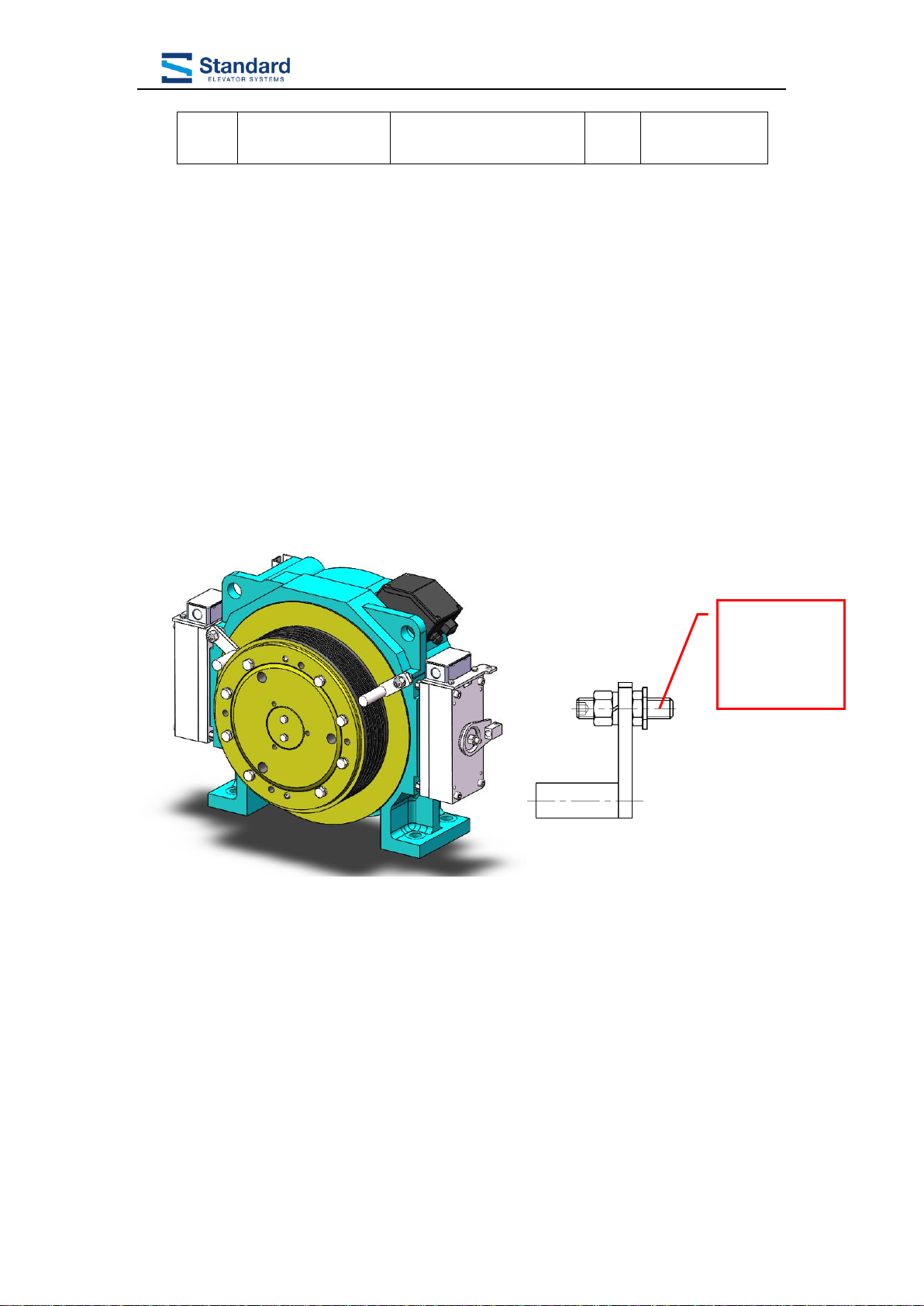

IGL15 Spare parts replacement manual

Version:S2018.05 1

Catalogue

ATALOGUE............................................................................................................................................1

1. PREFACE.......................................................................................................................................2

1.1. SAFETY DECLARATION .............................................................................................................2

