Staheli West DewPoint 6110 User manual

2010-2014

DewPoint 6110

Troubleshooting

Guide

R7

II

www.StaheliWest.com/customer

FOR THE MOST UP TO DATE SERVICE INFORMATION VISIT:

FOR SERVICE ASSISTANCE, CONTACT YOUR LOCAL DEALER

RAISING INDIVIDUAL, FAMILY, AND COMMUNITY STANDARDS WHILE

REVOLUTIONIZING THE AGRICULTURAL INDUSTRY.

III

2010-2014

DewPoint 6110

Troubleshooting Guide

This manual is intended to be used with soware version

2.6 or later installed on the DewPoint 6110 machine

• Operator Training

• Warranty Informaon

• Safety Informaon

• Pre-Operaon Requirements

• Operaon

• Winterizaon

• De-Winterizaon

• Maintenance Instrucons

See DewPoint 6210 Owners Manual

iv

Contents

Informaonal

Components Locaon List ............................................................... VI

Diagram 1 Full Machine................................................................... 1

Diagram 2 Boiler Components ........................................................ 2

Diagram 3 Boiler Components ........................................................ 3

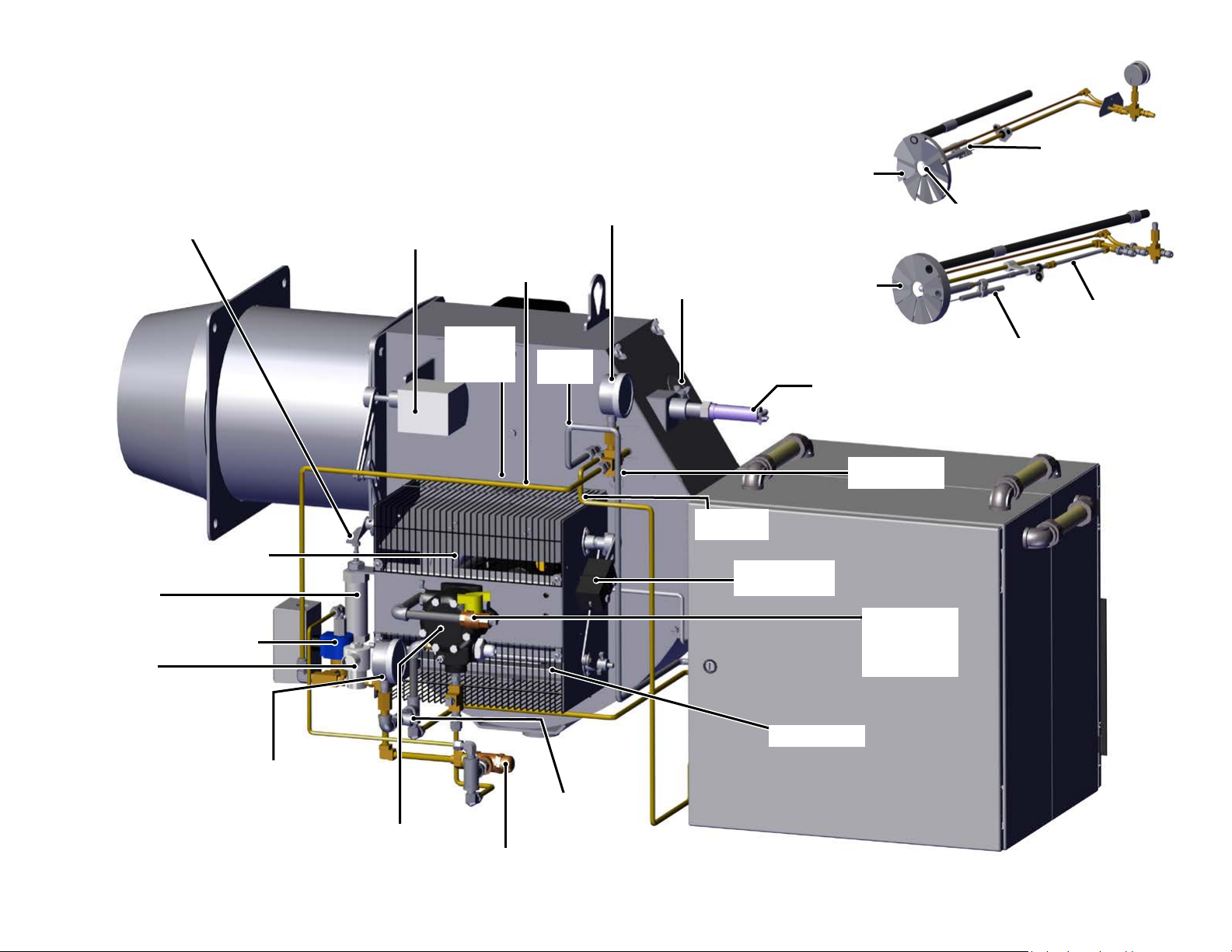

Diagram 4 Burner Components....................................................... 4

Diagram 5 Burner Components....................................................... 5

Diagram 6 Panel 1 and Door............................................................ 6-12

Diagram 7 Panel 2 and 3.................................................................. 7-13

Diagram 8 Under Frame .................................................................. 14

Diagram 9 Rear door area ............................................................... 15

Diagram 10 Engine/Generator ........................................................ 16

Sensors ............................................................................................ 17-19

Burner Nozzle Sizes ......................................................................... 20

Actuators ......................................................................................... 21

Fuses................................................................................................ 22

Circuit Breakers ............................................................................... 23

Connecons..................................................................................... 24-26

Touch Screen Wiring........................................................................ 27

Relay Block Wiring........................................................................... 28

Burner Wiring 2010-2013................................................................ 29

Burner Wiring 2014 (So Start Direct Spark) .................................. 30

Burner Wiring 2014 (So Start Propane) ........................................ 31

Burner Wiring 2014 (VFD Propane)................................................. 32

