PowerTransfer

Air-cooledSinglecylinderEngine isamountedaspower

source and Centrifugal Clutchis fixedonengine output

shaft.Petrol Engine(2 cycle,4cycle)and Diesel Gasoline

Engine can be mounted as option.CentrifugalClutch

engages byrunning up theengineand engine R.P.M. is

reduced to suitable number for compacting.The rotation

of engineistransmitted from V-pulleyintegrated with

ClutchdrumtoVibratorpulley through V-belt.

Vibrator Pulley rotates Eccentric rotor shaft that is contained in

Vibratorcase.Thegenerated vibration created

fromeccentric rotor is transmitted to Compaction with the

weightof themachinemakesthecompaction ofthe

groundpossible.

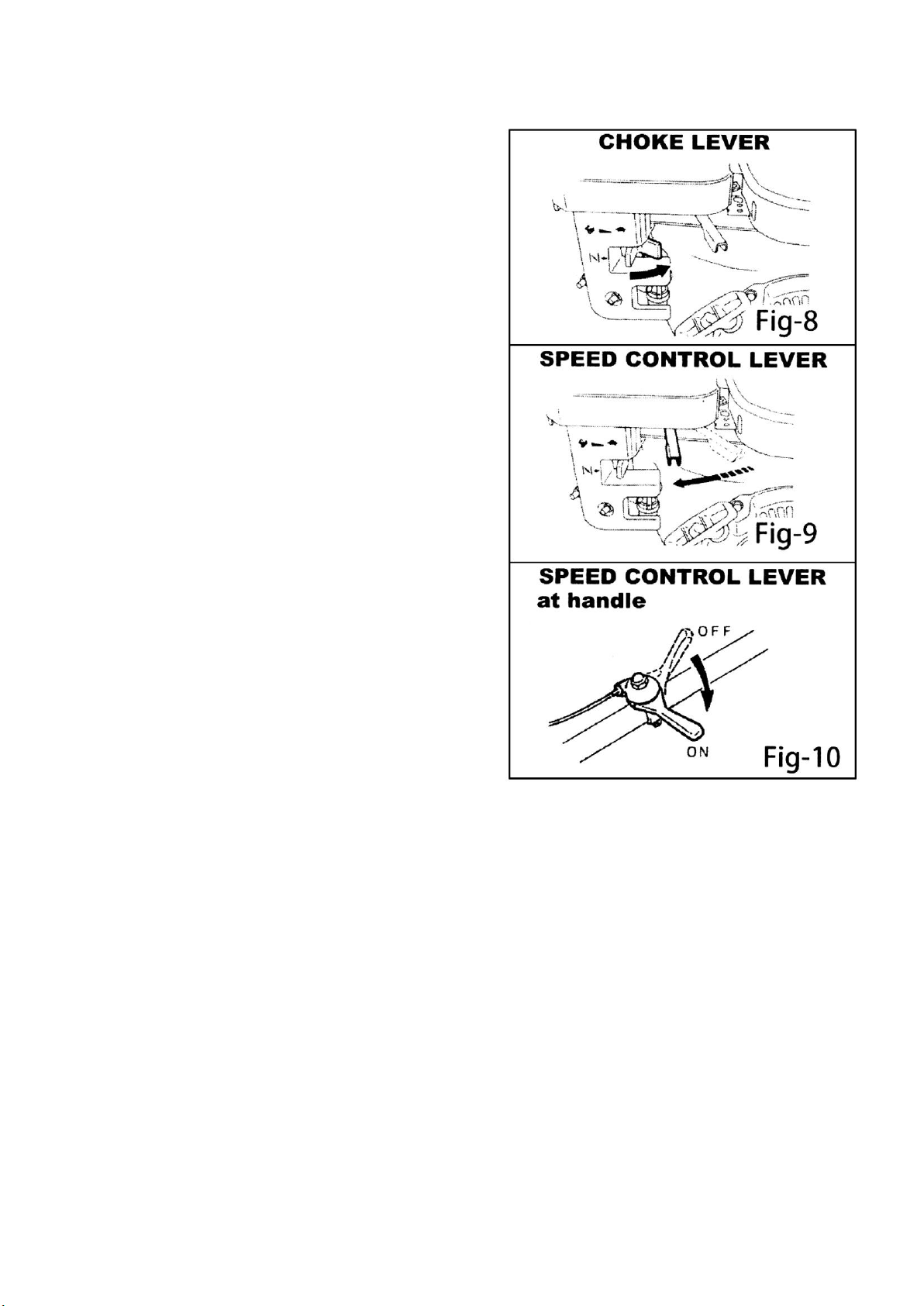

FUNCTIONS AND CONTROLS

Motor

The motor is controlled by an ON/OFF switch or push button

which is mountedon the motorbelowthe fuel tank.

The motor speed is controlled by a remote throttle lever which is

mountedonthemachine handle.

Honda and Kama motors are fitted with an oil alert device which

will stop the motor or prevent starting when the crankcase oil

level falls below a safe level.

Drive belt

Tension of the drive belt is adjustable.Loosen the four nuts on

the bolts which secure the motor to the base plate,Adjust the set

screws which bear against the motor crankcase to achieve the

requiredbelttension.Ensurethat thefour nuts andthe setscrew

locknutsaretightenedafteradjustment.

ACCESSORIES

Transport Trolley-facilitates handling.Hooks into the base-

plate.Fitted with 200mm rubber tyres.

FOR SAFETY OPERATION

!This safetyalert symbol identifies

importantsafetymessagesthroughout

thismanualand onthemachine.

Whenyouseethis symbol,carefullyread

the messagethat follows.Yoursafetyis

atstake!

Foreword:

It is important to readthis manual carefullyso

that you will fully understand the operational

characteristics and performanceofthe plate

compactor.Propermaintenance proceduresWill

insure long lifeand top performance of the unit.

