

P62 Maximum speed at fan 0...100 % (PWM/analogue signal) 100 %

P63 Maximum speed increase per 0.1 sec. 1...250 stages 4 stages

P64 Correcting variable in case of clocked operation 0...100 % (PWM / analogue signal) 50 %

P65 Lead/delay time of fan 1...60 sec. 5 sec.

P66 Time for start increase 1...60 sec. 5 sec.

P67 Starting boost (for P61/P62)0 ... 100% (PWM/analogue signal) 100%

Fryer parameters

P71 On time of heating clocking 1...255 sec. 60 sec.

P72 Off time of heating clocking 1...255 sec. 90 sec.

P73 Clock end below threshold -99...0,0 K -30 K

P74 Activation of burner clocking 0: Not active

1: Burner clocking below setpoint

1

P75 Duration of basket lowering at K3 at start of timer 0...30 sec. (0 sec. = inactive) 5 sec.

P76 Duration of basket raising at K4 at start of timer 0...30 sec. (0 sec. = inactive) 5 sec.

P77 Selection of post-frying time 0: Fixed time

1...20: Elastic time

0

P78 Activation of heating clocking 0: Not active, always turbo heating

1: Gentle heating

1

P79 Threshold for return to heating clocking mode 0.0...99.0 °C 50.0 °C

Operating time parameters

P81 Temperature limit for fat operating time elapsed 0.0...999 °C 999 °C

P82 Fat operating time until warning message 0...99 hrs. (0 hrs. = inactive) 0 hrs.

P83 Fat operating time until controller block 0...99 hrs. (0 hrs. = inactive) 0 hrs.

P84 Display of fat operating time ----- -----

P85 Temperature limit for reset of fat operating time

(only effective if P86 = 2)

-99...999 °C 100 °C

P86 Reset option of fat operating time 0: No restrictions

1: After warning message or blocking

2: After warning message or blocking plus

cool-down

2

Sensor and hardware parameters (if changed, Mains Off required)

P91 Selection of sensor type 0: Pt100 2-wire

1: Thermocouple type J (Fe-CuNi)

2: Thermocouple type K (NiCr-Ni)

0

P92 Display compensation ----- -----

P93 Software filter depth 1...64 8

P94 Mains frequency 0: 50 Hz

1: 60 Hz

0

P95 Type of analogue output 0: 0-10 V

1: 4-20 mA

1

LowFat and NoContact settings

H1 Temperature increase for test heating „LowFat“ 0.1…99.0 K 1.0 K

H2 Minimum duration for test heating „LowFat“ 0…240 sec.

(0 sec. = inactive)

0 sec.

H3 Maximum duration for test heating „NoContact“ 0…240 sec.

(0 sec. = inactive)

0 sec.

H4 Temperature increase for test heating „NoContact“ 0.1…99.0 K 1.0 K

H5 Max. temperature for LowFat- and NoContact settings 1…990 °C 60 °C

Order number: 900350.053 V2.73 Page 6

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

Parameter list

Order number: 900350.053 V2.73 Page 7

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

Function description

Para-

meter

Description of function Setting range Default

value

Cust.

value

Timer characteristics

tic Timer function 0: without multiple starts

1: with multiple timer starts

0

Address + version

L0 Controller address 1...255 5

Pro Program version -----

LowFat- and NoContact control

setting

General

Temperature monitoring a fryer can show

whether enough oil is available. The LowFat

and NoContact control settings provided by

the controller cary out this task. Low Fat and

No Contact operate independently, each

have their own parameters and can be de-

selected separately.

At the moment of turning on the burner the

control settings start running both at once

and a test heating starts.

Heating dynamics at various amounts

of oil:

Rule of thumb: The more oil, the slower the

heating rate at a given heat output.

T

H1

H2 t

little oil

much oil

Start

The illustration shows the heating up with

small or large quantities in the deep fryer

tank

Fryer design features

The special features in the design of the

deep-fryer must be taken into account. The

temperature measurement value depends

on the thermal coupling of the sensor to the

oil or heating system. If the thermal coupling

disappears with little oil, then the tempera-

ture also increases slowly or not at all.