1.2. IGL15 TRACTION MACHINE SPARE PARTS LIST ..........................................................................2

2. SPARE PARTS REPLACEMENT OPERATION.......................................................................3

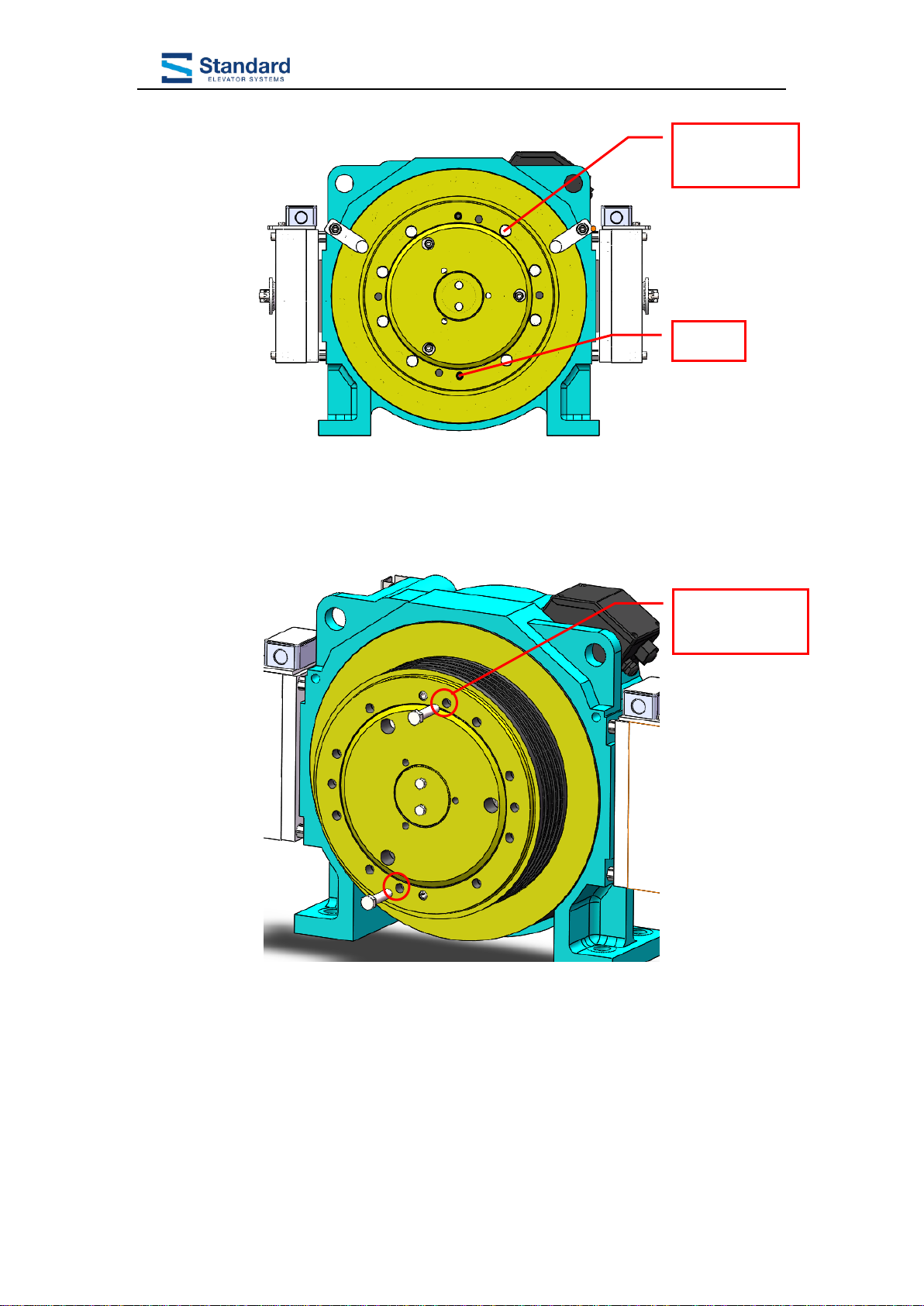

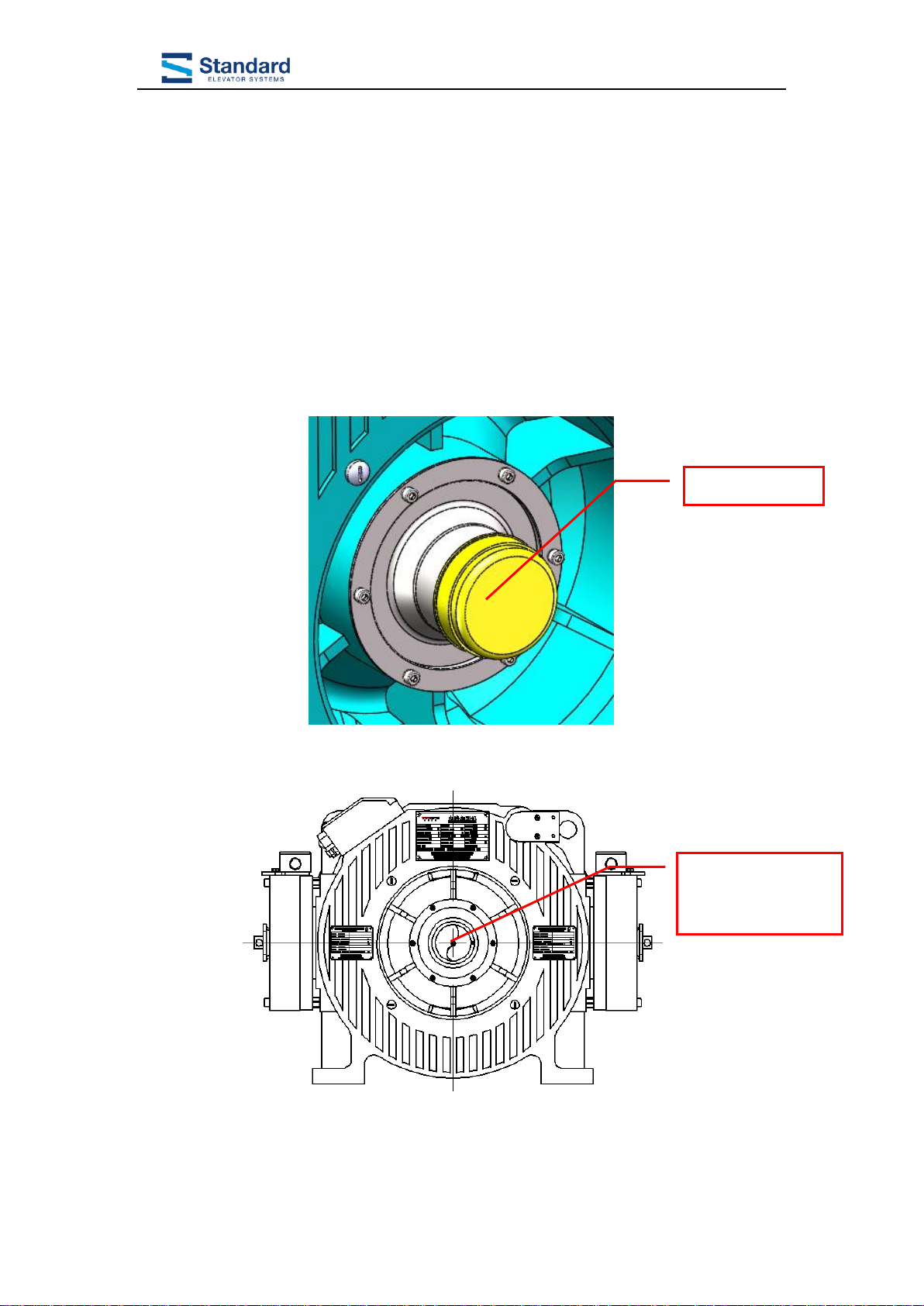

2.1. TRACTION WHEEL REPLACEMENT.............................................................................................3

2.1.1. Remove the traction sheave.............................................................................................3

2.1.2. Install the traction sheave ...............................................................................................5

2.2. ENCODER REPLACEMENT .........................................................................................................7

2.2.1. Remove the encoder ERN1387........................................................................................7

2.2.2. Install the encoder ERN1387...........................................................................................9

2.3. BEARING 6212-2RS REPLACEMENT .......................................................................................12

2.3.1. Remove the bearing 6212-2RS ......................................................................................12

2.3.2. Install the bearing 6212-2RS.........................................................................................15

2.4. BEARING 6317-2RS/C3 REPLACEMENT .................................................................................17

2.4.1. Remove the bearing 6317-2RS/C3.................................................................................17

2.4.2. Install bearing 6317-2RS/C3.........................................................................................21

