STARLINGER LOOM-CONTROL V Series User manual

LOOM-CONTROLSERIESV

LOOM-CONTROL

SERIESV

DBE-04547

Manufacturer

←

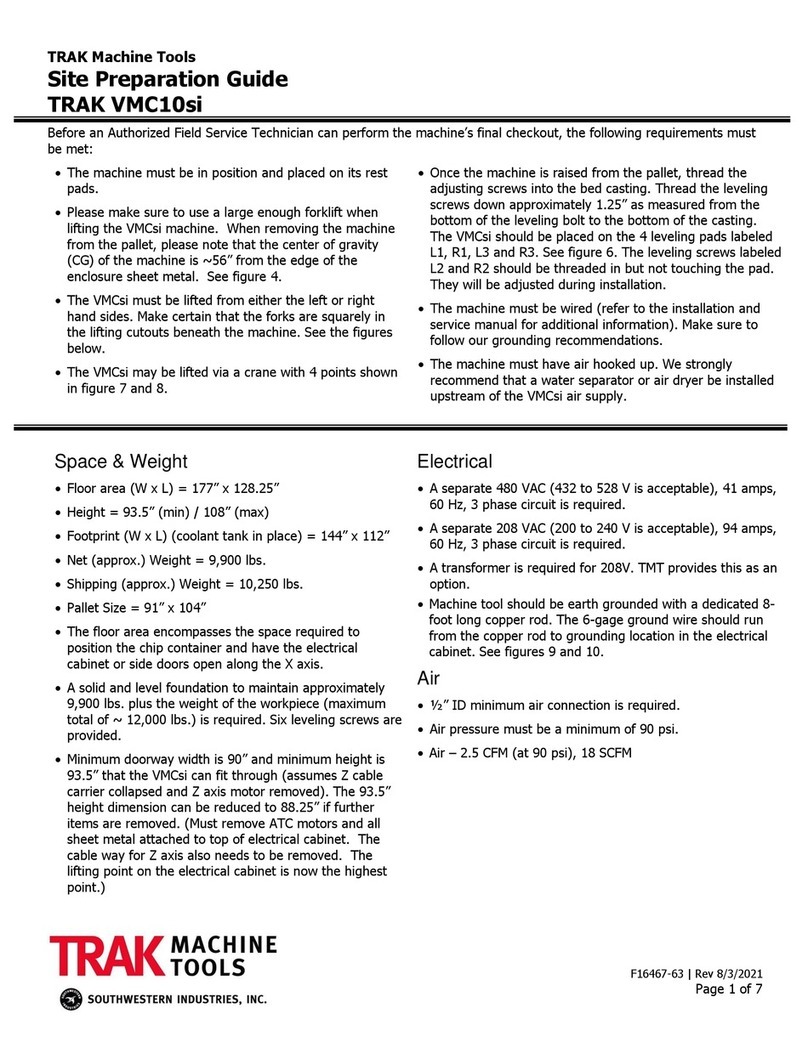

STARLINGER OMEGA-4

→M/C-Type(STACO-setting

madeinourworks)

Version 5.01

→Softwareversion

Customermachine

OMEGA-4 →M/Cadjustedbythe

customer

SAFETYAND WARNINGINSTRUCTIONS Page1

LOOM-CONTROL

SERIESV

DBE-04547

Before mountingthisdevice orsettingitintooperation,carefullyreadthe

safetyandwarninginstructionsandnoteall warninglabelsaffixedtothe

device.Makesure thewarninglabelsremainclearlylegibleandreplace

missingordamagedones.

WARNING

Thisdevice producesadangerouselectricaltensionandcontrolsdangerously

rotatingmechanicalparts.Death,grievousbodilyharmorimportantdamage

canresultiftheinstructionsofthisoperatingmanualarenotobserved.

Onlyqualifiedpersonnelshouldworkonthisdevice. Theseoperatorshaveto

befamiliarwithall warninginstructionsandthemeasurescontainedinthe

manualwithregardtothetransport,theinstallationandtheoperationofthe

device.Thecorrectfunctionandsafeoperationofthedevice dependson

appropriatehandling, installation, operationandmaintenance ofthedevice.

Theelectricalconnection,settingintooperationandtroubleshootingmust

becarriedoutonlybyspecialists.Thequalifiedpersonnelhastobefamiliar

withall warninginstructionsandmaintenance workdescribedinthis

operatingmanual.

Theloomcontrolmustnotbeopened!Otherwisetheguarantee ofgood

operationwill becancelled.

CAUTION

Childrenandthepublicmustnothaveaccess tothedevice!

Usethedevice onlyforthepurposeintendedbythemanufacturer.

Unauthorizedmodificationsandtheuseofsparepartsandaccessoriesnot

suppliedorrecommendedbythemanufacturercancausefire,electricshocks

andinjury.

Keeptheoperatingmanualincloseproximitytothemachineandhandit

overtoeveryoperator!

