Stac Zero Powermeter Quick start guide

1

Rev 3.0

Powermeter

Upgrade Manual

1

Welcome to the world of power training!

Congratulations on purchasing your STAC Zero Powermeter upgrade!

You will now be able to track your progress with real numbers, and

make use of online training apps. In our experience, training with the

Powermeter has led to substantial improvements in performance.

Follow the steps outlined in this manual and the upgrade process should

about 10 minutes.

Happy riding,

-The STAC Performance team

Table of Contents

UPGRADE AND TRAINER COMPONENTS..........................................................2

UPGRADE STEPS ..............................................................................................3

WHEEL MAGNET ALIGNMENT..........................................................................6

HEIGHT........................................................................................................6

CONCENTRICITY...........................................................................................7

PARALLELISM...............................................................................................8

POWERMETER SETUP AND CONFIGURATION................................................11

______________________________________________________

REQUIRED TOOLS

4mm Allen key

(Included with your original STAC Zero purchase)

5/32” Torx screwdriver.

3mm Allen key

2

UPGRADE AND TRAINER COMPONENTS

UPGRADE KIT

1. POWERMETER

2. STRAIN GAUGE

3. SET SCREW

4. WIRE

5. MAGNET SENSOR

6. 2 SCREWS

TRAINER COMPONENTS

RESISTANCE UNIT:

1. MOUNTING BOLTS

2. QUICK RELEASE

3. CALIPER

4. MAGNET ARRAY

5. MAGNETS

6. ALUMINUM BEAM

1

6

2

5

4

3

3

4

3

UPGRADE STEPS

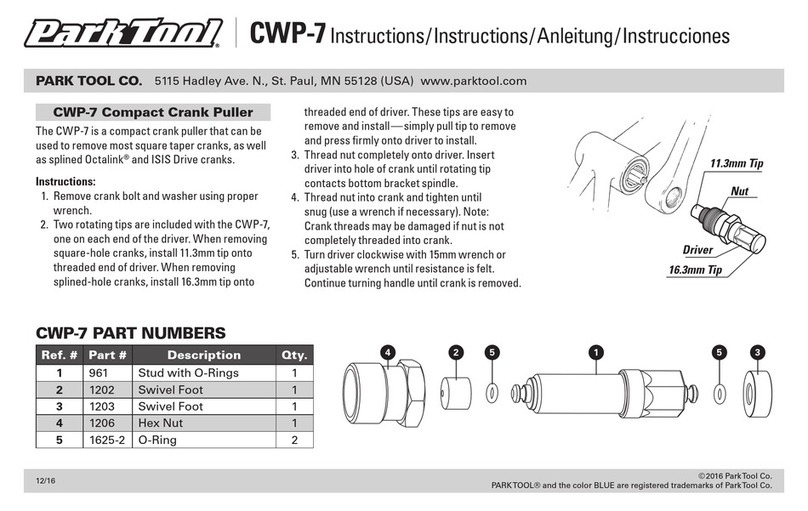

1) Confirm that the 2 Set Screws protrude slightly from the Strain

Gauge, as shown (Figure 1). If they do not, turn the Screws to the

right using the 3mm Allen Key until they extend past the Strain

Gauge by at least 2 threads.

Figure 1

2) Undo the two Mounting Bolts using a 4mm Allen key (included with

your original STAC Zero purchase) and remove the Resistance Unit

from the Frame (Figure 2).

Figure 2

4

3) Set up: a. Rotate the Magnet Array to the

open position.

b. Loosen the Quick Release

slightly so the Calipers can be

moved by hand

c. Open the Calipers and place the

Resistance Unit face down on a

flat, non-magnetic surface

(Figure 3).

Note: This allows you to remove

the Beam from the Quick Release

without the Magnets snapping

together.

4) Unscrew the Quick Release until you can remove the Aluminum

Beam (Figure 3).

Note: Make sure not to remove the thread of the Quick Release from

between the Calipers, as this will cause a spacing washer to slip out.

5) Thread the Quick Release into

the threaded hole on the Strain

Gauge nearest to the Wire, with the

Wire facing away from the

Magnets. Tighten the Quick Release

(Figure 4).

Figure 3

Figure 4

5

6) Snap the plastic casing of the

Powermeter onto the Caliper

that is directly touching the

Strain Gauge. Align the screw

holes and tighten the screws

using a 5/32” Torx screwdriver

(Figure 5).

7) Remount the Resistance Unit

on the Frame with the Mounting

Bolts (Figure 6).

