Star Celeste S220 User manual

Residential

Flush Pendent Sprinklers

Celeste™ S220

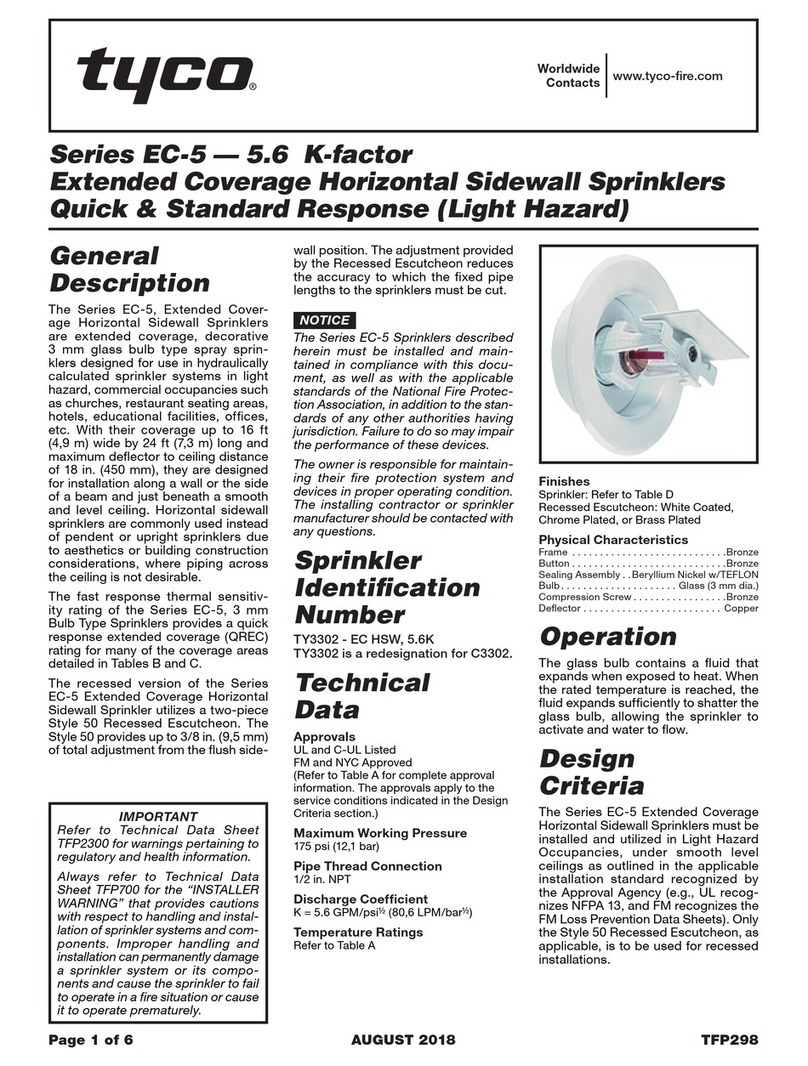

GENERAL DESCRIPTION

The Star Celeste S220 Residential Flush Pendent Sprin-

klers are decorative fusible solder sprinklers designed for

use in residential occupancies such as homes, apart-

ments, dormitories, and hotels.When aesthetics is the

major consideration, the Celeste S220 should be your

first choice.

They are to be used in wet pipe residential sprinkler sys-

tems for one- and two-family dwellings and mobile homes

per NFPA 13D; wet pipe residential sprinkler systems for

residential occupancies up to and including four stories in

height per NFPA 13R; or, wet pipe sprinkler systems for

the residential portions of any occupancy per NFPA 13.

The Celeste S220 has a 3.9 (56.2) K-factor which pro-

vides very low design flow rates at reduced residual pres-

sures, enabling smaller pipe sizes and water supply re-

quirements.

The flush design of the Celeste S220 features a separa-

ble escutcheon providing 3/8 inch (9.5 mm) vertical ad-

justment. This adjustment reduces the accuracy to which

the fixed pipe drops to the sprinklers must be cut to help

assure a perfect fit installation.

The Celeste S220 has been designed with heat sensitiv-

ity and water distribution characteristics proven to help in

the control of residential fires to improve the chance for

occupants to escape or be evacuated. However, residen-

tial fire sprinkler systems are not a substitute for intelli-

gent fire safety awareness or fire safety construction re-

quired by building codes.

WARNINGS

The Celeste S220 Residential Flush Pendent Sprin-

klers described herein must be installed and main-

tained in compliance with this document, as well as

with the applicable standards of the National Fire Pro-

tection Association, in addition to the standards of

any other authorities having jurisdiction. Failure to

do so may impair the integrity of these devices.

