Standen Unistar 2400 Service manual

Unistar 2400

Soil Separator

Standen Engineering Limited.

Hereward Works,

Station Road, Ely,

Cambridgeshire.

CB7 4BP

England.

Tel: 01353 661111 www.standen.co.uk Fax: 01353 662370

On delivery check that the machine is as ordered and has not been damaged in

transit. Please report any shortfall to your Standen dealer.

The contents of this handbook, although correct at the time of publication, may be

subject to alteration by the manufacturers without prior notice.

Standen Engineering Limited operates a policy of continual product development.

Therefore, some illustrations and/or text within this publication may differ from your

machine.

The copyright of this handbook is the property of Standen Engineering Limited,

Hereward Works, Station Road, Ely, Cambridgeshire. CB7 4BP. This handbook is

issued on the condition that it must not be used, copied or exhibited without their

written permission.

IMPORTANT

This operator’s handbook should be regarded as part of the

machine. Suppliers of both new and second-hand machines are

advised to retain documentary evidence that this handbook was

supplied along with the machine.

On installation of the machine (i.e. starting off in the field), the New

Machine Installation Record Card should be completed by the

dealer/distributor and be countersigned by the customer. The

document is proof that the correct procedures have been followed.

The New Machine Installation Record Card should be returned to

Standen Engineering Limited within 7 days of installation. Failure to

do so may invalidate the machine warranty.

INTRODUCTION

Introduction to the Handbook 1.1

Warranty 1.1

Replacement Parts 1.2

SAFETY PRECAUTIONS

Safety 1.3

HSE Information Sheet 1.5

INSTALLATION

Tractor Suitability 1.7

Tractor Wheel Settings 1.7

Drawbar 1.7

Hydraulically Damped Drawbar 1.8

PTO Shaft 1.9

Hydraulic Connection 1.10

Open/Closed Centre Hydraulics 1.10

OPERATION

Electrical Control System 1.11

Wheel Settings 1.13

Automatic Depth Control 1.14

Setting the Automatic Depth Control 1.14

Discs 1.16

Shares 1.16

Underweb 1.16

Boulder Box 1.17

Cross Conveyor 1.17

Braked Axles 1.18

Actiflow Star Spacing 1.18

Vari-Flow Web 1.18

MAINTENANCE

Lubrication 1.19

Drive Belt Maintenance 1.20

Electrical System Maintenance 1.20

Hydraulic System Maintenance 1.20

Residual Hydraulic Pressure Dump Procedure 1.21

Star Shaft Removal 1.21

Daily Maintenance 1.22

Weekly Maintenance 1.22

Annual Maintenance 1.22

Out of Season Storage 1.23

SPECIFICATIONS

Machine Dimensions 1.24

Machine Weight 1.24

Technical Data 1.24

CONTENTS

Introduction to the Handbook

This handbook provides the information for the operation, adjustment and

maintenance of your Standen Unistar 2400 Soil Separator. To enable you to achieve

the best results from the machine, the manufacturer recommends that you read the

handbook thoroughly prior to using the machine for the first time.

Record below the details of your machine.

Dealers name...............................................................................…………….

Address......................................................................................................

.................................................................................................................

Telephone number.................................................................................…….

Machine serial number...............................................................................…

Date purchased............................................................................................

Date started work........................................................................................

