4

© 2021. All rights reserved.

5

© 2021. All rights reserved.

INSTALLATION INSTRUCTIONS Continued

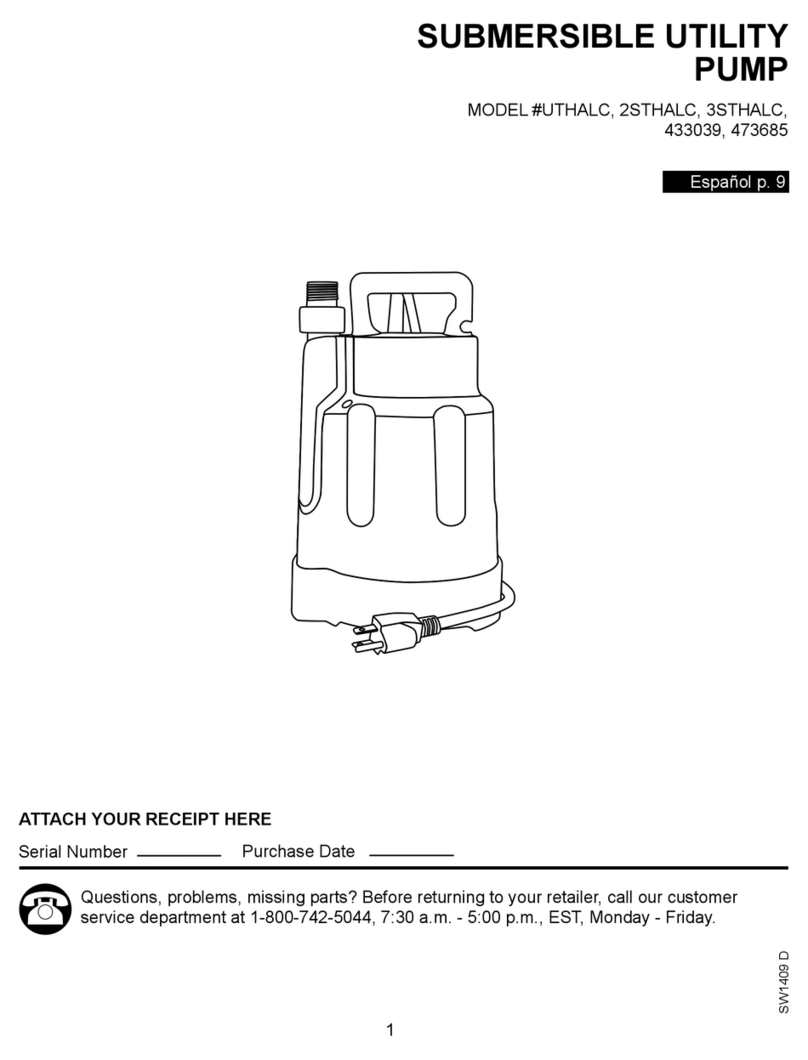

2. Flush piping with water before connecting the

hydrant to clear any gravel or other debris

that may have collected in the piping during

installation and assembly. If not ushed

thoroughly, this debris may jam the hydrant

mechanism or clog the ow ports.

3. Make the pipe connection, but do not bury

the hydrant at this time. Operate the hydrant

to be sure it functions properly and the pipe

connections do not leak. Open and close the

hydrant and check the ow and draining. If

leaks continue from the drain port, see the

following section on HOW TO ADJUST THE

FROST-PROOF YARD HYDRANT.

