Störk-Tronic ST46-IN1KAR.112 User manual

Order no. 900237.030 V1.0 Page 1

ST46-IN1KAR.112

Controller for cooling applications

Order number 900237.030

As of: 26.01.2017, Software V1.0

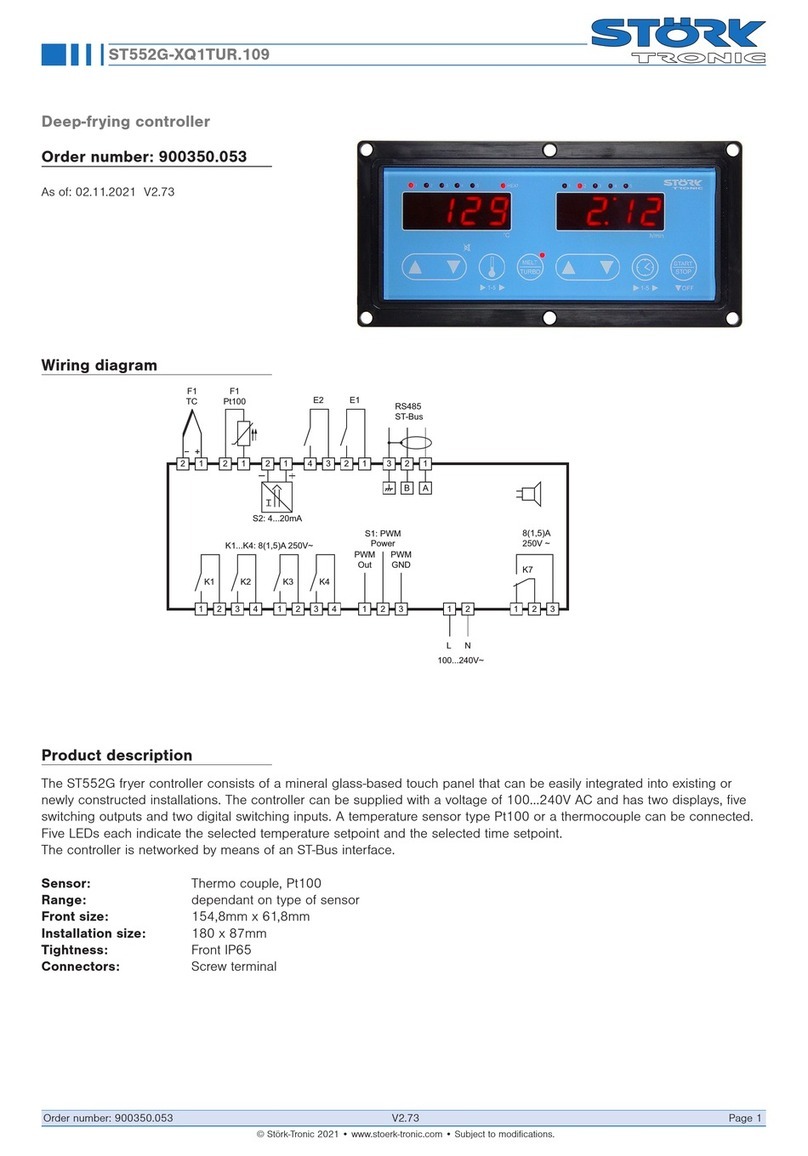

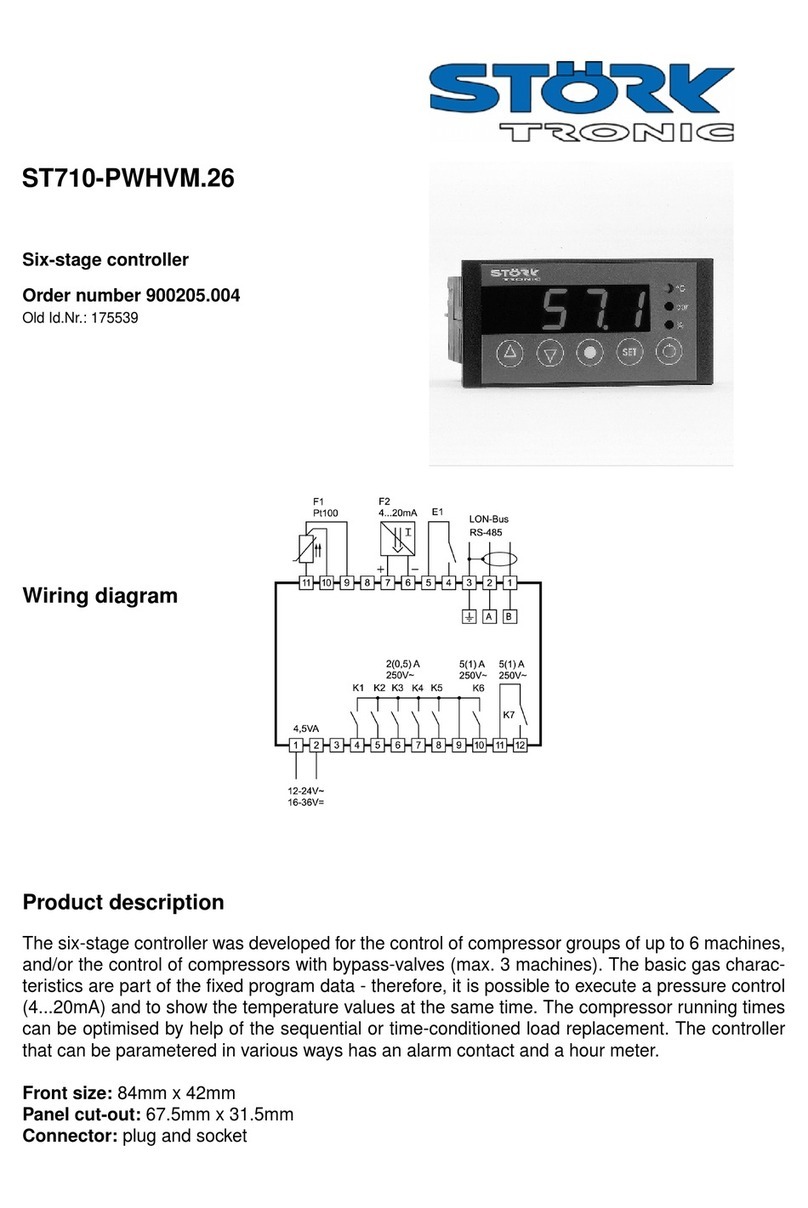

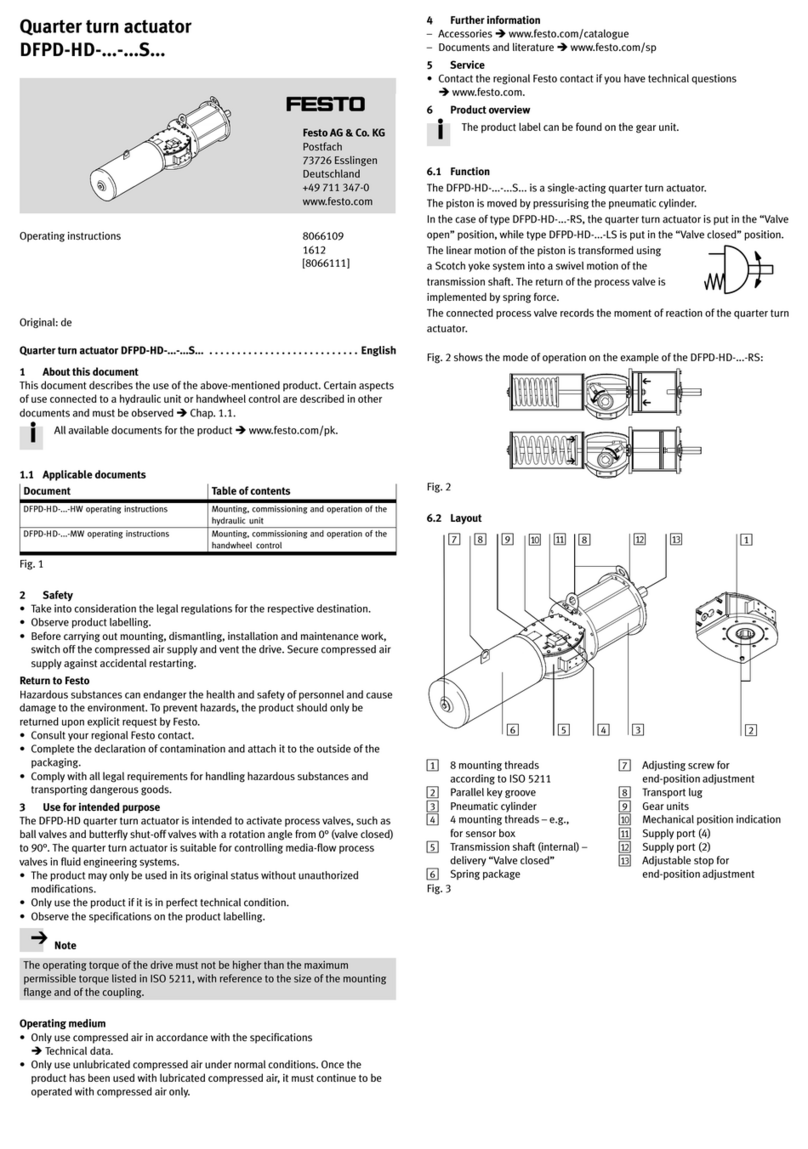

Wiring diagram

Product description

The controller ST46-IN1KAR.112 is intended for the assembly on DIN rail, which allows easy installation in the

switch gear cabinet. It has two analogue inputs for PTC sensors and four switching exits. The functions of the re-

lays can be freely selected, whereas various applications with only one controller are possible. The controller, for

example, can operate with two coolers if the evaporator sensor is parameterized as sensor for a second refrigerat-

ing chamber. The LEDs indicate the status of the control exits. The controller is supplied with 230V AC.

Networking of the controller takes place via ST Bus interface.

Sensor: PTC

Range: - 50 ... 130 °C

Housing size (L x W x H): 95 x 53 x 59mm

Installation: Clip-on mounting on DIN-Rail 35 x 7,5mm

Connector: screw terminal

Order no. 900237.030 V1.0 Page 2

Order no. 900237.030 V1.0 Page 3

SOFTWARE

COOLING CONTROLLER ST46-xxx.112

Order no. 900237.030 V1.0 Page 4

GENERAL INFORMATION

The ST……112 controllers are designed for general

use in refrigerating plants.