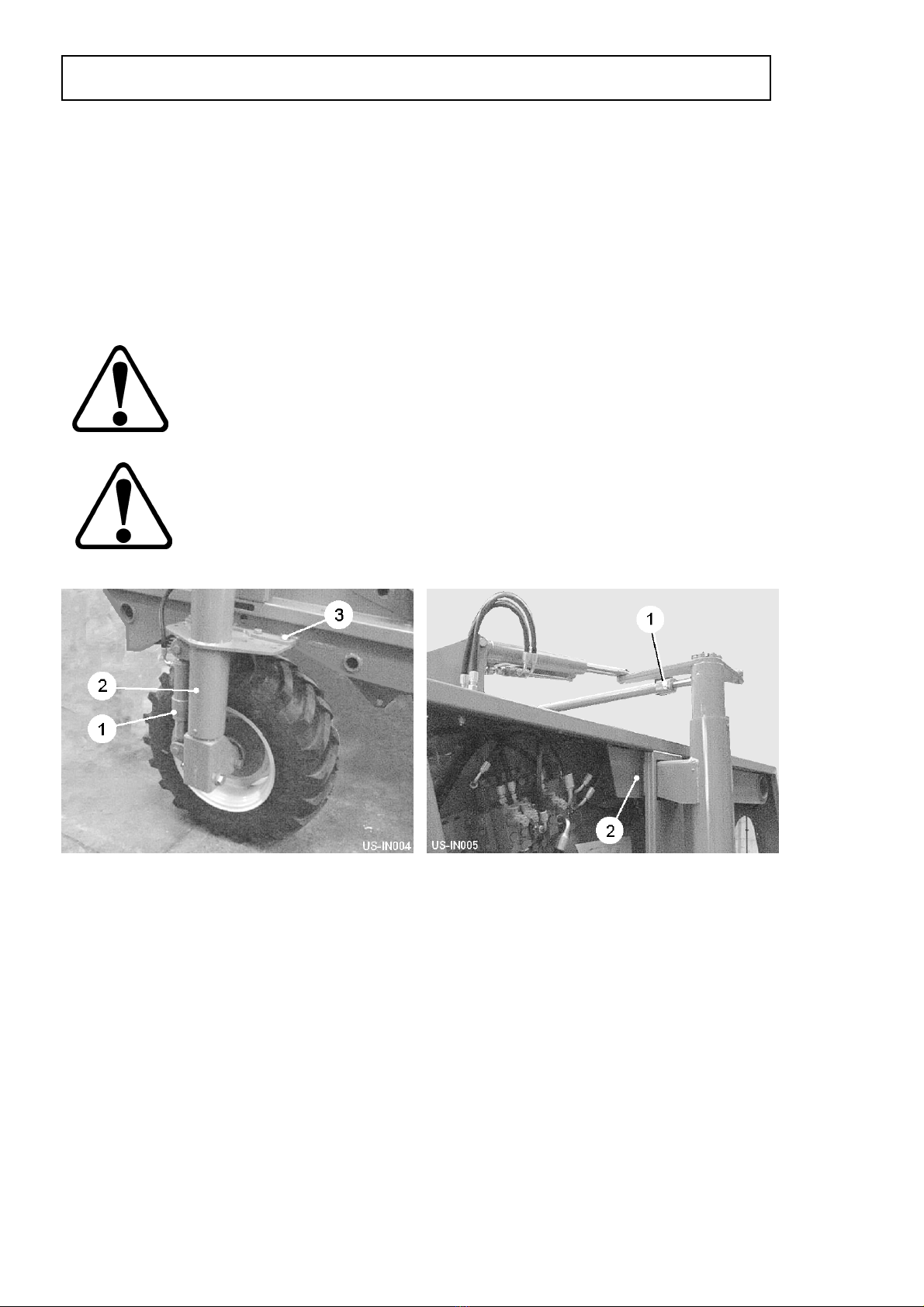

This symbol indicates important safety messages within this handbook.

When you see this symbol, be alert to the possibility of injury to yourself

or others and/or damage to the machine and carefully read the message

that follows.

Throughout this handbook the terms 'front', 'rear', 'left-hand' (LH) and 'right-hand'

(RH) are derived from the tractor driver’s position facing forward in the normal

direction of travel.

Adjustments to the machine may have to be made singly or in combination according

soil conditions. Always allow the machine to settle to a new setting before making

further adjustments.

Recommended lubrication and maintenance instructions are included in this

handbook and if followed will help to keep the machine in a safe working condition.

Warranty

Should the machine suffer any faults or defects within the warranty period, please

contact your dealer. The warranty shall be effective only if the dealer is informed of

any such defect as soon as practicable upon discovery.

1.1

INTRODUCTION

Replacement Parts

Recommended replacement parts are designed for your machine and have the full

backing of the warranty. Only when recommended parts are used can responsibility

be considered under the terms of the warranty.

The rear of this handbook contains lists of spare parts available through your

Standen Agents. Each illustration shows a complete unit or assembly in exploded

form. Standen's policy of continual product development means that components or

even complete assemblies are redesigned from time to time. Where possible the

modifications are shown in the remarks column.

The first printing of each page in the spare parts section is identified as issue 1 at the

foot of the page. When a complete unit or assembly has been redesigned the

appropriate pages are revised and printed as issue 2. The revised pages are filed

behind the existing issue so that a complete modification history is gradually built up.

When using an illustration and parts list it is essential that both are of the same issue.

Always quote the full serial number of your machine when ordering spare

parts.

INTRODUCTION

1.2

Safety

The Standen Unistar 2400 has been designed to comply with current Safety

Regulations. However, as with all machinery there will be inherent dangers whilst

operating and carrying out maintenance on the machine. The following list of

precautions should therefore be brought to the attention of all persons operating and

working on the machine. The list is not exhaustive. All machinery is potentially

dangerous and great care must be exercised by the operators at all times. Standen

Engineering Limited will not accept liability for damage or injury caused by their

products except when such liability is specifically imposed by English statute.

The machine must never be operated by untrained personnel or

children.

Always check that the machine has been correctly mounted to the

tractor before setting off on operations and the stabilizers are correctly

set.

Never set machinery in motion before ensuring that everyone in the

vicinity is aware of your intentions.

Never allow children or animals in the vicinity where machines are

working and never allow anyone to ride on the machine.

In dry, dusty conditions it is prudent to use a tractor with an enclosed

cab.

Never attempt to fit drive chains or drive belts to the machine while the

drive sprockets or pulleys are in motion.

Normal safe working procedures should be adopted at all times.

Reduce speed when transporting the machine on sloping ground.

Do not work on ground where there is a possibility of overturning or

across steep slopes.

The working area should be kept clear and free of obstructions at all

times. Be alert for hidden obstructions. Should the machine hit an

obstruction, stop and check for damage before proceeding.

Wear substantial or proper safety footwear. Avoid loose clothing near

moving parts. Wear gloves when handling the implement or parts with

sharp edges.

Before carrying out any work on the machine, lower the machine to the

ground, switch off the tractor engine, apply the handbrake, remove the

ignition key and disconnect the PTO shaft.

