Standfast TRAM TR-6-ST Series User manual

SEC

STAL

SEC

STAL

SEC

STAL

COMMITMENT

SECURITY

SECURITY

ANCHO

STALWARTNESS DURABLE

SUPPORT

STAY

REINFORCE

STALWARTNE

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMM

SECURITY

SE

RELIA

FAST

GRIP

AN

ANCHOR

STALWARTNESS

ST

SUPPO

STAY

R

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHO

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNE

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMM

SECURITY

SE

RELIA

FAST

GRIP

AN

ANCHOR

STALWARTNESS

ST

SUPPO

STAY

R

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHO

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNE

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMM

SECURITY

SE

RELIA

FAST

GRIP

AN

ANCHOR

STALWARTNESS

ST

SUPPO

STAY

R

RELIABLE

FASTENER

GRIP

ANCHOR

STRENGTH

POWER

STAY

SECURI

STALWARTNES

SU

SECURI

G

STALWARTNES

SU

SECURI

G

STALWARTNES

SU

G

COMMITMENT

CURITY

SECURITY

ANCHOR

WARTNESS DURABLE

SUPPORT

STAY

REINFORCE

STALWARTNESS

COMMITMENT

RITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

SS DURABLE

STRENGTH

POWER

UPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMMITMENT

CURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

WARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMMITMENT

RITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

SS DURABLE

STRENGTH

POWER

UPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMMITMENT

CURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

WARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMMITMENT

RITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

SS DURABLE

STRENGTH

POWER

UPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

RELIABLE

FASTENER

GRIP

ANCHOR

STRENGTH

POWER

STAY

COMMITMENT

SECURITY

SECURITY

RELIABLE

ANCHOR

STALWARTNESS DURABLE

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

COMMITMENT

SECURITY

SECURITY

RELIABLE

FASTENER

GRIP

ANCHOR

ANCHOR

STALWARTNESS DURABLE

STRENGTH

POWER

SUPPORT

STAY

REINFORCE

STAY

STALWARTNESS

FASTENER

GRIP

ANCHOR

STRENGTH

POWER

STAY

NT

TY

ER

OR

BLE

H

CE

TAY

NESS

NT

TY

ER

OR

BLE

H

CE

TAY

NESS

NT

TY

ER

OR

BLE

H

CE

TAY

NESS

MITMENT

CURITY

BLE

CHOR

DURABLE

RT

EINFORCE

STAY

TALWARTNESS

MITMENT

CURITY

BLE

TENER

CHOR

DURABLE

RENGTH

POWER

RT

EINFORCE

STAY

TALWARTNESS

MITMENT

CURITY

BLE

TENER

CHOR

DURABLE

RENGTH

POWER

RT

EINFORCE

STAY

TALWARTNESS

TENER

RENGTH

POWER

STAY

traMTM safety system

Technical manual

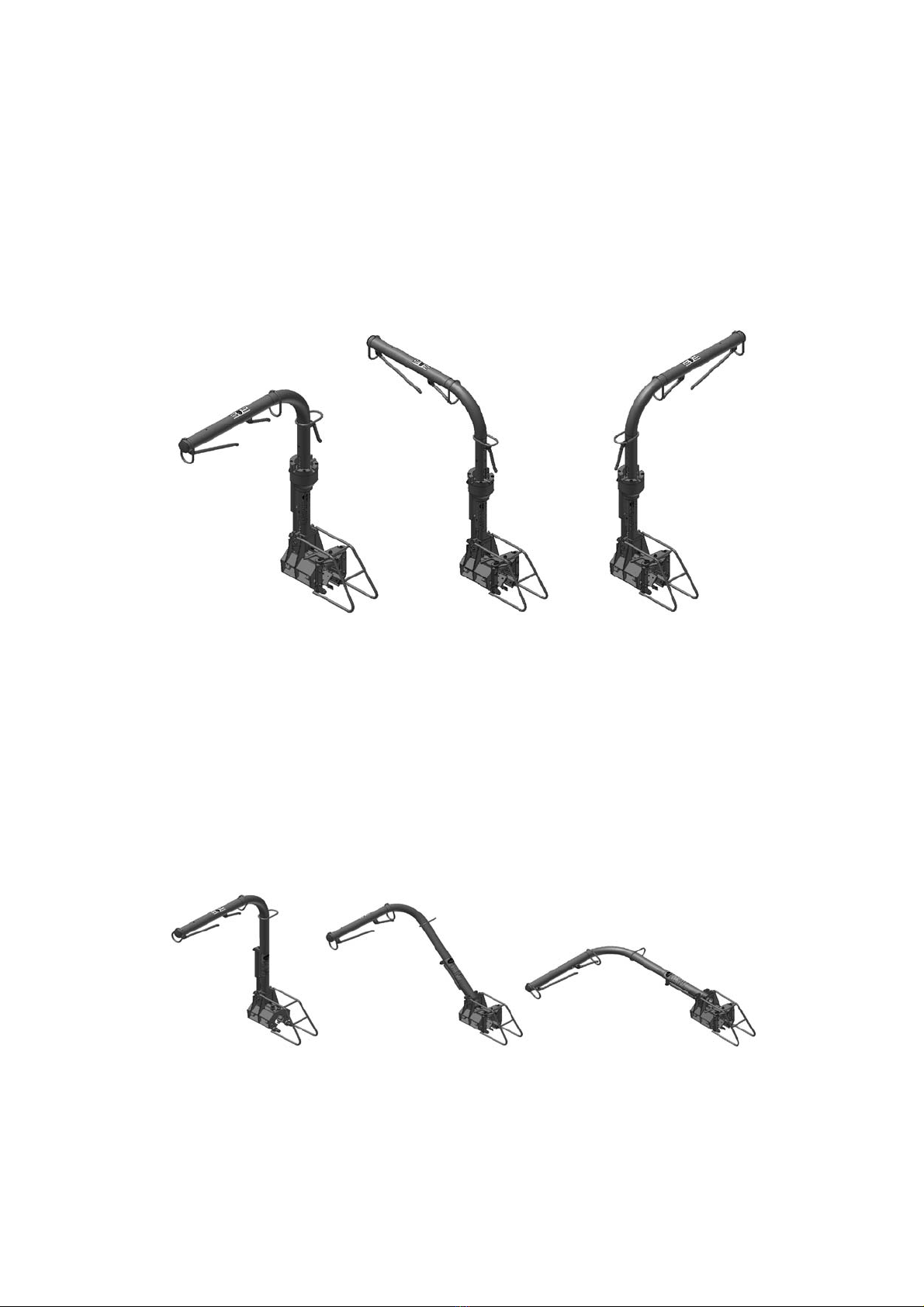

TR-6-ST Series – Standard TRAM

TR-6-RAT Series – Rotating Arm TRAM

Standfast Corporation Pty Ltd

ABN 49 108 256 917

PO Box 1224 Milton BC

Queensland 4064 Australia

Telephone +61 7 3369 9800

Facsimile +61 7 3369 9844

Email [email protected]

Website www.standfastcorp.com

DISCLAIMER AND COPYRIGHT NOTICE

1. The purpose of this Manual is to provide information about the Standfast TRAM Safety

System. It is not exhaustive in its coverage of rights or obligations nor is it legal advice.

2. This Manual has no legal status or legal effect whatsoever. Any reference to systems to

prevent falls is for guidance only. Readers of this Manual should seek appropriate guidance

