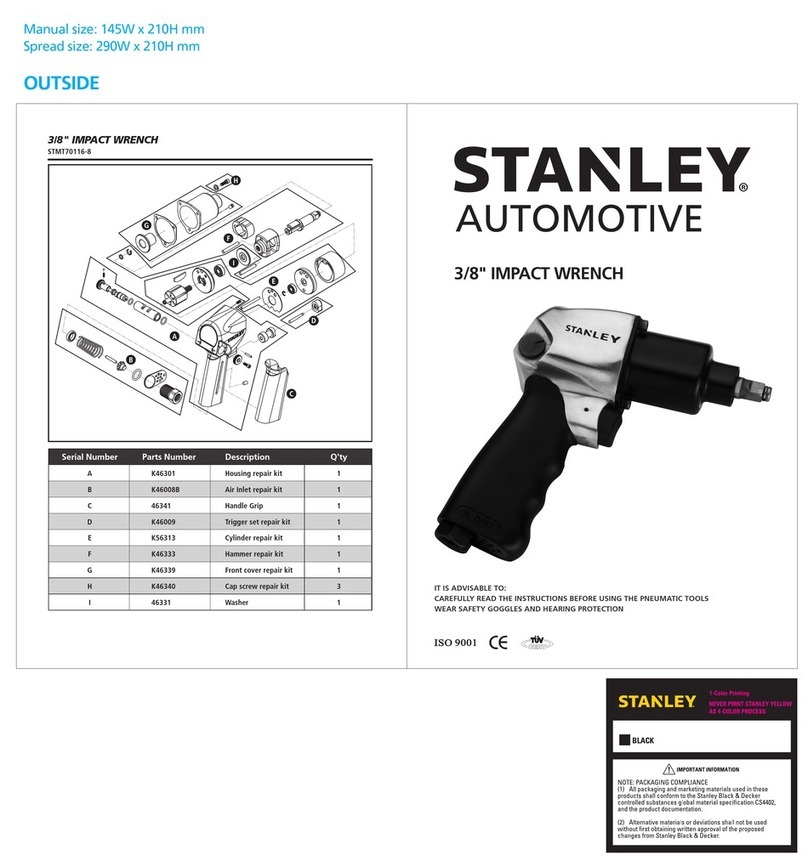

IW12 User Manual ◄ 5

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and

maintenance personnel.

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair

actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage

to the equipment.

Tool operators and maintenance personnel must always

comply with the safety precautions given in this manual

and on the stickers and tags attached to the tool and

hose. These safety precautions are given for your

safety. Review them carefully before operating the tool

and before performing general maintenance or repairs.

Supervising personnel should develop additional

precautions relating to the specic work area and local

safety regulations. If so, place the added precautions in

the space provided on in this manual.

The model IW12 Hydraulic Impact Wrench will provide

safe and dependable service if operated in accordance

with the instructions given in this manual. Read and

understand this manual and any stickers and tags

attached to the tool and hose before operation.

Failure to do so could result in personal injury or

equipment damage.

• The operator must start in a work area without

bystanders. Flying debris can cause serious injury.

• Do not operate the tool unless thoroughly trained

or under the supervision of an instructor. Establish

a training program for all operators to ensure safe

operation.

• Always wear safety equipment such as goggles,

gloves, ear, head and breathing protection and

safety shoes at all times when operating the tool.

Use gloves and aprons when necessary.

• Inspect tool daily for loose fasteners, missing parts

and leakage. Have tool repaired if necessary.

• The operator must be familiar with all prohibited work

areas such as excessive slopes and dangerous

terrain conditions.

• Maintain proper footing and balance at all times and

do not overreach.

• Do not inspect or clean the tool while the hydraulic

power source is connected. Accidental engagement

of the tool can cause serious injury. Be observant of

hydraulic and water hose lying about the work area,

as they can be a tripping hazard.

• Always connect hoses to the tool hose couplers

before energizing the hydraulic power source. Be

sure all hose connections are tight and are in good

condition.

• Do not operate the tool at oil temperatures above

140 °F/60 °C. Operation at higher temperatures can

cause higher than normal temperatures at the tool

which can result in operator discomfort.

• Do not operate a damaged, improperly adjusted or

incompletely assembled impact wrench.

• Never wear loose clothing that can get entangled in

the working parts of the tool.

• Keep all parts of your body away from the rotating

parts. Long hair or loose clothing can become drawn

into rotating components.

• Always use accessories that conform to the

specications given in “Specications” on page

14.

• Do not reverse impact wrench rotation direction by

changing uid ow direction.

• Release the trigger if the power supply has been

interrupted.

• When working near electrical conductors, always

assume that all conductors are energized and that

insulation, clothing and hoses can conduct electricity.

Use hose certied and labeled as non-conductive.

• To avoid personal injury or equipment damage,

all tool repair, maintenance and service must only

be performed by authorized and properly trained

personnel.

• Serious injury or death could result from a tool or

accessories dropped from an elevated height.

• Warning: Hydraulic uid under pressure could

cause skin injection injury. If you are injured by

hydraulic uid, get medical attention immediately.

• During operation do not contact the impact

mechanism, accessories or hardware as they can

become very hot; use your Personal Protection

Equipment (PPE).

• Warning: Use of this tool on certain materials could

generate dust potentially containing a variety of

hazardous substances such as asbestos, silica or

lead. Inhalation of dust containing these or other

hazardous substances could result in serious

injury, cancer or death. Protect yourself and those

around you. Research and understand the materials

you are cutting. Follow correct safety procedures

and comply with all applicable national, state or

provisional health and safety regulations relating to

them, including, if appropriate arranging for the safe

disposal of the materials by a qualied person.

SAFETY PRECAUTIONS