GEM F687 User manual

HOR. & REC. HOR. SIDEWALL SPRINKLERS, RESIDENTIAL

MODEL F687 DESIGNER, BULB TYPE, 5.8 K-FACTOR, 155°F

GENERAL DESCRIPTION

The 5.8 K-factor, Model F687 Designer

Residential Horizontal and Recessed

Horizontal Sidewall Sprinklers (Ref.

Figure A) are automatic sprinklers of

the frangible bulb type. They are to be

used in

•wet pipe residential sprinkler sys-

tems for one- and two-family dwell-

ings and mobile homes per NFPA

13D,

•wet pipe residential sprinkler sys-

tems for residential occupancies up

to four stories in height per NFPA

13R, and

•wet pipe sprinkler systems for the

residential portions of any occu-

pancy per NFPA 13.

The recessed versions of the Model

F687 Sprinkler are obtained by utiliz-

ing the Model F705 Recessed Es-

cutcheon (Ref.Figures A and B-2). The

F705 Recessed Escutcheon provides

1/4 inch (6,4 mm) of recessed adjust-

ment or up to 1/2 inch (12,7 mm) of

total adjustment from the flush sidewall

position.

The F705 has a separable two-piece

design which allows installation of the

sprinklers and pressure testing of the

fire protection system, prior to wall

construction and/or application of a fin-

ish coat to the wall. They also permit

refinishing of a wall surface without

having to first shut down the fire pro-

tection system and remove the sprin-

klers.

They are designed for installation

along a wall or lintel and just beneath

a smooth and level ceiling. Horizontal

sidewall sprinklers are generally used

in lieu of pendent or upright sprinklers

because of aesthetic, building con-

struction, or installation economy con-

siderations.