The illustrations show different constructions

and thermal coupling to the sensor.

Temperature behaviour of the different

designs

Example A:

If there is so little oil present that the sen-

sor is no longer immersed in oil, it measures

approximately the air temperature instead of

the oil temperature and hardly changes the

measured value during heating.

The lack of oil then becomes noticeable as

too little temperature rise.

Example B:

In design B, a mixing temperature can oc-

cur because the sensor has thermal contact

with the oil and the tank wall.

The temperature at the sensor rises when

the oil heats up, or when heat is transferred

to the sensor via the tank wall through heat

conduction.

Example C:

In design C, the sensor is always in thermal

contact with the medium.

In this case, the lower the amount of oil pres-

ent, the higher the temperature rise.

Example D:

Design D has the same characteristics as

design A.

Parameters involved

H1 Temperature rise for sample heat-

ing “LowFat”.

H2 Minimum duration for sample heat-

ing “LowFat”.

H3 Maximum duration for “NoContact”

test heating

H4 Temperature rise for “NoContact”

sample heating

H5 Maximum temperature for LowFat

and NoContact facial expressions

Order number: 900350.053 V2.73 Page 8

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

Function description

Test heating procedure and alarm

conditions

Once after start

After switching on the controller, it once exe-

cutes a test heating. This is to avoid that the

fryer is started, if there is no or insufficient

oil.

To fast temperature rise with little oil

Parameter H2 defines a minimum required

time for the temperature rise according to

parameters H1.

In case of a faster temperature rise the heat-

ing is switched off and an alarm with “lack of

oil” message is triggered.

To slow temperature rise without oil

Parameter H4 defines a minimum required

temperature rise for the duration according

to parameter H3.

A slower temperature rise may indicate that

no oil is present and the sensor is no longer

in the oil. The heating is switched off and an

alarm with “lack of oil” message is triggered.

Please note:

If a medium other than oil is used and the

heat output is changed, other parameter val-

ues will result.

In baking mode

In baking mode, i. e. above the temperature

of parameter H5, the process is no longer

reliable.

• Monitoring of the minimum tempera-

ture increase is not possible when cold

goods are thrown into the deep fryer.

• The monitoring of the maximum tem-

perature increase is not possible be-

cause this would require an unallowed

deviation from the setpoint.

Temperature range for LowFat- and No-

Contact settings

Parameter H5 sets a limit, up to which the

test heating is started after switching on the

controller.

Please note that the test heating is aborted if

this limit is exceeded.

Alarm and Reset

If the test heating causes an alarm, the

display flashes with “FAt” and the buzzer

sounds. The test heating is stopped and the

heater (i.e. burner and fan) is switched off.

The buzzer can be acknowledged immedi-

ately with the DOWN key. To reset the alarm

fill up oil and switch off and back on the con-

troller with the OFF key

Selection parameter post-frying

time

With parameter P77, you can define if the

frying time is exactly the programmed time

or if the frying time is to be extended if the

fried material causes a temperature de-

crease.

Extension of the frying time, also referred to

as elastic time or post-frying time, depends

on the deviation from the setpoint. If the set-

point is exceeded, the time is reduced.

ΔT

P77=1

P77=10

P77=20

f(ΔT)

-10°C 10°C 100°C

Weighing factor in case

of variable frying time

Setpoint > actual value

tvar = tfix * f (ΔT, Tact)

1.0

1.5

1.5

Setpoint 180 °C, selected frying time 100 s

Act.

value

P77 Effective frying

time

180 °C 0 100 sec.

150 °C 0 100 sec.

180 °C 1 100 sec.

150 °C 1 120 sec.

180 °C 10 100 sec.

150 °C 10 135 sec.

180 °C 20 100 sec.

150 °C 20 150 sec.

125 °C 20 210 sec.

100 °C 20 300 sec.