from the appropriate Regulatory Authority as well as obtain appropriate legal advice in respect

of the application of the legislation and regulation in respect of the safety system.

3. This Manual may be affected by changes to Legislation or Regulation. Standfast

Enterprises Pty Ltd and Standfast Corporation Pty Ltd (Standfast) accepts no responsibility

for the accuracy, completeness or currency of the material included in this Manual.

4. Users of this Manual are encouraged to obtain professional advice on the relevant

Legislation and Regulations and to exercise their own skill and care in relation to any

material contained in this Manual.

5. Standfast disclaims any and all liability or responsibility for any loss or damages arising

out any use, or reliance on, this Manual.

6. This Manual is copyright. You may use and reproduce this material in an unaltered form

only for your personal non-commercial use or non-commercial use within your organisation.

Apart from any use permitted under the Copyright Act 1968, all other rights are reser ved.

Requests for other types of use should be directed to Standfast.

7. TRAM is a trademark of Standfast Enterprises Pty Ltd.

2TRAM SAFETY SYSTEM TECHNICAL MANUAL

1 READING THE DOCUMENTATION

1.1 LITERATURE INFORMATION

This manual contains safety information and instructions for operation and maintenance of

the Standfast TRAM System. This Manual should be stored in an area where it is accessible

to those responsible for maintenance of the equipment.

The information, specifications, and illustrations in this publication are provided on the basis of

information available at the time of writing. Continued improvement and advancement of product

design may have caused changes to your TRAM System, which are not included in this Manual.

Some photographs or illustrations in this Manual show details or attachments that may be

different from your TRAM system:

• Subassemblies, guards or covers may have been removed for illustrative purposes.

• The specifications, torques, pressures, measurements, adjustments, illustrations, and

other items can change at any time.

Important! These changes can affect the ser vice given to the product.

Whenever a question arises regarding your TRAM System or this Manual, and before starting

any job, please consult your Standfast TRAM dealer to obtain the complete and most current

information available.

1.2 ALERTS USED IN THIS MANUAL

Please read the list below of alerts used in this manual. These alerts are used to indicate

important instructions. Be sure to obey these instructions.

TRAM SAFETY SYSTEM TECHNICAL MANUAL 3

ALERT MEANING

Indicates a warning concerning an operation or hazard that

may lead to death or injury to persons if not per formed

correctly or with due care. Always pay attention to these warnings.

Indicates a restriction or important information.

Important! Be certain to read these items to avoid improper

use or damage to the equipment.

Note! Indicates additional information or explanation.

Be certain to read these items. WEIGHT

2 IMPORTANT SAFETY INFORMATION

2.1 GENERAL

The purpose of the TRAM Safety System is to protect the user from a fall from height. If the

system is not properly used, maintained or repaired, it may no longer protect against a fall

from height.