The F687 Sprinklers have been de-

signed to operate with a particular tem-

perature rating and heat responsive

thermal characteristic, as well as to

discharge water in a specific pattern

and quantity per square foot relation-

ship. The combination of the perform-

ance characteristics which are associ-

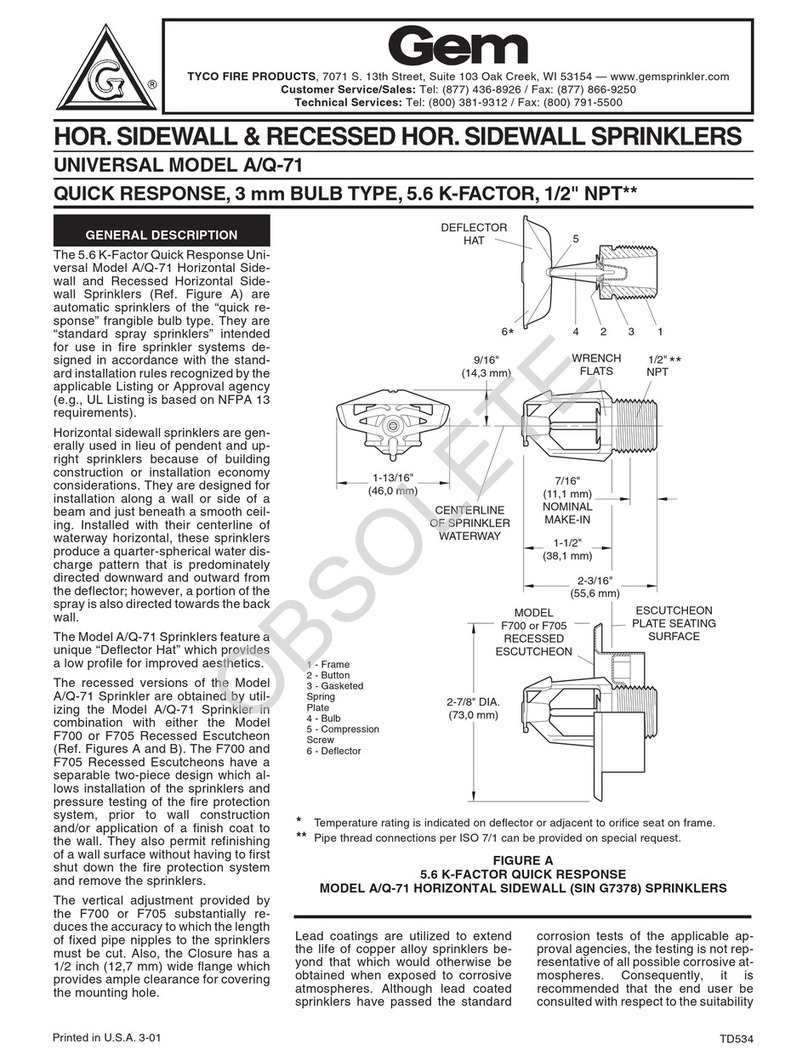

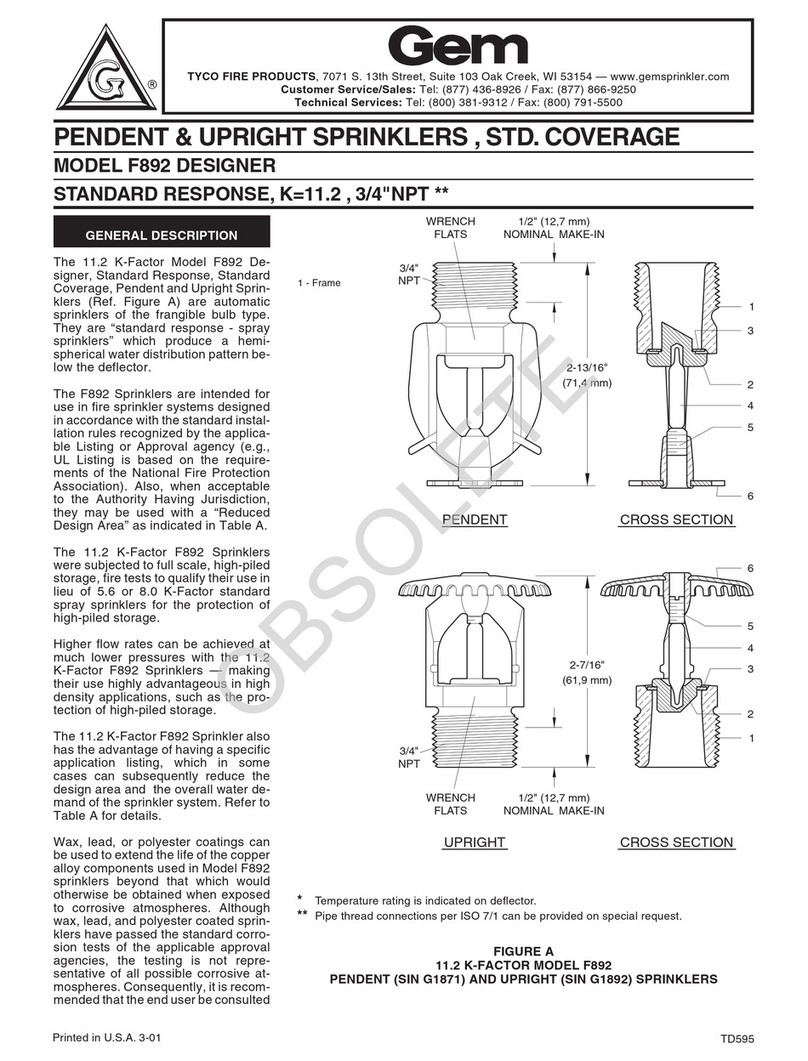

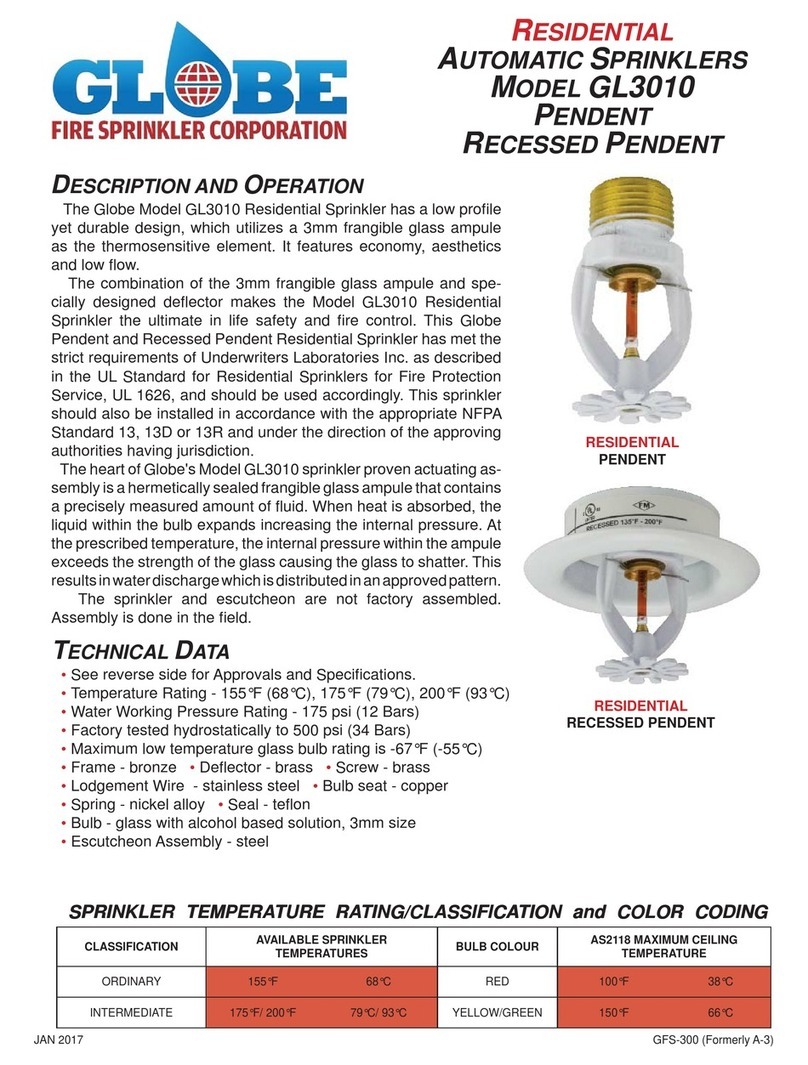

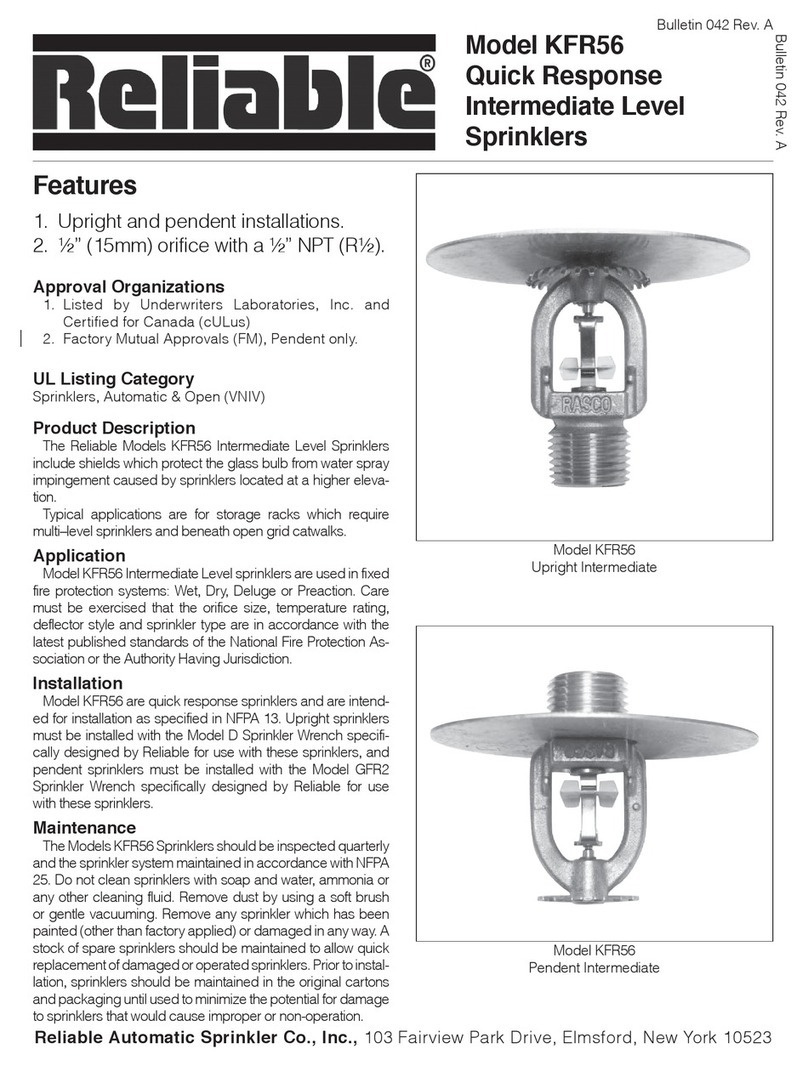

FIGURE A

5.8 K-FACTOR MODEL F687 (SIN G1687) RESIDENTIAL

HORIZONTAL AND RECESSED HORIZONTAL

SIDEWALL SPRINKLERS

Printed in U.S.A. 7-02

Components:

1 - Frame

2 - Button Assembly

TD587M

3 - Gasketed

Spring Plate

6 - Deflector

4 - Bulb

5 - Compression Screw

TYCO FIRE PRODUCTS, 7071 S. 13th Street, Suite 103 Oak Creek, WI 53154 — www.gemsprinkler.com

Customer Service/Sales: Tel: (800) 558-5236 / Fax: (800) 877-1295

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

SPRINKLERS FOR REPLACEMENT USE ONLY IN EXISTING SPRINKLER SYSTEMS

OBSOLETE

ated with the F687 Sprinklers have

been proven to help in the control of

residential type fires and, therefore, to

improve the chance for occupants to

escape or be evacuated.

Fire sprinkler systems are not a substi-

tute for intelligent fire safety aware-

ness or construction materials and

practices required by building codes.

APPROVALS AND STANDARDS

The 5.8 K-factor, Model F687 Residen-

tial Horizontal and Recessed Horizon-

tal Sidewall Sprinklers are listed by

Underwriters Laboratories Inc. and

Underwriters’ Laboratories of Canada.

The listings only apply to the sprinkler

finishes and service conditions indi-

cated in the General Technical Data

and Residential Design Criteria sec-

tions.

The 5.8 K-factor, Model F687 Residen-

tial Horizontal and Recessed Horizon-

tal Sidewall Sprinklers are also ap-

proved by the Scientific Services

Laboratory (Australia), as well as ac-

cepted by the City of New York under

MEA 39-92-M.