Feedback in case of heating modes

“Gas” and “Gas+fan”

In the case of heating modes “Gas” and

“Gas + Fan”, a feedback signal detected via

switching input E2 can be used. The feed-

back confirms that the burner has started

properly. Otherwise, the control is stopped.

The feedback signal is considered in differ-

ent ways in the case of these heating modes.

Heating mode “Gas”

Control at the heating output is effected only

if the feedback is present on switching input

E2. Without the feedback, the heating relay

is not switched on. If the feedback is miss-

ing during the heating process, the relay is

switched off. In this heating mode, no error

message is triggered nor is it necessary to

acknowledge an error..

Heating mode “Gas+Fan”

Restart with controller switched off:

Control at the heating input will be activat-

ed upon request by the controller part. After

that, the system waits for receipt of the feed-

back (for the time set in parameter P58). If

the feedback is received at switching input

E2 of if it is already present at the time of the

request, the control operation is continued.

If not, the control operation is switched off.

The “HEAT” lamp flashes slowly signalling

the start error. To acknowledge and restart

the control operation, press the “OFF” but-

ton, i.e. switch to Standby Off and on again.

Burner failure with restart chance:

If the feedback fails during the control oper-

ation, the fan is switched back to minimum

speed according to parameter P61 imme-

diately. The system waits for the restart of

the burner and the return of the feedback

signal (for the time set in parameter P58).

The “HEAT” lamp flashes quickly signalling

the restart chance. If the feedback signal is

received again, the control operation is con-

tinued. If the feedback is not received within

this time, the control operation is switched

off. The “HEAT” lamp flashes slowly sig-

nalling the burner failure. To acknowledge

and restart the control operation, press the

“OFF” button, i.e. switch to Standby Off and

on again.

Deactivation of feedback

Via parameter P53, you can deactivate the

feedback function by reversing the switching

mode of switching input E2. In this case, the

controller will interpret the open switching

input, to which nothing may be connected,

as a feedback signal. Independent of this,

the feedback will also be deactivated if you

assign other functions to the switching input

via P52.

The control function of the deep fryer con-

troller is explained in the following and

will always be valid while the controller is

switched on.