Failure to follow the instructions or heed the warnings contained in this manual could result

in injury or death. Improper operation, maintenance or repair of this product can be dangerous

and could result in injury or death.

All inspection, maintenance, servicing and repair work on the TRAM System shall be

carried out by a Competent Person.

A Competent Person is defined as a person:

• who is knowledgeable of recommendations and instructions on the TRAM System

issued by Standfast (including information contained in this manual)

• who is authorised* by Standfast to carry out inspection, maintenance, servicing and

repair work,

• who has the necessary training, skills and tools to per form the work properly,

• who is capable of identifying existing and predictable defects and hazards in any

component of the TRAM safety system and related equipment used in the work

environment,

• who is authorised to take prompt corrective action to eliminate or control hazards,

and has the skills and resources to do so,

• who is familiar with relevant guidelines and national and international safety

regulations.

*Your Standfast TRAM Dealer is authorised to carry out all inspection, maintenance,

servicing and repair work on the TRAM System. Your Standfast TRAM Dealer may also

be contacted to authorise a Competent Person.

All work must comply with the safety regulations of the jurisdiction in which the TRAM System

is installed and operated, including industry Codes of Practice and Standards.

No one should make any alterations or additions to the equipment. Any repair shall only be

carried out in accordance with authorized procedures.

The TRAM shall not be used outside its limitations as described in this Manual, or for any

purpose other than that for which it is intended.

Most accidents involving product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing

potentially hazardous situations before an accident occurs.

Standfast Corporation cannot anticipate every possible circumstance that might involve a

potential hazard. The warnings in this publication and on the product are therefore not all

inclusive. If a tool, procedure, work method or operating technique not specifically

recommended by Standfast Corporation is used, you must satisfy yourself that it is safe for

you and others. You should also ensure that the product will not be damaged or made unsafe

by the operation, lubrication, maintenance or repair procedures you choose.

4TRAM SAFETY SYSTEM TECHNICAL MANUAL

2.2 SAFETY SIGNS AND LABELS

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded the product may not protect you or others from bodily injury or death.

The TRAM system is permanently marked or labelled to indicate its purpose, correct use,

limitations and other relevant information aimed at reducing the incidence or misuse or

misfitting of the equipment.

Make sure that all safety signs can be read. Clean or replace these if illegible. When cleaning the

labels use a cloth, water and soap. Do not use solvents, gasoline, etc to clean safety signs.

Contact your Standfast TRAM Dealer to organise replacement signs and labels.

2.3 SAFE WORKING AT HEIGHTS

The operation and maintenance of the TRAM must comply with the safety Legislation and

Regulations of the jurisdiction in which it is used.

Users of the TRAM System must be properly trained and competent. Further enquiries

regarding training materials and courses should be directed to your Standfast TRAM Dealer or

The TRAM restraint belt must only be used when the TRAM system is used as a total restraint

system. The TRAM restraint belt must not be used if there is a risk of free fall.

Total restraint means that there is no risk of fall as the user is prevented from reaching a fall

edge. This is achieved through combination of anchor point and lanyard length.

2.4 FALL ARREST

It is essential for safety that if the TRAM System is used as a fall-arrest system a full body

harness and energy absorber should be used.

The TRAM Belt described in this Manual is for use in total restraint and must NOT be used

in fall arrest.

In fall arrest applications, the TRAM System should always be positioned, and the work carried

out in such a way, as to minimise both the potential for falls and potential fall distance.

When the TRAM system is used as a fall-arrest system consideration should be given as to

how any necessary rescue could be safely achieved.

The operator should ensure that when the TRAM is used as a fall-arrest system that the

distance required or necessary to arrest the fall of a falling worker does not exceed the

distance available on site.

If the TRAM has been used to arrest a fall it should be not used again until confirmed in writing

by a competent person that it is acceptable to do so.

TRAM SAFETY SYSTEM TECHNICAL MANUAL 5

2.5 PRE-USE CHECK

Users must carry out a Pre-Use Check of the equipment, as per the instructions in this

Manual, to ensure that it is in a serviceable condition and operates correctly before use.

It is essential for safety that equipment is withdrawn from use immediately should any doubt

arise about its condition for safe use.

2.6 SERVICING

Servicing should be carried out at regular intervals as described in this Manual.

Services should only be conducted by a Competent Person and strictly in accordance with

servicing procedures.

Equipment Records of Periodic and Overhaul Services must be maintained and be available

to the user.

2.7 INSTALLATION

Anyone installing the TRAM system must read, understand and strictly adhere to the

instructions and safety information in this manual and any Installation Instructions for the

TRAM Safety system.

The installer must verify the adequacy of anchor point(s) either by calculation or by carrying

out a test in a sample of the material in compliance with the specifications of the appropriate

Standards.

2.8 MAINTENANCE & REPAIR

Attach a DO NOT OPERATE or similar warning tag to start switch or controls before per forming

maintenance or repairing the TRAM, if it is a vehicular installation. When appropriate, attach

tags at the engine and at each user’s position and disconnect starting controls. Ensure any

protective locks, controls or inhibitors are in the applied position before commencing work.