Any questions concerning an interpre-

tation of NFPA 13, 13D, or 13R sprin-

kler system design/installation stand-

ards, as well as requests for system

design/installation standards not pres-

ently covered by NFPA 13, 13D, or

13R, should be addressed to the:

Secretary, Standards Council

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

WARNINGS

The Model F687 Residential Hori-

zontal and Recessed Horizontal

Sidewall Sprinklers described

herein must be installed and

maintained in compliance with

this document, as well as with the

applicable standards of the Na-

tional Fire Protection Associa-

tion, in addition to the standards

of any other authorities having

jurisdiction. Failure to do so may

impair the integrity of these de-

vices.

Because of the above cited stipu-

lations and the varied nature of

residential type architecture,

there may be some compartment

designs which cannot be fully

sprinklered in accordance with

the recommendations of NFPA 13,

13D, or 13R. In the event of this

condition, consult the authorities

having jurisdiction for guidance

and approval.

It is the responsibility of an in-

stalling contractor to provide a

copy of this document to the

owner or his representative and,

in turn, it is the obligation of the

owner to provide a copy of this

document to a succeeding owner.

The owner is responsible for

maintaining their fire protection

system and devices in proper op-

erating condition. The installing

contractor or sprinkler manufac-

turer should be contacted relative

to any questions.

—2—

NFPA 13D/13R NFPA 13D/13R

MINIMUM MINIMUM

SINGLE MULTIPLE

SPRINKLER(d) SPRINKLER(d)

WxL

(b) FLOW FLOW A B

APPLICATION FT x FT GPM (psi)(c) GPM (psi)(c) INCHES FEET

RES(a) 12 x 12 18 (9.6) 15.3 (7.0) 4 to 12(f) 6

RES(a) 16 x 18 28 (23.3) 23 (15.7) 4 to 6(e) 8

RES(a) 16 x 20 29 (25.0) 26 (20.1) 4 to 6(e) 8

NOTES:

(a) Wet pipe fire sprinkler systems in the residential portions of any occupancy per NFPA 13, in one- and two- family dwellings and mobile

homes per NFPA 13D, or residential occupancies per NFPA 13R.

(b) For coverage area dimensions less than or between those indicated, it is necessary to use the minimum required flow for the next highest

coverage area for which hydraulic design criteria are stated.

(c) Requirement is based on minimum flow in GPM from each sprinkler. The indicated residual pressures are based on the nominal K-factor.

(d) Refer to Hydraulic Design Criteria under Residential Design Criteria Section for details.

(e) To meet this requirement, the centerline of the waterway (Ref. Fig. A) must be installed between 4-3/8 and 6-3/8 inches below the ceiling.

(f) To meet this requirement, the centerline of the waterway (Ref. Fig. A) must be installed between 4-3/8 and 12-3/8 inches below the ceiling.

TABLE A

HYDRAULIC DESIGN CRITERIA FOR THE 5.8 K-FACTOR MODEL F687 RESIDENTIAL HORIZONTAL

AND RECESSED HORIZONTAL SIDEWALL SPRINKLERS

OBSOLETE

—3—

FIGURE B-1

TYPICAL INSTALLATION USING A STANDARD ESCUTCHEON

FIGURE B-2

MODEL F687 RECESSED HORIZONTAL SIDEWALL SPRINKLER ASSEMBLY

WITH TWO-PIECE MODEL F705 RECESSED ESCUTCHEON

Dim. Inches MM

A- 1/2†† 12,7

B-Min. 15/16 23,8

B-Nom. 1-1/16 27,0

B-Max. 1-3/16 30,2

C-Min. 1/4 6,4

C-Max. 1/2 12,7

FULLY RECESSED

DIMENSIONS†

Up to 1/4 inch adjustment from

minimum 1/4 inch to maximum

1/2 inch recessed position.

HIGH ADJUSTMENT

DIMENSIONS

Up to 1/2 inch adjustment from

the flush sidewall position to

1/2 inch recessed position.

Dim. Inches MM

A- 3/8±1/8†† 9,5±3,2

B-Min. 15/16 23,8

B-Nom. 1-3/16 30,2

B-Max. 1-7/16 36,5

C-Min. FLUSH —

C-Max. 1/2 12,7

† For best overall appearance.

†† Remaining 1/4 inch (6,4 mm) of adjust-

ment can be used to compensate for

variations in sprinkler make-in and fit-

ting take-out.

OBSOLETE

GENERAL TECHNICAL DATA

Sprinkler Assemblies:

The 5.8 K-factor, Model F687 Residen-

tial Horizontal Sidewall Sprinklers are

available in a 155°F/68°C temperature

rating and they are rated for use at a

maximum service pressure of 175 psi.

They are available chrome plated,

natural brass, or polyester coated in

any color.

The nominal flow “Q” in GPM (LPM) is

determined by the following formula:

Q=K(p

1/2)

where the nominal sprinkler discharge

coefficient “K” equals 5.8 (83,5) and “p”

equals residual pressure in psi (bar).

The F687 utilizes a 3 mm Bulb with a

cast dezincification resistant bronze

alloy Frame. The two pieces of the But-

ton Assembly are constructed from

brass per ASTM B16 (C36000) and

copper (C12200). The Gasketed

Spring Plate consists of a Beryllium

Nickel (N03360) disc spring that is

sealed on both its inside and outside

edges with a Teflon

gasket. The Com-

pression Screw is a brass per ASTM

B16 (C36000), and the Deflector is

brass per ASTM B36 (C22000).