INDEX Page2

LOOM-CONTROL

SERIESV

DBE-04547

1 Functionaldescription: 4

2 Descriptionofsymbols: 5

3 Menu handlingand menu selection: 6

4 Settingthelanguageand measuringunit: 8

5 Settingtheshiftchange: 9

6 Resettingtheshiftindication: 9

7 Readingtheshiftdata: 10

8 Settingtheweftdensity: 11

9 Settingofthestartcorrection: 12

10 Settingofthestartcompression: 13

11 Settingofthestopcompression: 14

12 Settingoftheweftbreakcorrection: 16

13 Settingtheweftbreakcompression: 17

14 Manualhaul-off control: 18

15 Settingtheroll change: 19

16 Settingtheperiodicalweftcramming: 20

17 Settingthelubricatingintervaland thelubricatingtime: 21

18 Indicationoforderchange: 22

19 Readingofthemachinestatistics: 23

20 Readingthemachineparameters: 24

21 Changingthemachineparameters: 26

INDEX Page3

LOOM-CONTROL

SERIESV

DBE-04547

22 Customerpassword: 29

23 Fabricwidth: 30

24 Specialparametersettingforcustomer: 32

25 Defaultsettings: 33

26 Testmenu: 34

27 Menu survey: 36

28 Faultdescription: 41

29 Min. and max. settingsoftheindividualparameters: 46

30 Software-Update: 47

31 Contrastsetting: 48

32 Assignmentofconnections: 49

33 Glossary: 51

TECHNICALDESCRIPTION Page4

LOOM-CONTROL

SERIESV

DBE-04547

1Functionaldescription:

Theloomcontrolworksonbasisofanelectricalgearing.Animpulsetransmitter

mountedonthesheddrive,detectsthespeedofthesheddriveandtransfersittothe

loomcontrol.

Theloomcontrolcalculatesthespeedofthesheddrivewiththefactoroftheweft

insertion(Picks/10 cmorpicks/inch)andcontrolsthehaul-off motor.

Functions:

•Shiftcounter(4shifts+totalofshifts)

•Theweftdensitycanbesetviathekeyboard

•Indicationofthemachinespeed(picks/min)

•Indicationofthehaul-off speed(meters/min)

•Roll changeindication

•Periodicalweftcramming

•Indicationforchangeoftheorder

•Machinestatistics(dataarerecordedstartingwiththedelivery):

−Efficiency

−Mainswitchon

−Operatinghours

−Warpbreak

−Weftbreak

−Weftend

•Softwareupdateispossiblevianotebook.