1.3

SAFETY PRECAUTIONS

The operator must not leave the tractor seat until the machine has been

lowered to the ground, the tractor engine switched off, the handbrake

applied and the ignition key removed.

Never reverse or turn unless the machine is in the raised position.

All guards, covers, warning transfers and safety devices must be

correctly fitted and operable at all times.

Inspect the machine on a regular basis and replace damaged or worn

parts as necessary.

Inspect the machine for damage after use. Rectify as required.

Never operate the machine in a state of disrepair.

Only transport the machine at a speed suitable to the prevailing

conditions. Be aware of the weight and overall length of the machine at

all times.

Before working on the machine, all free moving parts should be locked

to prevent them moving.

Regularly lubricate the machine as per the operator’s handbook and

check the tightness of all nuts and bolts, particularly those securing the

rotor blades/tines.

Always use mechanical or additional help when lifting heavy parts.

Regularly check hydraulic hoses for chafing or damage and replace as

necessary.

Care must be taken when carrying out any work on the hydraulic

system. Even when stopped and disconnected from the tractor, residual

pressure will exist within the hydraulic system. Therefore, before

commencing any work on the hydraulics ensure that the system is free

of residual pressure by carrying out the ‘pressure dump’ procedure

outlined within this handbook.

Before transporting the machine on a public road, set the hydraulic

levelling to its lowest position, fully raise the shares, lock the cross

conveyor into the transport position, set the drawbar and steering to the

straight-ahead position and switch off the control box to avoid

inadvertently operating any machine services. Finally, ensure road

lights are clean and in good working order.

Safety is the responsibility of the persons working with this

machine. Think "safety" at all times. Read and remember the

contents of this handbook.

SAFETY PRECAUTIONS

1.4

1.5

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

1.6

Tractor Suitability

The power requirement for the Unistar 2400 is 200 bhp minimum.

The tractor must be of a suitable size to lift the implement safely. This

may entail the fitting of front weights to counterbalance the machine

when in the raised position.

Tractor Wheel Settings

Both front and rear tractor wheels must be set to run down the centre of the

wheelings and must span the bed being lifted. Consult your tractor handbook for the

correct procedure for setting the tractor wheels.

When carrying out wheel adjustments, always place the jack on firm

ground under a solid part of the tractor. Before removing a wheel,

place a stout support under the tractor frame in case the jack should

become dislodged.

Drawbar

The drawbar is designed to be attached to the tractor pick-up hitch.