Escutcheon Plates:

A separately ordered escutcheon plate

is required for concealed piping instal-

lations.

Figure B-1 illustrates a typical installa-

tion of an F687 Sprinkler using a

standard one-piece escutcheon plate

like that described in Technical Data

Sheet TD805. Refer to Technical Data

Sheet TD805 for information on other

available flush mount escutcheons.

Figure B-2 illustrates the Model F705

Recessed Escutcheon which is the

only recessed escutcheon that is ac-

ceptable for use with the Model F687

Horizontal Sidewall Sprinkler. It has a

Closure and Mounting Plate fabricated

from low carbon steel. The Mounting

Plate prongs, which are compressed

back into the Mounting Plate as the

Closure is pushed over it, maintain a

tight friction fit between the two pieces.

The Mounting Plate and Closure can

also swivel relative to each other and

compensate for minor non-perpen-

dicularity between the Model F687

Sprinkler and the wall.

The F705 Escutcheons are available

with a chrome plated finish or a coated

finish in any color.

NOTES

Absence of an escutcheon may de-

lay the time to sprinkler opera-

tion in a fire situation.

Only use escutcheons which con-

sist of metallic materials that

will not deform or dislodge at a

temperature of less than

1200°F/649°C and/or which have

been listed by Underwriters Labo-

ratories Inc. for fire protection

service.

The escutcheon plates like those

shown in Technical Data Sheet

TD805, as well as the F705 Es-

cutcheon, cannot be used to hold

the F687 in position. The F687

mustbesecuredinpositionby

firmly fastening the sprinkler sys-

tem piping to the dwelling struc-

ture. If the F687 is not properly

secured in position, reaction

forces resulting from sprinkler

operation could alter its orienta-

tion and water distribution pat-

tern.

RESIDENTIAL DESIGN CRITERIA

The 5.8 K-factor, Model F687 Resi-

dential Horizontal and Recessed Hori-

zontal Sidewall Sprinklers must only

be installed and utilized in accordance

with the following described criteria

which are provided by the manufac-

turer.

NOTES

1. Residential Fire Sprinkler Sys-

tems should only be designed

and installed by those compe-

tent and completely familiar

with automatic sprinkler sys-

tem design, installation pro-

cedures, and techniques.

2. Several criteria may apply to

the installation and usage of

each sprinkler. Consequently,

it is recommended that the

sprinkler system designer re-

view and develop a working un-

derstanding of the complete

list of criteria, prior to initiat-

ing the design of the sprinkler

system.

3. Questions concerning sprink-

ler installation and usage cri-

teria, which are not covered by

the following instructions,

should be mailed to the atten-

tion of the Technical Data De-

partment. Include sketches

and technical details, as ap-

propriate.

4. In some instances, the require-

mentsofthisdocumentmay

concern specifications which

are more stringent and which

take precedence over those

specified in NFPA 13, NFPA

13D,NFPA13R,orbythe

authority having jurisdiction.

General Service Conditions. The

F687 Sprinklers must only be utilized

in wet pipe sprinkler systems with all

interconnecting system piping as well

as the sprinklers maintained at a mini-

mum temperature of 40°F/4°C, and

with water supplies which are substan-

tially free of contaminants and parti-

cles of a size greater than 1/8 inch (3,2

mm).

Hydraulic Design Criteria. The mini-

mum required flow rates for residential

applications are given in Table A as a

function of the maximum allowable

coverage areas. The NFPA 13D/13R

single sprinkler flow rate is the mini-

mum required discharge from the most

hydraulically demanding single sprin-

kler and the NFPA 13D/13R multiple

sprinkler flow rate is the minimum re-

quired discharge from each of the total

number of “design sprinklers” as speci-

fied in NFPA 13D or 13R.

TIA 99-1 (Tentative Interim Amend-

ment) with an effective date of May 22,

2000 states that the minimum re-

quired discharge from each of the “de-

sign sprinklers” for systems designed

to NFPA 13 must be calculated based

on delivering a minimum design den-

sity of 0.1 gpm/sq. ft. for each of the

listed coverage areas shown in Table

A. Consult with the Authority Having

Jurisdiction regarding the application

of this TIA to the currently adopted

NFPA 13.

NOTE

The number of sprinklers within

each compartment (as defined by

NFPA 13, 13D, or 13R), must be

kept as few as possible. Do NOT

use more sprinklers than neces-

sary to cover a particular space.

Spray Coverage Criteria. Each F687

Sprinkler must only be used in accord-

ance with one of the designated width

by length (W x L) coverage criteria

specified in Table A.

Ceiling mounted obstructions such as

heating or air conditioning diffusers,

overhangs, and light fixtures must be

located above an elevation, as shown

in Figure C, where they will not inter-

fere with the proper distribution of

water by the sprinkler.