Faults

Fault 1: No Purge Card..................................................................... 33

Fault 14: High Fire Switch / Purge Hold

T19 High Fire Switch (See Fault 222)................................. 33

Fault 15: Flame Detected (Standby) ................................................ 34

Fault 17: Main Flame Fail (See Fault 220)........................................ 35

Fault 18: Flame Detected (Pre-Purge) ............................................. 36

Fault 19: Main Flame Ign ................................................................. 37

Fault 20: Low Fire SW O / Purge Hold

T18 Low Fire Switch (See Fault 223).................................. 38

Fault 28: Pilot Flame Fail ................................................................. 39-40

Fault 29: Lockout ILK (Airow Switch / VFD) ................................... 41-42

Fault 45: Low Fire Switch OFF.......................................................... 42

Fault 46-127: Call Service ................................................................ 42

Fault 200: High Pressure Limit Switch (HPLS) is tripped .................. 43

Fault 201: Turn Burner Switch ON ................................................... 44

Fault 202: Operang Pressure Control

Switch (OPLS) is tripped ................................................. 44

Fault 203: Boiler Water Level is high ............................................... 45

Fault 204: Pilot Propane Level is low............................................... 45

Fault 206: Supply Water is Empty.................................................... 45

Fault 207: Pressure Dierenal Alarm............................................. 46

Fault 208: Flue Temp is High............................................................ 47

Fault 209: Feed Water and Boiler Water Temp.

Dierenal limit has been Exceeded.............................. 48

Fault 210: Ambient Temperature is High......................................... 49

Fault 211: Furnace Door Temp is High............................................. 49

Fault 212: Low Water 2 tripped....................................................... 49

Fault 213: Boiler taking longer than expected to ll ....................... 49

Fault 214: Data Logging Failed: Replace USB Drive ......................... 50

Fault 215: Manual Valve Operaon is On ........................................ 50

Fault 224: Trouble with one or more Sensors ................................. 50

Fault 225: Burner Modbus signal failure ......................................... 51

Fault 228: Steam Pressure is low..................................................... 51

Fault 229: Boiler water temp. is low and

steam pressure is normal ............................................... 51

Fault 230: Turn Water System On.................................................... 51

