Important Safety Instructions

WARNING

1. Before use, read this Instruction Manual thoroughly.

Do not expose the charger and battery to rain or use

them in damp or wet locations, as this may cause

overheating or electric shock.

2. Keep work area clean.

Cluttered areas and benches invite injuries.

3. Keep the work area well lit.

Working where there is insufcient light may cause

an accident

4. Keep children away.

Do not allow children or unauthorized personnel to

handle tool.

5. Store idle tools.

When not in use, tools should be stored in a dry and

secure place. Keep out of reach of children.

6. Do not force tool.

It will do the job better and safer at the rate for which

it was intended. Do not force tool to work beyond its

ability. Excessive load will cause seizure of the motor,

overheating, smoke and re.

7. Use right tool.

Do not force small tool or attachment to do the job of

a heavy-duty tool.

8. Wear safety glasses and protective clothing.

Always wear safety glasses, safety footwear, safety

gloves, and any other mandated or necessary protective

clothing while using this equipment. Failure to do so may

result in injury.

9. Dress properly.

Do not wear loose clothing or jewelry as they can be

caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

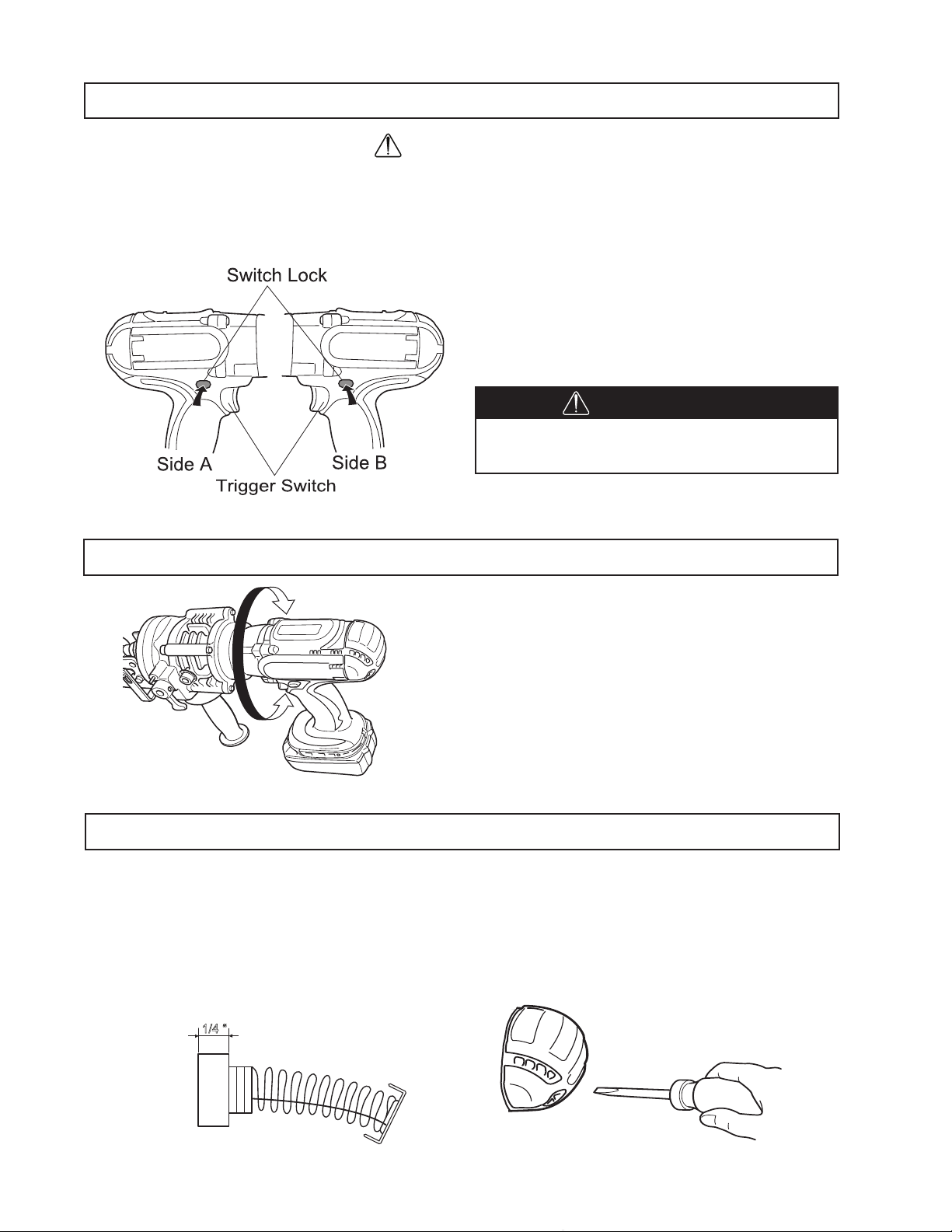

10. Hold tool securely.

A tool that is not held securely may injure you. Use

clamps or a vice to hold the work. This frees both

hands to properly hold, control, and operate the tool.

Failure to properly secure the work may result in injury.