Some installations will require the use of fall protection equipment during removal and

installation of the TRAM system. A service platform or walkway is recommended.

It is the responsibility of the owner to ensure that access is achieved in accordance with local

regulations and standards.

Wear a hard hat, protective glasses, hearing protection, gloves and other protective equipment

as required by job conditions.

Do not wear loose clothing or jewellery that can catch on controls or other parts of the TRAM.

Use caution when removing springs. Gradually loosen (do not remove) the last bolts or nuts

located at opposite ends of any spring energy device, until all elastic energy is dissipated,

before completely removing the fasteners.

Do not carry out hot work on the TRAM device without first consulting your Standfast TRAM

Dealer. Your TRAM contains plastic components that may not function correctly in the event

that hot work is carried out on the TRAM.

6TRAM SAFETY SYSTEM TECHNICAL MANUAL

Compressed air can cause personal injury. When using compressed air for cleaning, wear a

protective face shield, protective clothing and protective shoes. The maximum air pressure

must be below 200 kPa (30 psi) for cleaning purposes.

Wear eye protection at all times when cleaning the TRAM system with hot and/or pressurised

water. Pressurised water could cause debris and/or hot water to be blown at the worker and

result in personal injury.

Escaping fluid under pressure, even a pin-hole size leak, can penetrate body tissue, causing

serious injury or possible death. It fluid is injected into your skin, it must be treated by a doctor

familiar with this type of injury immediately.

The TRAM System and replacement parts (brake pads) shipped from the factory are

asbestos free.

Support equipment and attachments correctly when working beneath them.

Do not allow unauthorized personnel on or around the TRAM when it is being serviced.

Do not attempt repairs you do not understand.