3

2

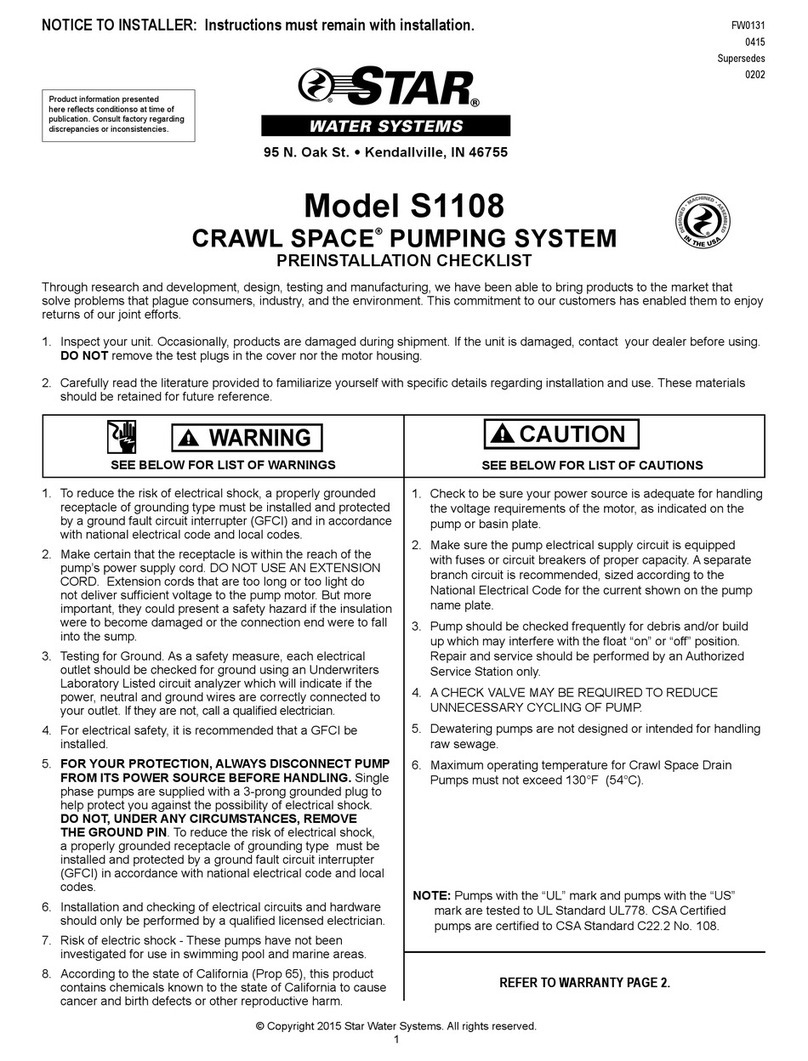

Water pressure requirements

Water supply pressure to the hydrant should be regulated at no more than 80 PSI. Higher pressures

will accelerate wear and may cause leakage that will saturate the ground and drain field and prevent

the hydrant from draining. If the hydrant is not allowed to drain, it can freeze and become damaged.

It might also cause flooding and loss of water. High pressure will also cause frequent hydrant

adjustments and lead to increased need for replacement parts. A normal operating pressure should

be 20 to 60 PSI.

NOTE: For installations on a municipal system, you must use a vacuum breaker or backflow device in

accordance with local plumbing codes.

Pipe requirements

160# PSI test pipe is recommended for municipal applications. For most other applications, 100# PSI

plastic coil pipe is recommended.

Drain eld requirements

Saturated ground in the hydrant drain field can prevent the hydrant from draining and may result in

freezing. If the area where the hydrant is located is low lying or has a tendency to collect standing

water, a larger drain field or pit may be required to provide proper draining.

GENERAL INFORMATION

1/8 IN.

DRAINAGE PIPE

WATER SUPPLY

CAUTION: Never leave a hose attached to the hydrant after use. The hose will prevent the hydrant

from draining properly and cause the hydrant to freeze in cold weather. Leaving the hose attached

might also siphon contaminants back into the water system.