Fault 231: Boiler water level is too high for operaon .................... 51

Fault 232: Generator Status ............................................................ 52-53

Fault 239: Iniate Hold: AC Frequency / Noise................................ 54

Fault 240: Control Switch Relay SR-1 did not annunciate................ 54

Fault 241: Low Water 1 Relay SR-2 did not annunciate................... 54

Fault 242: Low Water 2 Relay SR-3 did not annunciate................... 54

Fault 243: High Pressure Limit Switch

Relay SR-4 did not annunciate........................................ 54

Fault 244: Operang Pressure Control Relay SR-5

did not annunciate ......................................................... 55

Fault 245: Burner Relay SR-6 did not annunciate............................ 55

Fault 246: Fan VFD SR-7 did not annunciate ................................... 55

Fault 247: Airow Switch SR-8 did not annunciate ......................... 55

Fault 248: Touch Screen Version is

incompable with this DewPoint ................................... 55

Fault 249: Check Network or Fault 214: Missing USB Drive

(PLC-015: DEV001 No Device Found) ............................. 56

Fault 400: Low Water 1 or 2 tripped ............................................... 57-58

Fault 401: Boiler not lling / slowly lling with water..................... 59

v

Test 106: Intermient Pilot Flame Test............................................ 78

Test 108: HPLS Calibraon [15 PSI].................................................. 79

Test 109: OPLS Calibraon [14.5 PSI]............................................... 80

Test 110: Boiler Water Level Sensor Tesng .................................... 80-81

Test 111: Valve Repair...................................................................... 82

Test 112: Pump Service ................................................................... 83

Test 113: Input Card Tesng ............................................................ 84

Test 114: Program the VFD (See Fault 29) ....................................... 85

Test 115: Louver Actuator adjustments........................................... 86

Test 116: Tune the burner ............................................................... 87-89

Test 117: Remove burner gun assembly.......................................... 90

Test 118: Update to new boiler water level sensor ......................... 91-92

Test 119: Flue tube cleaning............................................................ 93-95

Test 120: Remove Panel 2 TS2 Jumpers........................................... 96

Test 121: Generator End Troubleshoong....................................... 97-98

Test 122: Release wires from terminal block................................... 99

Test 123: Maxed out sensor readings.............................................. 100-101

Test 124: All sensors oine / fuse keeps blowing ........................... 102-103

Maintenance

Maintenance Checklists:

Daily .................................................................. 104

Every 50 hours .................................................. 104

Every 250 hours / Yearly ................................... 105

Every 500 hours ................................................ 105

Every 1000 hours .............................................. 106

Every 1500 hours .............................................. 106

Every 2000 hours .............................................. 106

Maintenance Schedule.................................................................... 107-109

Contents

Fault 402: Faulty PLC Input Card...................................................... 59

Fault 403: Boiler water level higher than

set point / Boiler overowing......................................... 60

Fault 404a: Boom rear work lights will not turn on ...................... 61

Fault 404b: Side and top rear work lights will not turn on .............. 61

Fault 405: Touch Screen controller will not turn on ........................ 62

Fault 406: Steam is coming out of front water tanks ...................... 62

Fault 407: Burner Smoking .............................................................. 63-64

Fault 408: Actuators/Valves not opening/closing............................ 64

Fault 409: Loss of steam pressure during operaon ....................... 65

Fault 410: Feed Water Pump not running ....................................... 66

Fault 411: Circulaon Pump not running ........................................ 67

Fault 412: Water in Steam / Bales have Water splotches /

Sudden loss of Steam Pressure and Water Level ............ 68

Fault 413: Pilot Propane Pressure low............................................. 69

Fault 414: Fuel Nozzle Pressure is low in Low Fire .......................... 69

Fault 415: Fuel Nozzle Pressure is high in Low Fire ......................... 69

Fault 416: Fuel Nozzle Pressure is low in High Fire.......................... 70

Fault 417: Fuel Nozzle Pressure is high in High Fire......................... 70

Fault 418: Purge Delay: T19 High Fire Jumpered............................. 70

Fault 419: Purge Hold: T19 High Fire Switch

(Waing for Louver to Open) (See Fault 14)................... 71

Fault 420: Purge Hold: T18 Low Fire Switch

(Waing for Louver to Close) (See Fault 20)................... 71

Fault 421: Generator will not start form Touch Screen ................... 72

Fault 422: Generator will not shut o from Touch Screen .............. 72

Fault 423: Touch Screen Problems: Frozen,

won’t respond to touch................................................. 73

Fault 424: Generator Controller not working;