TRAM SAFETY SYSTEM TECHNICAL MANUAL 7

3 CONTENTS

1 Reading the documentation 3

1.1 Literature Information 3

1.2 Alerts used in this Manual 3

2 Important Safety Information 4

2.1 General 4

2.2 Safety Signs and Labels 5

2.3 Safe Working at Heights 5

2.4 Fall Arrest 5

2.5 Pre-Use Check 6

2.6 Servicing 6

2.7 Installation 6

2.8 Maintenance & Repair 6

3 Contents 8

4 Introduction 10

4.1 TRAM System Description 10

4.2 Safety 11

4.3 Compliance to Workplace Safety Laws 11

4.4 Customer Service 11

5 Description of Equipment 12

5.1 Features & Controls 12

5.2 TRAM Device Identification Plate 15

5.3 TRAM Belt Label 16

5.4 TRAM Installation Plate 17

6 Operation 18

6.1 General Operation 18

6.2 Operating the Rotary Joint (TR-6-RAT Series only) 22

6.3 Operating the Brake Override 22

7 Inspection & Maintenance 23

7.1 Inspection & Maintenance Activities & Schedule 23

7.2 Maintenance Records 25

8 TRAM Cleaning Procedures 26

8.1 TRAM Belt Cleaning Procedure 26

8.2 TRAM Device Cleaning Procedure 26

8.3 TRAM Installation Cleaning Procedure 27

9 Servicing Instructions 28

9.1 Fastener Torque Settings 29

9.2 Threadlocking Adhesive 29

9.3 Servicing the TRAM Belt 29

9.3.1 Periodic Service – TRAM Belt 30

9.3.2 Overhaul Service – TRAM Belt 31

8TRAM SAFETY SYSTEM TECHNICAL MANUAL

9.4 Servicing the TRAM Arm 31

9.4.1 Periodic Service – TRAM Arm 31

9.4.2 Overhaul Service – TRAM Arm 33

9.4.3 Latch Pin Adjustment Procedure 35

9.5 Servicing the TRAM Trolley 39

9.5.1 Periodic Service – TRAM Trolley 39

9.5.2 Overhaul Service – TRAM Trolley 41

9.5.3 ‘Play’ in the TRAM Arm 41

9.5.4 Procedure: Adjustment of the TRAM Wheel Set 41

9.5.4.1 Adjustment of Wheel position 43

9.5.5 Procedure: Replacement of the TRAM Wheel Set 43

9.6 Servicing the TRAM Brake System 44

9.6.1 Periodic Service – TRAM Brake System 46

9.6.2 Overhaul Service – TRAM Brake System 47

9.6.3 Brake Adjustment Procedure 48

9.6.3.1 TYPE I Brake System Adjustment 49

9.6.3.2 TYPE II Brake System Adjustment 49

9.6.4 Procedure: Replacement of the TYPE I Brake Cable

with the TYPE II Brake Cable 50

9.6.5 Procedure: To Replace the TYPE II Brake Cable 57

9.7 Servicing the TRAM Installation 60

9.7.1 Periodic Service – TRAM Installation 60

9.7.2 Overhaul Service – TRAM Installation 61

10 Repairs to the TRAM System 62

10.1 Damage to the TRAM System 62

10.2 The Repair Process 62

10.3 Verification of Repairs 62

11 Replacement & Spare Parts 63

11.1 Ordering Parts 63

11.2 Spare Parts List 63

12 Recertification of the TRAM System 64

13 Guidelines for Installation of the TRAM System 65

14 Specifications 66

Appendix A TRAM Pre-Use Check Procedure 67

Appendix B TRAM Service Toolbox List 68

Appendix C Equipment Record 69

TRAM SAFETY SYSTEM TECHNICAL MANUAL 9

4 INTRODUCTION

4.1 TRAM SYSTEM DESCRIPTION

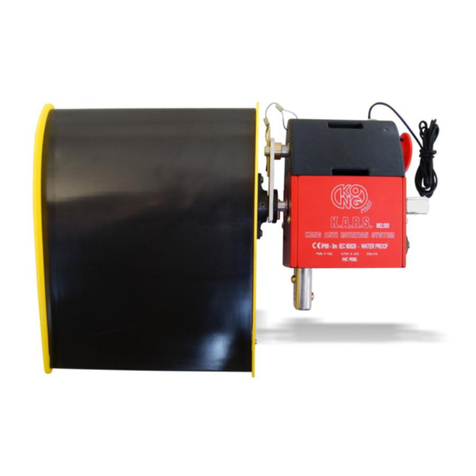

The TRAM Safety System described in this publication is a total restraint height safety system.

It is designed for various industrial, mining, defence, transport and domestic height safety

applications to provide the user with an ideal system of mobility, stability and restraint.

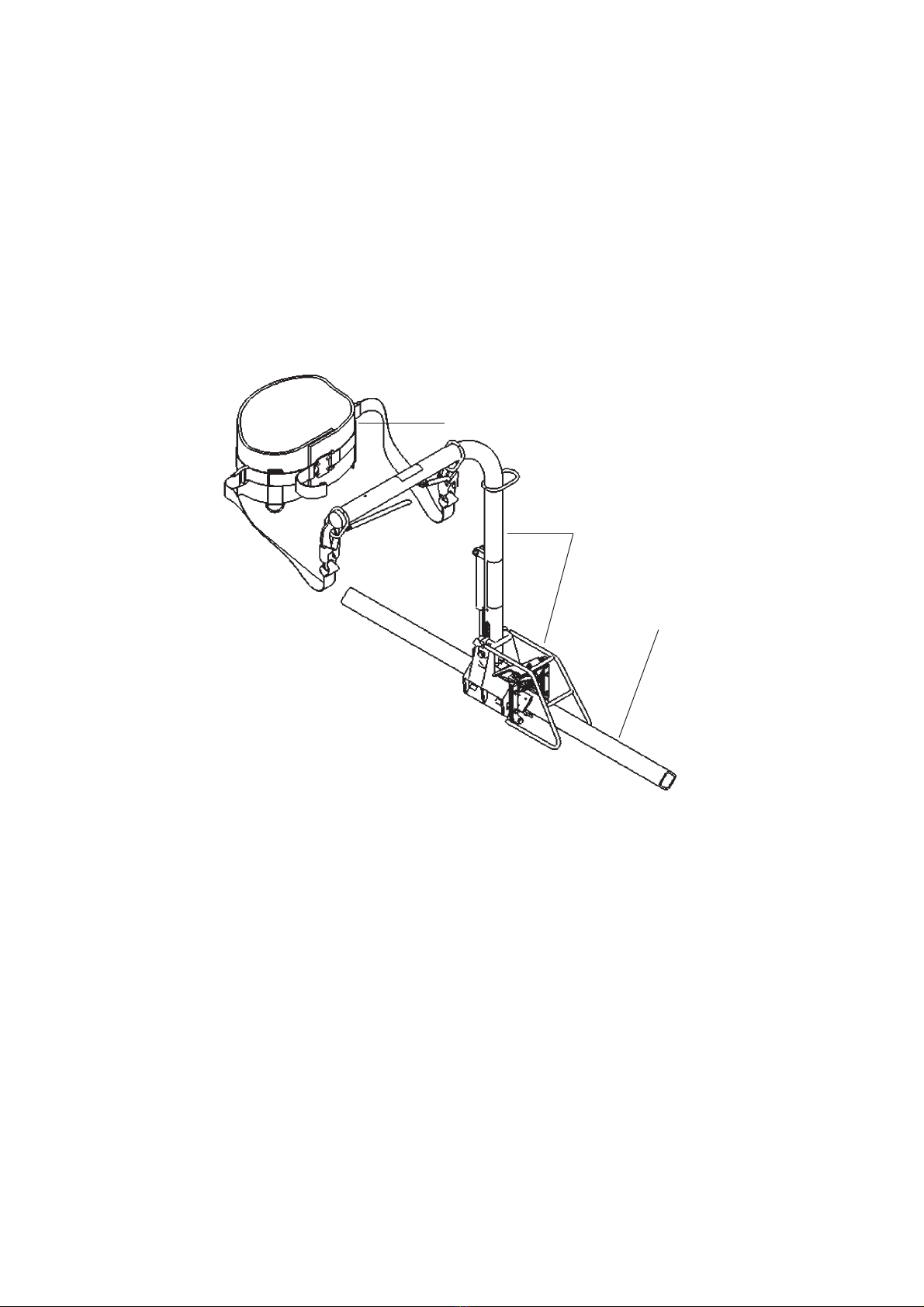

The TRAM (Safety) System consists of three components; the TRAM, the TRAM Belt and the

TRAM Installation.