Depending on the existing hardware, up to four

temperature sensors can be connected. These can

either be used for capturing the cold store

temperature, evaporator temperature, super-frost core

temperature, the temperature of a second control

circuit or the temperature of the condenser. The type,

function, offset and weighting of each sensor can be

configured separately via parameters. Additionally, an

analogue input (4..20mA) can be made available for

capturing pressure levels, e.g. for condenser/fan

control, provided that the required hardware is

available.

The max. four digital inputs can also be configured

separately, depending on the hardware installed.

Possible functions include: standby, door contact,

high-pressure or low-pressure switch.

Depending on the hardware, up to eight relay outputs

are possible the functions of which can be configured

as required via parameters. Please refer to the

specifications of the hardware installed to ensure that

the relays are not overloaded. Also refer to the circuit

diagram in the corresponding device manual.

All parameters can also be accessed via the RS485

interface. If an internal clock is provided in the

hardware, the corresponding functions, e.g. defrosting

or night-time increase/decrease of setpoint, can be set

and started via parameters.

CONTROL KEYS

Key T1: UP ( up-arrow )

By pressing this key the parameter or parame-

ter value is increased. A further function of the

key can be set with parameters .

Key T2: DOWN ( down-arrow )

By pressing this key the parameter or parame-

ter value is decreased. A further function of the

key can be set with parameter .

Key T3: SET

While SET key is pressed, the setpoint is indi-

cated. The function of the key can be set with

parameter (unchangeable in this case).

The cooling controller is generally controlled using the

buttons UP, DOWN and SET. The standard display

indicates the temperature of the cold store (actual

temperature value). Press SET button to switch over

the display to the required cold store temperature

(setpoint temperature).

The setpoint temperature can only be changed by

pressing buttons SET and UP or SET and DOWN at

the same time. While pressing the buttons, the

changing setpoint temperature is displayed. After

changing the setpoint temperature and releasing the

buttons, the actual temperature is displayed again.

This is the standard setting method.

In addition to setting the temperature value, the

buttons UP and DOWN perform other functions, too.

Pressing the UP for 3 seconds will trigger a non-

standard defrosting operation of the refrigerating

plant. In the case of an alarm (with buzzer triggered),

the DOWN button can be used for acknowledging the

buzzer sound.

T1

1

2

3

T2 T3

SET

Order no. 900237.030 V1.0 Page 5

PARAMETERISATION

Parameterisation of the cooling controller is done in

the factory or during commissioning of a cold store by

qualified staff. Wrong or inappropriate

parameterisation can result in malfunction and

damage of the refrigerated goods. Parameter setting

is possible only after entering one or more passwords.

In the following list of parameters, all parameters of a

complex cooling controller are listed. Please note,

however, that the parameters listed are only available

in controller designs where the relevant hardware

(outputs, inputs, sensors and internal clock) is

available.

Parameterisation is possible at any time. The control

operation is not interrupted during parameterisation,

but can have a direct influence on it. If no button is

pressed for 2 minutes, the operation is stopped and

the actual value is displayed again.

To activate parameterisation mode, press buttons UP

and DOWN at the same time. After approx. 3

seconds, the code word .will be displayed. Press

UP or DOWN to switch between code words and

. All other settings / value specifications in

parameter setting mode are performed using the

default value setting method, i.e. pressing buttons

SET and UP / DOWN at the same time.

NETWORK ADDRESS

Under code word you can set a

network address. This is required for

commissioning networked systems.

ENTERING A PASSWORD

By selecting code word , you can

enter a password required for

parameterisation. Once the password

has been entered , the name of the

first group of parameters is displayed

(alarms). Now, using the buttons

UP and DOWN you can select any of the

parameter groups quickly.

ALARMS

Once you have selected a parameter

group, it will normally be sufficient if you

press the button SET ( will be

displayed) and then release the button

again. Now, the first parameter of the

group will be displayed (parameter in

parameter group , for example).

Using the buttons UP and DOWN you can scroll the

parameter group and change certain parameter

values using the default value setting method. Press

buttons UP and DOWN at the same time to quit any

parameter group and return to the list of parameter

groups. To quit the list of parameter groups and return

to the standard level, press buttons UP and DOWN at

the same time.

In some cases, certain parameter groups may be

protected by a password. In this case, you will have to

enter a specific password for the parameter group like

in the case of activation of the parameterisation level.

Order no. 900237.030 V1.0 Page 6

Alarms

*

Buttons and switching inputs

Control circuits 1

Defrosting control circuits 1

Fan control circuits 1

Temperature sensors

*

Pre-defined sets of parameters

*

Networking and display

*

Week timer

*

Relay contacts and lamps

*

Control circuit 2

* These levels by default are protected by a password.

Order no. 900237.030 V1.0 Page 7

Alarms (password-protected)

Para-

meter

Description of function

Setting range

Values

default

Assignment of alarm sensors, detailed

description of sensors in parameters

through

0: none

1: Sensor F1

2: Sensor F2

3: Sensor F3

4: Sensor F4

5: weighted mean value from F1 and F2

1

Upper limit value

+0.1...+99.0°C (0.0: inactive)

10.0

Lower limit value

-99.0...-0.1°C (0.0: inactive)

-10.0

Switching mode of alarm relay

0: on if alarm present (normal)

1: off if alarm present (inverse)

1

Switching hysteresis for alarm

0.1...15.0°C

2.0

Alarm suppression after temperature alarm

0...240 min.