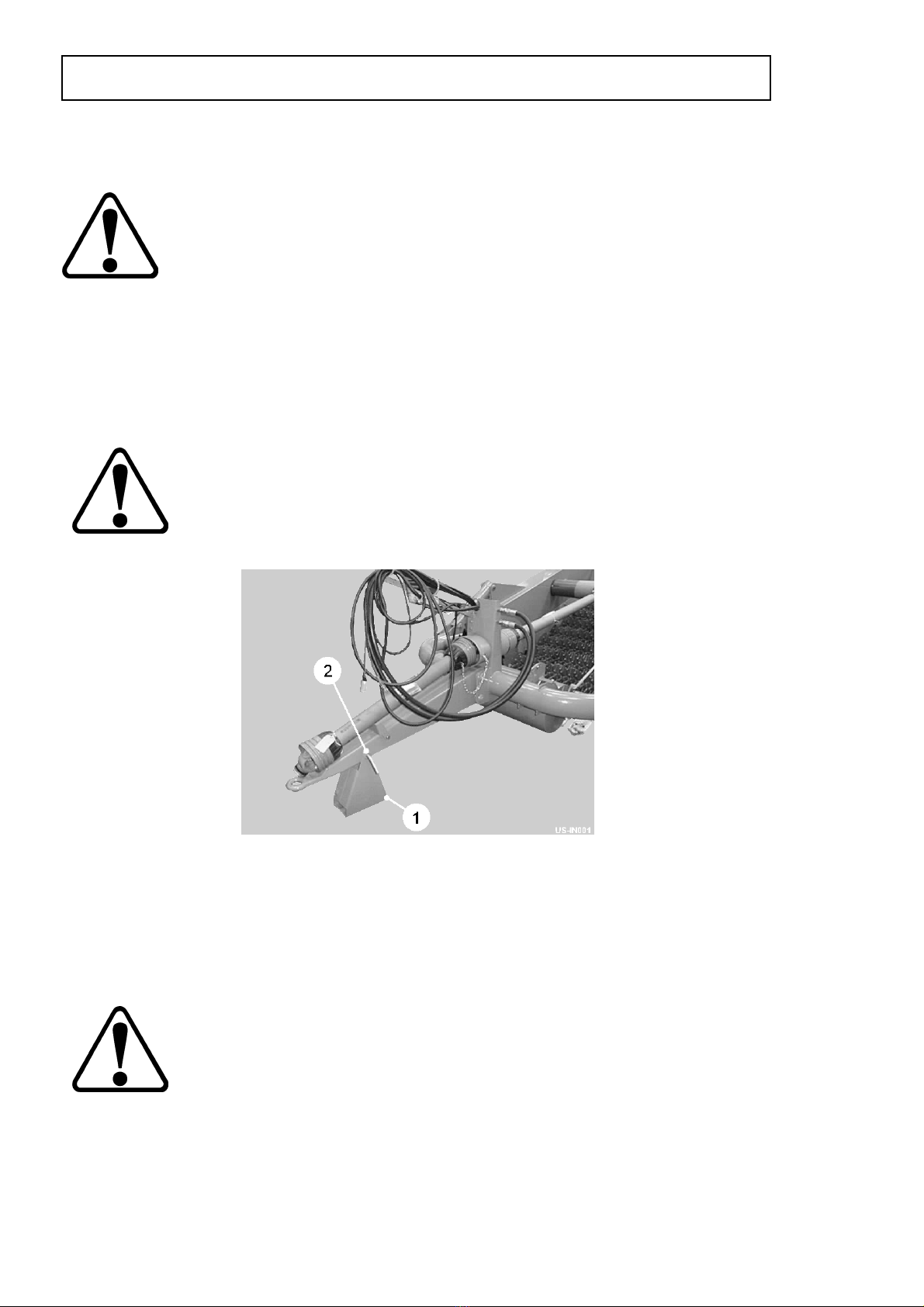

The jack stand (item 1, fig 1) is provided so that the machine is held at a suitable

height for safe coupling to the tractor.

Always ensure the stand is positioned on firm, level ground to avoid the

machine sinking or sliding whilst stood. Both wheels should be

chocked front and rear before removing from tractor.

Do not store the stand separately from the machine. You never know

when it will be needed.

When the machine has been securely attached to the tractor, the jack stand can be

folded back into the stored position by removing the anchor pin (item 2, fig 1),

rotating the stand and then securing it with the anchor pin.

1.7

INSTALLATION

Fig 1

Hydraulically Damped Drawbar (optional)

The hydraulically damped drawbar is fitted to protect the machine when operating in

soil conditions where buried obstructions may be encountered. The system consists

of a hydraulic cylinder mounted within the drawbar pressurised by an accumulator

(item 1, fig 2). The design allows the drawbar to extend by 200mm. After 25mm of

movement a proximity sensor triggers the control system which simultaneously lifts

the digger on full flow, and stops the boulder box stars, vari-flow and cross conveyor

webs. After activation the machine elements have to be restarted using the control

box. The drawbar must always be pressurised before commencing work.

To set the accumulator pressure, connect the hose (item 2, fig 2) to the tractor spool

valve and open the accumulator valve (item 3, fig 2). Open the tractor spool valve

while closely watching the pressure gauge (item 4, fig 2). When the pressure reaches

65 bar immediately close the spool valve and then close the accumulator valve. If

necessary, reduce the pressure slightly using the accumulator valve. The drawbar is

now pressurised and ready for operation. If in work, due to differing soil conditions,

the initial setting of 65 bar is found to be too low and the drawbar is extending in

normal work, increase the pressure setting by increments of 10 bar until the drawbar

is static. DO NOT EXCEED 120 BAR. If the drawbar is still not functioning correctly

when the maximum pressure is reached, consult your Standen dealer for further

advice.

Do not carry out maintenance on the drawbar with circuit pressurised.

Stop the tractor engine and reconnect the hose to the tractor spool

valve. Open the accumulator throttle valve and operate the spool valve

to dump the hydraulic pressure within the system.

INSTALLATION

1.8

Fig 2

minimum1/2 overlap

PTO Shaft

The machine is designed to operate with the tractors 540 rpm, 6 spline, 1 3/8” PTO

output shaft.

PTO speeds greater than 540 rpm will cause damage to the system

and if exceeded may invalidate the warranty.

Fit the two halves of the PTO shaft onto their respective drive shafts on the machine