“??????????” displayed on screen ................................. 73

Fault 425: Burner not going into high re / Stuck in low re .......... 74

Fault 426: Failed PTO Bearing(s)...................................................... 75

Fault 427: PTO sha slipping ........................................................... 75

Fault 428: Water coming out of steam purge valve......................... 75

Tests

Test 101: Flame Detector Tesng Procedures ................................. 76

Test 102: Fuel Solenoid Test ............................................................ 76

Test 103: Propane Solenoid Test...................................................... 76

Test 104: Ignion Transformer Test ................................................. 77

Test 105: Igniter Electrode Orientaon & Gap ................................ 77-78

• Operator Training

• Warranty Informaon

• Safety Informaon

• Pre-Operaon Requirements

• Operaon

• Winterizaon

• De-Winterizaon

• Maintenance Instrucons

See DewPoint 6210 Owners Manual

vi

Component Part # Locaon

24v Regulator 10302 Diagram 7

Airow Switch 10041 Diagram 5

Ambient Temperature Sensor 10373 Diagram 8

Blow Down Valve Actuator 10363 Diagram 2

Boiler Door Temperature Sensor 10372 Diagram 2

Boiler Drain Valve Diagram 9

Boiler Water Level Sensor update kit

Boiler Water Level Sensor

10344

11040

Diagram 2,3

Boiler Water Sight Glass (kit) 10625 Diagram 3

Boiler Water Temperature Sensor 10372 Diagram 3

Burner Cone Diagram 4

Burner Controller 10654 Diagram 6

Burner Gun Assembly … Diagram 4

Burner Nozzle Diagram 4

Circulaon Water Pump 10585 Diagram 2,9

Circulaon Water Pump Contactor 10298 Diagram 7

Control Relay (Burner Door Switch) Diagram 7

Control Switch Diagram 4

Fan Motor Three Phase 2014 VFD

Fan Motor Single Phase 2010-2014

10687

10036

Diagram 4

Feed Water Pump 10585 Diagram 2,9

Feed Water Pump Contactor 10298 Diagram 7

Feed Water Temperature Sensor 10372 Diagram 3

Feed Water Valve Actuator 10363 Diagram 2,9

Flame Amplier Card UV 10798 Diagram 6

Flame Detector UV 10047 Diagram 4,5

Flue Diagram 2

Flue Temperature Sensor 10366 Diagram 2

Front Boiler Sight Glass Diagram 5

Front Turn box Diagram 3

Fuel Filter (Burner) Diagram 8

Fuel Level Sensor 10371 Diagram 8

Fuel Pressure Gauge 10709 Diagram 5

Fuel Pump (Burner) 10045 Diagram 5

Fuel Pump PSI Sensor 10349 Diagram 5

Component Part # Locaon

Fuel Solenoid Valves 10730 Diagram 4

Generator Controller 11078 Diagram 1

High Pressure Limit Switch 10380 Diagram 3

Ignion Electrode 2010-2013: 10648

2014: 10721

Diagram 4

Ignion Transformer (Direct Spark)

Ignion Transformer (Propane)