10

Alarm suppression time after defrosting

0...240 Min

15

Alarm suppression time after control ON or

change of setpoint and/or alarm limits

0...300 Min.

180

Alarm suppression time, door open

0: no alarm

1 ... 600 sec.

180

Behaviour if temperature alarm disappears

again

0: without buzzer, delete automatically

1: with buzzer, delete automatically

2: without buzzer, with acknowledgement

3: with buzzer, with acknowledgement

0

Function buzzer and/or display

in the case of alarm (temp. alarm see

)

0: no display, no buzzer

1: display flashing only

2: buzzer active only

3: display flashing, buzzer active

4: like 2., can be acknowledged

5: like 3., buzzer can be acknowledged

6: like 5., recurring after

1

Buzzer recurring after acknowledgement

1 ... 120 min.

30

Reset MIN / MAX memory

0: -

1: reset MAX memory

2: reset MIN memory

3: Reset MAX and MIN memory

0

Display of current MAX memory

Measured value, not adjustable

Display of current MIN memory

Measured value, not adjustable

Function of high-pressure switch

Releases until permanent alarm

0: no permanent alarm

1..10 : releases per 15 min.

0

Function of low-pressure switch

Releases until permanent alarm

0: no permanent alarm

1...300 sec.

0

Password of parameter level

-99 ... 999

0

Order no. 900237.030 V1.0 Page 8

Buttons and switching inputs (password-protected)

Para-

meter

Description of function

Setting range

Values

default

Function button T1

0: without function

1:controller on/standby

2:defrosting request

3:acknowledge alarm

4:relay function light 1, not active in standby

5:relay function light 1, regardless of standby

6:relay function light 2, not active in standby

7:relay function light 2, regardless of standby

8:relay function window heating, not active in standby

9:relay function window heating, regardless of standby

10:relay function blade scraper, not active in standby

11:relay function blade scraper, regardless of standby

12:relay function door frame heating, not active in standby

13:relay function door frame heating, regardless of standby

14:relay function F, not active in standby

15:relay function F, regardless of standby

16:Set1 / Set2 change-over

17:day / night change-over

18:"super-frost“ on/off

19:evaporator fan on permanently

20:control circuit 1 on/off

21:control circuit 2 on/off

22:set for setpoint Y1

23:display MIN

24:display MAX

25:display sensor F1

26:display sensor F2

27:display sensor F3

28:display sensor F4

29:display sensor F5

30:reset both MIN/MAX

31:reset MIN

32:reset MAX

2

Function button T2

see

3

Function button T3

see

0

Function button T4

see

0

Function button T5

see

0

Function button T6

see

0

Function button T7

see

0

Function button T8

see

0

Order no. 900237.030 V1.0 Page 9

Para-

meter

Description of function

Setting range

Values

default

Function of external switching

input E1

0:without function

1:controller on/standby

2:high-pressure alarm (see

)

3:low-pressure alarm (see

)

4:door contact (light on, fan off, see

)

5:relay function A (light 1), not active in standby

6:relay function A (light 1), regardless of standby

7:relay function B (light 2), not active in standby

8:relay function B (light 2), regardless of standby

9:relay function C (window heating), not active in standby

10:relay function C (window heating), regardless of standby

11:relay function D (blade scraper), not active in standby

12:relay function D (blade scraper), regardless of standby

13:relay func. E (door frame heating), not active in standby

14:relay func. E (door frame heating), regardless of standby

15:relay function F, not active in standby

16:relay function F, regardless of standby

17:Set1 / Set2 change-over

18:day / night change-over

19:"super-frost“ on/off (see

...

)

20:evaporator fan on permanently

21:defrosting request circuit 1

22:defrosting request circuit 2

23:control circuit 1 on/off

24:control circuit 2 on/off

0

Switching input E1 inverse /

not inverse

0: normal

1: inverse

0

Function E2

see

0

E2 inverse / not inverse

see

0

Function E3

see

0

E3 inverse / not inverse

see

0

Function E4

see

0

E4 inverse / not inverse

see

0

Password of level

-99 ... 999

-19

Control circuit 1

Para

-

meter

Description of function

Setting range

Values

default

Assignment of cold store sensors, detailed

description of sensors in parameters

through

0:none

1:Sensor F1

2:Sensor F2

3:Sensor F3

4:Sensor F4

5:weighted mean value from F1 and F2

1

Setpoint for Set1

...

0.0

Night setpoint

(relative to current setpoint / )

-20 ... +20.0°C

5

.0

Setpoint for Set2

...

0.0

Order no. 900237.030 V1.0 Page 10

Para-

meter

Description of function

Setting range

Values

default

Switching mode

0: heating

1: refrigerating

1

Hysteresis

0.1...15.0°C

2.0

Hysteresis mode

0: symmetrical

1: one-sided

1

Upper setpoint limit

...+99°C

50.0

Lower setpoint limit

-99°C...

-50.0

Start protection after compressor start

0 ... 900 sec.

300

Start protection after compressor stop

0 ... 900 sec.

180

Start protection compressor after mains on

0 ... 60 min.

0

On-time in emergency operation

0 ... 100%

50

Cycle time in emergency operation

5 ... 60 min.