8) Mount your bike on the

trainer. Loosen the Mounting

Bolts slightly, and adjust the

Resistance Unit vertically so the

Magnet Holders line up with your

brake track. Tighten the Bolts.

Figure 5

Figure 6

6

WHEEL MAGNET ALIGNMENT

Support Video:

“Wheel Magnet

Alignment”

Due to some slight variation, the

Magnets may not be parallel to

your wheel after the upgrade is

executed, however this is easily

adjusted. Perform this step with

the bike mounted on the trainer

so you can see the results of the

adjustment.

Pictured (Figure 7): Location of

Set Screws.

Adjust the Set Screws using a 3mm Allen Key.

Adjust the Mounting Bolts using a 4mm Allen Key.

HEIGHT

Your Magnet Array should be level with your bike’s brake track. If the

Magnet Arrays are the correct height, proceed to the next section. If the

Magnet Array is sitting too low (touching the tire) or too high (not

contacting brake track):

1. Loosen the 2 Mounting Bolts and move the Resistance Unit

lower or higher as needed. Re-tighten the Mounting Bolts.

2. Adjust your Spoke Magnet.

Figure 7

7

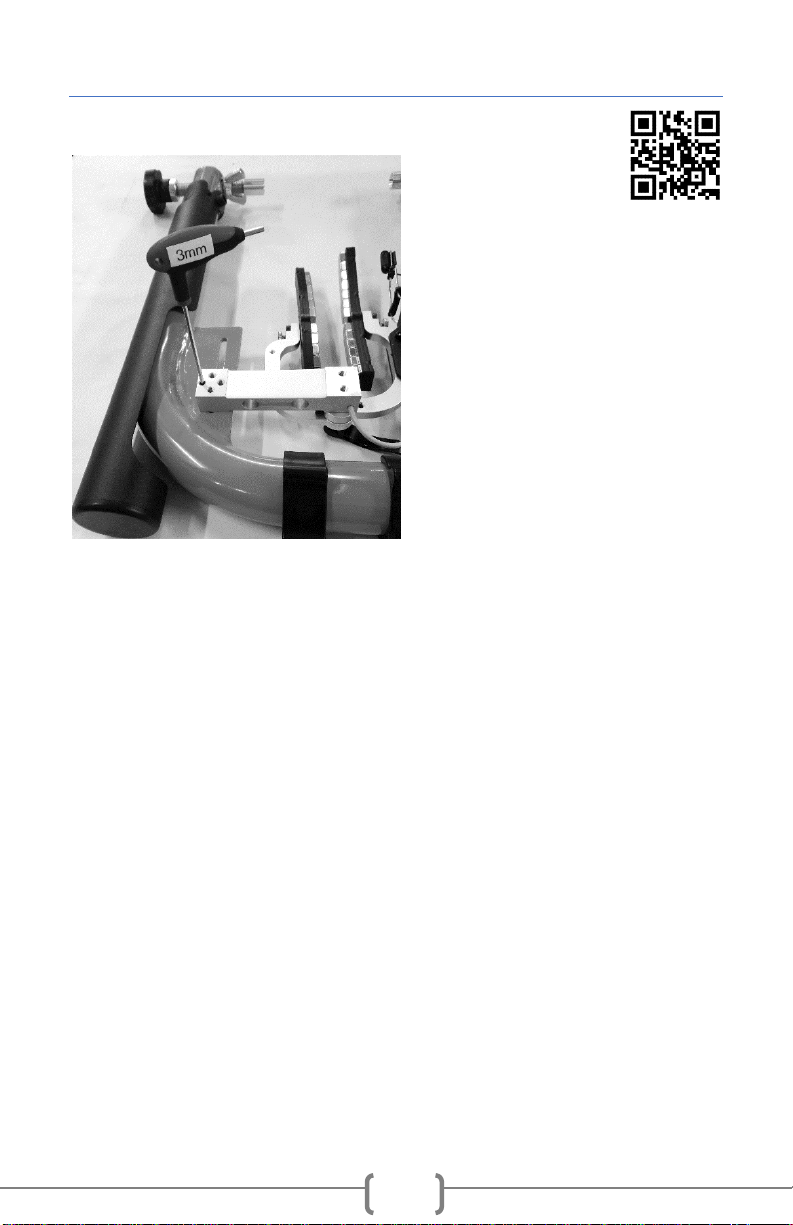

CONCENTRICITY

The Magnet Arrays should track the curve of the wheel when viewed

from the side. If the Magnet Arrays appear concentric, proceed to the

next section. If one end of the Magnet Array is higher/lower on the

brake track, follow these steps.

