2

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

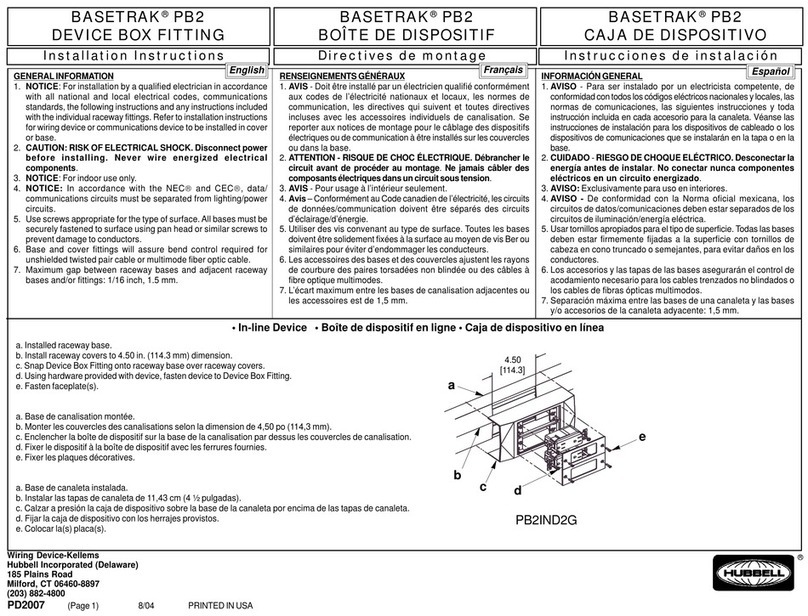

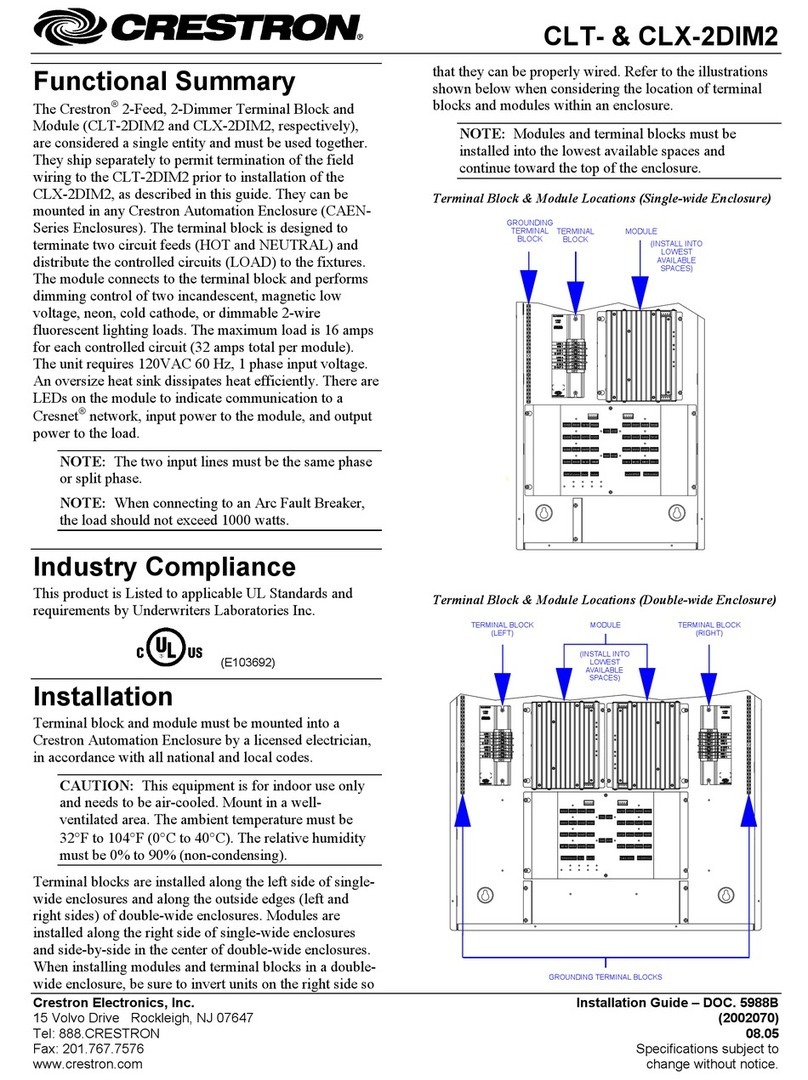

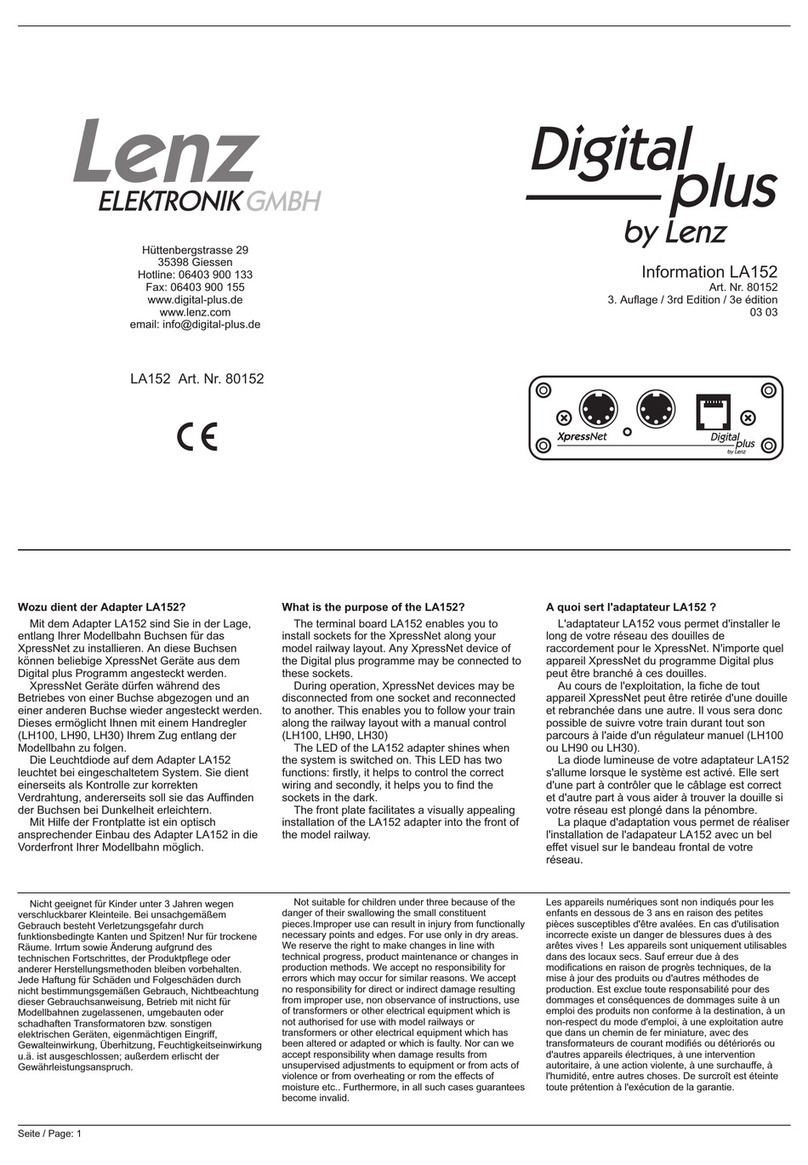

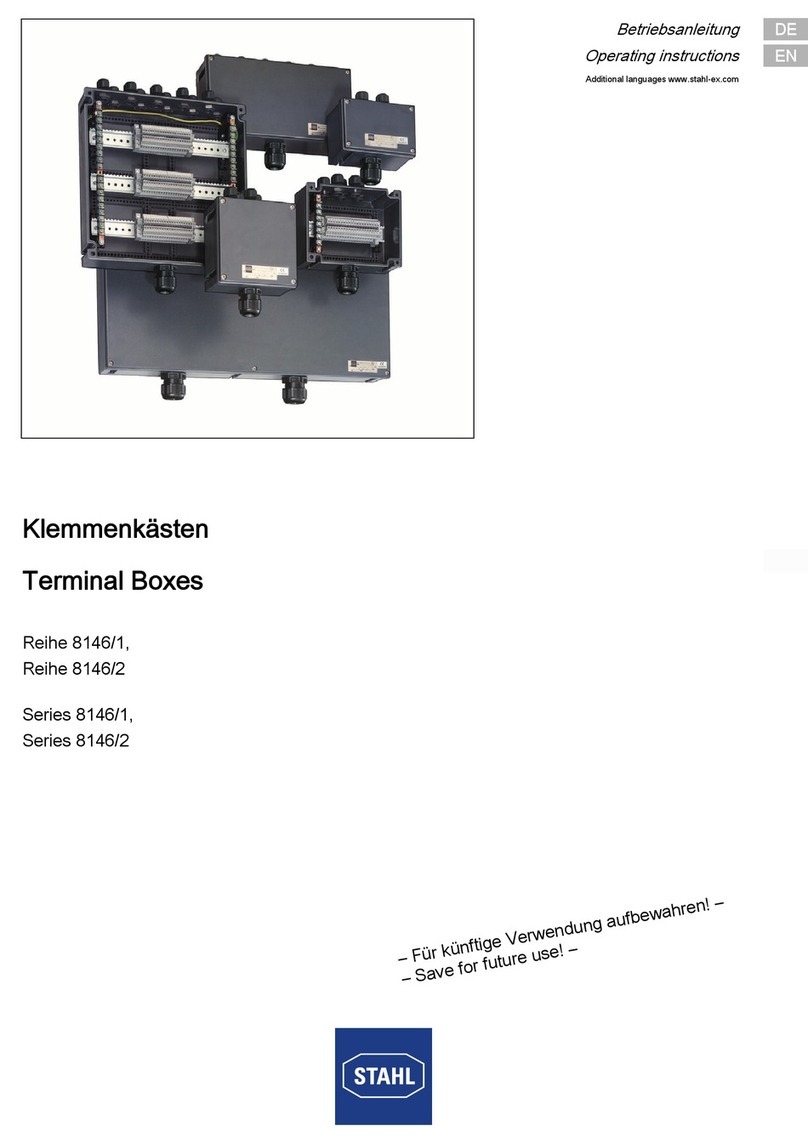

Terminal Boxes

Series 8146/1, Series 8146/2

Contents

1 General Information ............................................................................................3

1.1 Manufacturer .......................................................................................................3

1.2 About these Operating Instructions .....................................................................3

1.3 Further Documents .............................................................................................3

1.4 Conformity with Standards and Regulations .......................................................3

2 Explanation of the Symbols ................................................................................4

2.1 Symbols in these Operating Instructions ............................................................4

2.2 Symbols on the Device .......................................................................................4

3 Safety ..................................................................................................................5

3.1 Intended Use .......................................................................................................5