Order number: 900350.053 V2.73 Page 9

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

Function description

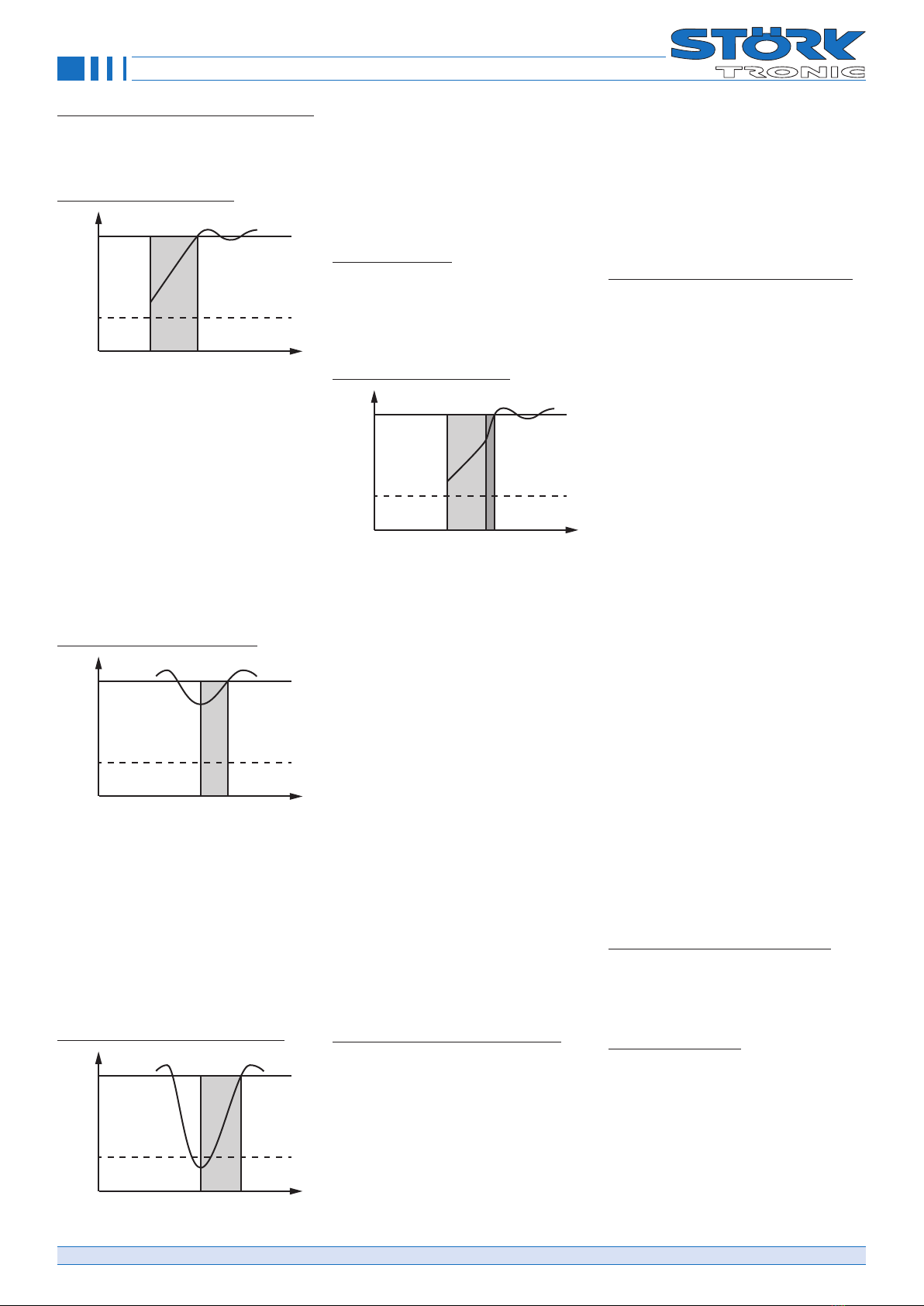

Control function

Heating phase without manual interven-

tion:

Heating phase after activation:

T

50°C

t

Setpoint

Heating phase

after activation

After activation and start of the controller, a

slow heating phase will always follow when

the fat is cold. This phase ends at latest

when the setpoint is reached. In this slow

heating phase, the heating relay clocks, i.e.

with the on time set in parameter P71 be-

ing followed by the off time set in parameter

P72. Slow heating is to ensure that con-

gealed fat is heated up gently at the start

of operation. Via parameter P73, you can

stop the slow heating phase before the set-

point is reached. If this is not desired, set

P73=0.0 K.

Heating phase after slight cooling:

T

50°C

t

Setpoint

Heating phase

after minor cooling

After a minor cooling down to temperatures

above 50 °C, e.g. by loading small amounts

of cold fat, the normal heating function of

the controller is maintained. The reheating

phase is therefore not slowed down; if the

thermostat function is set via the parameter-

isation, the heating relay does not cycle. If

the PID function is preset, the heating relay

only cycles within this range. The end of the

cycle set with P73 has no effect.

Heating phase after significant cooling:

T

50°C

t

Setpoint

Heating phase

after significant cooling

After significant cooling to temperatures be-

low 50 °C, e.g. loading of large quantities of

cold fat, the slow heating function is activat-

ed again. The heating relay cycles again like

in the initial heating phase, until the setpoint

or the cycle end below the setpoint defined

in parameter P73 is reached again. This is

to ensure gentle heating of the reloaded fat.

Control after heating

After the heating phase, the controller works

with the PID function based on parameter

group P11 to P14.

Heating phase with manual intervention:

Heating phase after activation.

T

50°C

t

Setpoint

Heating phase

with manual switchover

After activation and start, the slow heating

phase will start without manual intervention.

By pressing the quick heating button MELT/

TURBO, you can switch over to the normal

heating function. Now, the fat will be heated

more quickly. The heating relay will no longer

cycle based on the times set in parameters

P71 and P72 but based on the PID function

set via the PID parameters. The cycle end

defined via parameter P73 does not have

any influence after the manual intervention.