Because of the above cited stipulations and the var-

ied nature of residential type architecture, there will

be some compartment designs which cannot be fully

sprinklered in accordance with the recommendations

of NFPA 13, 13D, or 13R. In the event of this condi-

tion, consult the authorities having jurisdiction for

guidance and approval.

It is the responsibility of the installing contractor to

provide a copy of this document to the owner or his

representative, and in turn, it is the obligation of the

owner to provide a copy of this document to a suc-

ceeding owner.

The owner is responsible for maintaining his fire pro-

tection system and devices in proper operating condi-

tion. The installing contractor or sprinkler manufac-

turer should be contacted relative to any questions.

OPERATION

The sprinkler assembly contains a small fusible solder

element. When exposed to sufficient heat from a fire, the

solder melts and enables the internal components of the

sprinkler to fall away.At this point the sprinkler activates

with the deflector dropping into its operated position (Ref-

erence Figure 1C), permitting water to flow.

TECHNICAL DATA

Approvals

UL and C-UL Listed.

(The approvals apply only to the service conditions indi-

cated in the Design Criteria section.)

Maximum Working Pressure

175 psi (12.1 bar)

Discharge Coefficient

K=3.9GPM/psi

1/2 (56.2 LPM/bar1/2)

Temperature Rating

162°F/72°C

Adjustment:

3/8 inch (9.5 mm) vertical

Finishes

Sprinkler and Escutcheon: White, Chrome

DESIGN CRITERIA

The Celeste S220 Residential Flush Pendent Sprinklers

must only be installed and utilized in accordance with the

following described criteria which are provided by the

manufacturer.

NOTES

Residential Fire Sprinkler Systems should only be de-

signed and installed by those competent and com-

pletely familiar with automatic sprinkler system de-

sign, installation procedures, and techniques.

Several criteria may apply to the installation and us-

age of each sprinkler. Consequently, it is recom-

mended that the sprinkler system designer review

and develop a working understanding of the com-

414-570-5000 • 800-558-5236 • FAX 414-570-5010 6-99

1-3.2.40

STAR SPRINKLER INC.

E-mail starsprk@execpc.com

#4387

OBSOLETE

plete list of criteria prior to initiating the design of the

sprinkler system.

Questions concerning sprinkler installation and us-

age criteria which are not covered by the following in-

structions should be submitted to Star Sprinkler Inc.

Include sketches and technical details as appropriate.

In some instances, the requirements of this docu-

ment may concern specifications which are more

stringent and which take precedence over those

specified in NFPA 13, NFPA 13D, NFPA 13R, or by the

authority having jurisdiction.

The spray from the sprinkler is distributed radially

outward and downward from the sprinkler deflector.

Consequently, the sprinklers must be located such

that there will not be any blind spaces shielded from

spray by partitions, room dividers, overhangs or

other parts of the dwelling structure.

The number of sprinklers within each compartment

(as defined by NFPA 13, 13D, or 13R), must be kept

as few as possible. Do NOT use more sprinklers than

necessary to cover a particular space.

Use only the escutcheon provided with the Celeste

S220.

The sprinkler must be secured in position by firmly

fastening the sprinkler system piping to the struc-

ture. If the sprinkler is not properly secured in posi-

tion, reaction forces resulting from sprinkler opera-

tion could alter its orientation and its water

distribution pattern. The sprinkler escutcheon cannot

be used to hold the sprinkler in position.

General Service Conditions. The Celeste S220 must

only be utilized in wet pipe sprinkler systems.

Thermal Response Criteria. All residential sprinklers in-

stalled within a compartment (as defined by relevant

NFPA standards) must be of the same heat response ther-

mal characteristics, and their temperature ratings are to

be within 10°F (5.5°C) of each other.

Hydraulic Design Criteria. The minimum required single

and multiple sprinkler flow rates are given in Table A as a

function of temperature rating and the maximum allow-

able coverage areas.The single sprinkler flow rate is the

minimum required discharge from the most hydraulically

demanding single sprinkler and, the multiple sprinkler

STAR SPRINKLER INC.

Page 2 1-3.2.40

FIGURE 1

CELESTE S220 RESIDENTIAL

FLUSH PENDENT SPRINKLER

A

B

C

SPRINKLER

AREA

WRENCHING

TOLERANCE

CEILING LEVEL

LIMIT

FITTING

FACE OF

SPRINKLER

PROTECTIVE CAP

(27.8±4.8 mm)

1-3/32±3/16"

MOUNTING

SURFACE

9/32" (7.4 mm) TYP.