2010-2013: 10043

2014: 10698

Diagram 4

Louver Actuator 10038 Diagram 5

Low Water 1 Relay 2014: 10352 Diagram 6

Low Water 2 Relay 2014: 10352 Diagram 6

Low Water Cut O Probe 1/A 10354-19-3-8 Diagram 2,3

Low Water Cut O Probe 2/B 10354-19-5-8 Diagram 2,3

Low Water Cut O Sensor Head 10353 Diagram 2,3

Manual Steam Pressure Gauge Diagram 3

Modbus Card 10713 Diagram 6

Operang Pressure Limit Switch 10379 Diagram 3

PLC Ethernet Card 10377 Diagram 7

PLC Ethernet Switch 10378 Diagram 7

PLC Input Card 10375 Diagram 7

PLC Logic Controller 10374 Diagram 7

PLC Output Card 10376 Diagram 7

Pressure Relief Valve 10016 Diagram 2,3

Propane PSI Sensor 10656 Diagram 4

Propane Regulator 2014 only 10693 Diagram 4

Propane Solenoid Valve 2014 only 10692 Diagram 4

Purge Card 10712 Diagram 6

Rear Furnace Sight Glass 10014 Diagram 2

Rear Furnace Door Diagram 2

Steam PSI 1 10350 Diagram 3

Steam PSI 2 10350 Diagram 3

Steam Purge Valve Actuator 10364 Diagram 2

Steam Valves 1-4 Actuator 10363 Diagram 2

Supply Water Filter / T Strainer Diagram 9

Supply Water Level Sensor 10371 Diagram 8

VFD (Variable Frequency Drive) 10714 Diagram 6

Water Purge Valve Actuator 10365 Diagram 2

Y-Strainer 10588 Diagram 3

Components Location List

1

Diagram 1

Supply Water

Tanks

Generator

Burner

Fuel Tanks

Boiler

Generator

Controller

2

Diagram 2

Flue

Feed Water

Valve Actuator

Boiler Door

Temp. Sensor

Rear Furnace Door

Flue Temp.

Sensor

Water Purge

Valve Actuator

Steam Purge

Valve Actuator

Boom Front Steam

Valve Actuator

Boom Rear Steam

Valve Actuator

Top Front Steam

Valve Actuator

Top Rear Steam

Valve Actuator

Pressure Relief

Valve

Low Water

Cuto

Boiler Water

Level Sensor

Steam Valve Actuators

Feed Water

Pump

Circulaon

Pump

Rear Furnace

Sight Glass

Blow Down

Valve Actuator

3

Diagram 3

Boiler Water

Temp. Sensor

Feed Water

Temp. Sensor

Boiler Sight Glass

Front Turn box

Y-Strainer

Pressure Relief

Valve Low Water

Cuto Boiler Water

Level Sensor Steam PSI 1 Manual Steam

Pressure Gauge

Operang Pressure

Limit Switch (OPLS)

High Pressure

Limit Switch (HPLS)

Steam PSI 2

4

Diagram 4

Airow Switch

Flame Detector

Control Switch

Propane Solenoid

Valve (2014 only)

Fuel Safety

Solenoid Valve

Propane

Regulator

(2014 only)

Low Fire

Solenoid Valve

Ignion

Transformer

Fan Motor

Burner

Nozzle

High Fire Fuel

cylinder/piston

2014 Propane Burner

Gun Assembly

2010-2014 Direct Spark

Burner Gun Assembly

Single Ignion

Electrode

Burner Nozzle

20 GPH

Propane

line

Dual Ignion

Electrodes

5

Diagram 5

Low Fire oil

regulang

valve

Front Boiler

Sight Glass

Louver

Actuator

High Fire

Solenoid

Louver (Upper)

Fuel Pump

Pressure Gauge

Flame Detector

Low Fire

Solenoid

Fuel Pump

Fuel Pump

Pressure Sensor

High Fire Fuel

cylinder/piston

Fan cleaning

compressed air

aachment and

valve

Fuel Nozzle

pressure sensor

Fuel Nozzle

pressure gauge

Louver Close

counter-weight

Louver (Lower)

Fuel Return

line

Low Fire

adjustment

bolt/nut Propane

line

Fuel Feed

line

Fuel cylinder

push tab

2014 Propane Burner

Gun Assembly

2010-2014 Direct Spark

Burner Gun Assembly

Single Ignion

Electrode

Burner Nozzle

20 GPH

Propane

line

Dual Ignion

Electrodes

6

Purge Card

Burner Controller

Flame Amplier Card

Modbus Card

Diagram 6a (2010)

Panel 1Panel 1 door

Burner

Controller

Baldor So Start

Fan Contactor

TS1

(Terminal Strip 1)