To undo the switch-over, press the MELT/

TURBO button again. Now, the heating relay

will cycle like before the manual change-over

again.

The manual change-over function can be

used for reducing the heating phase if the

fat has melted visibly and can be heated at

a higher rate without any damage. Manual

change-over between slow heating and tur-

bo heating is possible only if the controller

actually is in the heating phase, i.e. below

the threshold set via parameter P73. Above

this threshold, the turbo button has no func-

tion.

Heating phase after significant cooling

After significant cooling to temperatures be-

low 50 °C, e.g. loading of large quantities

of cold fat, a slow heating phase will start,

although the change-over to normal heating

mode is effected earlier; the heating relay

clocks like in the initial heating phase.

Thus, manual change-over to normal heat-

ing function is only effective for the current

heating phase and will become ineffective

as soon as the setpoint is reached, at the lat-

est. After that, as well as after mains failure

and restart, the controller is in normal oper-

ation mode with slow heating phase when

the controller is switched on and started or

restarted later or in the case of cool-down to

temperatures below 50 °C. The switch-back

threshold is can be set via parameter P79.

Clocking of automatic burner device in

the case of heating mode “Gas+Fan”:

Control to setpoint with “burner clocking”:

To obtain a better control to the setpoint

in the case of heating mode “Gas+Fan”,

clocking of the automatic burner device can

be activated. If the correcting variable per-

centage determined by the control part is

smaller than the lower speed limit of the fan

defined in parameter P61, the fan remains

at this minimum speed and the automatic

burner device is clocked until the setpoint

is reached.

In this case, the control part calculates the

on phases from 0...100 % based on the cor-

recting variable values, with a minimum on

time / minimum off time being enforced by

parameter P59. The feedback is handled

such that the time between the activation

of the heating output and the receipt of the

feedback signal is not considered as effec-

tive on time. Thus, the effective on time will

start only upon receipt of the feedback sig-

nal.

Below the burner clocking range, the auto-

matic burner device will always be on at first.

Above the burner clocking range, i.e. after

the setpoint was reached, the automatic

burner device and the fan are switched off

if the correcting variable becomes zero. For

the fan, lead and delay times as well as a

start-up boost are always effective.

If burner clocking is deactivated, the auto-

matic burner device will always be switched

on below the setpoint, and the control is af-

fected by defining the fan speed based on

the correcting variable, within the limits spec-

ified via parameters P61 and P62, across

the whole proportional range. Above the set-

point, the automatic burner device and the

fan will be switched off.

Gentle heating with “heating clocking”

Two operation modes are available for gen-

tle heating of cold fat, with the effective cor-

recting variable always being defined via the

ratio of the on and off times in P71 and P72.

Heat clocking with fan:

If P56=2 the so-called heating clocking is

affected only via the fan, the burner will be

on permanently. The speed value of the on

phase is defined by P64, in the of-period,

the minimum value defined by P61 is valid.

Note that the percentage value specified in

P64 is relative to the area of P61 ... P62.

Further the final value of the “on-period” is

not reached in case of very short turn-on

times in P71 because the fan speed in-

crease is reduced with parameter P63.

Order number: 900350.053 V2.73 Page 10

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

Function description

Heat clocking with burner:

If P56=3, the heating clocking is affected

by switching the automatic burner device on

and off at the time values defined in P71

and P72, with the fan always maintaining its

minimum speed according to P61. Param-

eter P64 has no function in this operation

mode.

Heating with “Superturbo”

To obtain always instant heat output in case

of need, you can change and activate the

switch option to “Superturbo” with P16. Now

the Melt/Turbo button activates the thermo-

static control, provided that the limit of P73

is exceeded. This mode is called “Supertur-

bo” and applies to all operating modes until

reaching the one time switch-off limit that

was established with P15. Thereafter, switch

again to “Superturbo”, if necessary. So you

can toggle with the button above the limit

from P73 between the PID control and the

thermostat behaviour, in which the hysteresis

of P2 is effective. If you switch within this

hysteresis to “Superturbo”, the heating is

switched on immediately and only from then

on, the hysteresis will be activated. Once

“Super Turbo” is active, there are no burner

cycles.

