05

ECO SNM PUMPS

2- GENERAL PUMP DESCRIPTION

2.1- Pump Description

• ECO SNM series pumps are horizontal, radially split volute casing, single stage, end suction centrifugal pumps

with closed impeller.

• The dimensions of volute casing comply with EN 733.

2.2- Application Areas

ECO SNM series pumps are suitable for clean or slightly contaminated (max. 20 mg/dm3) liquids with low viscosities

and temperatures up to 140 º C . The main application areas, among others, are:

• Water supply, water treatment and irrigation systems,

• Heating, chilled and cooling water systems,

• Water systems for industrial uses,

• Industrial circulating systems,

• Fire fighting,

• Power plants.

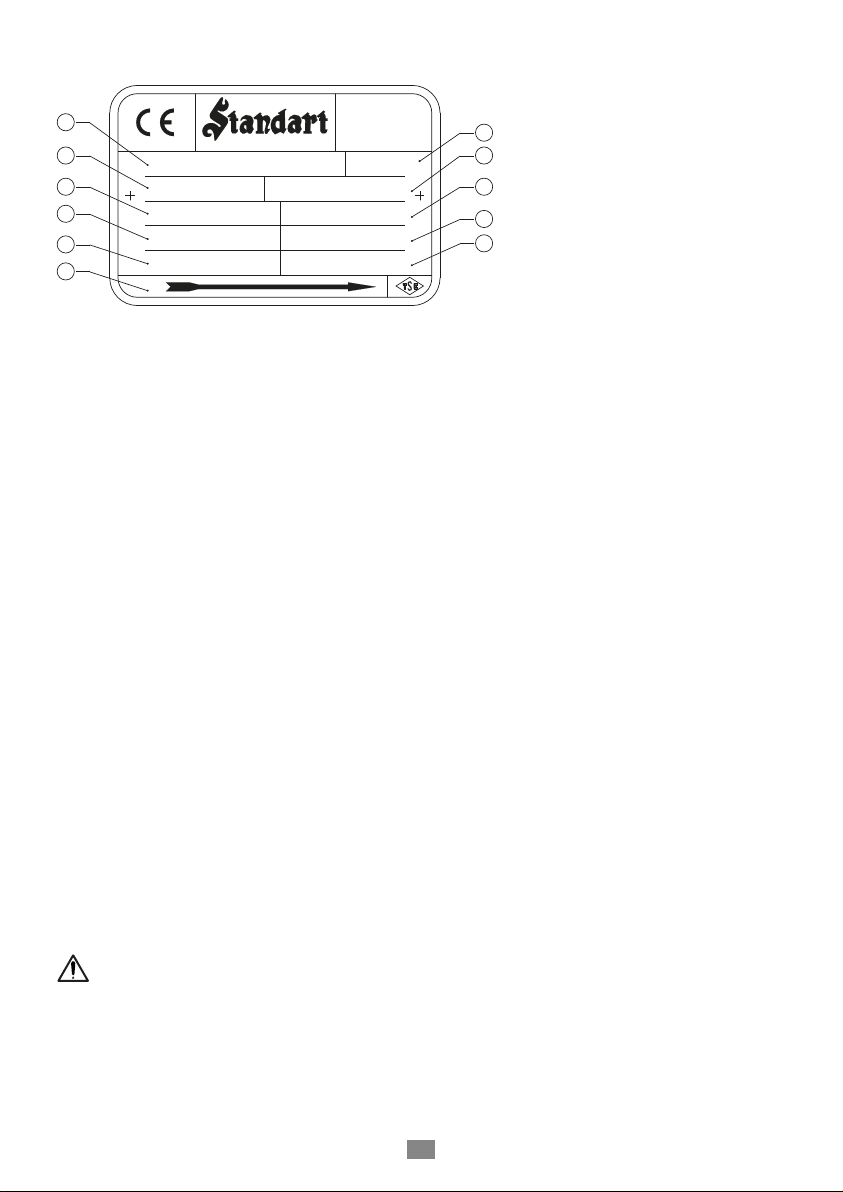

2.3- Pump Designation

2.4- Product information according to European Commission's Regulation EU 547/2012

Relevant Pump Series

Water pump, end suction own bearing (ESOB) -ECO SNT

Water pump, end suction close coupled (ESCC) - ECO SNM

Water pump, end suction close coupled inline (ESCCi) - ECO SNL

Minimum efficiency index: MEI>=0,4

The benchmark for most efficient water pumps is MEI>= 0,7

Year of production: Please see the pump label.

Manufacturer’s name or trademark: Standart Pompa ve Makina San. Tic. A.Ş.

Place of production: Turkey

Product’s type and size indicator: Please see the pump label and data sheets.

Pump performance curves, including efficiency characteristics: see documented characteristic curve

The efficiency of a pump with a trimmed impeller is usually lower than that of a pump with full

impeller diameter. Trimming of the impeller will adapt the pump to a fixed duty point, leading to

reduced energy consumption. The minimum efficiency index (MEI) is based on the full impeller

diameter.

Operation of this water pump with variable duty points may be more efficient and economic when

controlled, for example, by the use of a variable speed drive that matches the pump duty to the

system.

Information relevant for disassembly, recycling or disposal at end of life: see installation/operating

manual section 1.4

Information on benchmark efficiency graph is available at www.europump.org/efficiencycharts

Pump Type

Vertical Installation

Discharge Nozzle (DN-mm)

Nominal Impeller Diameter (mm)

Impeller Type

ECO SNM-V 100 - 250 ....