Figure 4.1 The TRAM Safety System

The TRAM (or TRAM device) is a mobile anchor point that moves along the fixed rail.

For inspection, maintenance and repair purposes, the TRAM is classified into three

subassemblies – the TRAM Arm, the TRAM Trolley and the TRAM Brake System.

The TRAM Belt is a restraint belt that is worn by the user and attached to the TRAM by

two lanyards.

The TRAM Installation consists of the fixed rail and the mounting hardware which attaches

the fixed rail to the structure or vehicle to which the TRAM System is fitted.

10 TRAM SAFETY SYSTEM TECHNICAL MANUAL

TRAM Belt

TRAM

TRAM Installation

4.2 SAFETY

The “Important Safety Information” section lists basic safety precautions. In addition, this

section identifies hazardous situations, which are identified within the text by the highlighted

warning symbol. Read and understand the basic precautions listed in the “Important Safety

Information” section before using or performing maintenance or repair of this product.

4.3 COMPLIANCE TO WORKPLACE SAFETY LAWS

The use and maintenance of the TRAM Safety System must comply with the Workplace Safety

Legislation and Regulations of the jurisdiction in which the TRAM System is used.

The TRAM and the TRAM Rail have been tested to the specifications of, and are compliant with:

EN 795:1997 Protection against falls from a height – Anchor devices – Requirements and

testing (Class D anchor device employing a horizontal rigid anchor rail)

The TRAM Belt has been tested to and is compliant with:

EN 358:2000 Personal protective equipment for work positioning and prevention of falls

from a height – Belts for work positioning and restraint and work positioning lanyards

(Waist belt intended for restraint)

4.4 CUSTOMER SERVICE

Your satisfaction is a primary concern to Standfast Corporation and its dealers. When a

problem arises concerning the sale, operation or service of your TRAM System, please contact

the Standfast TRAM Dealer in your area.

The Standfast TRAM Dealer nearest to you can be located by consulting the website:

www.standfastcorp.com.

Standfast Corporation may be contacted directly by email or phone by consulting the website:

www.standfastcorp.com, or in writing to:

The Customer Service Manager

Standfast Corporation

PO Box 1224,

Milton BC, Queensland

Australia, 4064

TRAM SAFETY SYSTEM TECHNICAL MANUAL 11

5 DESCRIPTION OF EQUIPMENT

This chapter provides the names and location of major components of the TRAM Safety

System, and also describes their functions.

5.1 FEATURES & CONTROLS

Refer to Figures 5.1 and 5.2 to identify the features and control components of the TRAM

System. Figure 5.1 illustrates a TRAM in the TR-6-ST Series of products and is also termed

the “Standard TRAM”. Figure 5.2 illustrates the TR-6-RAT Series of products and consists of

a Standard TRAM with a rotary joint incorporated into the TRAM Arm. This type of TRAM is

termed the Rotating Arm TRAM.