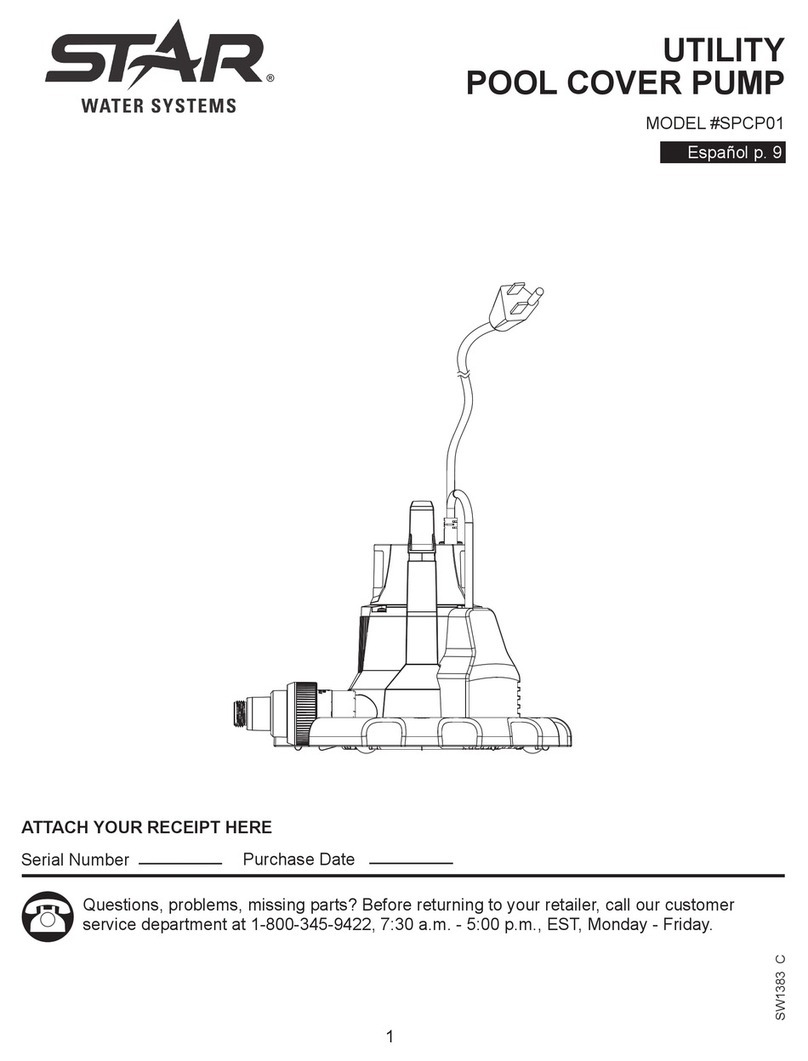

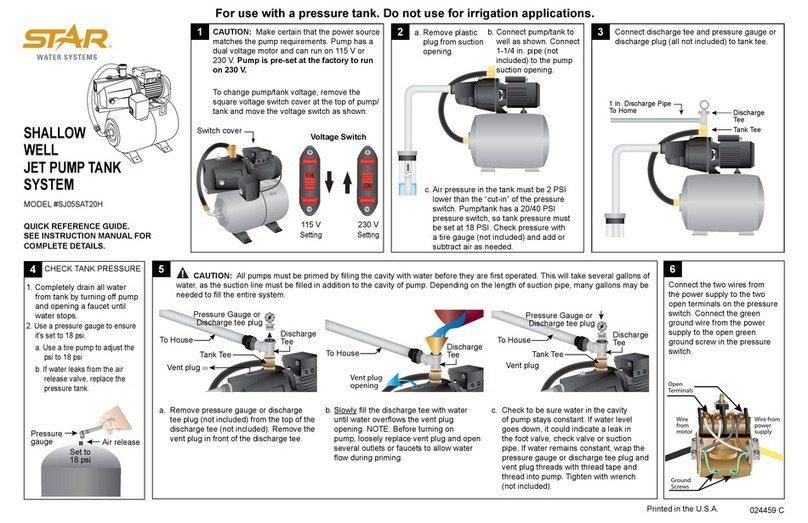

Installing hydrant in a building or in asphalt or concrete

If the hydrant will be installed inside a barn or other

structure, or if it is installed in asphalt or concrete such

as a driveway, connect a 1/8” drain pipe or tube to

the drain port and dig a remote drain field outside the

structure for the drain pipe to empty into. Without this

remote piping and drain field, the water from the hydrant

drainage will percolate up to the surface around or near

the hydrant and will damage the flooring or cause muddy

areas in stalls or walkways.