Above the cut-off line, which was established

with P15, the Melt/Turbo button is blocked

because an active “Superturbo” was already

deactivated and should remain also inactive.

You can only switch back to slower heating

(melt function) below the limit from P73.

Please note that the switch option to “Super-

turbo” remains in those named limits if the

controller was configured as a pure thermo-

stat with P54. In this case, the switch does

not create a change in the control behav-

iour, and it is recommended to disable the

“Superturbo” in P16. On the other hand,

you can activate “Superturbo” if you waive

in special cases the gentle heating phase

with P78.

The status of ”Superturbo” is always dis-

played with a flashing buttons light, it doesn’t

matter how P17 is configured

Switch-off delay for heating relay:

With parameter P18, you can define a

switch-off delay for the heating relay which is

effective in all operation modes. The param-

eter is provided for cases, where the ignition

of the gas heating is always delayed.

Caution: The setting P18 must be done tak-

ing utmost care, as it is active independent

of the control part. For this reason, short cy-

cle times might result in unintended perma-

nent heating.

Operation of the timer group

Version without multiple start (tic=0):

Single start:

After the start of a timer it is not possible to

select or start another timer. At the end of a

timer the buzzer sounds and the LED of the

concerning timer flashes while the buzzer is

on.

With parameter P28 the buzzer can be spec-

ified for continuous or pulsating operation.

Basket activity:

If the basket operation is activated (P75>0

and P76>0) the basket is lowered at start

of the timer and is raised at every stop of

the timer.

By keeping pressed the Stop key the timer is

cancelled and the basket is raised.

If the basket operation is deactivated (P75=0

and P76=0) the basket is not lowered or

raised. The timer works as above.

Please note that it is mandatory to always

adjust both parameters P75 and P76 either

to “0” or to a time value!

Version with multiple start (tic=1):

Multiple start:

After the start of a timer it is possible to se-

lect another time and start the timer. In the

display you always see the time of the se-

lected timer and the LED of this timer is on.

At the end of a timer the buzzer sounds

and the LED of the concerning timer flashes

while the buzzer is on.

The display shows the time of the selected

timer and the LED of this timer is on.

It is possible to start all 5 timers simultane-

ously, however a multiple start of a single

timer is not possible!

With parameter P28 the buzzer can be spec-

ified for continuous or pulsating operation.

Basket activity:

If the basket operation is activated (P75>0

and P76>0) the basket is lowered at every

start of a timer and is raised at every stop or

end of a timer.

If the basket is raised or the Start/Stop key is

pressed, the lapse of all timers is interrupted

and can be continued by restarting.

It is possible to finally stop all timers by

pressing the Start/Stop key for more than 4

seconds.

If the basket operation is deactivated (P75=0

and P76=0) every timer works independent-

ly and only the currently selected timer is

started, stopped or cancelled. By pressing

the Start/Stop key for more than 4 seconds

all timers are cancelled.

Please note that it is mandatory to always

adjust both parameters P75 and P76 either

to “0” or to a time value!

Longer blinking of the timer lamps:

It is possible to let the timer lights flash at

timer end for up to 3 minutes. This results in

a longer signalling of expired timers, if only

a short buzzer period. With parameter P29

the flashing duration is specified, at P29 = 0

is no further flashing.

The flashing can, like the buzzer, be ac-

knowledged with the down button. If a mul-

ti-start occurred, the flashing of all timers is

always acknowledged together.

Flashing during timer sequence, at buzz-

er sound and after a timer has expired:

If P37 = 2, flashing already takes place in a

fast flashing cycle during the timer sequence.