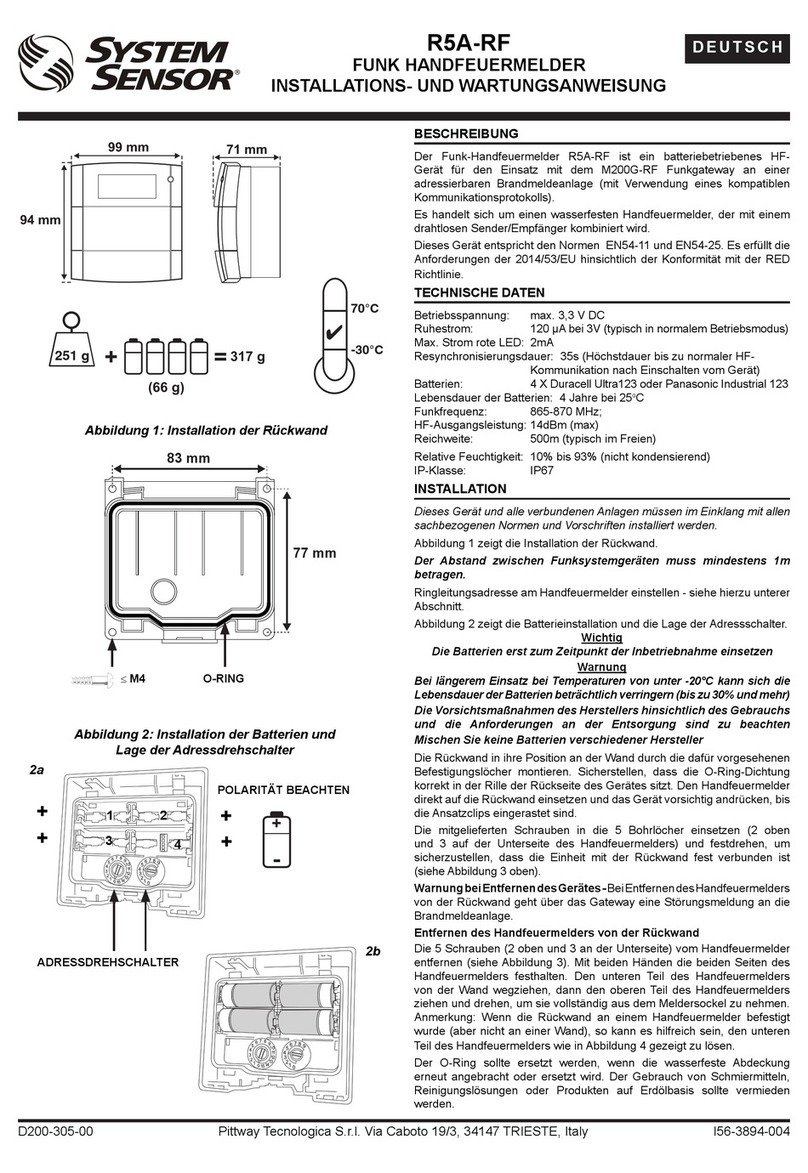

Figure 5.1 Features and Controls of the TRAM System – TR-6-ST Series

Figure 5.2 Features and Controls of the TRAM System (with Rotary Joint fitted) – TR-6-RAT Series

12 TRAM SAFETY SYSTEM TECHNICAL MANUAL

Attachment Ring

TRAM Belt

Rail

Lanyard

Clutch Lever

Brake Lever

Attachment Ring

Arm

Brake Override

Double-action Hooks

Attachment Ring

TRAM Belt

Rail

Lanyard

Clutch Lever

Brake Lever

Attachment Ring

Arm

Brake Override

Double-action Hooks

Rotary Joint Lever

Rotary Joint

Arm

The TRAM Arm provides a handhold that moves with the user and also supports the

Attachment Rings which are anchor points for the restraint belt. A Rotary Joint is fitted to the

TRAM Arm as part of the TR-6-RAT Series.

Rotary Joint (TR-6-RAT Series ONLY)

The Rotary Joint allows the horizontal segment of the Arm to rotate relative to the TRAM

Device. By activating the Rotary Joint Lever, the Arm can be rotated through 180 degrees,

in 90 degree increments. This is illustrated in Figure 5.3.

Figure 5.3 TRAM Arm Positions with Rotar y Joint fitted (TR-6-RAT Series ONLY)

Clutch Lever

The pivoting movement of the TRAM Arm is controlled by the Clutch lever. Activating the lever

allows the user to pivot the TRAM Arm between vertical and horizontal positions. The arm

position can be locked into either the horizontal, 45 degree or the vertical position and will

lock in place in position when the pivot clutch lever is released. See Figure 5.4.

Figure 5.4 TRAM Arm positions

TRAM SAFETY SYSTEM TECHNICAL MANUAL 13

O

o

Position 90

o

Position 180

o

Position

Brake Lever

In its normal position, the Brake system is locked and the TRAM Device is locked in its location

on the TRAM rail. Activating the Brake lever by hand releases the TRAM Device from its locked

position and allows it to move along the rail with the user. Releasing the Brake lever allows it to

return to the normal position and again lock the brake system and TRAM onto the rail.

Attachment Rings

Attachment Rings are anchor points provided on the TRAM Arm for attachment of the Lanyards

via the Double-action Hooks.

Double-action Hooks

The Double-action Hooks are attached to the end of the lanyards and are used to attach the

user to the TRAM Arm via the Attachment rings.

TRAM Belt

The TRAM Belt is a purpose designed restraint belt with two lanyards that attach to the TRAM

with double action hooks. The Belt is fixed around the user’s waist using a quick lock and

release buckle mechanism and must be fastened when the Belt is in use

The TRAM Belt is available in the following sizes:

TRAM Belt Sizes

WAIST SIZE TRAM BELT SIZE TRAM BELT COLOUR

Up to 70cm [27.5”] Small Purple

70-100cm [27.5-39.4”] Medium Red

100-125cm [39.4-49.2”] Large Blue

125-150cm [49.2-59.1”] Extra-Large Black

Lanyards

The lanyards are of fixed length and allow the user to move and work while attached to the

TRAM Arm.

Brake Override Foot Lever

In its normal position, the Brake system is locked and the TRAM Device is fixed in its

location on the TRAM rail. In the event that the Brake lever fails to function, the Brake

override foot-lever may be used to unlock the TRAM Device from its fixed location, allowing

it to move along the rail with the user.

Rail & Fixtures

The Rail provides a path for the TRAM Device to move along. Rail fixtures hold the rail in position

and are designed to comply with Design Strength requirements of legislation. Rail fixtures

provide the inter face between the Rail and the structure to which the TRAM is to be fixed.

14 TRAM SAFETY SYSTEM TECHNICAL MANUAL

5.2 TRAM DEVICE IDENTIFICATION PLATE

The TRAM (Device) is supplied with an identification plate as illustrated in Figure 5.2.1 below.

The plate is usually affixed to the lower section of the TRAM Arm. The plate contains important

information about the TRAM system including the type of TRAM Product, a unique serial

number, a date of manufacture and a statement of compliance to legislation.