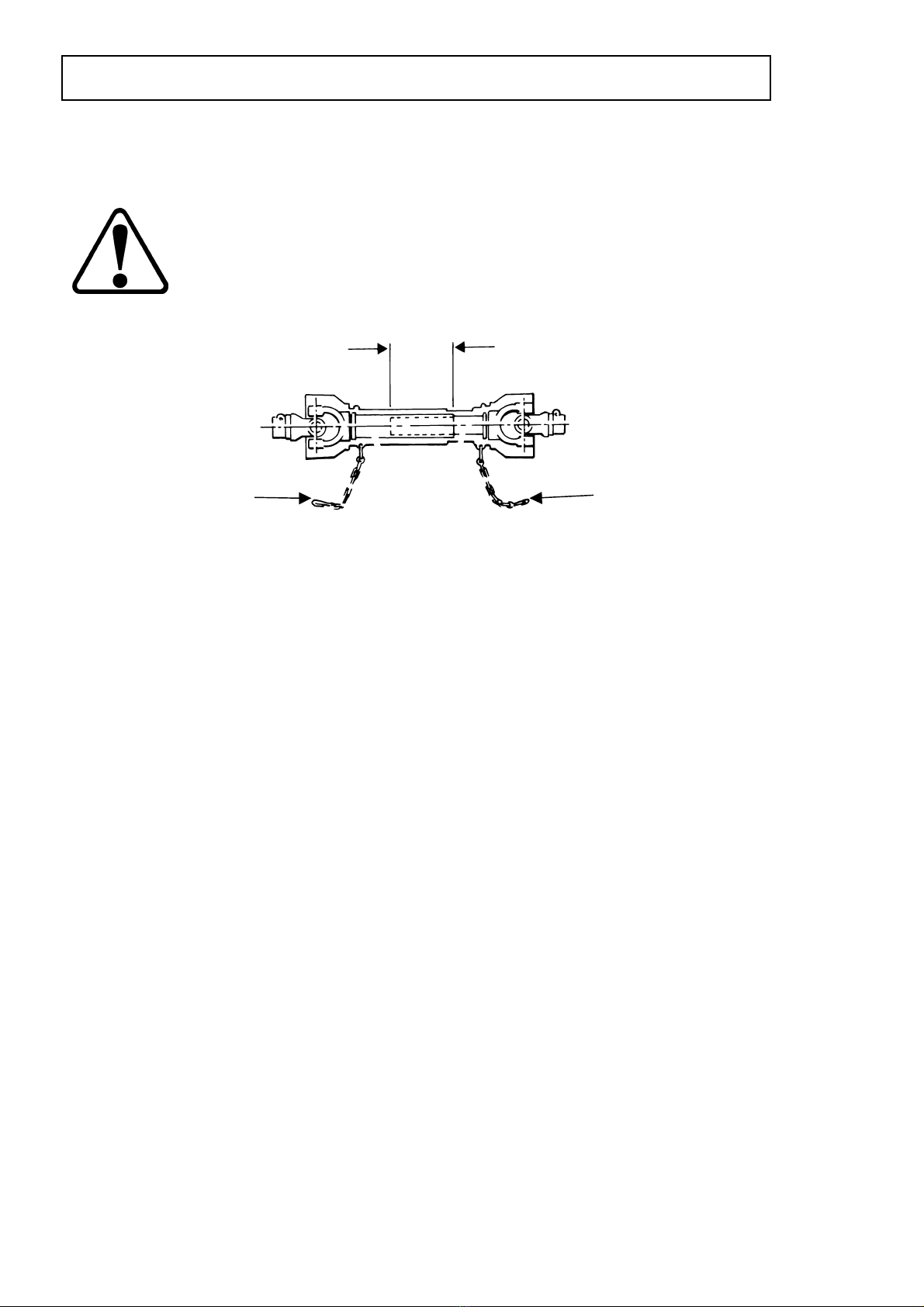

and tractor. Check the shaft length by turning the tractor fully in both directions with

the machine in its working position while attached to the tractor’s pick-up hitch.

Ensure the sliding tubes, when fully extended, have an overlap at least half the

closed length (see figure 3). Ensure that the ends of the sliding tubes when at the

shortest point are not in contact with other parts of the PTO shaft. If necessary,

shorten both tubes and guards equally to achieve end clearance at the minimum

length position.

Make sure that the drive shaft is fitted correctly and that the lock pins are engaged.

All the parts of the PTO shaft, especially the guards, must be kept in good order.

Check regularly that the guard is undamaged and fully protects the whole of the

shaft, and that both the guard and the shaft will telescope freely.

If it is possible to engage the inner and outer parts of a drive in more than two

positions circumferentially then make sure that the universal joint yokes are correctly

aligned.

Check that when in the continuous working position, the drive shaft is not at an angle

of more than 20° from the PTO centre line. The angle between the drive shaft and

the input and output shafts should be equal.

Ensure that the safety chains (item 1, fig 3) used to prevent the guards from turning,

are fixed to the tractor and implement in such a way that they will not be stretched

when the drive shaft is at maximum articulation. When disconnected from the tractor,

position the PTO shaft on the drawbar PTO rest as shown in figure 1.

1.9

INSTALLATION

1

1

Fig 3

Hydraulic Connection

The feed and return hoses from the machine must be connected to the respective

external service connections of the tractor hydraulic system. Both feed and return

hoses have labels with arrows indicating the direction of oil flow.

The tractor hydraulic system must be set to constant pumping. Consult the tractor

manufacturers handbook for details about connecting external equipment to the

hydraulic system and hydraulic pump settings.

Required oil flow from tractor system minimum 70 ltr/min

(Set to constant pump) maximum 100 ltr/min

(For flows greater than 100 ltr/min consult your officially appointed Standen dealer)

There must no restriction in this return oil. Ensure that there is a full flow return, or

even better return straight back into the tractor gearbox. Consult your tractor

handbook or dealer for further information.

Open/Closed Centre Hydraulics

Two types of hydraulic system are currently in use by tractor manufacturers, namely

OPEN CENTRE or CLOSED CENTRE configurations. Consult the tractor

manufacturers handbook or dealer for further information.

The main hydraulic valve bank, situated behind the rear LH guard of the machine,

incorporates an adjustable screw (item 1, fig 4) which enables easy changing from

closed to open centre and vice versa. For closed centre configuration tractors, turn

the screw clockwise until fully closed. For open centre, turn the screw anticlockwise

until fully out.