CB

(Circuit Breakers)

Safety Relays

Low Water 1Low Water 2

10R

7

Diagram 7a (2010)

Panel 3Panel 2

TS1

(Terminal Strip 1)

TS2

(Terminal Strip 2)

24v Regulator

FB (Fuse Block)

FB (Fuse Block)

RB (Relay Block)

PLC (Programmable

Logic Controller)

AI1 (Input Card 1)

AI2 (Input Card 2)

AO (Output Card)

Ethernet Card

Ethernet Switch

Control

Relay

Circ Pump

Contactor

Feed Pump

Contactor

TS1

(Terminal Strip 1)

CB

(Circuit Breakers)

Boiler Water

Level Sensor

12v Regulator

8

Diagram 6b (2011-2013)

Panel 1Panel 1 door

Baldor So Start

Fan Contactor

TS1

(Terminal Strip 1)

CB

(Circuit Breakers)

Safety Relays

Low Water 1Low Water 2

Purge Card

Burner Controller

Flame Amplier Card

Modbus Card

Burner

Controller 10R

9

Diagram 7b (2011-2013)

Panel 3Panel 2

TS1

(Terminal Strip 1)

TS2

(Terminal Strip 2)

24v Regulator

FB (Fuse Block)

FB (Fuse Block)

RB (Relay Block)

PLC (Programmable

Logic Controller)

AI1 (Input Card 1)

AI2 (Input Card 2)

AO (Output Card)

Ethernet Card

Ethernet Switch

Control

Relay

Circ Pump

Contactor

Feed Pump

Contactor

TS1

(Terminal Strip 1)

CB

(Circuit Breakers)

Boiler Water

Level Sensor

12v Regulator

10

Diagram 6c (2014-Soft Start)

Panel 1Panel 1 door

Siemens So Start

Fan Contactor

TS1

(Terminal Strip 1)

CB

(Circuit Breakers)

Safety Relays

Low

Water 1

Purge Card

Burner Controller

Flame Amplier Card

Modbus Card

Burner

Controller

Low

Water 2

10R

11

Diagram 7c (2014-Soft Start)

Panel 3Panel 2

TS1

(Terminal Strip 1)

TS2

(Terminal Strip 2)

24v Regulator

FB (Fuse Block)

FB (Fuse Block)

RB (Relay Block)

PLC (Programmable

Logic Controller)

AI1 (Input Card 1)

AI2 (Input Card 2)

AO (Output Card)

Ethernet Card

Ethernet Switch

Control

Relay

Circ Pump

Contactor

Feed Pump

Contactor

TS1

(Terminal Strip 1)

CB

(Circuit Breakers)

Boiler Water

Level Sensor

12v Regulator

12

Diagram 6d (2014-VFD)

Panel 1Panel 1 door

Low Water 1 & 2

VFD

24v Power

TS1

(Terminal Strip 1)

CB

(Circuit Breakers)

Safety Relays

Purge Card

Burner Controller

Flame Amplier Card

Modbus Card

Burner

Controller

VFD

11R9R

10R

13

Diagram 7d (2014-VFD)

Panel 3Panel 2

TS1

(Terminal Strip 1)

TS2

(Terminal Strip 2)

24v Regulator

FB (Fuse Block)

FB (Fuse Block)

RB (Relay Block)

PLC (Programmable

Logic Controller)

AI1 (Input Card 1)

AI2 (Input Card 2)

AO (Output Card)

Ethernet Card

Ethernet Switch

Control

Relay

Circ Pump

Contactor

Feed Pump

Contactor

TS1

(Terminal Strip 1)

CB

(Circuit Breakers)