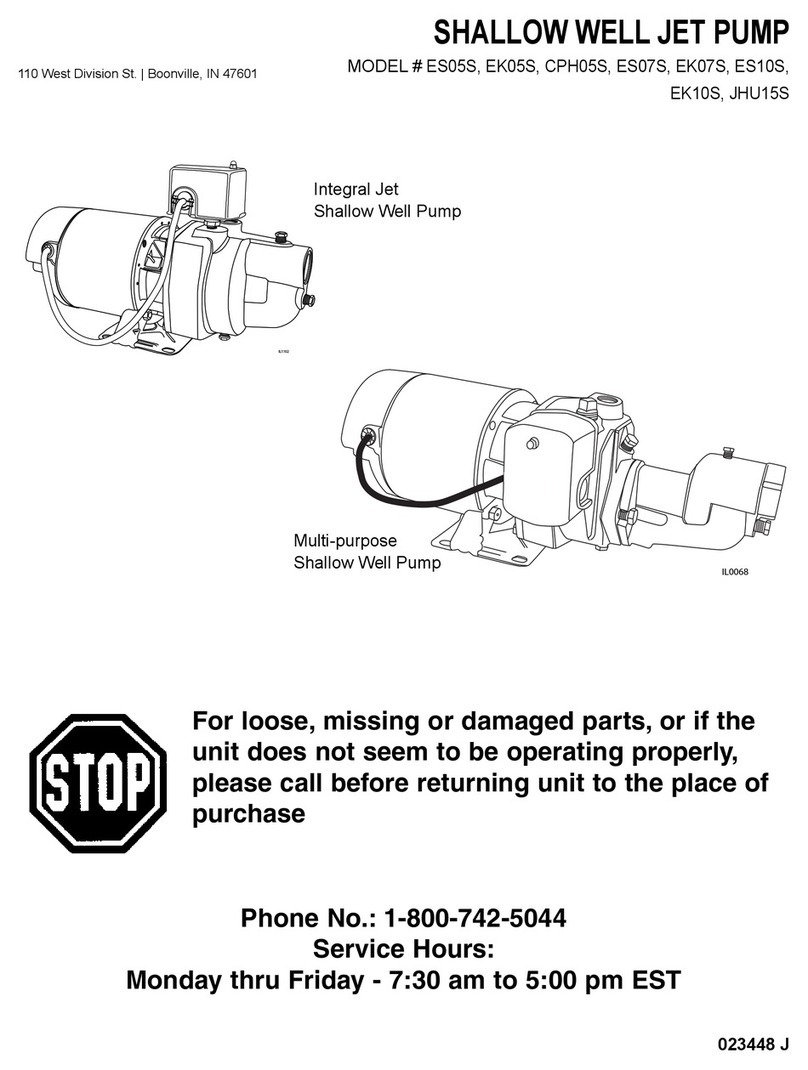

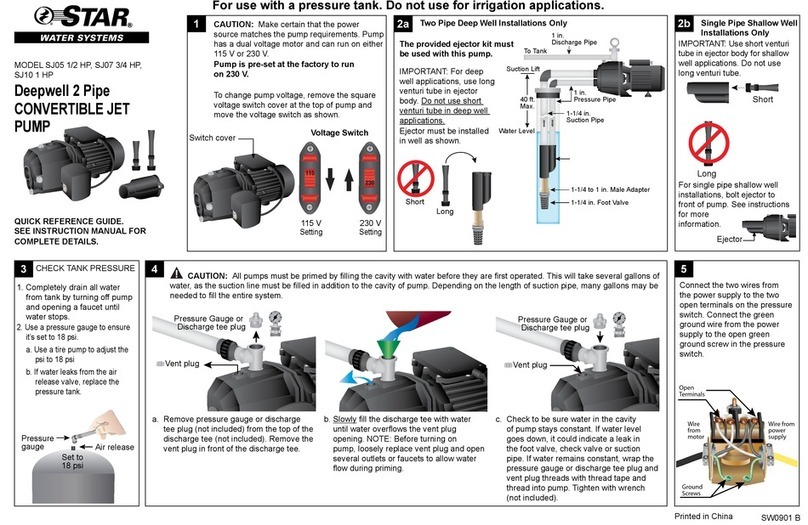

INSTALLATION INSTRUCTIONS

1. Locate the hydrant away from any septic

systems or vehicle trac and convenient for

stock or other watering purposes. Dig a hole for

the hydrant approximately 2 ft. in diameter and

1 ft. deeper than the bury depth.