INSTALLATION

1.10

Fig 4

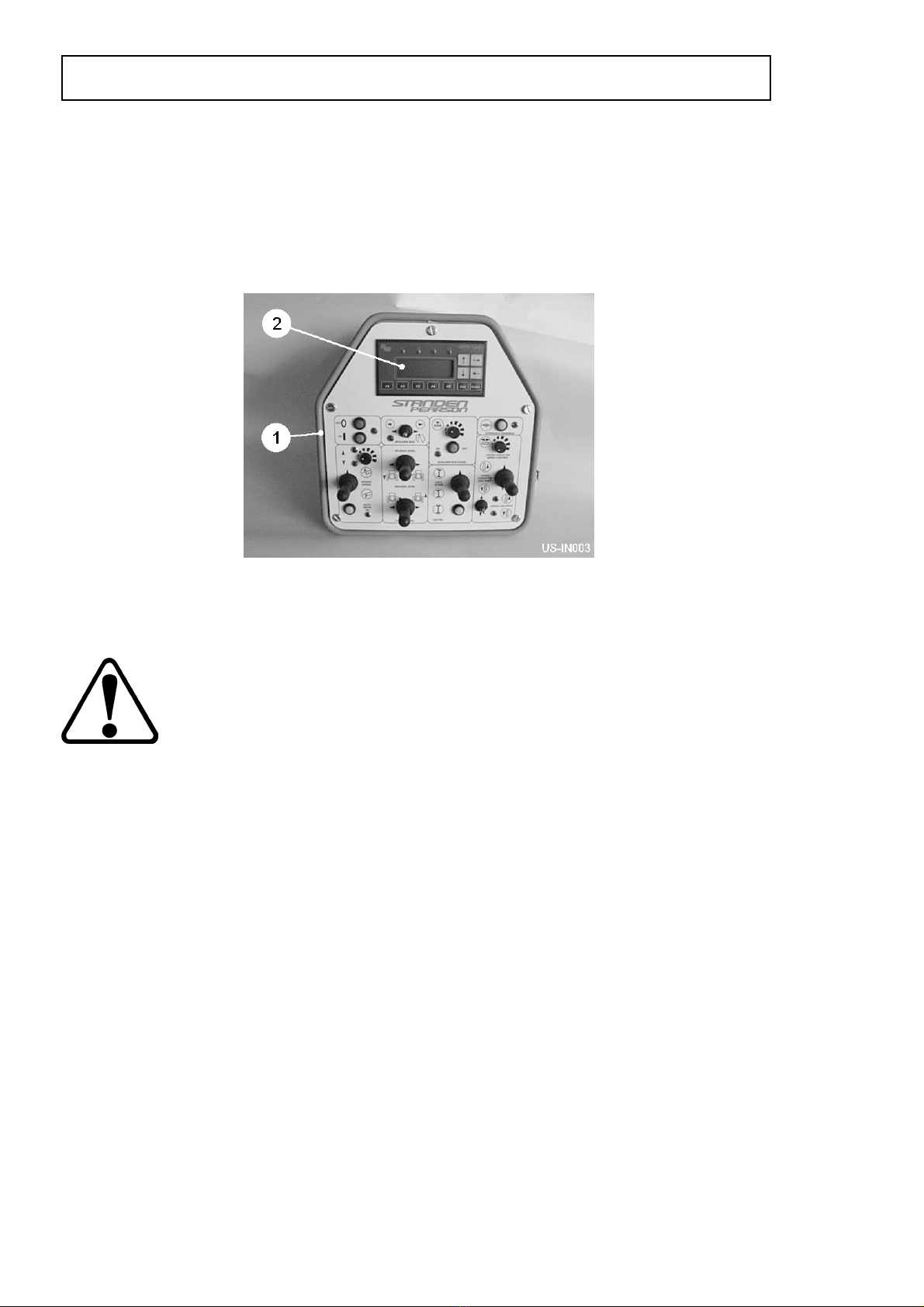

Electrical Control System

Control for the major functions of the Standen Unistar 2400 are provided

electronically by the switches mounted on the in-cab control box (item 1, fig 5)

switching the valves on the machine via a CAN-Bus control system. The functions

can be monitored from the control box display screen (item 2, fig 5). Setting and

monitoring can be carried out by following the instructions in the CAN-Bus operating

instructions.

Ensure that all plug and socket connections are clean and coupling pins undamaged

before connection, and that they are securely locked together before the power is

switched on. The function of each control box switch is explained below.

Do not leave or store the control box outside in the open and always

disconnect the control box from the tractor electrical supply when not in

use, so avoiding the possibility of draining the battery.

Hydraulic Drawbar (optional)

The hydraulic drawbar push button activates/deactivates the hydraulically damped

drawbar system. The LED is illuminated when the system is switched on.

Digger Share Raise/Lower

The 3 position spring toggle switch manually raises/lowers the digger assembly

increasing/decreasing the depth of the shares below the soil. Releasing the switch to

the central position leaves the share depth at the present setting. Setting the switch

to the locked lower position enables the depth rams to free float.

Auto-Depth

With the digger share switch set in the lower position, the push button

activates/deactivates the digger share auto-depth system. The share depth is

automatically adjusted by the movement of the diablo roller. The LED is illuminated

when the system is switched on. Operating the manual digger share raise/lower

switch will override the auto-depth system. The auto-depth indicator lights show

when the depth control sensors are operating. In work the digging depth can be

varied using the digger share dial. Turn the dial clockwise to increase the share

depth and anticlockwise to decrease the depth.

