SETUP AND INSTALLATION

The suction line should ascend steadily toward the pump to prevent air pockets.

Sufcient water supply must be assured; the end of the suction line should always be in water.

All components of the pressure line must be compression-proof.

All components of the pressure line must be professionally installed.

DANGER: Avoid damage to the device. The suction line must be installed so

that it does not exert any mechanical force or tension on the pump.

The device can also be connected rmly to a pipe system (domestic water supply in the interior). In this

case, the device should be connected to the pipe sytem with elastic high pressure exible hose lines in

order to prevent vibrations.

DANGER: If components are not compression-proof or if they are improperly

installed, the pressure line can burst causing serious injury. Seek professional help if

you are unsure.

OPERATING THE DEVICE

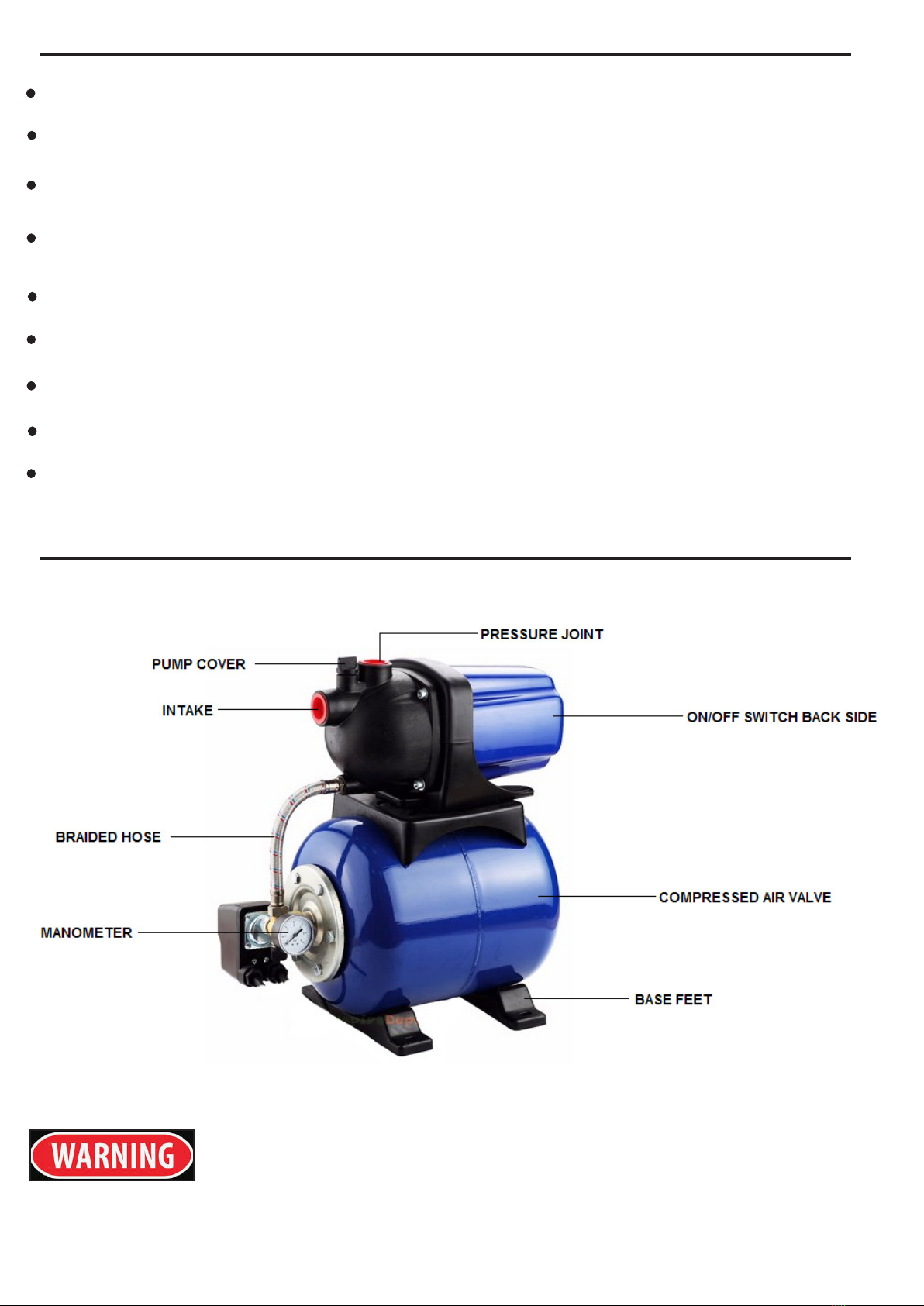

1. Unscrew the pump cover

2. Fill completely with water

3. Reinstall the lter and screw on the pump cover and seal back on

4. To shorten the intake time, ll the suction line as well

5. Open the pressure line so the air can escape during intake

6. Switch the device on

7. When the water runs out evenly, switch the device off

For better performance, installing a check line valve between the pump and suction line is

recommended so that the water column remains in the suction line.

If Domestic Water Works is installed directly in the water distribution network, it is important that the

water pressure from this network is added to the pump pressure. A total pressure of 6 bar must not

be exceeded.

NOTE: The boiler includes rubber bellows, which is under air pressure from the manufacturer. This

enables small amounts of water to be removed without starting up the pump. Check the pressure

before operating the pump and increase if necessary. The pump must not be placed in direct sunlight

as this could result in too high pressure.

1. Plug in the mains plug

2. Open the pressure line (turn on the spigot or nozzle)

3. Turn on the pump at the ON/OFF switch

4. Check to be sure water is coming out.

If the motor does not start up or the pump does not build up any pressure or if similar faults occur, turn

the device off and try to remedy the error.

The pump is equipped with a pressure switch. This turns the pump on if the water pressure in the

boiler drops below the start-up pressure due to water removal. The pressure switch turns the pump

off when the shutoff pressure is reached.

NOTE: The pressure switch is preset to the correct start-up and shutoff pressure by the manufacturer.

5