2-9/16" (65 mm) DIA.

IN OPERATED

POSITION

DEFLECTOR

29/32±3/16"

(23.0±4.8 mm)

2" (50 mm) DIA.

DO NOT

OVER-TIGHTEN

COLLECTOR

HEAT

(61.9 mm)

2-7/16"

NOMINAL MAKE-IN

7/16" (11.1 mm)

1/2" NPT

(a) For coverage area dimensions less than or between those

indicated, it is necessary to use the minimum required flow for

the next highest coverage area for which hydraulic design

criteria are stated.

(b) Requirement is based on minimum flow in GPM from each

sprinkler. The associated residual pressures are calculated

using the nominal K-factor. Refer to Hydraulic Design Criteria

Section for details. TABLE A

HYDRAULIC DESIGN CRITERIA

12 x 12

MAXIMUM

COVERAGE

AREA (a)

FT. x FT.

SINGLE

SPRINKLER

Minimum Flow (b)

(Residual Pressure)

14 x 14

16 x 16

18 x 18

20 x 20

13 GPM

(11.1 PSI) 13 GPM

(11.1 PSI)

13 GPM

(11.1 PSI) 13 GPM

(11.1 PSI)

14 GPM

(12.9 PSI) 13 GPM

(11.1 PSI)

19 GPM

(23.7 PSI) 19 GPM

(23.7 PSI)

13 GPM

(11.1 PSI) 13 GPM

(11.1 PSI)

162°F

MULTIPLE

SPRINKLERS

Minimum Flow (b)

(Residual Pressure)

162°F

OBSOLETE

flow rate is the minimum required discharge from each of

the total number of “design sprinklers” (as specified in

NFPA 13, 13D, or 13R).

Spray Coverage Criteria. ( Level Ceilings Only). Figure

2 provides spacing rules that must be followed to assure

that the Celeste S220 Sprinklers will provide their design

distribution of water spray. The nominal wetting pattern at

the minimum required flow conditions (Ref. Table A) for a

20 ft. x 20 ft. coverage area is illustrated in Figure 3.

Operational Sensitivity Criteria. For proper operational

sensitivity, the Celeste S220 must be installed beneath a

solid ceiling having a smooth or textured surface.

The Celeste S220 must NOT be used above or below

open-gridded type suspended ceilings; beneath soffits or

beams exceeding 3 inches in height; or, with beams,

joists, or ducts having a height of more than 3 inches lo-

cated within the sprinkler coverage areas. Beams having

a height of more than 3 inches may be located with their

centerlines along the boundaries separating adjacent

sprinkler coverage areas.

Cold Soldering Criteria (Level Ceilings Only). Figure 2

provides the minimum spacing requirements necessary

for preventing the wetting (i.e., cold soldering) of the heat

responsive element of a non-operated Celeste S220,

which is adjacent to one which has operated.

Heat Source Criteria. Refer to NFPA 13D for the require-

ments relating to preventing the possible release of a Ce-

leste S220 heat responsive element, due to exposure to

heat sources other than abnormal fire.

INSTALLATION

The Celeste S220 must be installed in accordance with

the following instructions:

NOTES

The Protective Cap is to remain on the sprinkler dur-

ing installation and until the ceiling installation is

complete. The Protective Cap must be removed to

place the sprinkler in service.

A leak tight 1/2 inch NPT sprinkler joint should be ob-

tained with a torque of 7 to 14 ft.lbs. (9.5 to 19.0 Nm).

A maximum of 21 ft.lbs. (28.5 Nm) of torque is to be

used to install sprinklers. Higher levels of torque may

distort the sprinkler inlet with consequent leakage or

impairment of the sprinkler.

Do not attempt to compensate for insufficient adjust-

ment in an Escutcheon Plate by under- or over-tight-

ening the Sprinkler. Readjust the position of the sprin-

kler fitting to suit.

1. TheSprinklermustbeinstalledonlyinthependentposition

and with the Sprinkler waterway centerline perpendicular

to the mounting surface.

2. Install the sprinkler fittingsothatthedistancefromtheface

of the fitting to the mounting surface will be nominally

1-3/32 inches (27.8 mm) as shown in Figure 1A.

3. With pipe thread sealant applied to the pipe threads, hand

tighten the Sprinkler into the sprinkler fitting.

4. Wrench tighten the Sprinkler using only the #4947 Sprin-

kler Socket or #4948 Wrench & Socket Combination (Ref.

Figure 4). The wrench recess of the #4947 is to be applied

to the sprinkler wrenching area (Ref. Figure 1A).

STAR SPRINKLER INC.