F687 Sprinklers may be installed along

overhangs or soffits that are a maxi-

mum of 8 inches wide (distance from

wall); with a maximum vertical dis-

tance of 4 inches from the centerline of

the sprinkler waterway to the bottom of

the overhang/soffit; and, with a de-

flector-to-soffit surface distance of

—4—

DuPont Registered Trademark

OBSOLETE

1-7/16 to 3 inches when using a flush

mount escutcheon as shown in Figure

B-1, or with the Model F705 Escutch-

eonasshowninFigureB-2.

NOTE

Use of overhangs or soffits with

dimensions exceeding the above

specified criteria is permitted if

additional sprinkler protection is

provided for the area below the

overhang/soffit.

The F687 Sprinklers must NOT be lo-

cated

1. along a wall/partition having a re-

cessed range oven, countertop, or

alcove,

2. along a wall/partition having an ad-

joining wood or coal burning stove,

or

3. along a wall/partition containing a

fireplace or wall oven.

NOTE

The spray from the F687 is dis-

tributed radially outward and

downward from the sprinkler

deflector. Consequently, the

sprinklers must be located

such that there will not be any

blind spaces shielded from

sprayby partitions, room divid-

ers, overhangs or other parts of

the dwelling structure.

Operational Sensitivity Criteria. The

F687 Sprinklers must only be installed

1. beneath level ceilings,

2. beneath solid ceilings having a

smooth or textured surface,

3. with a deflector-to-wall surface dis-

tance of 1-7/16 to 6 inches or a de-

flector-to soffit surface distance of

1-7/16 to 3 inches when using a flush

mount mount escutcheon as shown

in Figure B-1, unless the Model F705

Recessed Escutcheon is being util-

ized as shown in Figure B-2.

4. with a deflector-to-ceiling distance

per Table A, and

5. at least 4 inches away from an inside

or outside corner.

The F687 Sprinklers must NOT be

used

1. beneath soffits or overhangs, unless

they are only providing protection for

the area underneath the soffit/over-

hang and additional sprinkler protec-

tion is provided for the area in front

of the soffit/overhang,

2. above or below open-gridded type

suspended ceilings, or

3. with beams, joists, or ducts located

within the sprinkler coverage areas.

NOTE

Where utilized, beams, joists, or

ducts must be located with their

centerlines along the boundaries

separating adjacent sprinkler

coverage areas.

It is recommended that as part of the

sprinkler system design, the designer

review the dwelling plans and, where

appropriate, advise the owner or his

representative as to the following.

I. Lintels of at least 3 inches in height

and preferably 8 inches should be

used over all passageways from one

space to another, in order to reduce

the possibility of sprinkler operations

outside of the fire area.

II. Beams of at least 3 inches of height

should be used to border each of 3

or more adjoining areas of F687

Sprinkler coverage (within the same

compartment), in order to decrease

the time to first sprinkler operation as

well as to reduce the possibility of

multiple sprinkler operations.

Cold Soldering Criteria. With refer-

ence to Table A, the F687 Sprinklers

must be located such that

1. the minimum lateral distance “C” be-

tween adjacent sprinklers is 8 feet,

and

2. the minimum distance “D” between

sprinklers located opposite or with

their waterway centerlines at 90° to

each other is 14 feet, except where

a portion of the dwelling structure or

a partition will shield the spray of one

sprinkler from the other.

Heat Source Criteria. Refer to NFPA

13D or NFPA 13R for the requirements

relating to preventing the possible re-

lease of an F687 heat responsive ele-

ment (Bulb), due to exposure to heat

sources other than abnormal fire.

—5—

FIGURE C

ALLOWABLE ELEVATION FOR CEILING MOUNTED OBSTRUCTIONS

SUCH AS HEATING OR AIR CONDITIONING DIFFUSERS, OVERHANGS

AND LIGHT FIXTURES

NOTES:

1. For a given position within the coverage area, ceiling mounted obstructions must not

hang below the elevation dimension given in the graph.

2. Elevation dimensions are with respect to the top of the Deflector Hat (Ref. Figure A),

where positive (+) dimensions are above the Deflector Hat and negative (-) dimen-

sions are below. (Reference: the Deflector Hat is 3/8" above the sprinkler centerline of

waterway.)

OBSOLETE

INSTALLATION

NOTES

Residential Fire Sprinkler Sys-

tems should only be designed and

installed by those competent and

completely familiar with auto-

matic sprinkler system design, in-

stallation procedures, and tech-

niques.

The Technical Data Department

should be contacted relative to

any questions.

Do not install any bulb type sprin-

kler if the bulb is cracked or if

there is a loss of liquid from the

bulb. With the sprinkler held

horizontal, a small air bubble

with an approximate diameter of

1/16 inch should be be present.

The Model F687 Residential Sprin-

klers must be installed in accordance

with the following instructions:

1. The F687 Sprinkler must be installed

with the centerline of the waterway

horizontal and perpendicular to the

backwall surface.

NOTE

It is recommended that a spirit

level be used to level the sprin-

kler fitting as shown in Figure F

and that a square be used to

check perpendicularity of the

waterway centerline to the

mounting surface.