1.11

OPERATION

Fig 5

Axle Steer

The axle steer switch manually steers the machine wheels to left/right.

The auto-centre button when pressed operates the self-centring circuit to

automatically set the wheels to the straight-ahead position.

Axle Level

The two axle level switches operate the LH and RH levelling rams (item 1, fig 6).

Moving the switch to left will lower the LH side machine. Moving the switch to the

right will raise the machine.

Cross Conveyor Side Shift

The 3 position spring toggle switch operates the side shift ram which moves the

cross conveyor to discharge to LH or RH position.

Cross Conveyor Drive

The switch marked ‘cross conveyor drive’ starts/stops the cross conveyor web to

discharge to the LH or RH side of the machine. With the switch in the centre position

the discharge web is stopped. Move the switch up to discharge to the RH side of the

machine, or down to discharge to the LH side. The corresponding LED will illuminate.

The dial marked ‘cross conveyor speed control’ sets the speed of the discharge web.

Turn the dial clockwise to increase or anticlockwise to decrease the speed.

Boulder Box Stars (optional)

The push button starts/stops the boulder box stars. The LED is illuminated when the

unit is running. The dial increases/decreases the speed of the stars. Turning the dial

clockwise will increase the speed, while turning the dial anticlockwise will reduce the

speed. The switch opens/closes the boulder box for emptying. To empty the boulder

box move the switch to the right. The LED will illuminate when the box is open.

OPERATION

1.12

Wheel Settings

The machine wheels must be set for work in a specific bed width. The wheels should

be set to match the tractor wheels.

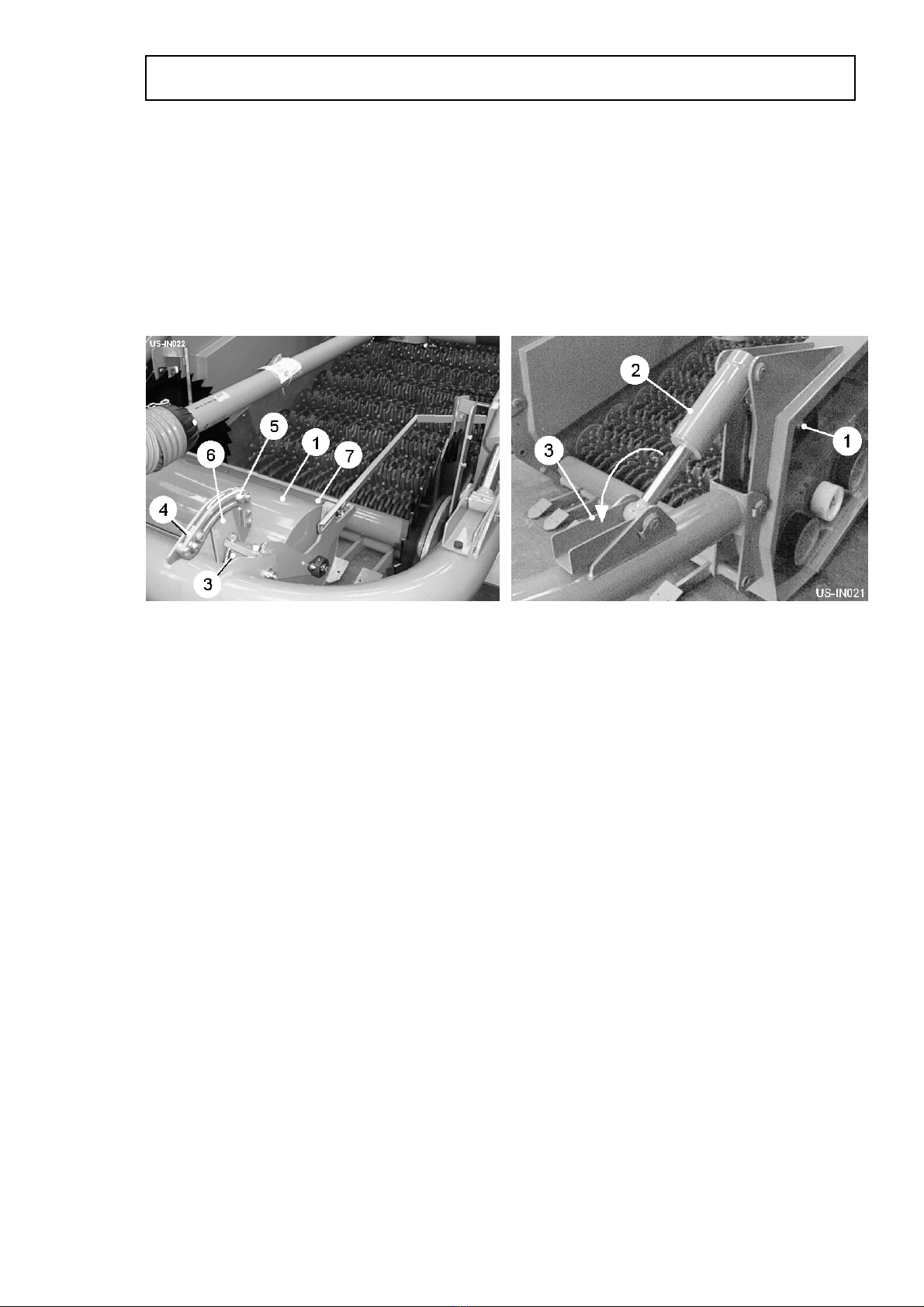

Each wheel is carried by a wheel leg pillar (item 2, fig 6) The pillars have a top and

bottom flange plate containing a series of fixing holes. Moving the pillars in or out

adjusts the wheel centres to suit the selected bed width. Both wheel legs must be set

to the same hole positions so that the wheels remain symmetrical about the

centreline of the machine. Lifting equipment must be used when setting the wheels.