TECHNICALDESCRIPTION Page5

LOOM-CONTROL

SERIESV

DBE-04547

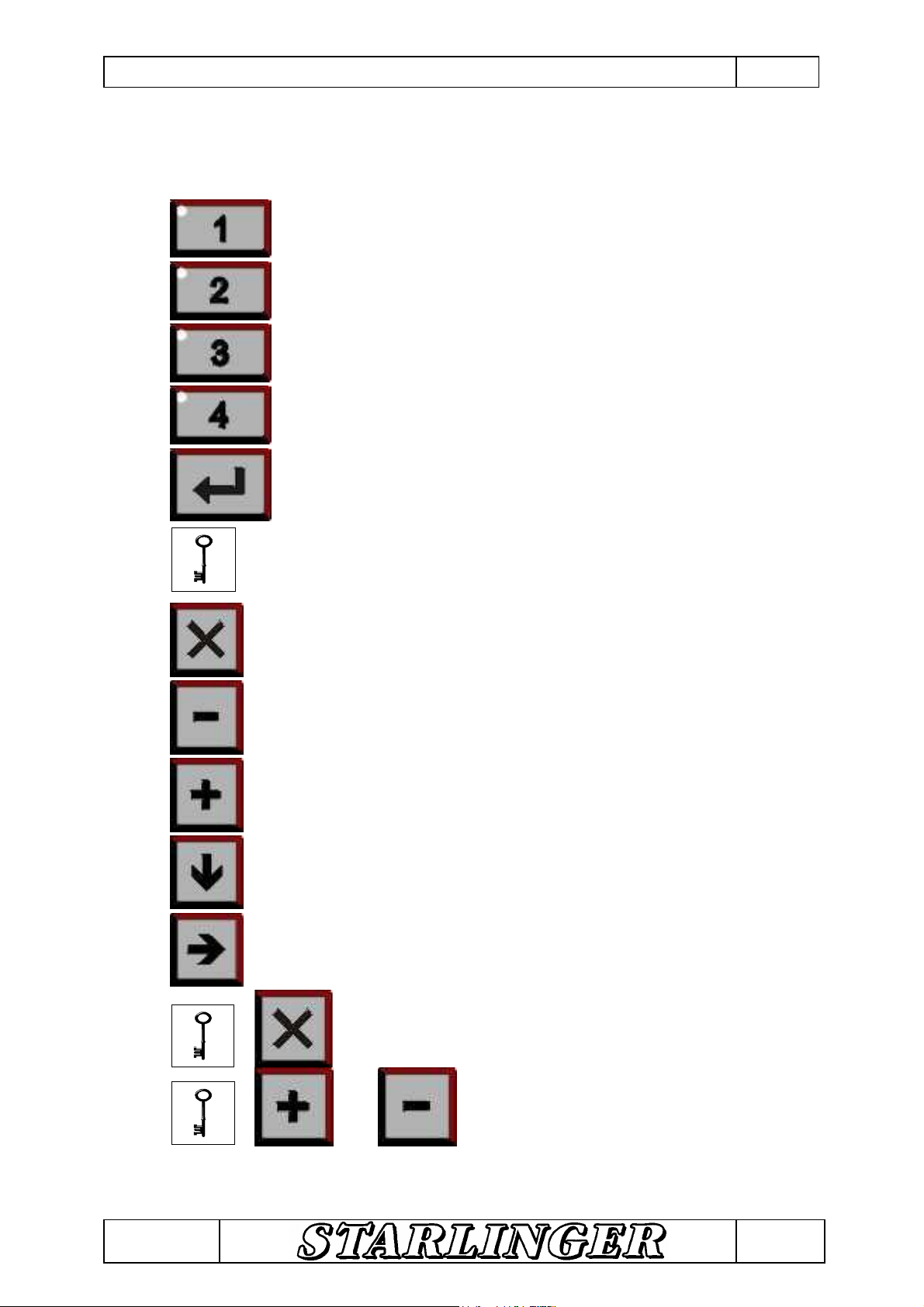

2Descriptionofsymbols:

Shift1

Shift2

Shift3

Shift4

Exit(Moving totheactiveshift)

Keyswitch

Reset

Reducing thevalue(inthetext[-] )

Increasing thevalue(inthetext[+])

Scrolling (inthetext[↓])

Formenu selection(intothemarkedmenu)

(inthetext[→])

Clearthevalue(Reset)

or

Increasing orreducing thevalues

TECHNICALDESCRIPTION Page6

LOOM-CONTROL

SERIESV

DBE-04547

3Menu handlingandmenu selection:

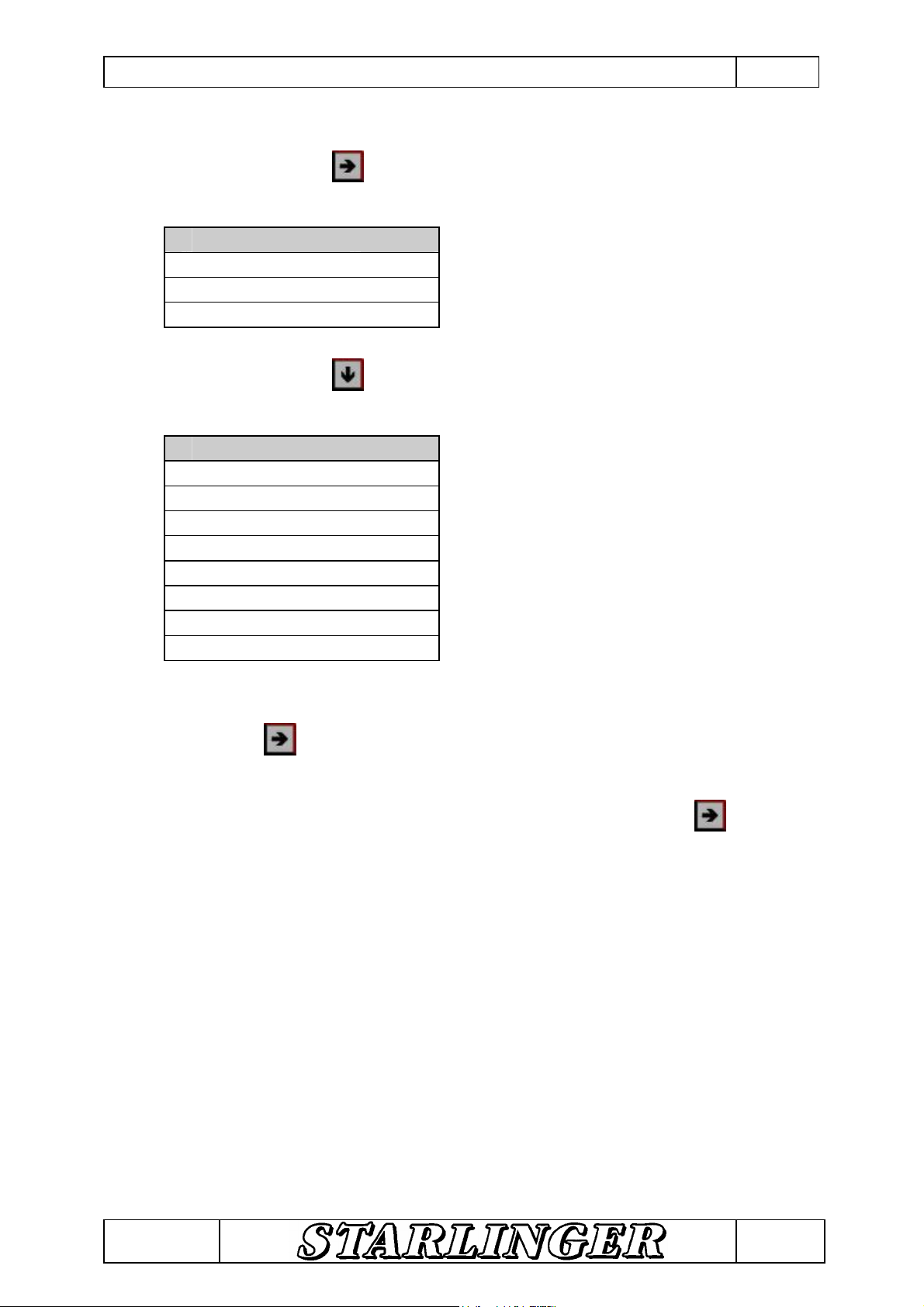

Whencuttinginthemainswitchtherewill automaticallyappear:

STARLINGER OMEGA-4

Version 5.01

Customermachine

OMEGA-4

Afterapprox. 3sec. youwill automaticallymovetotheselectedshifte.g. shiftmenu1:

>

SHIFT 1

Fabric 5687m

Efficiency 91%

Mainswitch 56h

Scrolling

>

SHIFT 1

Fabric 5687m

Efficiency 91%

Mainswitch 56h

Operat. time 51h

Warpbreak 9

Weftbreak 12

Weftend 153

Whenthesymbol>isshowingtoshift,youmovetotherespectiveshiftbyactuating

thekey , or (possibleonlyontheshut-off machine).

TECHNICALDESCRIPTION Page7

LOOM-CONTROL

SERIESV

DBE-04547

Bydepressingthekey youwill movetothemenuselection:

>

Menuselection

Weftdensity ->

Haul-off manual ->

Fabriccorrect. ->

Bydepressingthekey (scrolling)youcanselectamenu.

>

Menuselection

Weftdensity ->

Haul-off manual ->

Fabriccorrect. ->

Roll change ->

Period.cramming ->

Order ->

Shiftdata ->

Furthermenus ->

Themenuactuallyselectedcanbeseenbythemark>.

Withthekey (fortherespectivemenuselection)youmovetotheselectedmenu.

Atmachinestoppageyoucanchangetothenextmenuwiththekey onlyinthe

menuselection.

TECHNICALDESCRIPTION Page8

LOOM-CONTROL

SERIESV

DBE-04547

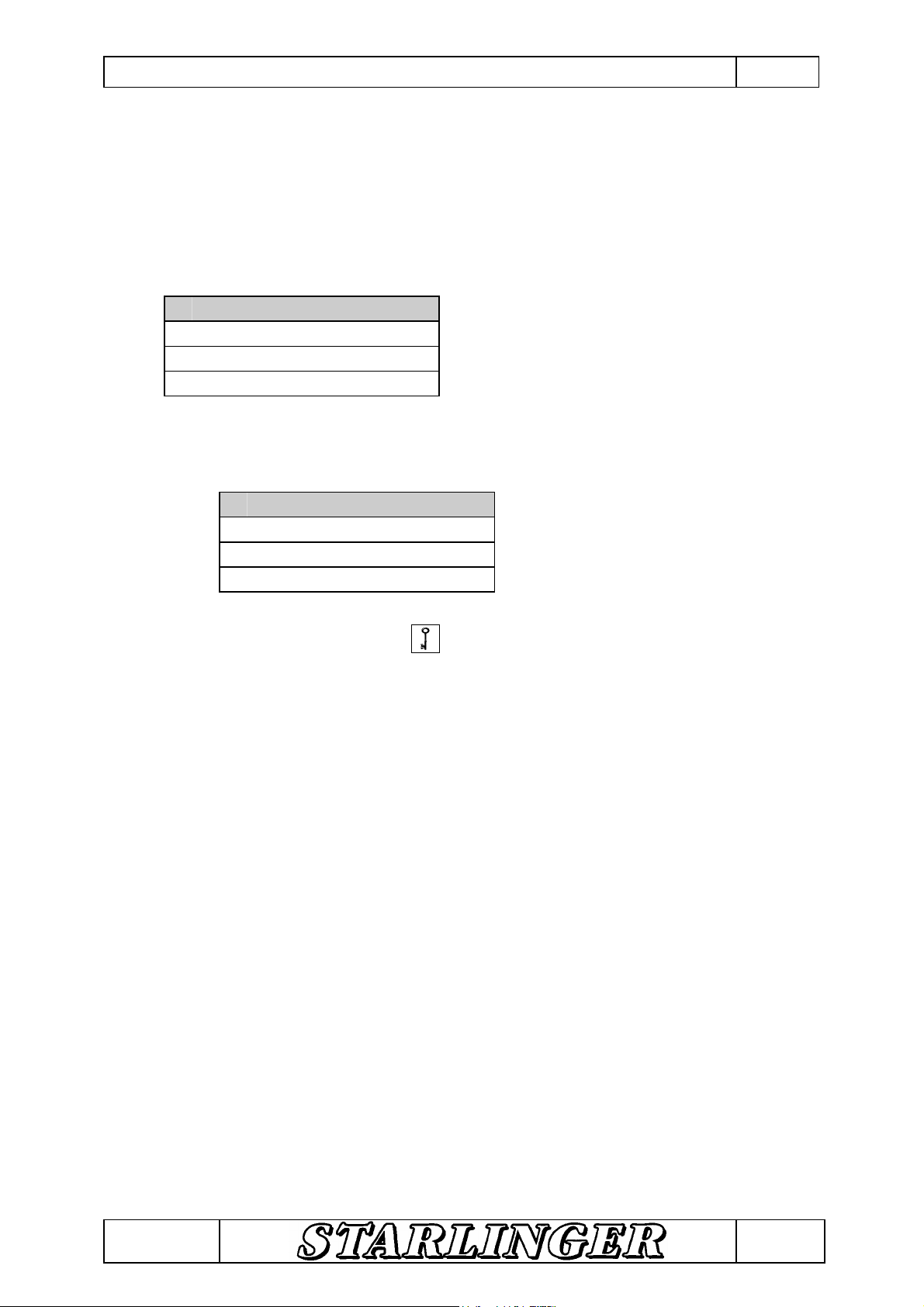

4Settingthelanguageandmeasuringunit:

•Settingofthelanguageandthemeasuringunitcanbedoneinthemainmenu[Menu

selection].

•Withthekey[↓]youwill moveto[Furthermenus].

Menuselection

Order ->

Shiftdata ->

>

Furthermenus ->

•Bydepressingthekey[→]and[↓]youwill movetothe[Systemmenu].

FURTHERMENUS

>

Systemmenu ->

Statisticmenu ->

Testmenu ->

•Bydepressingthekey[→]and[↓]youwill moveto[Language]and

subsequentlyto[Measuringunit].

SYSTEMMENU

Mach-No. 00-0000-00

>

Language English

Measuringunit cm

•Cutinthekeyswitch anddepress thekey[+]or[-] until the

desiredlanguageappearsonthedisplay. Youcanchoosebetweenthe

German,English,French,Spanish,Turkish,Portuguese,Hungarian

andChineselanguages.

Jumpingbacktothestandardlanguage,English:Thisisonlypossible

whenyouareinthestartmenu(3seconds).Afterhavingcutinthe

keyswitch youcanchangeovertoEnglishbysimultaneously

depressingthekeys and .

•Astothe[Measuringunit]youcanselectbetweencmorinchby

depressingthekey[+]or[-].

TECHNICALDESCRIPTION Page9

LOOM-CONTROL

SERIESV

DBE-04547

5Settingtheshiftchange:

>

SHIFT 1

Fabric 5687m

Efficiency 91%

Mainswitch 56h

scrolling[↓]:

>

SHIFT 1

Fabric 5687m

Efficiency 91%

Mainswitch 56h

Operat. time 51h

Warpbreak 9

Weftbreak 12

Weftend 153

•Ashiftchangecanbeeffectedonlyatmachinestoppage.

•Bydepressingthekey , or youwill movetotherespectiveshift.

(IndicationonthedisplayandwiththeLEDintheshiftkey).

•Withthekey (EXIT)youalwaysmovetotheactiveshift.

6Resettingtheshiftindication:

>

SHIFT 1

Fabric 0m

Efficiency 0%

Mainswitch 0h

•Afterhavingcutinthekeyswitch ,youcanclearthedataoftheindicatedshift

(setto0)byactuatingtheresetkey .

TECHNICALDESCRIPTION Page10

LOOM-CONTROL

SERIESV

DBE-04547

7Readingtheshiftdata:

Duringoperationthedataofall shiftscanbereadwithoutshutting-downthemachine.

•Readingoftheshiftdataisprovidedinthemainmenu[Menuselection].

•Withthekey[↓]youwill movetothe[Shiftdata].

Menuselection

Period. cramming ->

Order ->

>

Shiftdata ->

•Afteroperatingthekey[→]and[↓]youmoveto[Shift1].(Youcanalsoselectthe

Shift2, 3, 4andShiftTotal.)

Shiftdata

>

Shift1 ->

Shift2 ->

Shift3 ->

Scrolling[↓]:

Shiftdata

>

Shift1 ->

Shift2 ->

Shift3 ->

Shift4 ->

Shifttotal ->

•Whenactuatingthekey[→]youmovetothe[SHIFT DATA1].

>

SHIFT DATA1

Fabric 5687m

Efficiency 91%

Mainswitch 56h

Bydepressingthekey[↓]youcanscroll andreadall values.

>

SHIFT DATA1

Fabric 5687m

Efficiency 91%

Mainswitch 56h

Operat. time 51h

Warpbreak 9

Weftbreak 12

Weftend 153

Whenactuatingthekey[→]youmovebacktothesurvey[Shiftdata].

TECHNICALDESCRIPTION Page11

LOOM-CONTROL

SERIESV

DBE-04547

8Settingtheweftdensity:

•Settingoftheweftdensitycanbecarriedoutinthemainmenu[Menuselection].

•Withthekey[↓]youmoveto[Weftdensity].

Menuselection

>

Weftdensity ->

Haul-off manual ->

Fabriccorrect. ->

•Whenactuatingthekey[→]and[↓]youchangeoverto[....Weft/10cm].

WEFT DENSITY

>

32.0Weft/10cm

0Picks/min

Haul-off speed0.0m

•Cutinthekeyswitch andenterthedesiredvaluebymeansofthekeys

[+]or[-].

Youcanenterminimum10 weftinsertions/10 cm

maximum500 weftinsertions/10 cm.

Theweftinsertiondependsonthemachineandontheproduct.