NOTE: It is helpful to place a brick or cinder block

under the hydrant to support the hydrant and pipe

when the ground settles.

Be sure the total depth of the hole is sucient to

allow the brass valve to be installed below the frost

line. (See local plumbing codes.)

BURY

DEPTH

WATER

SUPPLY

2 FT.

1 FT.

APPROX.

24 IN.

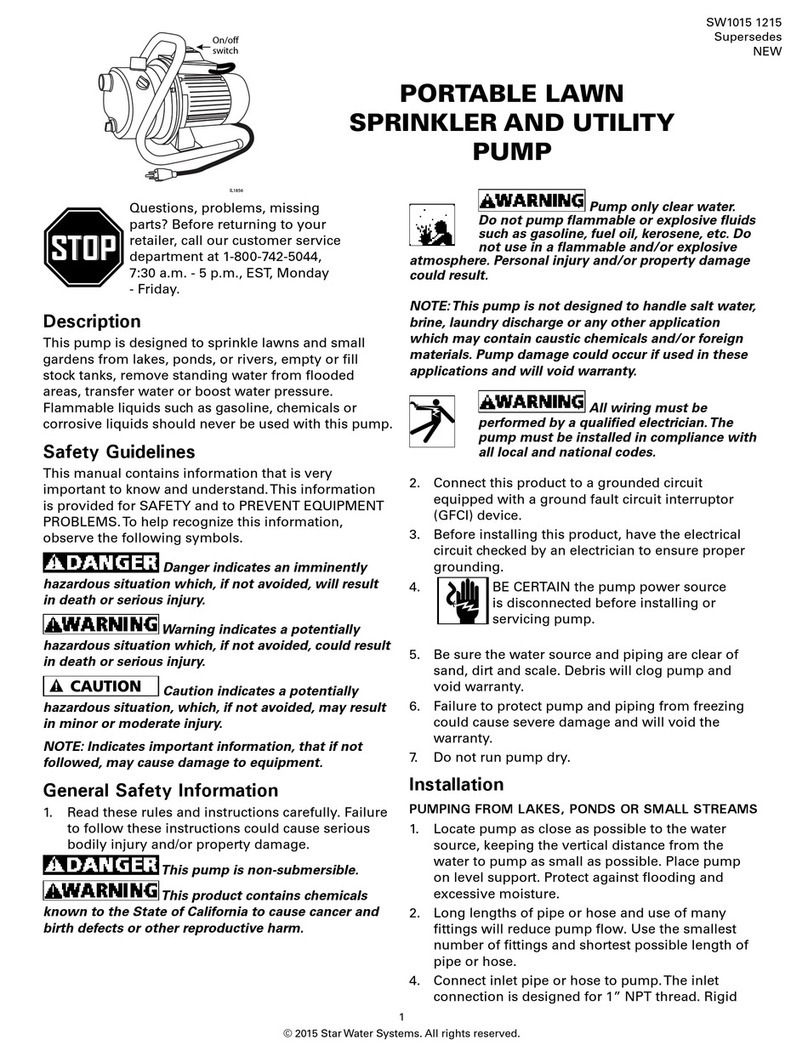

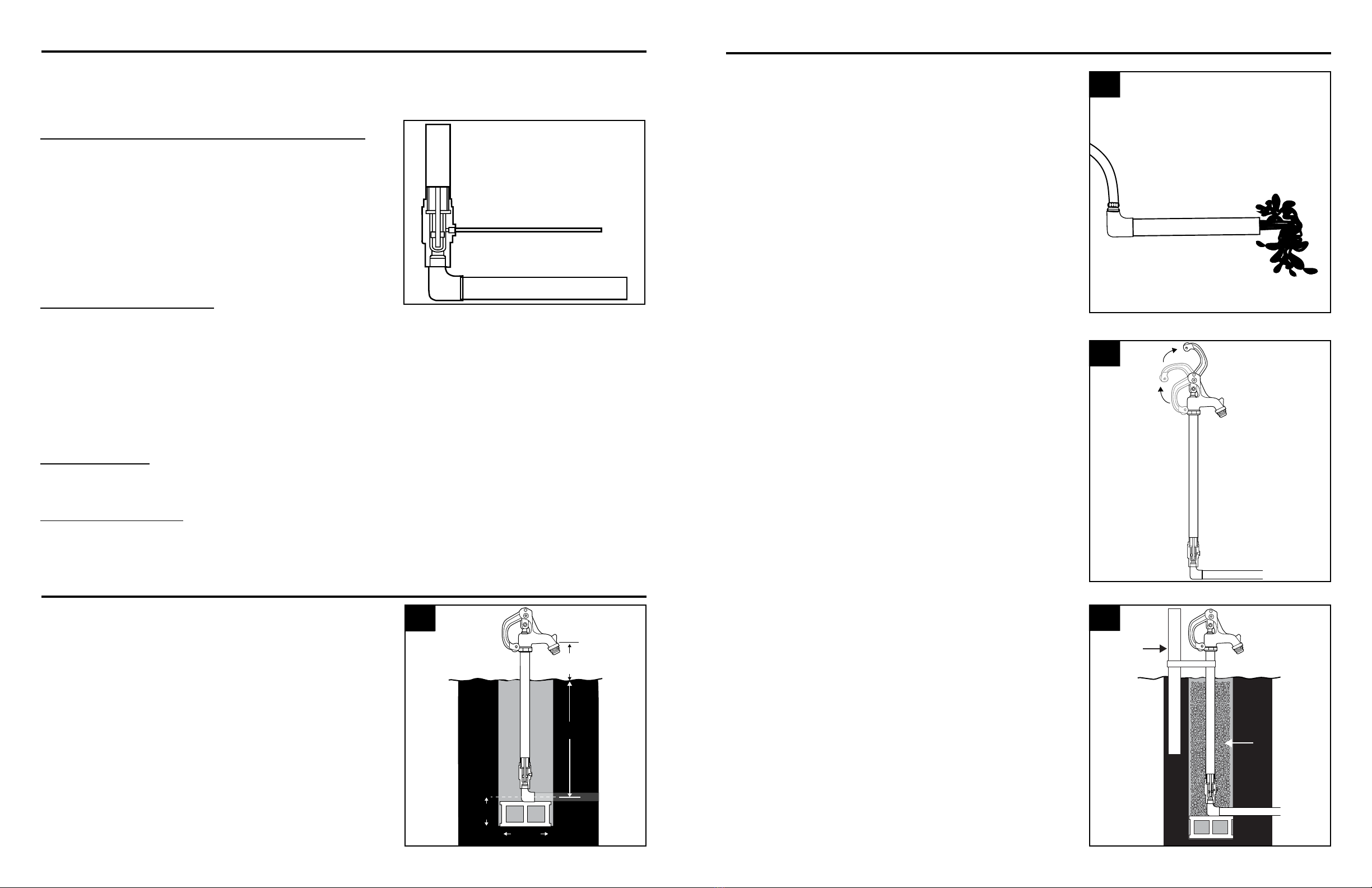

14. Set the hydrant in the hold vertically and ll

the hole around and below the hydrant with

medium size gravel. This will provide a drain

eld for the hydrant. Without a drain eld, the

hydrant will not empty itself and it will freeze

in cold weather. This will damage the hydrant

and cause loss of water and possible ooding

damage.

NOTE: For additional support, install a 4x4 post

next to the hydrant and clamp the pipe to the

post to help keep the hydrant level.

4x4

POST

GRAVEL

4