1-3.2.40 Page 3

FIGURE 2

SPACING RULES UNDER LEVEL CEILINGS

S = THE LENGTH OF THE COVERAGE AREA BEING

HYDRAULICALLY CALCULATED (REF. TABLE A).

Figure 2-1 (Plan View) Figure 2-2 (Plan View)

Figure 2-3 (Plan View) Figure 2-4 (Plan View)

Figure 2-5 (Plan View)

Figure 2-6 (Plan View)

Figure 2-7 (Plan View)

Figure 2-8 (Plan View) Figure 2-9 (Elevation View)

OBSOLETE

STAR SPRINKLER INC.

Page 4 1-3.2.40

FIGURE 3

NOMINAL WETTING PATTERN

AT MINIMUM REQUIRED FLOW CONDITION

FOR 20’ x 20’ COVERAGE AREA

FIGURE 4

#4947 SPRINKLER SOCKET

#4948 WRENCH & SOCKET COMBINATION

FIGURE 5

#4300 PROTECTIVE CAP REMOVAL TOOL

DRIVE

3/8" SOCKET

ACCEPTS

WRENCH

RECESS

WRENCH

COMBINATION

WRENCH & SOCKET

#4948

#4947

SOCKET

8'

6'

4'

0'

2'

8'

6'

4'

0'

2'

10' 8' 6' 4' 2'

8'

6'

4'

2'

20' x 20' Coverage Area

1

9G

PM

Horizontal Minimum Vertical

Distance from Clearance

Sprinkler to Below

Obstruction Sprinkler

Below Sprinkler Heat Collector,

Heat Collector, ft. in.

More than 6.0 24

From 3.0 to 6.0 19

Between2.0and3.0 16

From 1.0 to 2.0 13

Less than 1.0 10

TABLE C

MINIMUM VERTICAL CLEARANCE BETWEEN

TOP OF FREE STANDING OBSTRUCTION AND

SPRINKLER HEAT COLLECTOR

Horizontal Maximum

Distance from Vertical

Sprinkler to Clearance

Obstruction Below

Below Sprinkler Sprinkler

Deflector, ft. Heat Collector, in.

Less than 0.5 Not Permitted

0.5 to less than 1.0 0

1.0 to less than 2.0 1

2.0 to less than 2.5 2

2.5 to less than 3.0 3

3.0 to less than 3.5 4

3.5 to less than 4.0 6

4.0 to less than 4.5 7

4.5 to less than 5.0 9

5.0 to less than 5.5 11

5.5 to less than 6.0 14

TABLE B

MAXIMUM VERTICAL DISTANCE

FROM SPRINKLER HEAT COLLECTOR

TO BOTTOM OF CEILING OBSTRUCTION

OBSOLETE

5. Use the “ceiling level tolerance limit” indicator on the

Protective Cap to check for proper installation height.

Relocate the sprinkler fitting as necessary. If desired the

Protective Cap may also be used to locate the center of

the clearance hole by gently pushing the ceiling material

against the center point of the Cap.

6. After the ceiling has been completed with the 2 inch (50

mm) diameter clearance hole, use the Protective Cap

RemovalTool(Ref.Figure5)toremovetheProtectiveCap

and then push on the Escutcheon until its flange just

comes in contact with the ceiling. Do not continue to push

on the Escutcheon such that it lifts a ceiling panel out of its

normalposition. IftheEscutcheoncannotbeengaged with

the Sprinkler, or the the Escutcheon cannot be engaged

sufficiently to contact the ceiling, relocate the sprinkler

fitting as necessary.

MAINTENANCE AND SERVICE

The Celeste S220 must be maintained and serviced in ac-

cordance with the following instructions:

NOTES

It is the responsibility of the installing contractor to

provide a copy of this document to the owner or his

representative, and in turn, it is the obligation of the

owner to provide a copy of this document to a suc-

ceeding owner.

Wet pipe sprinkler systems must be maintained at a

minimum temperature of 40°F/4°C to prevent freezing

and bursting of the pipe and/or sprinklers.

Automatic sprinklers are not to be tested with a heat

source. Operation of the heat responsive element can

result.

Absence of an Escutcheon Plate may delay the time

to sprinkler operation in a fire situation.

Before closing a fire protection system main control

valve for maintenance work on the fire protection sys-

tem which it controls, permission to shut down the af-

fected fire protection system must be obtained from

the proper authorities and all personnel who may be

affected by this action must be notified.

Do NOT enclose sprinklers within drapes, curtains, or

valances.

Do NOT hang anything from the sprinklers.