10

Assignment of sensor for "super-frost"

(also core or product temperature)

detailed description of sensors in parameters

through

0:none

1:Sensor F1

2:Sensor F2

3:Sensor F3

4:Sensor F4

5:weighted mean value from F1 and F2

1

"super-frost“: time limit

("shock-frost", "max. cooling power")

1 ... 36 hrs.

10

"super-frost“: temperature limit

("shock-frost", "max. cooling power")

-40 ... 0°C

0.0

"super-frost“: automatic off

("shock-frost", "max. cooling power")

0: none, manual only

1: controlled by time

2: controlled by time or temperature

2

Password of parameter level c

-99 ... 999

0

Defrosting control circuit 1

Para-

meter

Description of function

Setting range

Values

default

Assignment of evaporation sensors

(defrosting sensors)

detailed description of sensors in parameters

through

0:none

1:Sensor F1

2:Sensor F2

3:Sensor F3

4:Sensor F4

5: weighted mean value from F1 and F2

2

Defrosting interval

0: no automatic defrosting

1...99 hrs.

8

Type of defrosting

0: no defrosting

1: compressor off only (circulating air)

2: electrical

3: with hot gas

2

Stop at defrosting temperature

0 ... +30.0°C

10.0

Defrosting time limitation

1...99 min.

30

Temperature difference to cold store setpoint

in previous cooling

-15°C ... 0.0°C

0.0

Time limitation in previous cooling

1 ... 180 min.

10

Order no. 900237.030 V1.0 Page 11

Para-

meter

Description of function

Setting range

Values

default

Delay of start of defrosting after compressor

off =2

0 ... 900 sec.

60

Dripping time

0 ... 15 min.

1

Stop delay drip tray heating

0 ... 60 min.

10

Password of parameter level

-99 ... 999

0

Fan control circuit 1

Para-

meter

Description of function

Setting range

Values

default

Fan speed control mode, Set1

0 ... 100%

80.0

Fan speed defrosting, Set1

0 ... 100%

80.0

Fan speed control mode, Set2

0 ... 100%

100

Fan speed defrosting, Set2

0 ... 100%

100

Start-up time

0 ... 60 sec.

5

Minimum speed (output variable if result=0)

0 ... 100%

10.0

Evaporator fan

Fan mode normal operation

Remark: Control setpoint if

>4

is

or

0: off

1: continuous operation

2: like 1, with drip interruption

3: with compressor on

4: temperature-controlled

evaporator sensor only

5: temperature-controlled, diff. between cold

store and evaporator sensor

3

Evaporator fan,

Fan mode defrosting

0: off

1: on

0

Evaporator fan, delay after compressor start

0 ... 600 sec.

0

Evaporator fan, Delay after defrosting

0 ... 600 sec.

120

Evaporator fan

Drip interruption time if =2

0 ... 600 sec.

18

0

Evaporator fan, Control offset if =4 or 5

-15.0 ... +15.0°C

0.0

Evaporator fan, hysteresis if =4 or 5

0.1 ... 15.0°C

2.0

Password of parameter level

-99 ... 999

0

Order no. 900237.030 V1.0 Page 12

Temperature sensors (password-protected)

Para

-

meter

Description of function

Setting range

Values

default

Mains frequency

0: 50Hz

1: 60Hz

0

Act. value sensor F1

Measured value, not adjustable

Calibration sensor F1 (act. value correction)

-20...+20.0°C

0.0

Weighting factor sensor F1

0.50...1.50

1.00

Selection sensor F1

Depending on hardware, not all types are

available. Sensor will be deactivated in this case.

0: not existing

1: PTC (-50..+150°C)

2: Pt100 2-wire (-100…+600°C)

3: Pt100 3-wire (-100…+500°C)

4: NTC (-40…+40°C)

5: Pt1000 2-wire (-100…+330°C)

6: Pt1000 3-wire (-100…+300°C)

7: 0-20mA

8: 4-20mA

1

Software filter sensor F1

1 ... 32

8

Display at 0/4mA and sensor selection =7/8

-99...+999

0.0

Display at 20 mA and sensor selection =7/8

-99...+999

100

Act. value sensor F2

Measured value, not adjustable

Calibration sensor F2 (act. value correction)

-20...+20.0°C

0.0

Weighting factor sensor F2

0.50...1.50

1.00

Selection sensor F2

see

1

Software filter sensor F2

1 ... 32

8

Display at 0/4 mA and sensor selection =7/8

-99..+999

0.0

Display at 20 mA and sensor selection =7/8

-99..+999

100

Act. value sensor F3

Measured value, not adjustable

Calibration sensor F3 (act. value correction)

-20...+20.0°C

0.0

Weighting factor sensor F3

0.50...1.50

1.00

Selection sensor F3

see

1

Software filter sensor F3

1 ... 32

8

Display at 0/4 mA and sensor selection =7/8

-99..+999

0.0

Display at 20 mA and sensor selection =7/8

-99...+999

100

Act. value sensor F4

Measured value, not adjustable

Calibration sensor F4 (act. value correction)

-20...+20.0°C

0.0

Weighting factor sensor F4

0.50...1.50

1.00

Selection sensor F4

see

0

Software filter sensor F4

1 ... 32

8

Display at 0/4 mA and sensor selection =7/8

-99…+999

0.0

Display at 20 mA and sensor selection =7/8

-99…+999

100

Display of weighted mean value of F1+F2

= (* + (100-)*)/100

Weighting of sensor F1 for

0 ... 100%

100

Password of parameter level

-99 ... 999

-19

Order no. 900237.030 V1.0 Page 13

Pre-defined parameter sets (password-protected)

Para-

meter

Description of function

Setting range

Values

default

Parameter set

---

0

Password for entering level selection (in

display )

-99 ... 999

-19

Password of parameter level

-99 ... 999

-19

Parameter can only be viewed and set via ST-bus.