2. Prior to installing each Sprinkler,

verify that the outer face of the mat-

ing fitting is within the proper range

of distance of the mounting surface,

which can be accommodated by the

particular type of escutcheon plate

being used.

When installing a Model F687 Pen-

dent Sprinkler with the F705 Re-

cessed Escutcheon, for best overall

appearance, use Dimension “A” in-

dicated under the “Fully Recessed

Dimensions” heading of Figure B-2.

Otherwise, use Dimension “A” under

the “High Adjustment Dimensions”

heading. In either case, the remain-

ing adjustment can be used to com-

pensate for the possible manufac-

turing variations in the take-out of

the fitting, as well as in the make-in

of the sprinklers (as permitted by

ANSI B1.20.1).

3. After installing the F705 Mounting

Plate (or other escutcheon, as appli-

cable) over the sprinkler threads and

with pipe thread sealant applied to

the pipe threads, hand tighten the

sprinkler into the sprinkler fitting.

4. Wrench tighten the sprinkler using

only a W-Type 9 Sprinkler Wrench

(Ref. Figure D) for horizontal side-

wall sprinkler installations or the W-

Type 10 Wrench (Ref. Figure E) for

recessed horizontal sidewall sprin-

kler installations. The wrench recess

is to be applied to the sprinkler

wrench flats (Ref. Figure A). The

word “TOP” on the deflector must

face towards the ceiling.

NOTES

A leak tight 1/2 inch NPT sprin-

kler joint should be obtained

with a torque of 7 to 14 ft.lbs. (9,5

to 19,0 Nm). A maximum of 21

ft.lbs. (28,5 Nm) of torque is to be

used to install sprinklers.

Higher levels of torque may dis-

tort the sprinkler orifice seat

with consequent leakage.

It is recommended that a spirit

level be used to level the Deflec-

tor, as shown in Figure F.

Do not attempt to make-up for

insufficient adjustment in an

Escutcheon Plate by under- or

over-tightening the Sprinkler.

Readjust the position of the

sprinkler fitting to suit.

5. In recessed horizontal sprinkler in-

stallations, after the wall has been

installed or the finish coat has been

applied, slide on the F705 Closure

over the Model F687 Sprinkler and

push the Closure over the Mounting

Plate until its flange comes in con-

tact with the wall.

—6—

FIGURE F

LEVELING OF

SPRINKLER FITTING

AND DEFLECTOR

FIGURE D

W-TYPE 9 SPRINKLER WRENCH

WRENCH

RECESS

FIGURE E

W-TYPE 10 RECESSED

SPRINKLER WRENCH

OBSOLETE

CARE AND MAINTENANCE

The Model F687 Sprinklers must be

maintained and serviced in accord-

ance with the following instructions:

NOTES

Absence of an Escutcheon Plate

may delay the time to sprinkler

operation in a fire situation.

Before closing a fire protection

system main control valve for

maintenance work on the fire pro-

tection system which it controls,

permission to shut down the af-

fected fire protection systems

must be obtained from the proper

authorities and all personnel who

maybeaffectedbythisaction

must be notified.

Particular care to prevent over-

heating must be exercised when

storing sprinklers in cars, trucks,

trains, or other vehicles on warm,

bright sunny days.

Sprinklers which are found to be leak-

ing or exhibiting visible signs of cor-

rosoin must be replaced.

Automatic sprinklers must never be

shipped or stored where their tempera-

ture will exceed 100°F/38°C and they

must never be painted, plated, coated,

or otherwise altered after leaving the

factory. Modified sprinklers must be re-

placed. Sprinklers that have been ex-

posed to corrosive products of com-

bustion, but have not operated, should

be completely cleaned by wiping the

sprinkler with a cloth or by brushing it

with a soft bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers - before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed. Also, replace any sprinkler that

has a cracked bulb or that has lost

liquid from its bulb (Ref. Installation

Section).

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

addition to the standards of any other

authorities having jurisdiction. The in-

stalling contractor or sprinkler manu-

facturer should be contacted relative to

any questions.

It is recommended that automatic

sprinkler systems be inspected,

tested, and maintained by a qualified

Inspection Service.

The F687 Sprinklers must only be re-

placed with pendent sprinklers which

are listed for residential fire protection

service and which have the same

nominal K-factor, the same coverage

area, and the same or lower flow rat-

ings (as indicated under “Hydraulic

Design Criteria”).

All residential sprinklers installed

within a compartment (as defined by

the NFPA) must have the same heat

response thermal characteristic, and

their temperature ratings are to be

within 10°F of each other.

NOTES

Wet pipe sprinkler systems must

be maintained at a minimum tem-

perature of 40F/4C. Exposure to

freezing temperatures can result

in bursting of the pipe and/or

sprinkler.

Do NOT enclose sprinklers within

drapes, curtains, or valances.

Do NOT hang anything from the

sprinklers.

Automatic sprinklers are NOT to

be tested with a heat source. Op-

eration of the heat responsive

element (Bulb) can result.

Do NOT cleanse the sprinklers

with soap and water, detergents,

ammonia, cleaning fluids, or

other chemicals. Remove dust,

lint, cobwebs, cocoons, insects,

andlarvaebygentlybrushing

with a feather duster or gently

vacuuming with a soft bristle (i.e.,

dusting) brush attachment.