•Inthismenuyoucanalsoreadthemachinespeed(Picks/min)andthehaul-

off speed(m/min).

TECHNICALDESCRIPTION Page12

LOOM-CONTROL

SERIESV

DBE-04547

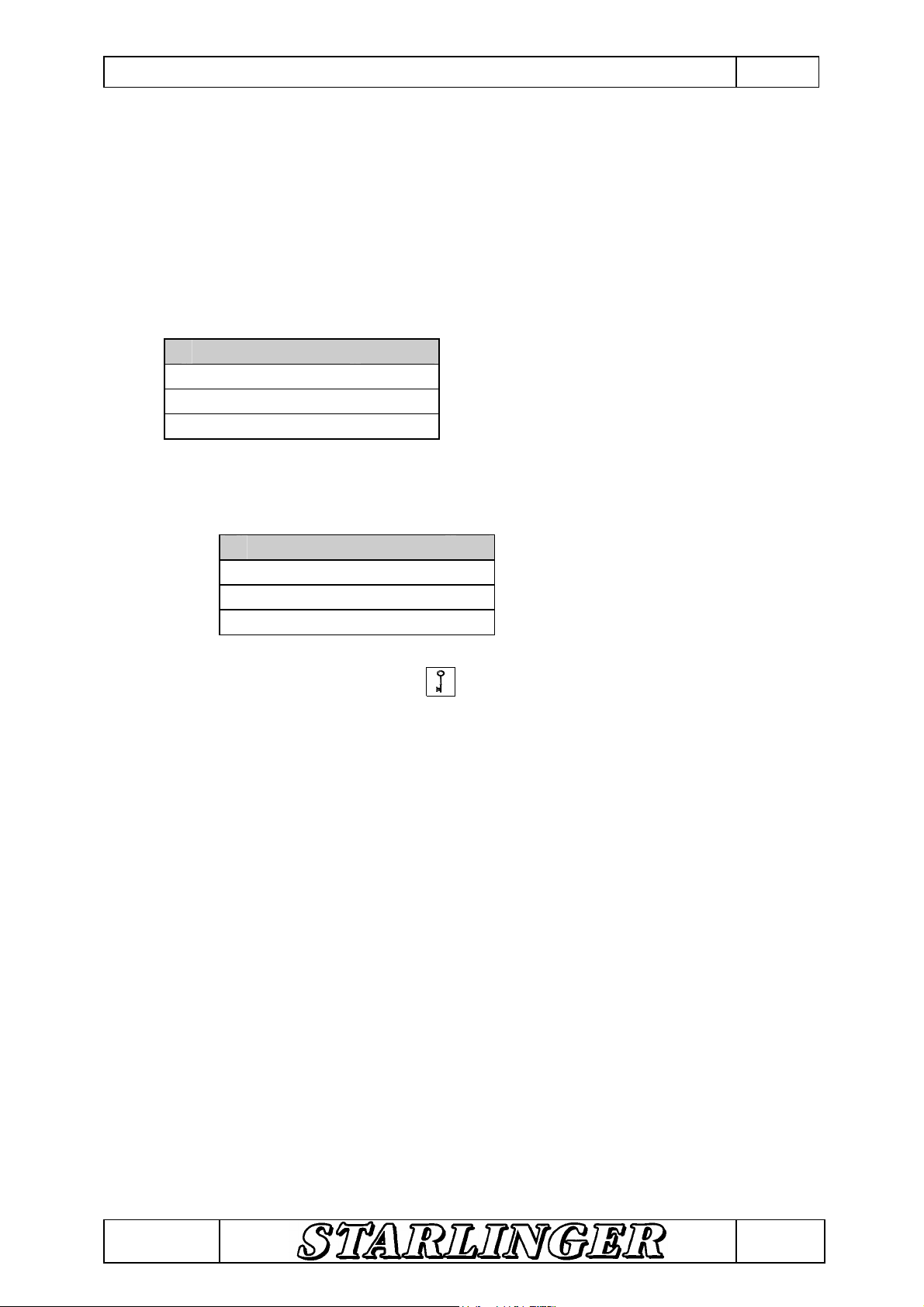

9Settingofthestartcorrection:

Thestartcorrectionisthatfabriclengthincentimetresinwhichthefabricwill be

compressedatthepercentageofthe“Startcompression”afterstart-up ofthemachine.

•Whenyouareinthemainmenu[Menuselection],youjumpwiththekey[↓]to

[Fabriccorrection].

Menuselection

Weftdensity ->

Haul-off manual ->

>

Fabriccorrect. ->

•Whenactuatingthekey[→]and[↓]youjumpto[Startcorrection].

FABRIC-CORRECT

>

Startcorrec 0.0cm

Startcompr. 0%

Stopcompress 10%

•Cutinthekeyswitch andsetthevalueincmwiththekeys[+]or

[-].

TECHNICALDESCRIPTION Page13

LOOM-CONTROL

SERIESV

DBE-04547

10 Settingofthestartcompression:

Thestartcompressionisthatpercentageatwhichthefabricwill becompressedwhen

themachineisstarting.

•Whenyouareinthemainmenu[Menuselection],youjumpwiththekey[↓]to

[Fabriccorrection].