Safety:

Thissectionoutlines basicsafetyprocedures that

applytotheoperation,maintenanceand

adjustmentoftheplatecompactor.This

unitisdesignedasapowerful,productive

machine thatshouldbe operated withrespectand

caution.

Misuse orcarelessnesscanresult inserious injury

orpropertydamage,orboth.Safetyprecautions

mustbeobservedatalltimes.

Operator Qualifications:

Before operating this equipment,anindividual

shouldreadthis manual.Wheneverpossible,he

should be shownhow to operate the unit byan

experiencedoperator.Inexperience ishazardous

in operatinganymachineorattachment.Trialand

error is not the wayto become familiar with a

pieceofequipment.This isexpensive,cuts

equipmentlife andcan createmachinedowntime.

Inexperiencecancauseinjuryordeath.The

machine should not be left unattended when

operating.

GeneralSafety:

! CAUTION

Protectionrequired.Wearhardhat.shatterproof

glasses,steeltoedbootsandotherprotective

devices requiredbyjobconditions.Avoidjewelry

orlooseclothing.These manycatchoncontrols

or in moving partsand cause seriousinjury.

Starting Safety:

! CAUTION

Poisonousfumes.Start and operate only in well

ventilatedarea.Breathingexhaustgases can

resultin sicknessordeath.

Servicing Safety:

! CAUTION

Flammableliquid.Stopengineanddonot

smokeorallow workinimmediatearea

when refueling.Fireor explosioncould

resultfromflamesorsparks.

Movingparts.Shutdownenginebefore

performing.Service or maintenance.

Contact with moving parts can cause

serious injury.

High temperature.Allowmachineand

engineto coolbeforeperformingservice

or maintenance.Contact with hot

componentscancauseserious bums.

Engine

See engine operationsmanual

SHUTDOWN

EMERGENCYSHUTDOWN

Movethrottleleverto "OFF"position

andalso turn stop switchto "OFF".

NORMALSHUTDOWN

Movethrottleleverquicklyfrom

"ON"to "OFF" and runengine for3

to5 minutesatlowspeed.After

engine cools, turn stop switch to

"OFF"position.Closefuelshutoff

valve.