3.2 Personnel Qualification .......................................................................................5

3.3 Residual Risks ....................................................................................................6

4 Transport and Storage ........................................................................................8

5 Product Selection, Project Engineering and Modification ...................................8

5.1 Additional Through Holes in Flange Plates .........................................................9

5.2 Additional Through Holes in the Enclosure with

an internal Brass or Flange Plate ......................................................................10

5.3 External Attached Components

(Cable Entries, Stopping Plugs, Breathers) ......................................................13

5.4 Internal Built-In Components

(Conductors, Terminals, Fuses) ........................................................................14

6 Mounting and Installation ..................................................................................17

6.1 Mounting / Dismounting, Operating Position .....................................................17

6.2 Installation .........................................................................................................18

7 Commissioning .................................................................................................21

8 Maintenance and Repair ...................................................................................21

8.1 Maintenance .....................................................................................................21

8.2 Maintenance .....................................................................................................21

8.3 Repair ...............................................................................................................21

9 Returning the Device ........................................................................................21

10 Cleaning ............................................................................................................22

11 Disposal ............................................................................................................22

12 Accessories and Spare Parts ...........................................................................22

13 Annex A ............................................................................................................23

13.1 Technical Data ..................................................................................................23

14 Annex B ............................................................................................................26

14.1 Dimensions / Fastening Dimensions .................................................................26