Menuselection

Weftdensity ->

Haul-off manual ->

>

Fabriccorrect. ->

•Afterhavingactuatedthekey[→]and[↓]youjumpto[Startcompression].

FABRICCORRECT:

Startcorrec 0.0cm

>

Startcompr. 0%

Stopcompress 10%

•Cutinthekeyswitch andadjustthepercentagewiththekeys[+]or[-].

TECHNICALDESCRIPTION Page14

LOOM-CONTROL

SERIESV

DBE-04547

11 Settingofthestopcompression:

Thestopcompressionisthatpercentageatwhichthefabricwill becompressedwhen

themachinestops.

•Whenyouareinthemainmenu[Menuselection]youjumpwiththekey[↓]to

[Fabriccorrection].

Menuselection

Weftdensity ->

Haul-off manual ->

>

Fabriccorrect. ->

•Afterhavingoperatedthekey[→]and[↓]youjumpto[Stopcompress].

FABRICCORRECT:

Startcorrec 0.0cm

Startcompr. 0%

>

Stopcompress 10%

•Cutinthekeyswitch andsetthepercentagewiththekeys[+]or

[-].

TECHNICALDESCRIPTION Page15

LOOM-CONTROL

SERIESV

DBE-04547

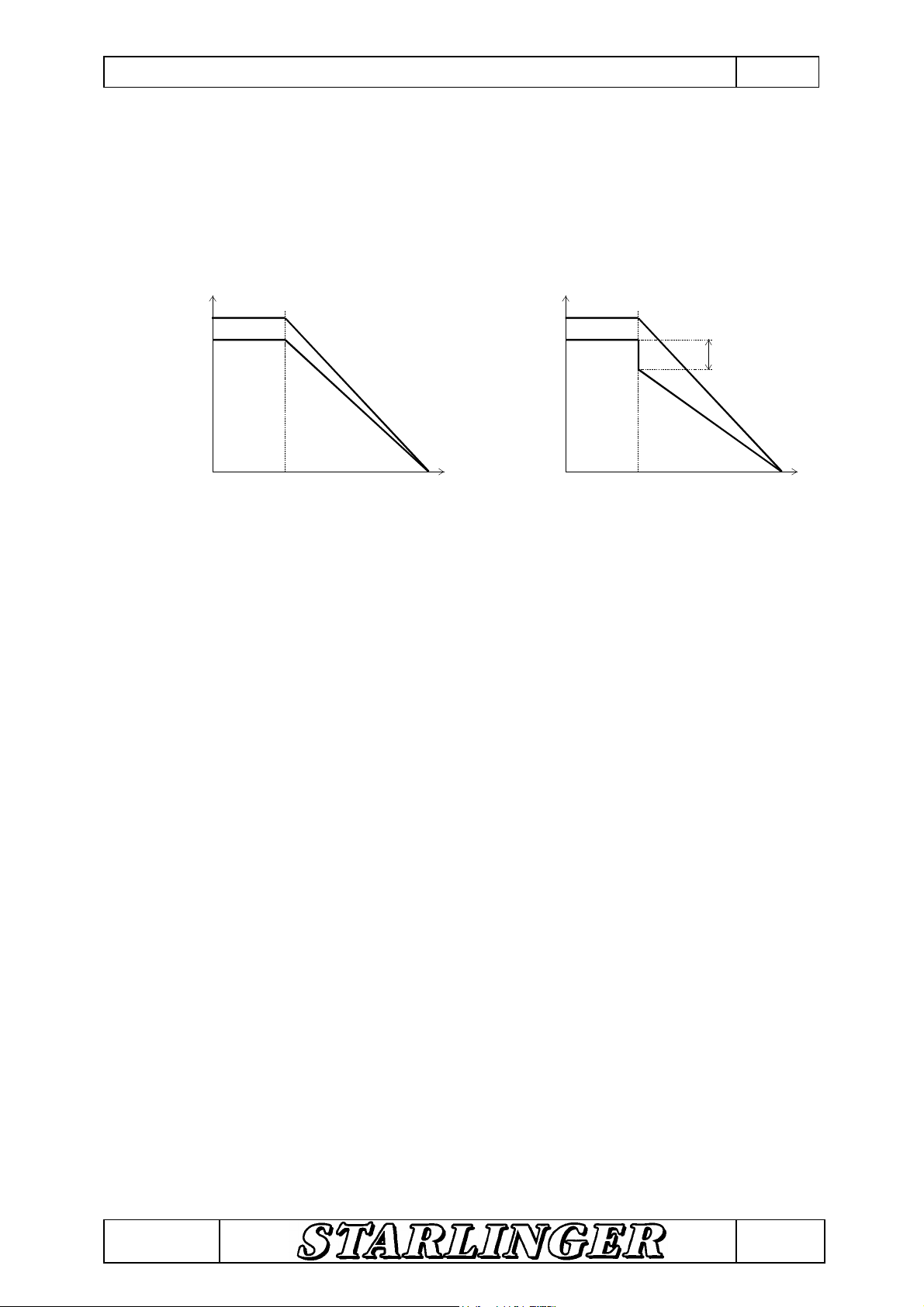

Example:

withoutstopcompression withsetstopcompression

Speed

Stopkey has been depressed

U

H

M

U

A

Z

Rampwith ramp down time

Time/s

Stopcompressin %ofthe

haul-off speedUAZ

Speed

Stopkey has beendepressed

U

HM

U

AZ

Ramp withramp down time

Time/s

Stop compress“0”

UHM -instantaneousspeedofcamrotation

UAZ -instantaneoushaul-off speed

e.g.:UAZ =78%-whenactuatingthestopkey,thehaul-off speedisreducedbytheset

slowdownorstopcorrection(e.g.:10%) toUAZ =68%.