Warning: Changes made in the parameter set will change all parameter settings.

Networking and display (password-protected)

Para

-

meter

Description of function

Setting range

Values

default

Own address ST-bus

Identical to setting

0: deactivated

1 ... 250

1

Temperature scale

0: °C

1: °F

0

Display mode

0: 3 digits, integers

1: 3 digits, rounded to 0.5

2: 3 digits, 0.1

3: 4 digits, integers

4: 4 digits, rounded to 0.5

5: 4 digits, 0.1

2

Display value

See act. value table

0

Software version

Display in standby mode

0: OFF

1: AUS

2: right decimal point

3: right decimal point flashing

4: time, OFF in case of an error

1

ST bus release mask for functions

0 ... 255

249

ST bus release mask for functions

0 ... 255

255

Release for a deletion of the

counter/runtimes

0: no release

1: Delete is approved for 10 min.

(see A17, N98 and T98)

0

Password of parameter level

-99 ... 999

-19

Order no. 900237.030 V1.0 Page 14

Relay contacts and lamps (password-protected)

Para

-

meter

Description of function

Setting range

Values

default

Function relay K1

0: no function (off)

1: compressor

2: defrosting circuit 1

3: evaporator fan

4: condenser fan

5: alarm

6: control contact circuit 2

7: defrosting circuit 2

8: relay function A (light 1)

9: relay function B (light 2)

10: relay function C (window heating)

11: relay function D (door frame heat.)

12: relay function E (blade scraper)

13: relay function F

14: drip tray heating

15: buzzer

16: on if controller active

17: on if control circuit 1 active

18: on if control circuit 2 active

19: on if Set 1 active

20: on if Set 2 active

21: on if day mode active

22: on if night mode active

1

Function relay K2

see

2

Function relay K3

see

3

Function relay K4

see

5

Function relay K5

see

0

Function relay K6

see

0

Function relay K7

see

0

Function relay K8

see

0

Order no. 900237.030 V1.0 Page 15

Para-

meter

Description of function

Setting range

Values

default

Function LED1

0: no function (off)

1: compressor/magnetic valve

2: defrosting control circuit 1

3: evaporator fan

4: condenser fan

5: alarm

6: control circuit 2

7: defrosting circuit 2

8: Light 1

9: Light 2

10: window heating

11: blade scraper

12: door frame heating

13: relay function F

14: drip tray heating

15: "super-frost“

16: "humidity"

17: control circuit 1 active

18: control circuit 2 active

19: set 1 active

20: set 2 active

21: day mode active

22: night mode active

23: display "MIN"

24: display "MAX"

1

Function LED2

see

2

Function LED3

see

3

Function LED4

see

0

Function LED5

see

0

Function LED6

see

0

Function LED week days

0: no function (off)

1: display weekday

2: see ...

0

Function LED7 (Mo)

see

0

Function LED8 (Tu)

see

0

Function LED9 (We)

see

0

Function LED10 (Th)

see

0

Function LED11 (Fr)

see

0

Function LED12 (Sa)

see

0

Function LED13 (Su)

see

0

Password of parameter level

-99 ... 999

-19

Order no. 900237.030 V1.0 Page 16

Control circuit 2 (password-protected)

Para

meter

Description of function

Setting range

Values

default

Assignment of sensors to control circuit 2

detailed description of sensors in parameters

through

0:none

1:Sensor F1

2:Sensor F2

3:Sensor F3

4:Sensor F4

5:weighted mean value from F1 and F2

0

2nd control circuit: setpoint

...

10.0

2nd control circuit: abs. setpoint or DeltaW

0: absolute

1: DeltaW

1

2nd control circuit: switching mode

0: heating

1: refrigerating

1

2nd control circuit: hysteresis

0.1...99.0°C

2.0

2nd control circuit: hysteresis mode

0: symmetrical

1: one-sided

1

Upper setpoint limit

... +999°C

50.0

Lower setpoint limit

-99°C ...

-50

Function in the case of sensor fault

0: contact off

1: contact on

1

Defrosting interval control circuit 2

0: no defrosting

1...99 hrs.

0

Defrosting time limitation thermostat 2

1...99 min.

30

Password of parameter level

-99 ... 999

-19

N-level (counters)

Parameters are only accessible via ST-Bus.

Para-

meter

Description of function

Setting range

Values

default

N0

Switching cycles of K1 (lower 16bit)

---

N1

Switching cycles of K1 (upper 16bit)

---

N2

Switching cycles of K2(lower 16bit)

---

N3

Switching cycles of K2 (upper 16bit)

---

N4

Switching cycles of K3 (lower 16bit)

---

N5

Switching cycles of K3 (upper 16bit)

---

N6

Switching cycles of K4 (lower 16bit)

---

N7

Switching cycles of K4 (upper 16bit)

---

N98

Reset counter

0: ---

1: Reset

0

N99

Password for N-level

-99 … 999

0

The number of switching cycles is calculated as follows (i.e. for K1): number =65536 * N1 + N0.