The minimum vertical clearance

between the tops of free standing

partitions, room dividers, cab-

inets, storage racks, stock piles,

etc., and the sprinkler deflector is

NOT to be less than the clearance

given below.

Horizontal Distance Vertical

from Sprinkler Clearance

to Item, ft. In.

Morethan9........32

From6to9 ........26

Lessthan6 ........18

Exercise suitable safety precau-

tions in the use and storage of

highly flammable and potentially

explosive materials. The rapid

rate of fire development and

spread which can be caused by

such materials can reduce the

ability of the sprinkler system to

aidinthecontrolofafirein

which they are involved.

LIMITED WARRANTY

Products manufactured by Tyco Fire

Products are warranted solely to the

original Buyer for ten (10) years

against defects in material and work-

manship when paid for and properly

installed and maintained under normal

use and service. This warranty will ex-

pire ten (10) years from date of ship-

ment by Tyco Fire Products. No war-

ranty is given for products or

components manufactured by compa-

nies not affiliated by ownership with

Tyco Fire Products or for products and

components which have been subject

to misuse, improper installation, corro-

sion, or which have not been installed,

maintained, modified or repaired in ac-

cordance with applicable Standards of

the National Fire Protection Associa-

tion, and/or the standards of any other

Authorities Having Jurisdiction. Mate-

rials found by Tyco Fire Products to be

defective shall be either repaired or

replaced, at Tyco Fire Products’ sole

option. Tyco Fire Products neither as-

sumes, nor authorizes any person to

assume for it, any other obligation in

connection with the sale of products or

parts of products. Tyco Fire Products

shall not be responsible for sprinkler

system design errors or inaccurate or

incomplete information supplied by

Buyer or Buyer’s representatives.

IN NO EVENT SHALL TYCO FIRE

PRODUCTS BE LIABLE, IN CON-

TRACT, TORT, STRICT LIABILITY OR

UNDER ANY OTHER LEGAL THE-

ORY, FOR INCIDENTAL, INDIRECT,

SPECIAL OR CONSEQUENTIAL

DAMAGES, INCLUDING BUT NOT

LIMITED TO LABOR CHARGES, RE-

GARDLESS OF WHETHER TYCO

FIRE PRODUCTS WAS INFORMED

ABOUT THE POSSIBILITY OF SUCH

DAMAGES,ANDINNOEVENT

SHALL TYCO FIRE PRODUCTS’ LI-

ABILITY EXCEED AN AMOUNT

EQUAL TO THE SALES PRICE.

THE FOREGOING WARRANTY IS

MADE IN LIEU OF ANY AND ALL

OTHER WARRANTIES EXPRESS OR

IMPLIED, INCLUDING WARRANTIES

OF MERCHANTABILITY AND FIT-

NESS FOR A PARTICULAR PUR-

POSE.

REMODELING

When remodeling, such as by adding

false beams or light fixtures or chang-

ing the location of compartment walls,

first verify that the new construction

will not violate the installation require-

ments stated under WARNINGS. Alter

the new construction and/or the sprin-

kler system to suit the requirements of

this document.

—7—

OBSOLETE

ORDERING PROCEDURE

A Product Symbol Number (PSN) is

not specified when ordering polyester

coated Model F687 Sprinklers with

other than a white color or when order-

ing color coated F705 Recessed Es-

cutcheons with other than white color.

It is suggested that a color chip be

provided when ordering special color

finishes. Otherwise, responsibility for

duplication cannot be accepted.

Contact your local distributor for avail-

ability.

Sprinkler Assembly:

Specify: 155°F Model F687 Residen-

tial Horizontal Sidewall Sprinkler with

(specify type) finish, PSN (specify).

Chrome Plated Finish

155F/68C . . . . . . . . . . . . . . . . PSN 51-687-9-155

Natural Brass Finish

155F/68C . . . . . . . . . . . . . . . . PSN 51-687-1-155

White Polyester Finish

155F/68C . . . . . . . . . . . . . . . . PSN 51-687-4-155

Recessed Escutcheon:

Specify: 1/2" (15 mm) Model F705 Re-

cessed Escutcheon with (specify fin-

ish), PSN (specify).

1/2" (15 mm) F705

Chrome Plated . . . . . . . . . PSN 56-705-9-010

1/2" (15 mm) F705

White Color

Coated. . . . . . . . . . . . . . . . PSN 56-705-4-010

Sprinkler Wrench:

Specify: W-Type 9 Sprinkler Wrench,

PSN 56-000-1-849.

Specify: W-Type 10 Recessed Sprin-

kler Wrench, PSN 56-000-1-948.

Order for NFPA publications should be

addressed to the:

Publication Sales Department

NFPA

Batterymarch Park

Quincy, MA 02269

WEIGHT

The nominal weight of the Model F687

Residential Horizontal Sidewall Sprin-

kler is 2.9 ounces.

OBSOLETE

Table of contents

Other GEM Irrigation System manuals