Do NOT cleanse the sprinklers with soap and water,

detergents, ammonia, cleaning fluids, or other chemi-

cals. Remove dust, lint, cobwebs, cocoons, insects,

and larvae by gently brushing with a feather duster or

gently vacuuming with a soft bristle (i.e., dusting)

brush attachment.

Exercise suitable safety precautions in the use and

storage of highly flammable materials. The rapid rate

of fire development and spread of which can be

caused by such materials can reduce the ability of

the sprinkler system to aid in the control of a fire in

which they are involved.

The minimum vertical clearance between the tops of

free standing partitions, room dividers, cabinets, stor-

age racks, stock piles, etc., and the sprinkler deflector

is NOT to be less than the clearance given in Table C.

It is recommended that automatic sprinkler systems

be inspected and maintained in accordance with the

advice and suggestions given in NFPA 25.

Automatic sprinklers must never be shipped or stored

where its temperature will exceed 100°F/38°C and they

must never be painted, plated, coated, or otherwise al-

tered after leaving the factory. Modified or over heated

sprinklers must be replaced.

Care must be exercised to avoid damage - before. dur-

ing, and after installation.Sprinklers damaged by drop-

ping, striking, wrench twist/slippage, or the like, must be

replaced.

It is recommended that automatic sprinkler systems be in-

spected quarterly by a qualified Inspection Service.

The Celeste S220 must only be replaced with pendent

sprinklers which are listed for residential fire protection

service and which have the same nominal K-factor, the

same coverage area, and the same or lower flow ratings

(as indicated under “Hydraulic Design Criteria”).

When remodeling, such as by adding false beams or light

fixtures or changing the location of compartment walls,

first verify that the new construction will not violate the in-

stallation requirements stated under WARNINGS.Alter

the new construction and/or the sprinkler system to suit

the requirements of this document.

ORDERING PROCEDURE

Please Specify:

1. Celeste S220, K=3.9, Residential Flush Pendent

Sprinkler (#4387)

2. Sprinkler Wrench

(# 4947 Socket or #4948 Wrench & Socket)

3. Protective Cap Removal Tool (#4300)

Refer to Price List for a complete listing of Part Numbers

with respect to temperature ratings, finishes, replacement

escutcheons, etc.

AVAILABILITY AND SERVICE

Star Sprinkler Inc. products and devices are available

worldwide through a network of independent distributors.

Please contact Star Sprinkler Inc. for information and the

name and address of the Star distributor in your area.

STAR SPRINKLER INC.

1-3.2.40 Page 5

OBSOLETE

LIMITED WARRANTY

The manufacturer warrants for a period of one year from the date

of sale (warranty period) that the product(s) sold hereunder are

free from defects in material and workmanship. Our obligation un-

der this warranty is limited to repair or replacement, or, at our op-

tion, we will repay the price paid for the product(s), plus any trans-

portation charge paid by the purchaser. In the case of

replacement, we will pay the transportation charges to the loca-

tion of the defective product. We must be given the opportunity to

inspect any product you believe to be defective.To make a claim

under this limited warranty, you should contact our Sales Serv-

ices Manager at (800) 558-5236.

THERE ARE NO OTHER WRITTEN OR ORAL WARRANTIES.

ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FIT-

NESS FOR A PARTICULAR PURPOSE ARE LIMITED IN DURA-

TION TO THE DURATION OF THE LIMITED WARRANTY SET

FORTH ABOVE.

The manufacturer does not assume any other obligation in con-

nection with the sale of the product(s) by purchaser.

This warranty shall not apply to any product(s) which have been

installed in violation of written instructions furnished by the manu-

facturer, repaired or altered, misused or damaged, or not properly

maintained.

The manufacturer is not liable for indirect, incidental or conse-

quential damages in connection with the use of the product(s).

Some states do not allow limitations on how long an implied war-

ranty lasts, or exclusion or limitation of incidental or consequen-

tial damages, so the above limitations or exclusion may not apply

to you.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND

YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

STAR SPRINKLER INC.

Page 6 1-3.2.40

7071 S. 13th Street • Suite 103

Oak Creek, WI 53154

414-570-5000 • 800-558-5236 PRINTEDINU.S.A.6-99

OBSOLETE

Table of contents

Popular Irrigation System manuals by other brands

Reliable

Reliable F3QR80 Dry Pendent Quick start quide

Perrot

Perrot VP3 VAC Maintenance and operating instructions

Tyco Fire Product

Tyco Fire Product Star Mizar S215 instruction manual

Reliable

Reliable F1 LO quick start guide

Reliable

Reliable DDX PrePaK Instructions for installation, operation care and maintenance

GEM

GEM F687 manual