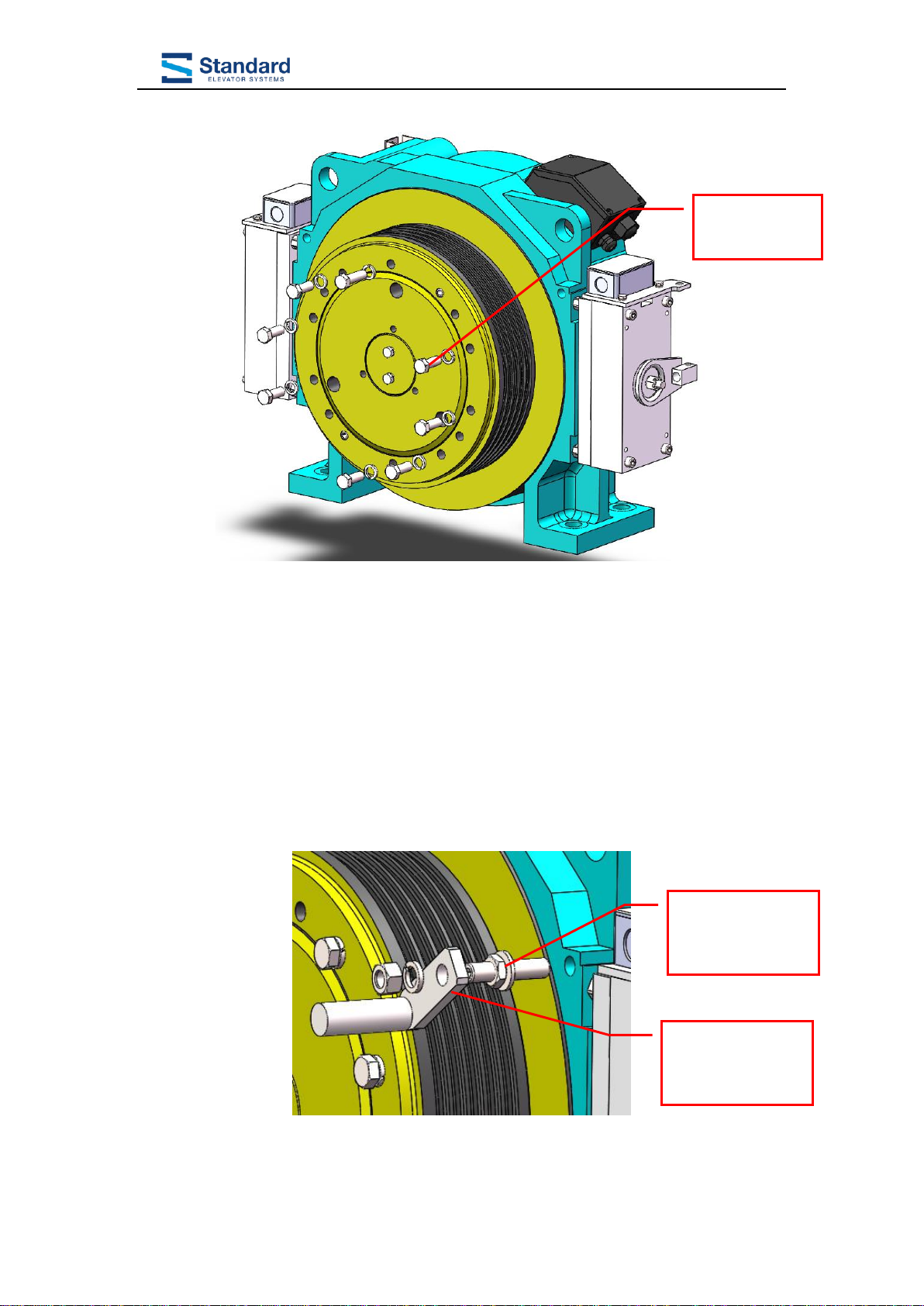

2.5. BRAKE FZD10 REPLACEMENTAND ADJUSTMENT (SHOWNAS THE RIGHT SIDE BRAKE) .........25

2.5.1. Remove the FZD10 brake..............................................................................................25

2.5.2. Install the FZD10 brake ................................................................................................27

2.5.3. Adjust brake noise .........................................................................................................31

2.6. BRAKE RUBBER ASSEMBLY REPLACEMENT............................................................................32

2.6.1. Remove the brake rubber assembly...............................................................................32

2.6.2. Install the brake rubber assembly .................................................................................33

2.7. STROKE SWITCH REPLACEMENT.............................................................................................34

2.7.1. Remove the stroke switch assembly ...............................................................................34

2.7.2. Install the stroke switch assembly..................................................................................36

2.8. MICRO-SWITCH REPLACEMENT..............................................................................................38

2.8.1. Remove the Micro-Switch assembly ..............................................................................38

2.8.2. Install and adjust the Micro-Switch assembly ...............................................................41