Concentric Magnet

Array

Non-concentric

Magnet Array

1. Slightly loosen both Mounting Bolts.

2. Adjust the mounting angle:

a. If the front end of the Magnet Array is low relative to

the brake rim, tighten the upper Mounting Bolt until the

Magnet Array comes into alignment.

b. If the front end of the Magnet Array is high relative to

the brake rim, tighten the lower Mounting Bolt until the

Magnet Array comes into alignment.

8

If a greater change in the mounting angle is necessary:

a. Further loosen the opposing Mounting Bolt.

b. Tighten both Set Screws to lift the Strain Gauge slightly

further away from the Frame.

c. Re-tighten the appropriate Mounting Bolt.

3. Ensure both Mounting Bolts are tight to secure the Resistance

Unit.

4. Re-check Concentricity and Height.

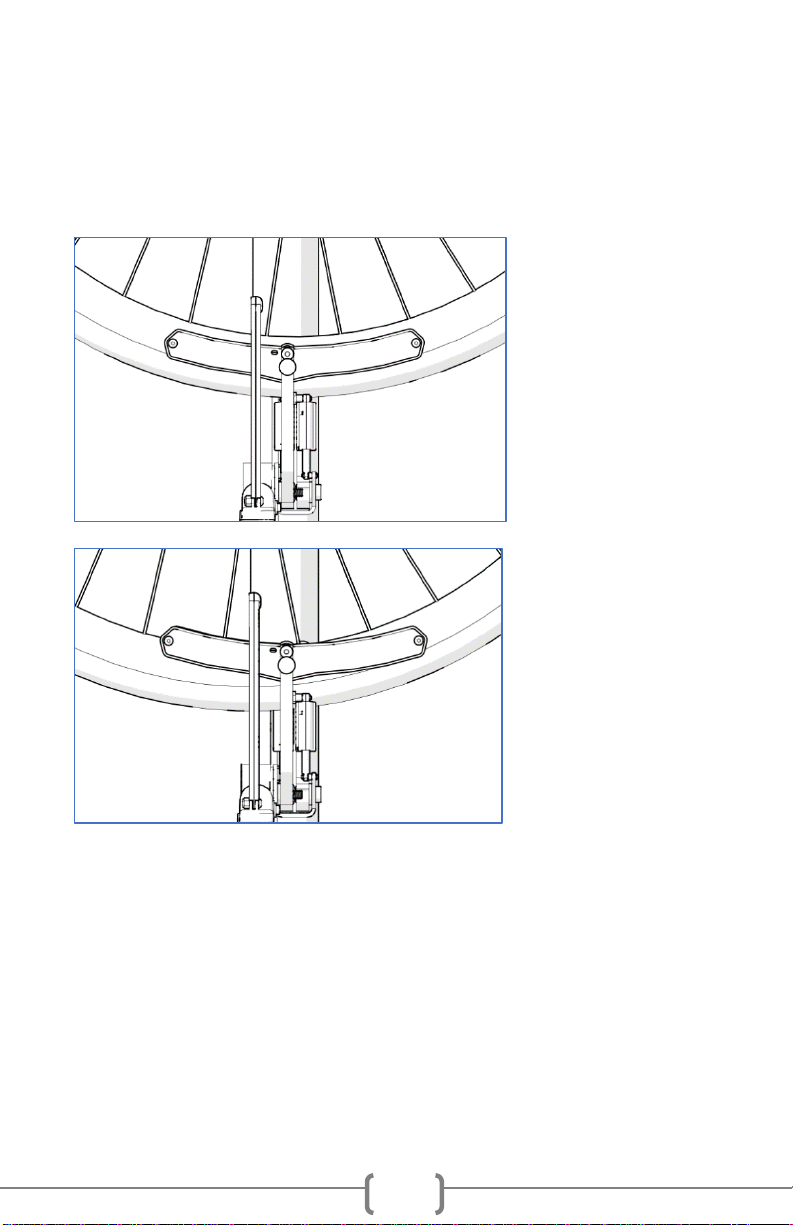

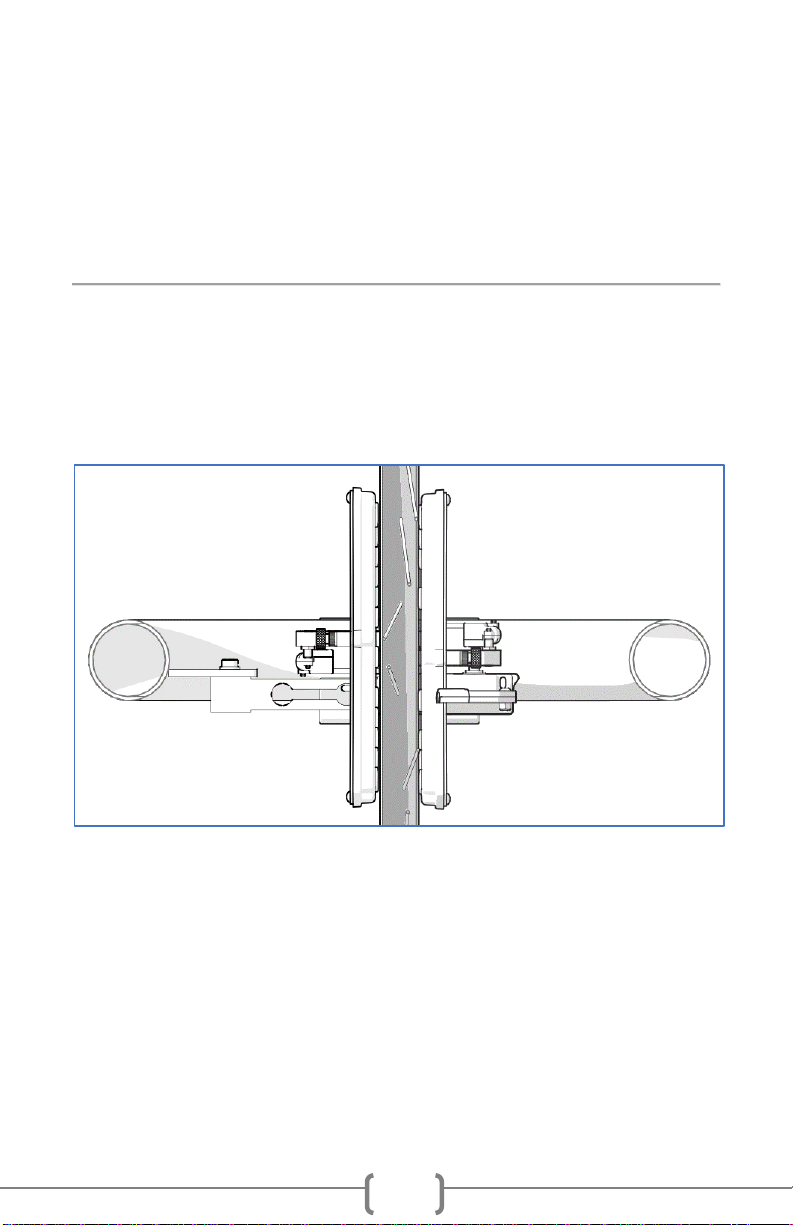

PARALLELISM

The space between the Magnet Array and your brake rim should be

even from the front end of the Magnet Array to the back.

If the Magnet Arrays appear parallel, proceed to the next section.

Parallel Magnet Array

If the Magnet Arrays are not perfectly parallel with the wheel (as seen in

the following diagrams), follow these steps.