Before commencing axle adjustment, ensure adequate jacks, axle

stands of minimum 2500 kg capacity, wheel chocks and suitable lifting

equipment are available.

It is important that the machine is correctly fitted to the tractor and that

the tractor handbrake is applied whilst axle adjustments are made.

Place chocks at the front and rear of the opposite side wheel to the one being

adjusted. Jack up the machine and place an axle stands under the chassis and lower

the jack to allow the axle stands to take the weight of the machine.

Release the track rod locking bolt (item 1, fig 7) and remove the flange plate

mounting bolts (item 3, fig 6 & item 2, fig 7). Using lifting equipment, carefully slide

the leg pillar to the required position. Refit the mounting bolts (item 3, fig 6 & item 2,

fig 7) through the relevant hole in the flange plates. Repeat the procedure for the

opposite wheel. Finally, set the track rod to the correct length and secure using the

locking bolt. Ensure all nuts and bolts are fully tightened after adjustments have been

completed.

1.13

OPERATION

Fig 6 Fig 7

Automatic Depth Control

The machine is fitted with an automatic depth control system which ensures an even

depth of soil in the finished bed. The depth roller (item 1, fig 8) runs on top of the

preformed bed following the contours. The depth roller is linked to a depth sensor

(item 1, fig 9) and via the hydraulic valve bank actuates the depth rams (item 2, fig 9).

A depth indicator is fitted to the RH depth ram giving the operator a visual indication

of the action of the sensing system. The ram stop brackets (item 3, fig 9) must be set

in the position shown before commencing work.

The depth roller frame pivots on rubber torsion mountings (item 3, fig 8). By adjusting

these mountings it is possible to adjust the amount of pressure the roller exerts on

the soil. The pressure setting needs to be made with the machine in work so that the

relative working position of the roller and shares is correct.

1. Release the front and rear quadrant stops (item 4 & 5, fig 8) on both sides of

the roller unit.

2. Lower the machine into work until the shares are at the required digging

depth.

3. Slide the front stops (item 4, fig 8) up against front edge of the quadrant arms

(item 6, fig 8) and lightly secure.

4. Raise the machine slightly, causing the quadrant arms (item 6, fig 8) to rotate

backwards away from the front stops (item 4, fig 8), and then reposition the

front stops up against the quadrant arms and secure fully. The higher the

machine is raised prior to repositioning the front stops, the greater spring

pressure will be.

5. Lower the machine back into work and set the rear stops (item 5, fig 8)

approximately 15mm away from the rear of the quadrant arms (item 6, fig 8).

This gap allows the depth roller to drop slightly, maintaining digging depth,

when the tractor rides out of the bed onto the headland.

OPERATION

1.14

Fig 8 Fig 9

The scrapers (item 7, fig 8) should be set as close to the roller as possible without

fouling it.

Before transporting the machine on the road, reset the ram stop brackets

(item 3, fig 9).

Setting the Automatic Depth Control

1. Set the machine into work and adjust the digging depth using the ‘Digger

Share Raise/Lower’ switch on the control box.

2. Note the reading on the depth indicator.

3. Lift the machine out of work and then switch on the auto-depth system. The

LED will illuminate when the system is activated.

4. Turn the depth control dial until the depth indicator aligns with the noted

reading.

5. Note the reading on the control box display highlighted ‘AUTO DEPTH

SENSOR ANALOG’. This figure together with the reading on the depth

indicator will represent the initial depth setting. To increase the depth turn the

depth control dial clockwise. To decrease the depth turn the dial anticlockwise.

Note: For every 1mm deviated from the initial reading on the display, the

share depth will alter by 6mm.

The default screen on the control box display is the depth control and steering

indicator display.

1.15

OPERATION

Table of contents

Other Standen Water Filtration System manuals

Popular Water Filtration System manuals by other brands

EINHELL

EINHELL BT-VC500 Original operating instructions

Global Industrial

Global Industrial 641753 manual

Clean Water Systems

Clean Water Systems Fleck 9100 Installation & start?up guide

Siemens

Siemens FDCL221 manual

Miganeo

Miganeo 040385GP user manual

Beko

Beko CLEARPOINT HP100S040 Instructions for installation and operation

Pure Blue H20

Pure Blue H20 PB-TLRO4H50T instruction manual

Hydro

Hydro Up-Flo Operation and maintenance manual

Filtration Group

Filtration Group Pi 211 manual

Super

Super SK Operation manual

Clean Water Systems

Clean Water Systems 7500 Series Installation & start?up guide

Du Pont

Du Pont WFQTR13000 Series installation instructions