Parameter N98 resets the counters for all relays. It depends on the setting of parameter L42. The return value is

set back to “0” automatically.

Order no. 900237.030 V1.0 Page 17

T-level (operating times)

Parameters are only accessible via ST-Bus.

Para-

meter

Description of function

Setting range

Values

default

T10

Overall operating time (lower 16bit)

---

T11

Overall operating time (upper 16bit)

---

T12

Operating time since last reset (lower 16bit)

---

T13

Operating time since last reset (upper 16bit)

---

T14

Operating time relay K1 (lower 16bit)

---

T15

Operating time relay K1 (upper 16bit)

---

T16

Operating time relay K2 (lower 16bit)

---

T17

Operating time relay K2 (upper 16bit)

---

T18

Operating time relay K3 (lower 16bit)

---

T19

Operating time relay K3 (upper 16bit)

---

T20

Operating time relay K4 (lower 16bit)

---

T21

Operating time relay K4 (upper 16bit)

---

T98

Reset operating times

0: ---

1: Reset

0

T99

Password for T-level

-99 … 999

0

The operating time is calculated as follows: Operating time (in minutes) =65536 * T11 + T10.

Parameter T98 resets the counters for all operating times (except for T10 und T11). It depends on the setting of

parameter L42. The return value is set back to “0” automatically

Order no. 900237.030 V1.0 Page 18

MASTER PASSWORD

All passwords can be edited through parameterisa-

tion. If you don't remember a password, you can still

parameterise the controller and look up and/or edit the

password via a master password. To do that, follow

these steps:

1. Switch off power supply (disconnect from mains or

switch off power supply unit)

2. Press buttons UP, DOWN and SET at the same

time and switch on power supply again.

3. Now, a ("Challenge") number will be displayed for

approx. 5s.

In no case disconnect the controller from power sup-

ply now. Otherwise, the number will become invalid.

Using this number, you can call our sales staff, phone

+49 711 68661-0 to request the master password

("Response"). Enter this master password in the 1st

control level in .

Important: Even if you remember the password, you

must enter the master password here. If the pass-

word is accepted, you will enter the parameter selec-

tion levels and all passwords will be deactivated. By

pressing the SET button (display ) you can switch

to the relevant parameter level.

Now, the master password is no longer required. The

passwords will remain deactivated until the controller

is disconnected from power supply again. In case you

leave the parameter level now, simply press the SET

button in in order to access the parameter selec-

tion levels again.

STATUS DISPLAYS AND ERROR MESSAGES

Message

Cause

Remedy

Overtemperature, temperature above

alarm limit of parameter A1/A31

Undertemperature, temperature below

alarm limit of parameter A2/A33

Error on sensor F1, short-circuit

check sensor F1

Error on sensor F1, wire broken

check sensor F1

Error on sensor F2, short-circuit

check sensor F2

Error on sensor F2, wire broken

check sensor F2

Error on sensor F3, short-circuit

check sensor F3

Error on sensor F3, wire broken

check sensor F3

Error on sensor F4, short-circuit

check sensor F4

Error on sensor F4, wire broken

check sensor F4

Door open for too long

close door

High

-pressure fault

Check: Condenser fan and check for dirt ac-

cumulation

Low-pressure fault

Plant leaking, to little coolant

Internal error in control unit

Repair control unit

Error in parameter memory

Check all parameters

Error in data memory

Repair control unit

Error of internal clock

Set clock again. If error occurs again, the co

n-

troller must be repaired

Errors and will disable the controller. The controller will only be enabled again once the error has been

repaired. Error (and ) can only be eliminated by repair. The errors and the current temperature will be

displayed alternately.

Order no. 900237.030 V1.0 Page 19

Alarms

Alarm sensor assignment

With this parameter, you can set which sensor input is

to be used as the alarm sensor.

Upper limit value

Lower limit value

The limit values are used for monitoring the cold store

temperature. They are relative values, i.e. they always

refer to the setpoint S1. If the temperature increases

above or falls below the upper and lower limits, re-

spectively, an alarm as specified in will be trig-

gered. If [ = 0] and/or [ = 0], the relevant limit

alarm is deactivated.

Switching mode of alarm relay

With this parameter you can define if the relay is to be

closed or opened in the case of an alarm.

Switching hysteresis for alarm

The alarm contact hysteresis is set asymmetrically,

downward at the upper alarm value and upward at the

lower alarm point.

Alarm suppression time after temp. alarm

If the temperature of the cold store exceeds the limits

set in , , a temperature alarm should normally be

triggered. Based on the suppression time set in ,

triggering of the alarm can be delayed.

Alarm suppression time after defrosting

Triggering of a temperature alarm is prevented for the

set time after defrosting so that the plant can reach

normal operating conditions again.

Alarm suppression time after Refrigerating On

Triggering of an alarm is suppressed for the set time

after activation of refrigeration. This is to allow the

refrigerating plant to reach the working temperature

range without triggering of an alarm.

Alarm suppression time, door open

With this parameter you can define after which time an

alarm is to be triggered when the door is opened. If

the door is closed again within the specified time, no

alarm will be triggered.