If an flashing time is set in P29, flashing now

takes place in a slow flashing cycle during

the buzzer time. After the buzzer is off, the

flashing continues for the specified time, still

in a slow flashing cycle. This flashing can

again be acknowledged with the down key

for all timers together.

Note once again that the flashing of the timer

lamps on expiry or after the end of the timer

can only apply to unselected timers if sever-

al timers are expiring or have expired.

Order number: 900350.053 V2.73 Page 11

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

Status messages

Display Cause Remedy

E1 Sensor error

(Heating relay and analogue output are switched off!)

Check sensor

Ptc Sensor error on compensation element for thermocouple

measurement (P91=1,2)

Repair of controller

UEb Overtemperature at E2 (P35=0, P52=1) -----

Hot Overtemperature at E2 (P35=1, P52=1) -----

FAt Alarm of the LowFat or NoContact control settings Check oil level and/or switch on/off by press-

ing OFF button

EP Error in parameter memory Repair of controller

OIL

Control active

Warning message, fat operating time is exceeded (see P82)Acknowledge with the temperature DOWN key

OIL

Control blocked

Control is blocked,, fat operating time is exceeded (see P82)Acknowledge with the MELT and START key

rES Reset of fat operating time (see P86)-----

Display flashing Threshold alarm (P25=1) -----

Timer lamp flashing Timer has elapsed (see P27 and P29)Acknowledge with the DOWN key

Lamp “HEAT”

flashing slowly

Burner fault (see P58)Switch on/off by pressing OFF button

Lamp “HEAT”

flashing quickly

Burner restart chance (see P58)Waiting for restart or burner malfunction

Lamp “MELT2”

flashing slowly

Thermostatic “Super Turbo” is active

---

flashing during setup

Button lock (P19=1) -----

Order number: 900350.053 V2.73 Page 12

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

Technical data

Analogue inputs F1: Temperature sensor Pt100 or thermocouple TC

Measuring range: Pt100 -80...+400 °C

TC -50...+400 °C

Measuring accuracy referred to controller at 25 C: +/-0.5 K and +/-0.5 % of measuring range

Digital inputs E1: External start-stop button

E2: Overtemperature signal contact from temperature limiter

Switching outputs K1: Relay, 8(1.5) A / 250 V~, normally-open contact (heating contact)

K2: Relay, 8(1.5) A / 250 V~, normally-open (control contact 2)

K3: Relay, 8(1.5) A / 250 V~, normally-open (raise basket)

K4: Relay, 8(1.5) A / 250 V~, normally-open (lower basket)

K7: Relay, 8(1.5) A / 250 V~, change-over contact (alarm contact)

S2: Linear analog output with 0 to 20 mA output range

PWM output S1: PWM output 3.6 KHz, output of PID correcting variable for control via a fan

Power supply 100 ... 240 V~ 50/60 Hz

Connectors Screw terminals, grid 5.00 mm, for cables up to 2.5 mm²

Ambient conditions Storage temperature -20...+70 °C

Operating temperature 0...55 °C

Relative humidity max. 75 % r.H., no condensation

Weight approx. 600 g

Enclosure type IP65 front, IP00 rear

Protection class Protection class II, rated voltage 250 V~

Interface Shielded 2-wire cable, twisted pair, maximum cable length 1000 m

Interface driver: RS485, galvanically not isolated.

The network must be designed in line topology with termination resistor of 120 Ohm on both sides.