The TRAM Identification plate is permanently attached to your TRAM system and should not

be removed or modified in any way.

The Installation Plate may vary in design and content subject to Workplace Safety Legislation

and Regulations of the jurisdiction in which the TRAM System is used

Figure 5.2.1 TRAM Identification Plate

TRAM SAFETY SYSTEM TECHNICAL MANUAL 15

Important!

Important!

5.3 TRAM BELT LABEL

The TRAM Belt is supplied with an information label sewn into the belt material and illustrated

in Figure 5.3.1 below. The label contains important information about the TRAM Belt including

a description of the product, product identification, serial number, date of manufacture and

date to be taken out of service, a statement of compliance to legislation and a pictogram.

The TRAM Belt label is permanently attached to your TRAM Belt and should not be removed

or modified in any way.

The Installation Plate may vary in design and content subject to Workplace Safety Legislation

and Regulations of the jurisdiction in which the TRAM System is used.

Figure 5.3.1 TRAM Belt Label

16 TRAM SAFETY SYSTEM TECHNICAL MANUAL

Important!

Important!

5.4 TRAM INSTALLATION PLATE

The TRAM Installation Plate is an information plate affixed in a visible location at the TRAM

Installation (the anchorage point). This plate should be clearly visible to the user before the

user is in a position to operate the TRAM System. The plate contains important information

about the TRAM Installation including the installer’s identification, the installation serial

number, the date of installation, a statement of compliance to legislation and a pictogram.

The TRAM Installation Plate is permanently attached to your TRAM Installation and should not

be removed or modified in any way.

The Installation Plate may vary in design and content subject to Workplace Safety Legislation

and Regulations of the jurisdiction in which the TRAM System is used.

Figure 5.4.1 TRAM Installation Plate

TRAM SAFETY SYSTEM TECHNICAL MANUAL 17

Important!

Important!

6 OPERATION

The instructions provided in section 6.1 should be used to operate the TR-6-ST Series and the

TR-6-RAT Series TRAM Systems. Section 6.2 applies to operation of the Rotary Joint supplied

with the TR-6-RAT Series TRAM System. Section 6.3 describes operation of the Brake Override.

6.1 GENERAL OPERATION

STEP 1

Perform a pre-use check in accordance with

the TRAM Pre-Use Check Procedure. (A copy

of the Pre-use check procedure is contained

in Appendix A.)

STEP 2

Put on the TRAM restraint belt.

STEP 3

Fasten the belt buckle.

Pull belt strap tight.

Note: The lanyards are kept in a ‘carry position’

hooked back to the belt.

Note: When worn correctly, the restraint belt should

look like the restraint belt in the illustration.

18 TRAM SAFETY SYSTEM TECHNICAL MANUAL

Note: Double action hooks are operated by first

depressing the latch on the back spine of the

hook and then opening the hook gate.

STEP 4

Move to the work area into a position where the

TRAM Arm can first be reached and held.

When climbing a ladder, three points of contact

should be maintained on the ladder at all times.

STEP 5

One-at-a-time, unclip the double-action hooks and

take the hooks from their ‘carry position’ on the

belt and attach them to the attachment rings on

the TRAM arm.

Do this one-at-a-time and maintain three points of

contact throughout.

Note: Once the double-action hooks are attached to

the attachment rings on the TRAM Arm, the user is

in a position of total restraint and can work safely.

STEP 6

Activate the clutch lever. The TRAM Arm will pivot

from the horizontal “lay down” position to its

vertical position. Whilst this takes place move

from the ladder onto the walkway.

Grip the Arm with both hands when activating the

clutch lever to maintain three points of contact

throughout the transition.

TRAM SAFETY SYSTEM TECHNICAL MANUAL 19

Important!

Important!

Important!

STEP 7

Once on top of the walkway, move the TRAM

arm along the rail by activating the brake lever.

You are in total restraint and can move safely

along the walkway.

Note: Whilst standing and walking the anchor

points are at waist level.

Note: Horizontal travel along the walkway is

controlled by the brake lever.

STEP 8

Once at the required work position, release the

brake lever to apply the brake and lock the TRAM

in position.

STEP 9

If the user needs to kneel, squat or sit, the TRAM

Arm and attachment points can be lowered by

pivoting the TRAM Arm. Pivot the TRAM Arm by

operating the clutch lever.

STEP 10

Once the required task is complete, activate the

brake lever and move back along the walkway.

The lanyards are of suitable length to allow the

user to turn around and walk back along the

walkway head first.

20 TRAM SAFETY SYSTEM TECHNICAL MANUAL

Important!

This manual suits for next models

1

Table of contents

Other Standfast Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Survitec Group

Survitec Group Crewsaver Crewfit Twin 275N Service manual

E2S

E2S GNExCP6A-PB instruction manual

Milwaukee

Milwaukee HEAVY DUTY L4 HBLB Original instructions

Mittelmann

Mittelmann LiftEvac Instructions for Use/Test Book

Innotech

Innotech EAP-POINT-11 quick start guide

3M

3M DBI-SALA EZ-Line User instructions