TECHNICALDESCRIPTION Page16

LOOM-CONTROL

SERIESV

DBE-04547

12 Settingoftheweftbreakcorrection:

Theweftbreakcorrectionisthatfabriclengthincentimetreswithinwhichafteraweft

breakthefabricwill becompressedatthepercentageof“Weftbreakcompression”.

•Whenyouareinthemainmenu[Menuselection],youjumpwiththekey[↓]tothe

[Fabriccorrection].

Menuselection

Weftdensity ->

Haul-off manual ->

>

Fabriccorrect. ->

•Whenactuatingthekey[→]and[↓]youjumpto[Weftbrk.corr].

FABRICCORRECT

Startcompr. 0%

Stopcompress 10%

>

Weftbrk.corr 0.5cm

•Cutinthekeyswitch andadjustthecentimetreswiththekeys[+]or

[-].

TECHNICALDESCRIPTION Page17

LOOM-CONTROL

SERIESV

DBE-04547

13 Settingtheweftbreakcompression:

Incaseofabrokenwefttapetheclothiscrammedinordertoavoidanyvisibleweft

fault.

•Whenyouareinthemainmenu[Menuselection],youwill moveto[Fabric

correction]withthekey[↓].

Menuselection

Weftdensity ->

Haul-off manual ->

>

Fabriccorrect. ->

•Whenactuatingthekey[→]and[↓]youjumpto[Weftbrk. comp.].

FABRICCORRECT

Stopcompress 10%

Weftbrk.corr 0.0cm

>

Weftbrk.comp. 10%

•Cutinthekeyswitch andadjustthepercentagevaluewiththekeys[+]

or[-].

Incaseofabrokenweftyouloosetwoweavesinthefabrici.e.withasix

shuttleloomtherewill remainonly4weavesincaseofaweftbreak.

Witha4shuttleloomthetheoreticalreductionwill be1/2=50%

Witha6shuttleloomthetheoreticalreductionwill be1/3=33%

Witha8shuttleloomthetheoreticalreductionwill be1/4=25%

TECHNICALDESCRIPTION Page18

LOOM-CONTROL

SERIESV

DBE-04547

14 Manualhaul-off control:

•Themanualhaul-off controlisarrangedinthemainmenu[Menuselection].

•Withthekey[↓]youmoveto[Haul-off manual].

Menuselection

Weftdensity ->

>

Haul-off manual ->

Fabriccorrect. ->

•Whendepressingthekey[→]and[↓]youmoveto[Haul-Off].

HAUL-OFF MANUAL

>

Haul-Off 10%

•Cutinthekeyswitch andkeepthekey[+]indepressedposition.The

haul-off speedwill be10%ofthemaximumspeed.

TECHNICALDESCRIPTION Page19

LOOM-CONTROL

SERIESV

DBE-04547

15 Settingtheroll change:

•Whenyouareinthemainmenu[Menuselection],youmoveto[Roll change]with

thekey[↓].

Menuselection

Haul-off manual ->

Fabriccorrect. ->

>

Roll change ->

•Afterhavingactuatedthekey[→]youmovetothemenu[ROLL CHANGE].

>

ROLL CHANGE Off

→

•

Cutinthekeyswitch

andsetthe

Roll length 1000m

roll changetoON bymeansof

Toweave 800m

thekeys[+]or[-].

Ready 200m

Roll changeinactivated:Roll changeactivated:

> ROLL CHANGE Off

>

ROLL CHANGE On

Roll length 1000m

Roll length 1000m

Toweave 800m

Toweave 800m

Ready 200m

Ready 200m

ROLL CHANGE On

>

Roll length 1000m

Toweave 800m

Ready 200m

•Whenactuatingthekey[↓]youmoveinthemenu[ROLL CHANGE]to

[Roll length].

•Cutinthekeyswitch andsetthedesiredroll lengthwiththekeys[+]or

[-].

•Inthismenuyoucanread:

theroll length

thelengthofthefabricnotyetfinished

thelengthofthefabricbeingready

•Incaseofaninterruptionoftheroll lengththereexiststhepossibilitytoreset

theroll changedata(Reset).

Reset:keyswitch andkey

This manual suits for next models

1

Popular Industrial Equipment manuals by other brands

Depstech

Depstech DS300 user manual

Graco

Graco Reactor 2 E-30 Operation

Grundfos

Grundfos CIM 200 Functional profile and user manual

Reliable

Reliable N2-Blast DDX Instructions for installation, operation care and maintenance

Pepperl+Fuchs

Pepperl+Fuchs VisuNet FLX quick start guide

Extec

Extec E-7 Operating and maintenance manual