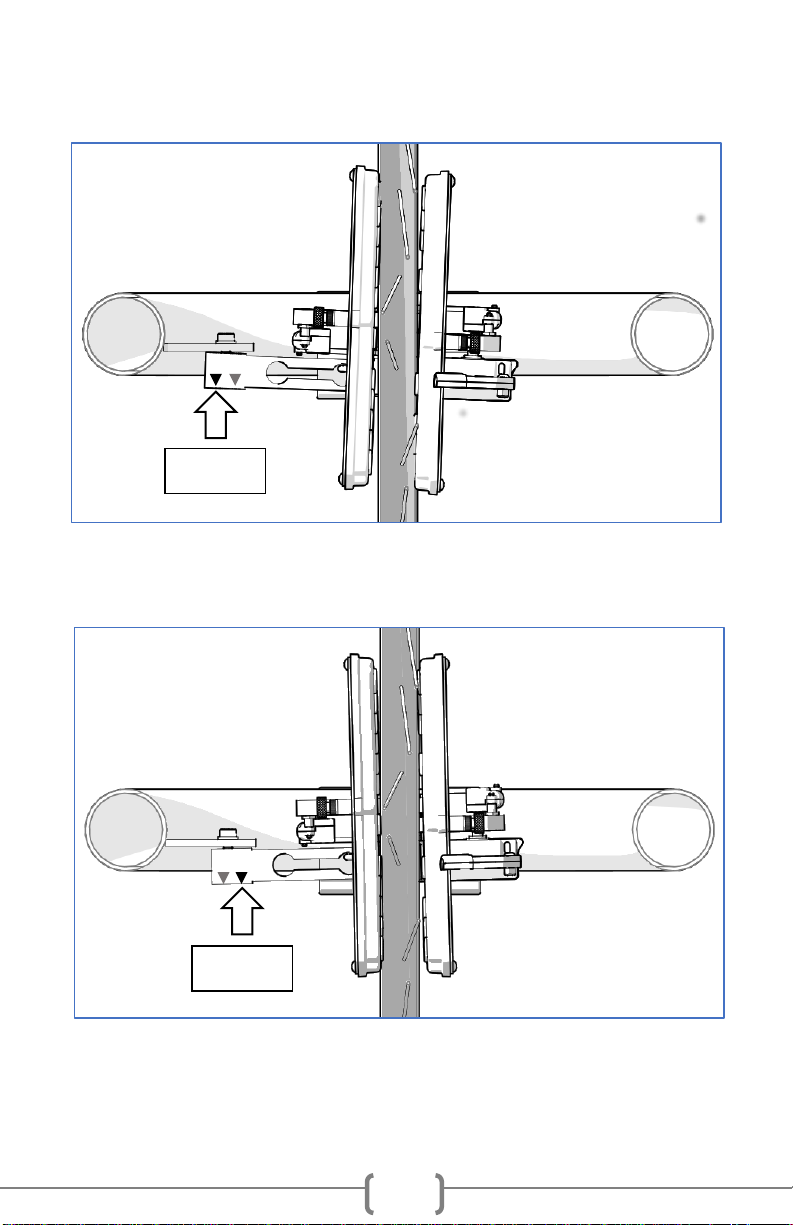

1. Loosen Mounting Bolts slightly.

2. Use a 3mm Allen Key to adjust one of two Set Screws to change

the mounting angle.

9

a. If the Magnet Arrays skew right towards the front of the

bike when viewed from above, tighten the Set Screw

closer to the arm of the Frame.

b. If the Magnet Arrays skew left towards the front of the

bike when viewed from above, tighten the Set Screw

closer to the center of the trainer.

c. If you adjust the Set Screw too far in one direction on

your first attempt, resulting in the opposite parallelism

error, untighten the over tightened Set Screw slightly

before attempting to tighten the other one.

Tighten

Tighten

10

3. Re-tighten the Mounting Bolts.

4. Re-check Parallelism and Concentricity.

FINAL STEPS:

1. Re-align your Spoke Magnet with the tip of the Speed Sensor.

You are ready to ride!

11

POWERMETER SETUP AND CONFIGURATION

Support Video:

"Getting to know your Powermeter/Understanding the

Powermeter Lights"

Installation of Spoke Magnet and startup of Powermeter

1. Install the included spoke magnet on a drive side spoke.

2. Align the spoke magnet with the end of the Magnet Sensor

nearest the center of your wheel.

3. Adjust the Magnet Sensor within 5mm-10mm (¼”-½”) of the

spoke magnet. The red light on the Powermeter should toggle

on/off as the spoke magnet goes by.

4. Rotate the wheel a couple of revolutions slowly by hand to make

sure the spoke magnet will not hit your bike or the Magnet

Sensor.

5. Allow the unit to sit for 15 seconds after the Powermeter lights

have activated to allow for self-calibration.

12

[This page intentionally left blank]

13

[This page intentionally left blank]

14

Regulatory Compliance

Product: STAC Zero Powermeter

Model: Rigado BMD-300

FCC ID: 2AA9B04

IC: 12208A-04

European Compliance Statement

STAC Performance hereby declares that this device is in compliance with the

essential requirements and other relevant provisions of the R&TTE Directive.

FCC Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

1) this device may not cause harmful interference, and

2) this device must accept any interference received, including interference

that may cause undesired operation.

Changes or modifications not expressly approved by STAC Performance, could

void the user’s right to operate the product.

This equipment has been tested and found to be compliant to FCC radiation

exposure limits. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy. If not installed and

used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful

interference, the user is encouraged to try to correct the interference with one

or more of the following measures

1) Reorient or relocate the receiving antenna

2) Increase the separation between the equipment and receiver

3) Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected

4) Consult the dealer or an experienced radio/TV technician

15

For support go to:

www.staczero.com/support

For additional assistance, contact us at:

support@staczero.com

Looking for more speed on the bike?

Check out the STAC Virtual Wind Tunnel:

Improve your speed at your next race!

All the benefits of wind tunnel testing without the

cost and inconvenience of going to one.

Book your session today!

www.staczero.com/vwt

Follow us on social media:

@STACPerformance

This manual suits for next models

1

Table of contents