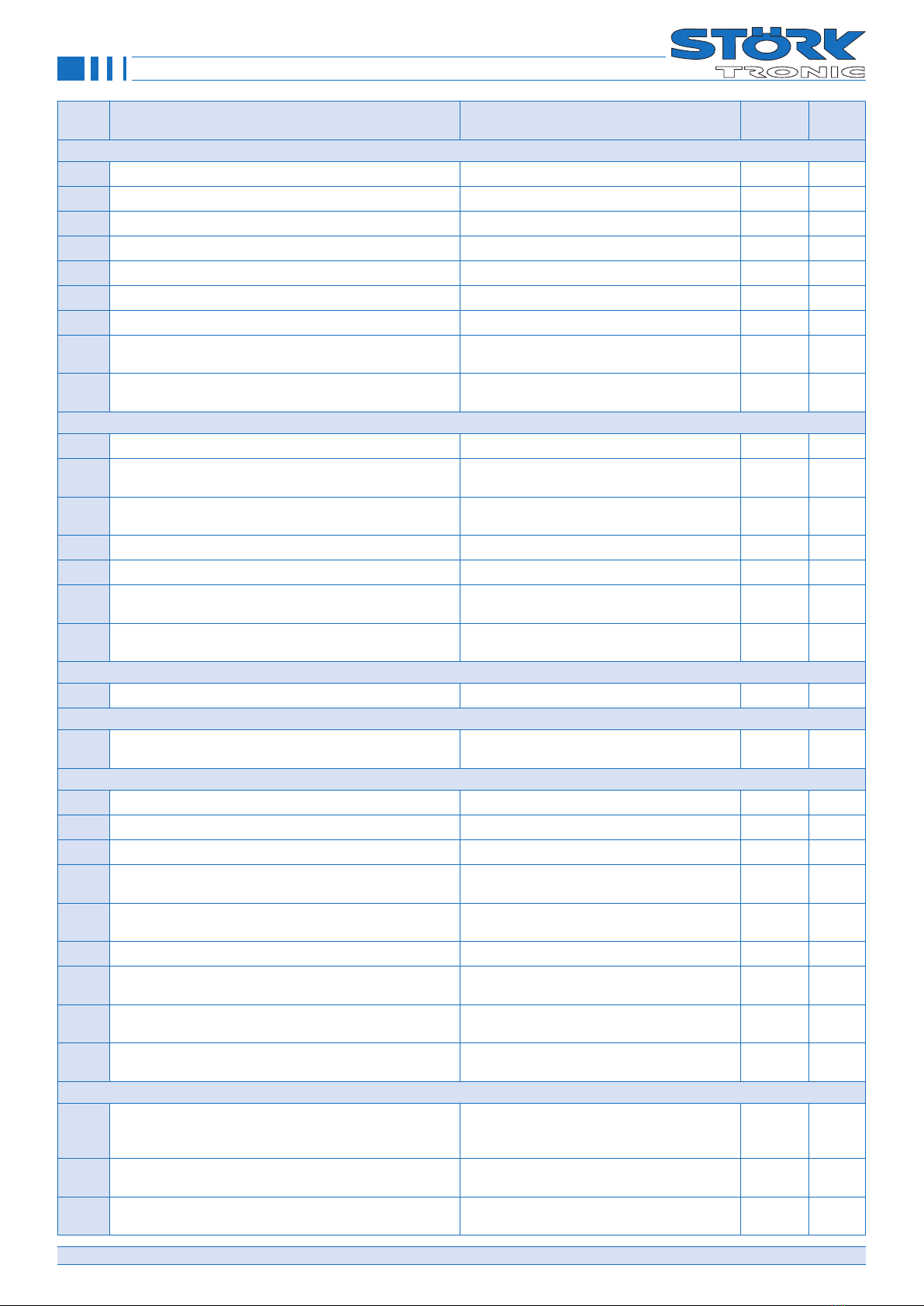

Installation data The display unit is designed for installation in a switching panel (note dimensioned drawing).

Front size: 154.8mm x 61.8mm

Assembly size: 180 x 87mm

Assembly depth: approx. 25mm

25

1

7,3

154,8

180

61,8

62,1

155,2

172

79

This manual suits for next models

1

Table of contents

Other Störk-Tronic Controllers manuals

Popular Controllers manuals by other brands

Niles

Niles MVC100 installation guide

Morningstar

Morningstar SunSaver-10 Installation and operation manual

Hanna Instruments

Hanna Instruments HI 504 instruction manual

Omega Engineering

Omega Engineering HE-XE103 user guide

HomeyLux

HomeyLux 4406707 user manual

Mitsubishi Electric

Mitsubishi Electric MELSERVO MR-JET-G-N1 user manual