Boiler Water

Level Sensor

12v Regulator

14

Diagram 8

Fuel Level

Sensor

Supply Water

Level Sensor

Burner

Fuel Filter Low Fire oil

regulang

valve

Burner

Fuel Pump

Ambient

Temp. Sensor

Table of contents

Other Staheli West Kitchen Appliance manuals

Popular Kitchen Appliance manuals by other brands

Alfresco Chef

Alfresco Chef VERONA Manual & user guide

Outdoor Gourmet

Outdoor Gourmet 156633 Assembly instructions & user manual

Bartscher

Bartscher 500393 instruction manual

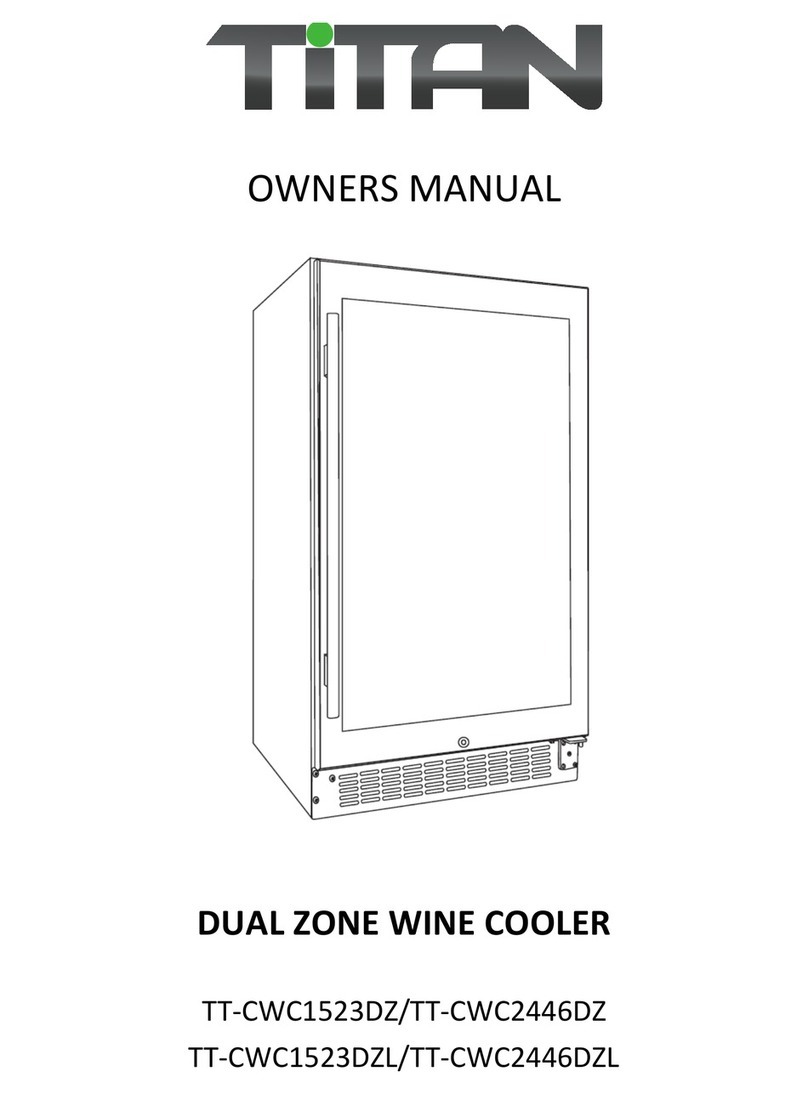

Titan

Titan TT-CWC1523DZ owner's manual