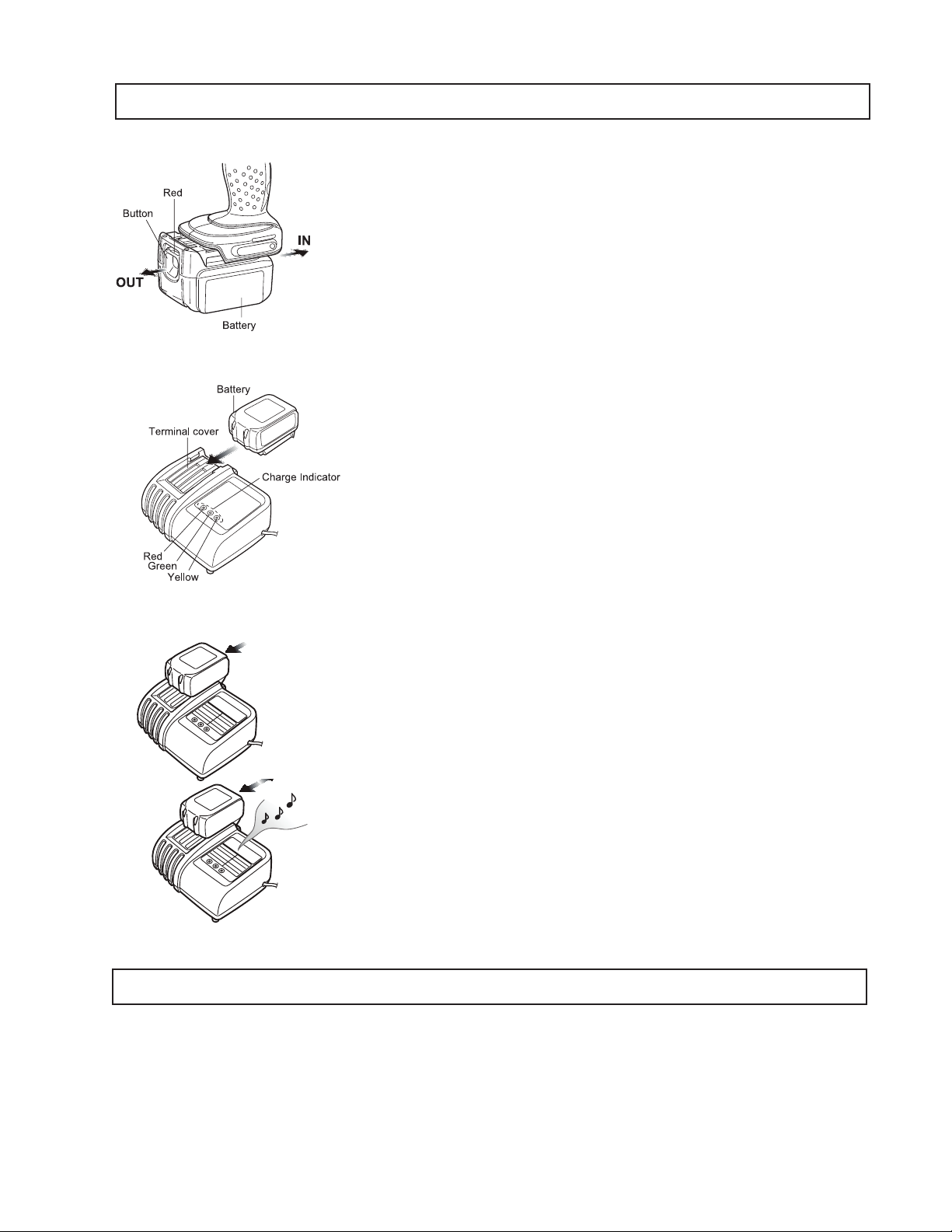

11. Disconnect the tools power supply, by removing

the battery and engaging the Trigger Switch Lock,

whenever one of the following situations occur:

The tool is not in use or is being serviced, any parts

such as a blade, are being replaced. There is a

recognized hazard. Failure to do so may result in

unexpected operation and damage or injury.

12. Avoid unexpected operation.

Do not carry the tool by the Trigger Switch as this may

cause unexpected operation and damage or injury.

13. Do not abuse power cord.

Never carry battery charger by its power cord or pull

on the cord to disconnect it. Keep cord away from heat,

oil and sharp objects. Place cord so that it will not be

stepped on, tripped over, or otherwise subjected to

damage or stress. If the tool is dropped or struck,

check carefully that the body is not damaged, cracked,

or deformed.

14. Do not overreach.

Keep proper footing and balance at all times.

15. Maintain tools carefully.

Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and

changing accessories. Inspect battery charger power

cord periodically and, if damaged, have it repaired

by Hougen Manufacturing, Inc. Keep handles dry,

clean, and free from oil and grease.

16. Remove keys and wrenches.

Always check to see that keys and wrenches

are removed from tool before starting operation.

17. Stay alert when using electric tools.

• Consider safety of others.

• Operate tool with care.

• Watch what you are doing.

• Use common sense.

• Do not operate tool when you are tired.

18. Check for damaged parts.

• Before using the tool, carefully check all parts for

damage, including guards, to ensure that they will

operate properly and perform their intended function.

• Check for any misalignment or binding of moving

parts; damaged or broken parts and mountings; and

any other conditions that may affect its operation.

• Do not use battery charger if electric plug or cord is

damaged or if it was dropped or damaged in any way.

• A guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

instruction manual.

• Do not use tool if switch does not turn it on and off.

Have damaged or defective switch replaced by

Hougen Manufacturing, Inc.

19. Service at Hougen Manufacturing Only.

Service this electric machine in accordance with

the relevant safety regulations. Repairs to electric

machines should only be done by a qualied person.

Repairs by others may endanger the user. Contact

Hougen Mfg., Inc. to arrange servicing.

20. Only use the specied accessories or attachment.

Use only the specied accessories or attachment

described in this Instruction Manual and the Ogura

catalog. Use of any other accessories or attachments

may result in an accident or injury.

3