Behaviour when temp. alarm disappears

Here, you can define if a temperature alarm can be

deleted automatically as soon as the temperature is in

the permissible range again or if it must be acknowl-

edged. This is to ensure, for example, that a tempera-

ture alarm that occurred at night remains present until

the error is acknowledged the next day. If the tempera-

ture alarm is still present when it is acknowledged, the

buzzer will be switched off as set in , the alarm

message in the display, however, will remain present

until the temperature is within the permissible range

again. Then, the acknowledged alarm will be deleted

automatically.

Buzzer function and/or display in the case

of an alarm

Here, you can define if a temperature alarm is to be

displayed or not and if the buzzer is to sound. Addi-

tionally, you can define if the buzzer is to sound again

after acknowledgement. The corresponding time is

indicated in . The error message and the tempera-

ture will be displayed alternately as long as the alarm

is present. If more than one alarm messages are pre-

sent, they will be displayed alternately. The alarm relay

will signal the alarm at all times.

Buzzer recurring after acknowledgement

Alarms which have not been eliminated will be

switched on again by the buzzer after the set time.

This only applies if [=6].

Reset MIN / MAX memory

With this parameter, you can delete the MIN and/or

MAX memory.

Display of current MAX memory

Here, you can view the current MAX memory.

Display of current MIN memory

Here, you can view the current MIN memory.

High-pressure function: Releases until alarm

In the case of a high-pressure signal via a parameter-

ised switching input, the compressor will be switched

off immediately and a message will be displayed. If the

high-pressure signal disappears within 15 minutes, the

error message will be deleted and the compressor will

be started again. However, an alarm via the alarm

relay will only be triggered if the number of registered

releases (within 15 min.) set in this parameter is ex-

ceeded or if the signal is present for more than 15

minutes. This fault will only be deleted after discon-

nection of the plant from mains supply (and repair!).

Low-pressure function: Delay until alarm

If a low-pressure signal is present via a parameterised

switching input and it does not disappear within the

time specified here, the compressor will be switched

Order no. 900237.030 V1.0 Page 20

off and an error message will be displayed. This fault

will only be deleted after disconnection of the plant

from mains supply (and repair!).

Password for parameter level

With this parameter, you can set the password for

parameter level .

Buttons and switching

inputs (password-protected)

… Function buttons 1 … 8

Certain functions can be assigned to the buttons. The

buttons are arranged according to the front foil, the

layout may differ from case to case. For the function of

the buttons, refer to the operating manual of the rele-

vant device. The "SET" cannot be assigned another

function!

, , , Function E1 … E4

Certain functions can be assigned to the switching

inputs.

, , , Switching mode E1 … E4

Here, you can define if the switching input is used as a

make contact (normal) or break contact (inverse).

Password for parameter level

With this parameter, you can set the password for

parameter level .

Control circuit 1

Assignment of cold store sensors

With this parameter, you can set which sensor input is

to be used as the cold room sensor. The selected sen-

sor must be set up accordingly in the parameters.

Control circuit 1: Setpoint (Set1)

Control circuit 1: Night-time incr./decr.

Control circuit 1: Setpoint (Set2)

With this parameter, you can set the setpoint. It will be

displayed directly if you press the SET button and can

be edited. The setting range is defined by the settings

in parameters and . Setpoint becomes active

if the Set2 function is switched on via a button, a digital

switching input, the internal clock or the ST-bus. Set-

point becomes active if the night-time increase/

decrease function is switched on via a button, a digital

switching input, the internal clock or the ST-bus. The

value of is added to the currently active setpoint

or .

Control circuit 1: Switching mode

The switching mode of the control output can be set to

heating or refrigerating function. In the case of the

heating function, the control output is switched on if the

actual temperature is lower than the set temperature.

In the case of the refrigerating function, the output is

on if the temperature is higher than the setpoint.

Control circuit 1: Hysteresis

In this parameter, you can specify the control hyste-

resis. A small hysteresis enables exact control, but will

result in frequent switching of the relay.

Hysteresis mode

With this parameter you can define if the hysteresis will

be active at the corresponding switching point symmet-

rically or on one side only. In the case of a one-sided

hysteresis, the hysteresis will be active below the set-

point in the case of the heating function [=0] and

above the setpoint in the case of the refrigerating func-

tion [=1]. In the case of a symmetrical hysteresis,

there is no difference.

Upper setpoint limit

Lower setpoint limit

Setpoints and can only be set within the limits

defined here.

Start protection after compressor start

This protection time starts as soon as the compressor

is switched on. When the compressor is switched off, it

cannot be switched on again until this time has

elapsed. This is to avoid excessive activation and to

increase the service life as a consequence.

Start protection compressor after

compressor stop

This protection time starts as soon as the compressor

is switched off. The compressor cannot be switched on

again until this time has elapsed. This is to avoid ex-

cessive activation and to increase the service life as a

consequence.

Start protection compressor after mains On

Activation of the control output is prevented after

"Mains On" until this time has elapsed. This function

can be used, for example, to avoid that several control-

lers are switched on at the same, which would result in

a high load on the power supply network.

On-time in emergency operation

Cycle time in emergency operation

With these parameters, you can define how the com-

pressor is to behave in the case of a sensor fault. In

This manual suits for next models

1

Table of contents

Other Störk-Tronic Controllers manuals