Brentwood Appliances

Brentwood Appliances FD-1026BK Operating and safety instructions

Ceado

Ceado ES500S Instruction and maintenance manual

Byzoo

Byzoo SV03 Instruction and Care Manual

Pyle

Pyle PSTMH22 instructions

Dash

Dash DRG001 Instruction manual & recipe guide

Blomberg

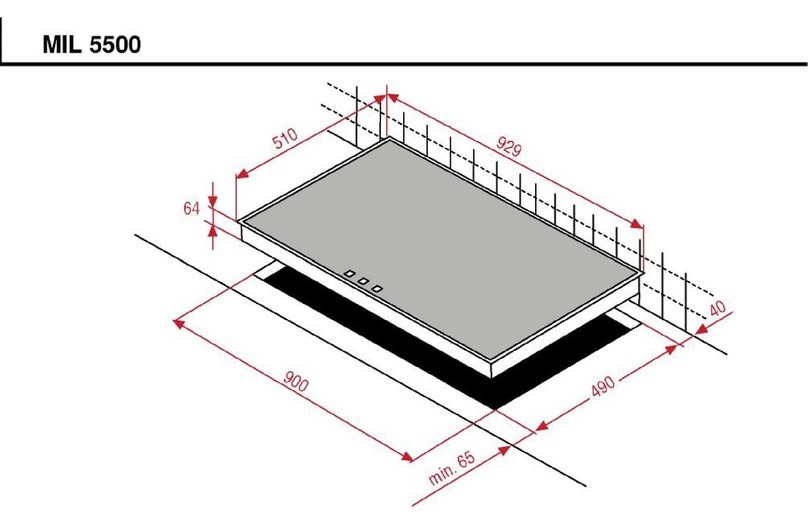

Blomberg GEB 3536 Dimensions

Koncar

Koncar SE 5640 SERIES Operating, installation and connecting instructions

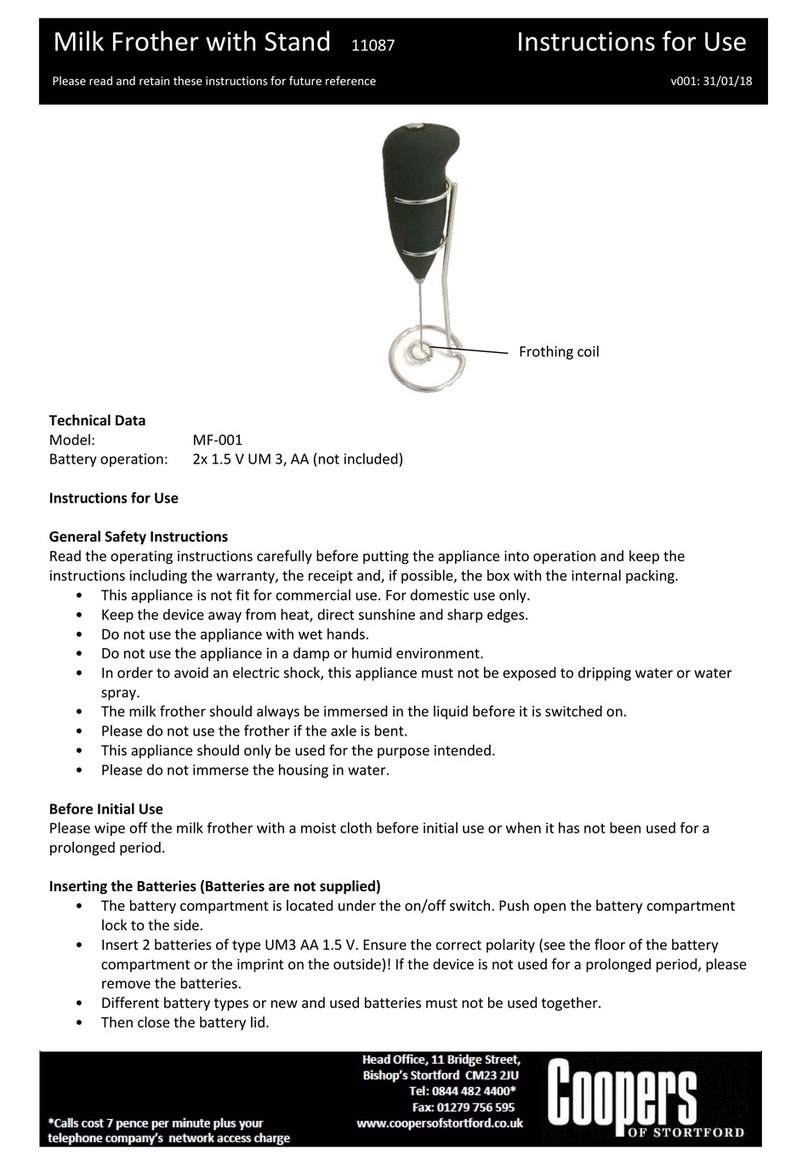

Coopers of Stortford

Coopers of Stortford MF-001 Instructions for use